Polyurethane flexible foam composite board with sound-absorbing function

A polyurethane soft foam and sound-absorbing technology, which is applied in the field of composite boards, can solve problems such as difficult control, shedding, and deformation of the board surface, and achieve the effects of simple combination, good mechanical rigidity, and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

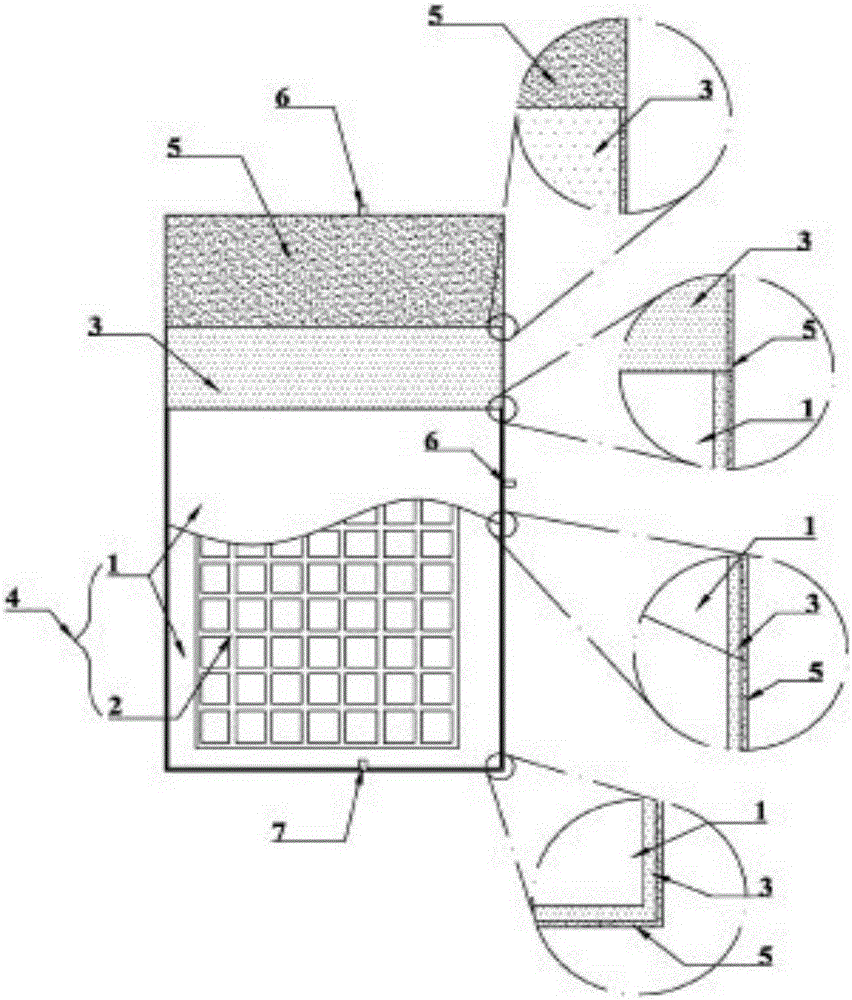

[0019] The main structure of this embodiment, such as figure 1 As shown, a polyurethane soft foam composite board with sound-absorbing function includes a polyurethane soft foam layer 1, and sound-absorbing micropores are evenly distributed on the polyurethane soft foam layer 1 . The polyurethane soft foam layer 1 itself has a good sound-absorbing effect, and sound-absorbing micropores are dug out on its surface, which can further increase the specific surface area of the polyurethane soft foam layer, thereby greatly improving the sound-absorbing effect.

Embodiment 2

[0021] This embodiment is further limited on the basis of Embodiment 1, the length of the polyurethane soft foam layer 1 is 800 mm, the width is 550 mm, and the thickness is 20 mm. Here, the structure and shape of the polyurethane soft foam layer 1 are specifically limited, and the polyurethane soft foam layer 1 is rectangular, and not less than two layers, and other equivalent technical shape changes are within the protection scope of the present invention. Other structures involved in the invention are common knowledge in the field and will not be repeated here.

Embodiment 3

[0023] This embodiment is further limited on the basis of the above embodiments, and also includes an anti-aging layer 3, which is a layer made of polyethylene, high-strength polyester, black masterbatch and anti-aging agent through one-time composite processing. Wrapped on the outer surface of the polyurethane soft foam layer 1, wherein the anti-aging layer 3 is fully coated to prolong the service life of the composite board and improve the functionality of the material. Other structures involved in the present invention are common knowledge in the field and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com