A sewage sedimentation tank with inner and outer nested bellows groups and its operation method

A bellows and sedimentation tank technology, applied in the field of sewage treatment, can solve the problems of poor adaptability to water impact load and water temperature change, influence on sedimentation effect, sludge adhesion, etc., to eliminate sedimentation stagnation area, increase sedimentation area, Easy to remove silt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

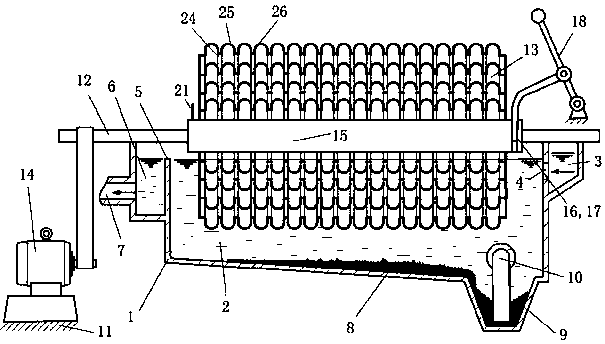

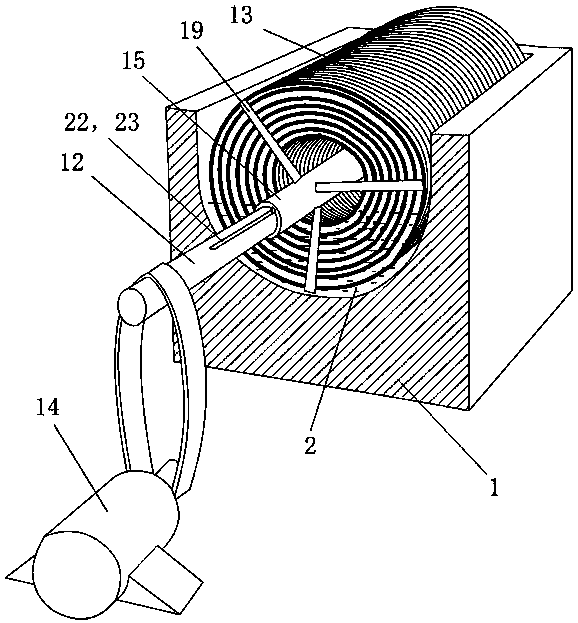

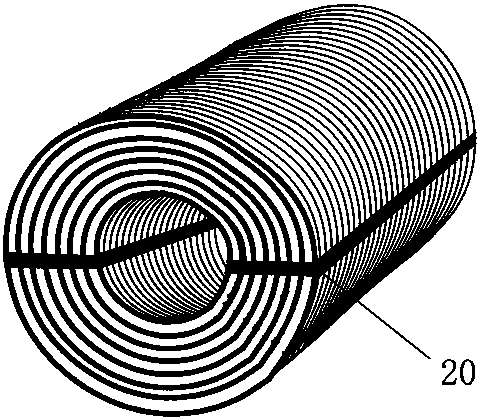

[0024] exist figure 1 , 2 . In the embodiment shown in 3, the settling tank (1) of the present invention is arranged horizontally, with a semicircular cross section, a certain slope at the bottom of the pond, one end of the water outlet is high, and one end of the water inlet is low; one end of the water inlet is provided with a mud collecting Bucket (9); a group of equal lengths and different diameters; cylindrical bellows (24) with diameters ranging from small to large, with equal diameter differences, nested in each other, arranged in parallel from inside to outside to form a concentric circle The cylinder group (13), fixed on the sleeve (15) on the axis position; the cylindrical bellows (24) is a cylindrical thin-wall corrugated shell with multiple transverse corrugations; the cylindrical bellows (24) The number is 4; the axis of the cylindrical bellows (24) must coincide with the axis of the sleeve (15) to form a concentric and coaxial structure; the cylindrical bellows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com