Appts for preparing catalyst layer for proton exchange film fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, solid electrolyte fuel cells, battery electrodes, etc., can solve the problems of uneven load thickness, waste of catalysts, waste of precious metal catalysts, etc., to improve spraying quality and efficiency, high The effect of motion precision, good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

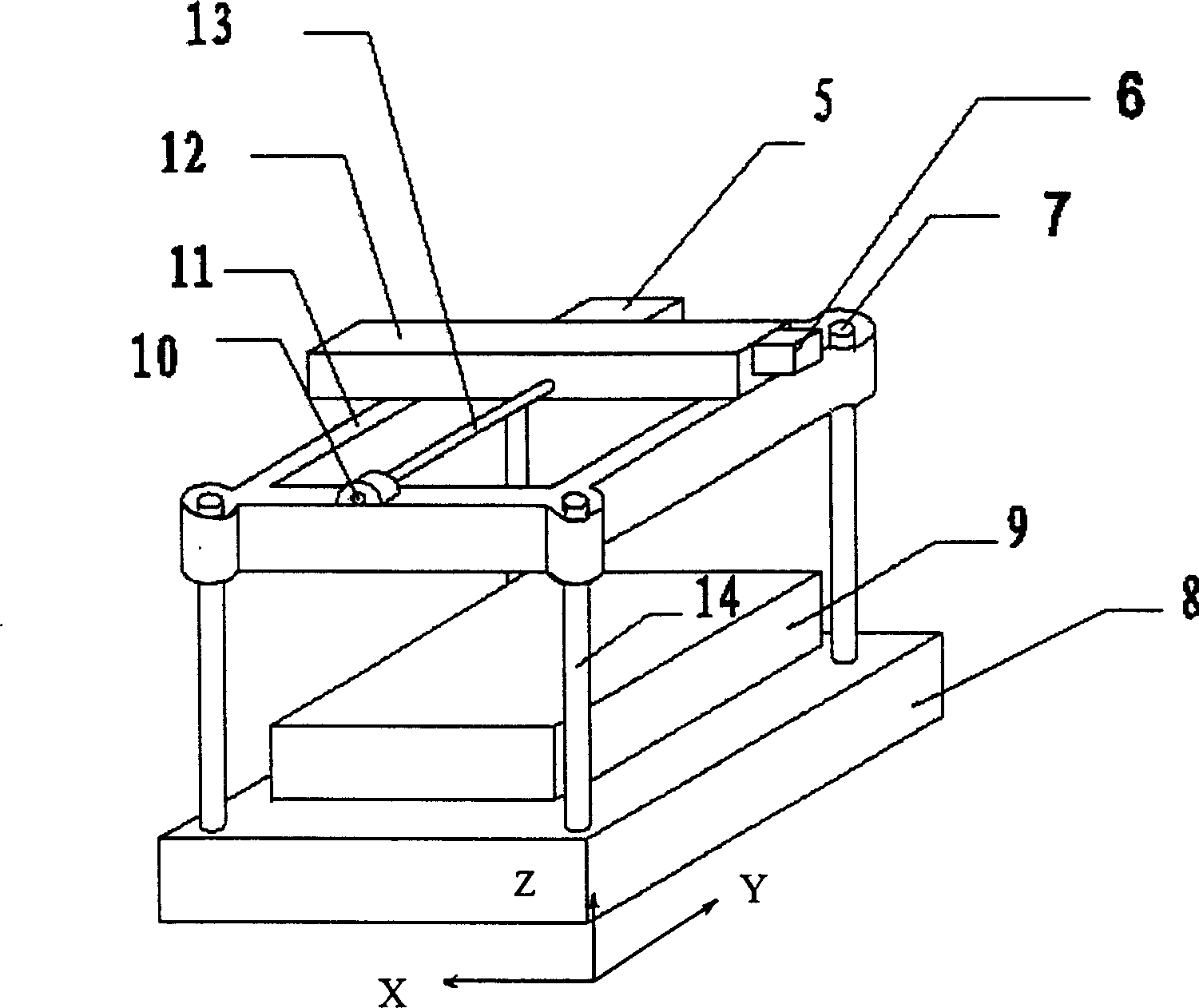

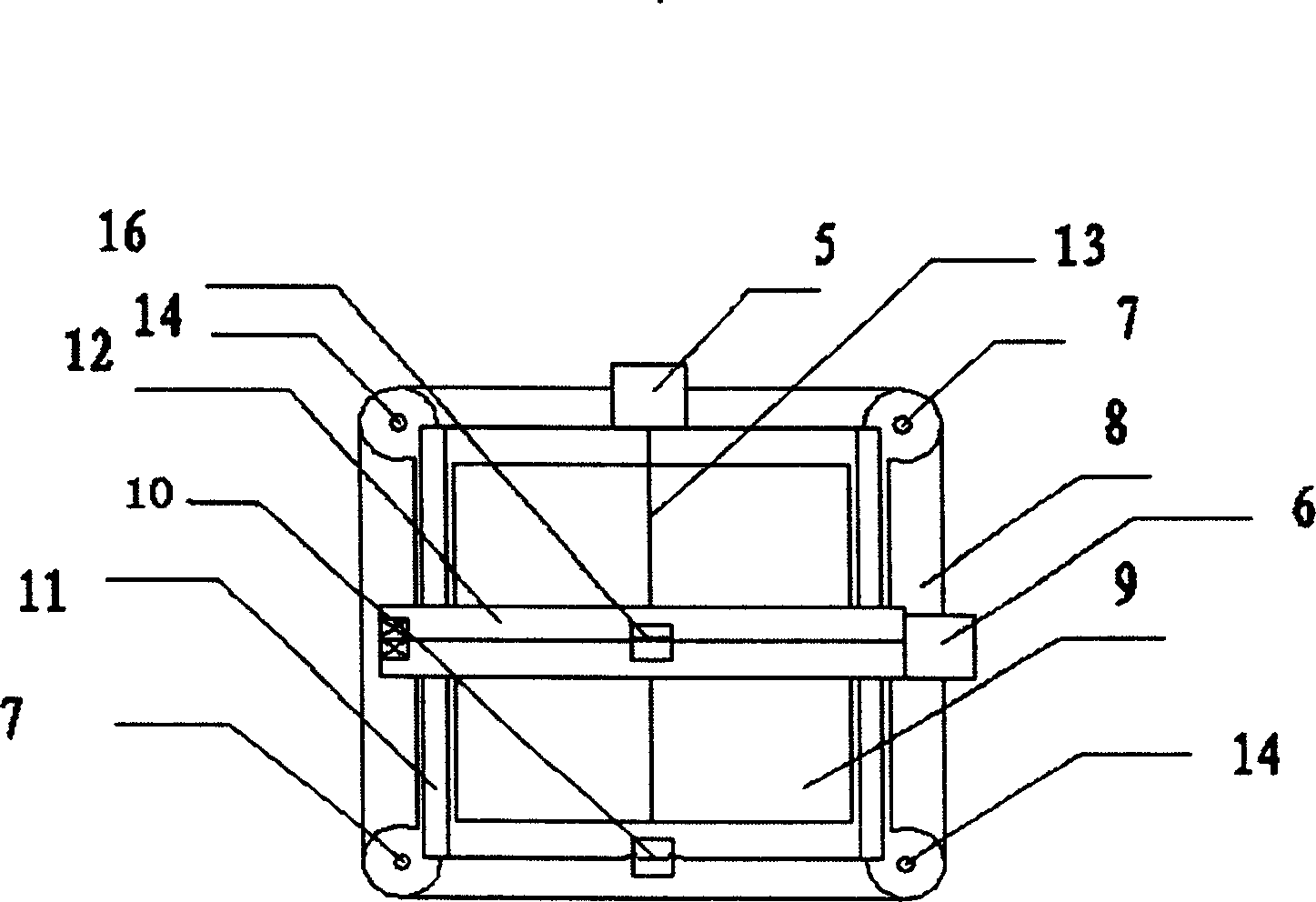

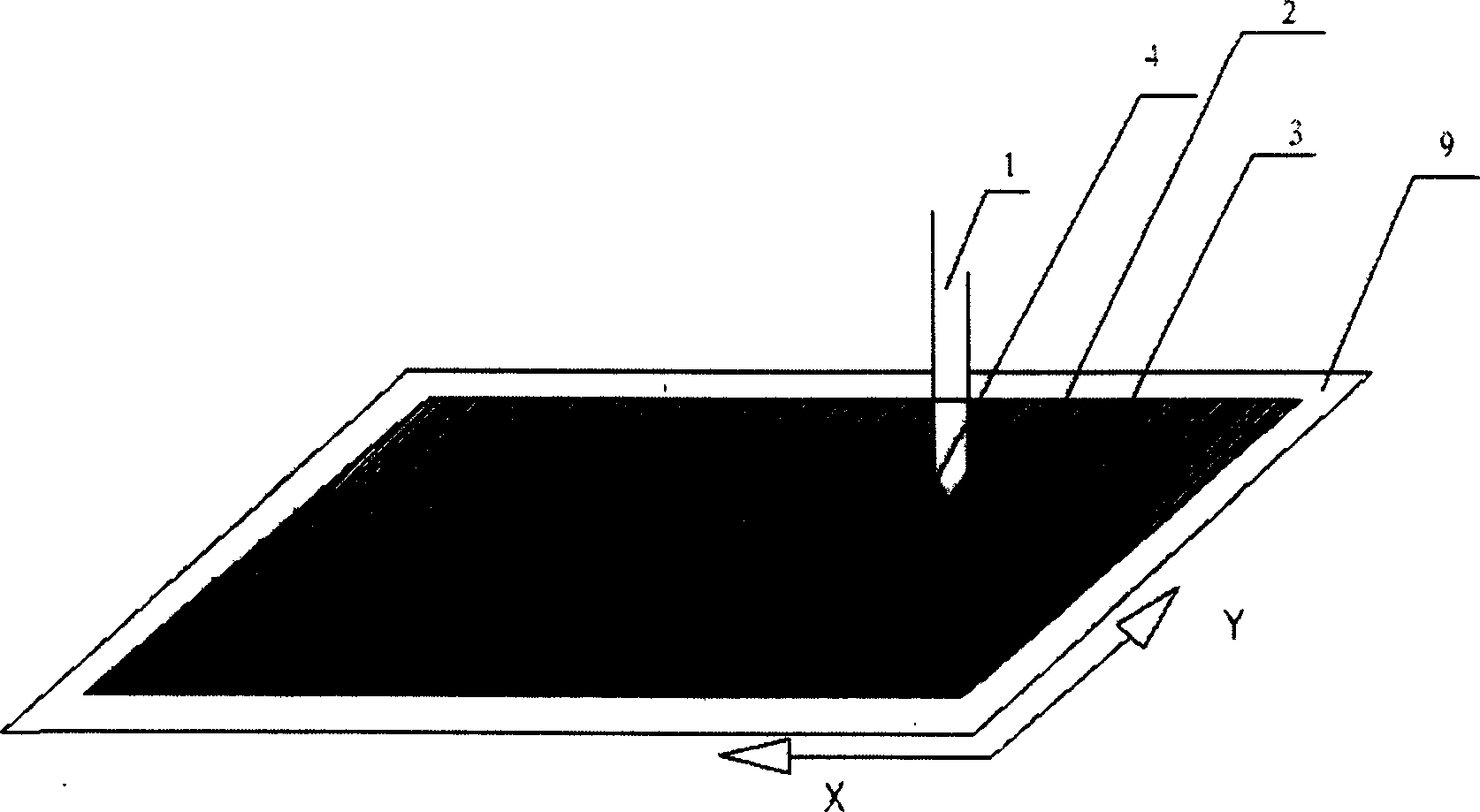

[0032] Preparation of the catalyst ink: a platinum carbon catalyst (60% precious metal content), water and 5% Nafion solution were mixed uniformly in a weight ratio of 9:20:60 to form a catalyst ink mixture. When in use, first heat the heating plate to a predetermined temperature, then add the prepared catalyst ink to the spray gun, and adjust the square wave duty cycle to control the movement and switch of the spray gun according to the size of the spraying required. Since the weight gain of the entire catalytic layer support is very consistent each time the spray gun is sprayed, the catalyst loading capacity in the catalytic layer can be determined by controlling the number of times the spray gun sweeps the catalytic layer support.

[0033] Carbon paper size: 50mm×50mm

[0034] Heating table size: 600mm×600mm

[0035] Spray angle: 70 degrees

[0036] Maximum spraying distance: 60mm

[0037] Spray height: 30mm

[0038] Spray gun working pressure: 0.2MPa

[0039] Carrier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com