Polyurethane soft foam composite board with high structural strength

A polyurethane soft foam, high-structure technology, applied in the field of composite panels, can solve problems such as shedding, deformation of the board surface, troublesome operation, etc., and achieve the effects of good mechanical rigidity, prolonging service life, and resisting wall deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

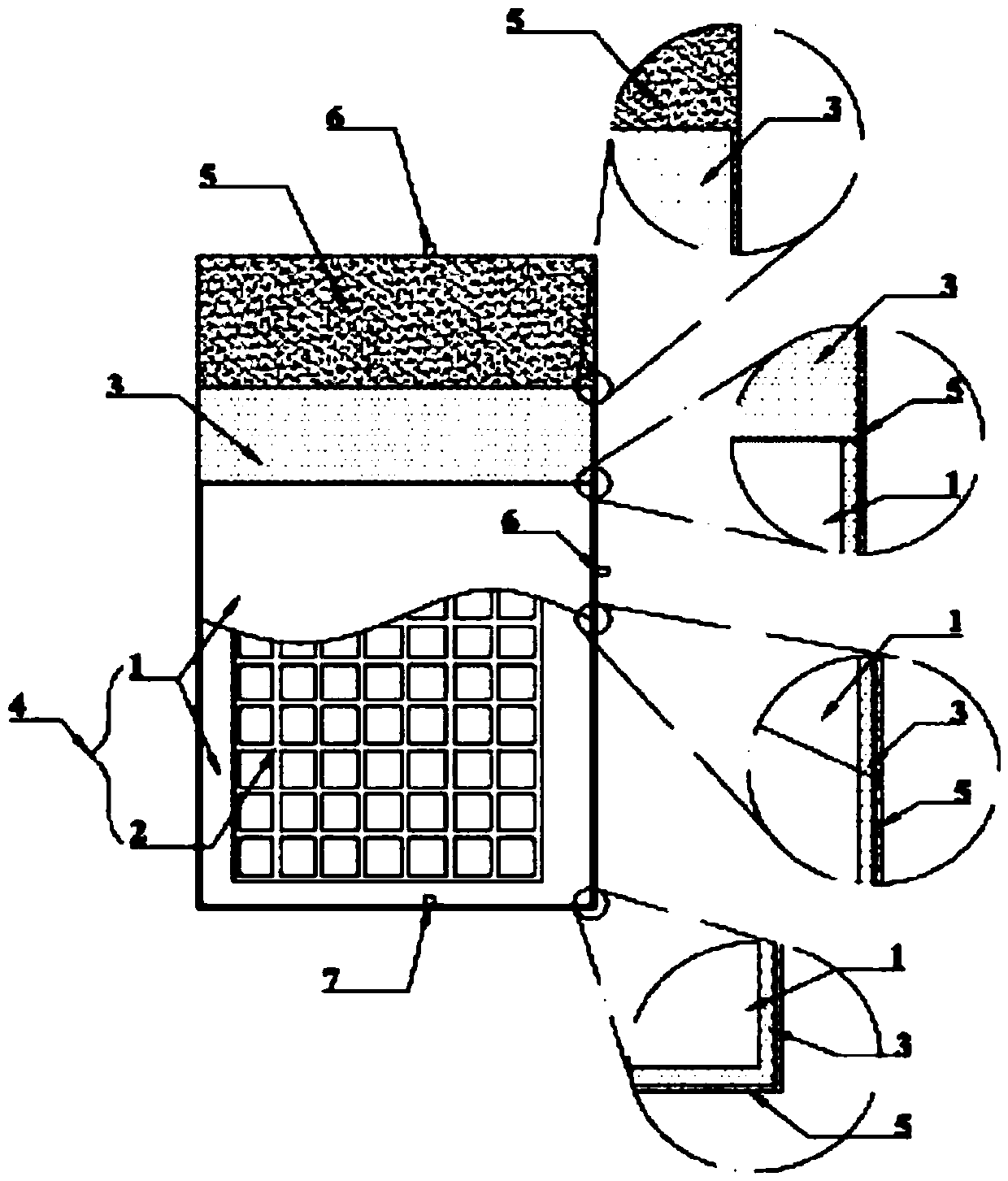

[0018] The main structure of this embodiment, such as figure 1 As shown, a polyurethane soft foam composite board with high structural strength includes at least two layers of polyurethane soft foam layer 1 and a supporting frame 2. The supporting frame 2 is welded by metal alloy frames evenly and tightly arranged, and thermally compounded on polyurethane Between the soft foam layer 1, the thickness of the support frame 2 is 20-30mm, and the support frame 2 is an aluminum alloy mesh frame composed of a square, so that the composite board has good mechanical rigidity and can effectively withstand pressure and resist wall deformation. Moreover, the combination of the mesh skeleton is simple, and the contact surfaces of each frame are flat and straight. After the positive force is applied, it will not produce lateral force like other complex shape skeletons, and can effectively maintain the soft two-layer polyurethane itself. The overall shape of the soft foam layer.

Embodiment 2

[0020] This embodiment is further limited on the basis of embodiment 1, the thickness of the support frame is 25 mm or 20 mm, and other structures involved in the present invention are common knowledge in the field, and will not be repeated here.

Embodiment 3

[0022] This embodiment is further limited on the basis of the above embodiments, and also includes an anti-aging layer 3, which is a layer made of polyethylene, high-strength polyester, black masterbatch and anti-aging agent through one-time composite processing. Wrapped on the outer surface of the polyurethane soft foam layer 1, wherein the anti-aging layer 3 is fully coated to prolong the service life of the composite board and improve the functionality of the material. Other structures involved in the present invention are common knowledge in the field and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com