Methyl tertiary butyl ether crude product purification method

A technology of methyl tert-butyl ether and crude products, which is applied in the field of purification of methyl tert-butyl ether crude products, can solve the problems of high equipment investment and maintenance costs, high energy consumption, low MTBE sulfur content, etc., and achieve good industrial application prospects , high structural strength, avoiding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

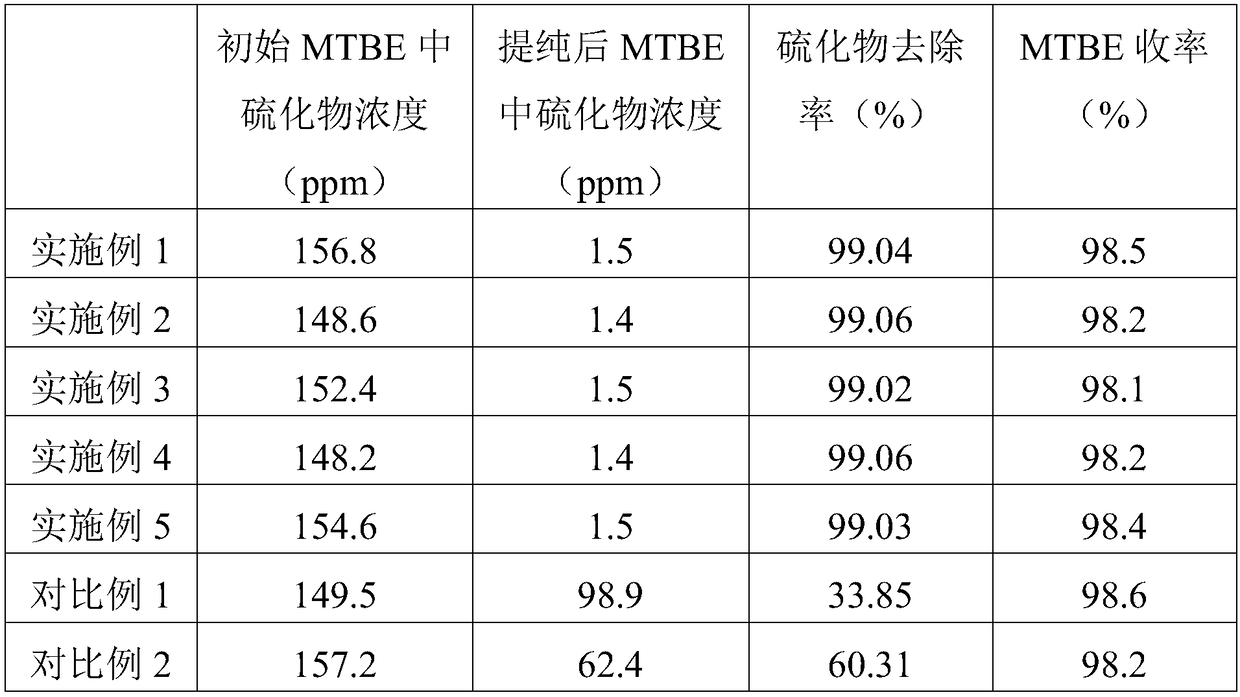

Examples

Embodiment 1

[0027] A method for purifying crude methyl tert-butyl ether, comprising passing the crude methyl tert-butyl ether through a fixed bed equipped with a sulfur removal plate to obtain a methyl tert-butyl ether product with a total sulfide content lower than 10 mg / kg ;

[0028] The preparation method of described desulfurization plate comprises:

[0029] Add ferrous fumarate, 13X molecular sieve (particle size 2mm), attapulgite powder and activated carbon fiber (fiber diameter 5-20 μm, length 5-15 mm) into a high-speed mixer and mix to obtain a dry powder mixture; The weight ratio of the ferrous fumarate, 13X type molecular sieve, attapulgite powder and activated carbon fiber is 1:0.5:0.4:6;

[0030] Add the dry powder mixture, polyvinyl alcohol and polyacrylamide into water in proportion, stir and mix evenly, pour it into a mold, and compact it to shape; the molded blank is vacuumed at 0.05-0.45Mpa and the temperature is 35 drying at ~55°C to obtain the desulfurization plate. ...

Embodiment 2

[0034] The method for purifying the crude product of methyl tert-butyl ether as described in Example 1, the difference is that in the preparation method of the sulfur removal board, the ferrous fumarate, 13X molecular sieve, attapulgite powder and active The weight ratio of carbon fiber is 1:0.3:0.2:3.5; the rest remains unchanged, the sulfur removal plate is prepared, and the crude methyl tert-butyl ether is purified according to the method of Example 1.

Embodiment 3

[0036] The method for purifying the crude product of methyl tert-butyl ether as described in Example 1, the difference is that in the preparation method of the sulfur removal board, the ferrous fumarate, 13X molecular sieve, attapulgite powder and active The weight ratio of carbon fiber is 1:0.7:0.6:8; the rest remains unchanged, the sulfur removal plate is prepared, and the crude methyl tert-butyl ether is purified according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com