Motor with deep drawing type motor shell

A technology of motor casing and motor, applied in the field of motor, can solve the problem of strong acceleration of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

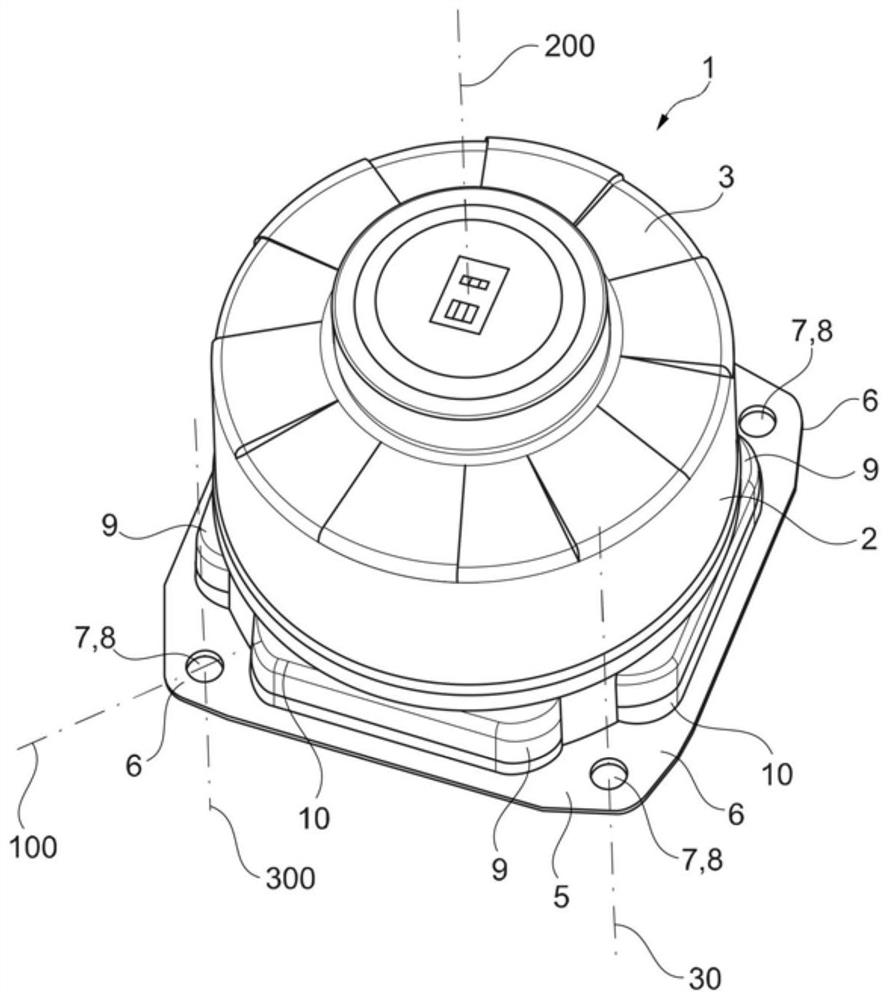

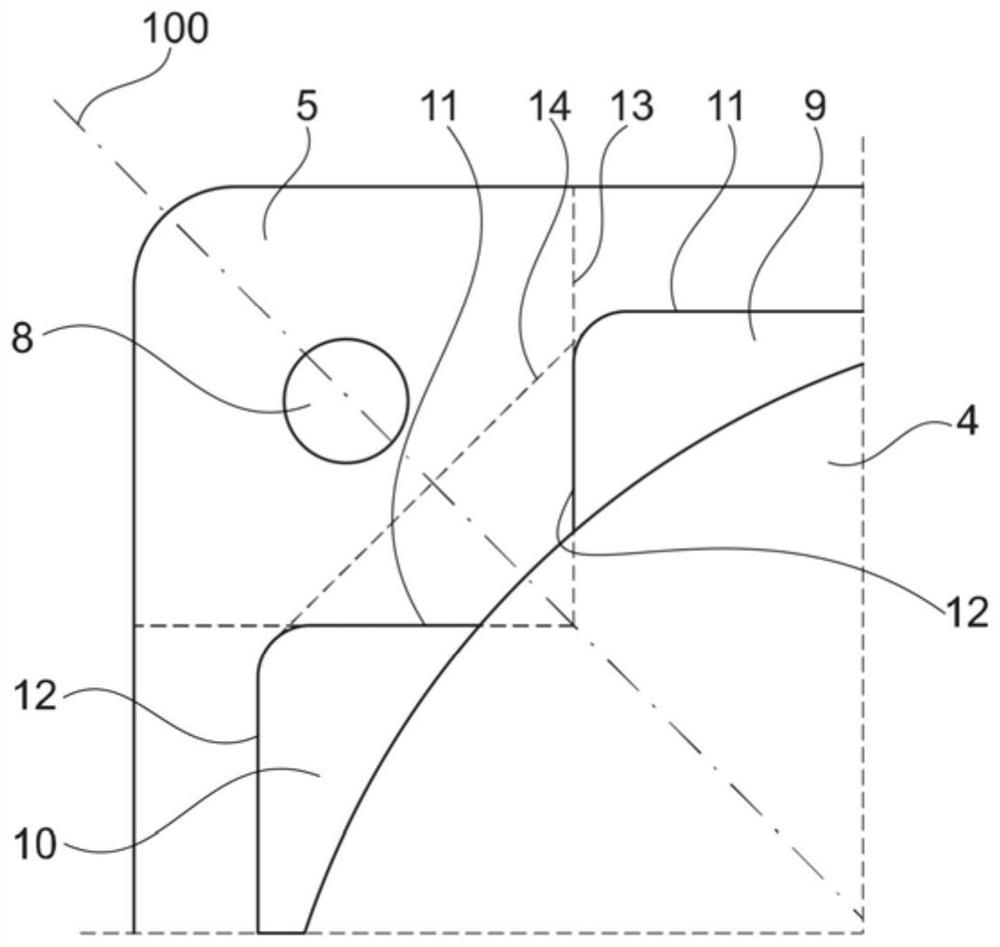

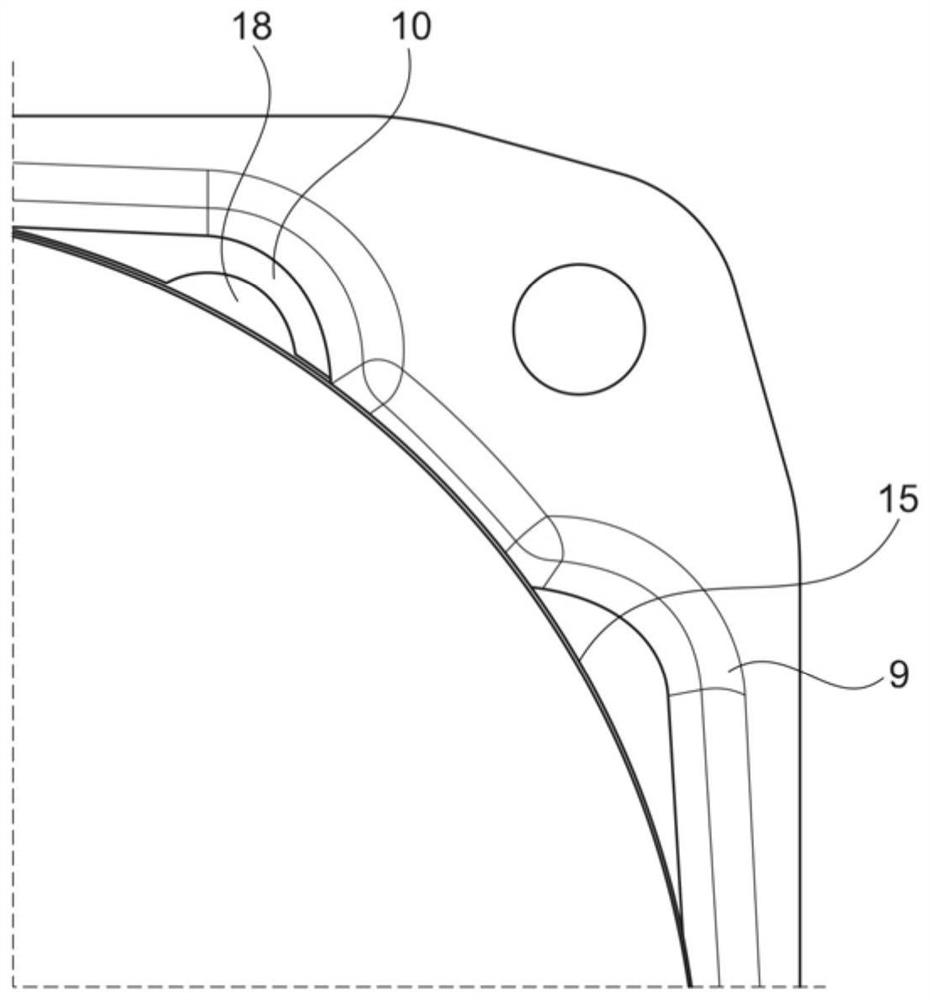

[0020] figure 1 A deep-drawn motor housing 1 of the electric motor is shown. The motor housing 1 is a pot-shaped body with a substantially cylindrical outer surface 2, a closed, continuous base 3, and an opening opposite the base 3, the opening being circumferentially surrounded by a flange 5 having a substantially cylindrical shape. Rectangular base with four flange corners 6, of which only three flange corners 6 are shown, these flange corners 6 are evenly distributed in the circumferential direction, and each flange corner 6 is provided separately There are through holes 7 for screw-on fixing points 8 . In the area of the flange corners 6 , the flange 5 also has projections 9 and 10 extending downward in the direction of the base 3 . Each flange corner 6 corresponds to two projections 9 and 10 , and the two projections The symmetry axis 100 is arranged in mirror symmetry, and the symmetry axis 100 is respectively connected with the central axis or longitudinal axis 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com