Lifting device

A lifting device and lifting frame technology, applied in the direction of lifting device, elevator, lifting frame, etc., can solve the problem of high requirements for lateral stability of the lifting frame of the lifting component, high requirements for holding accuracy and transmission control accuracy, and high lifting requirements. problems such as lateral stability and stiffness fluctuation, to achieve the effect of good longitudinal and lateral stability, good synchronization, and strong environmental test ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

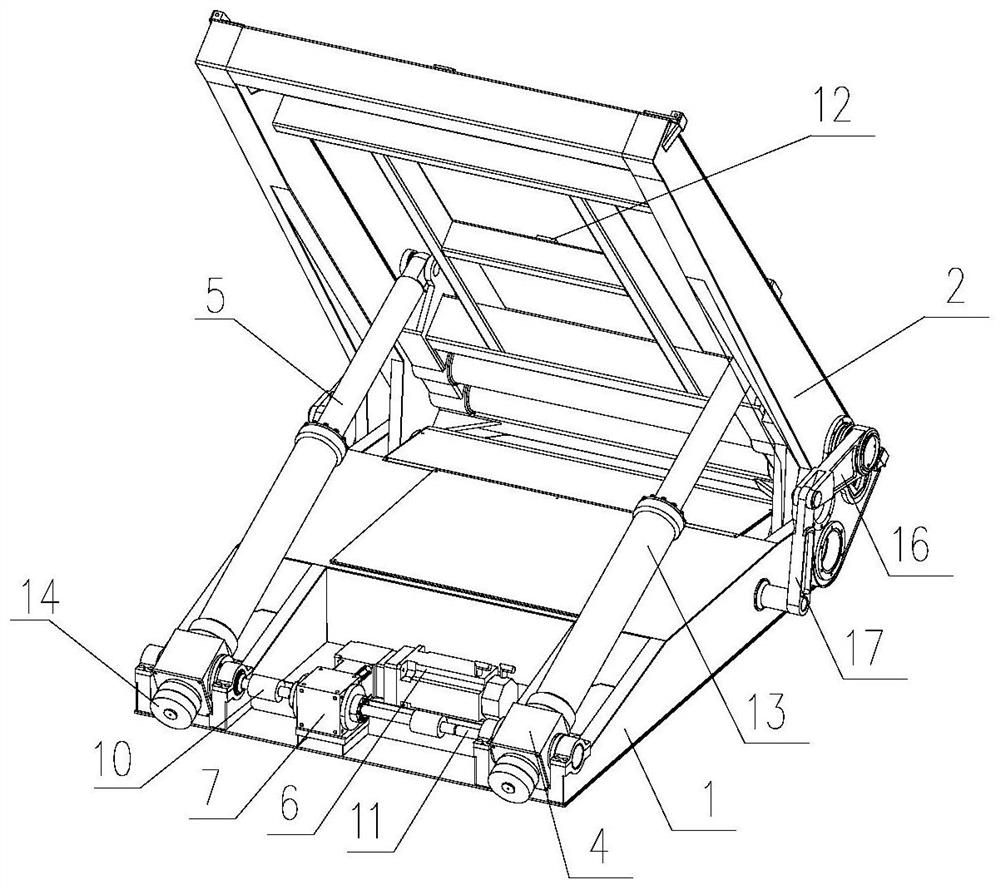

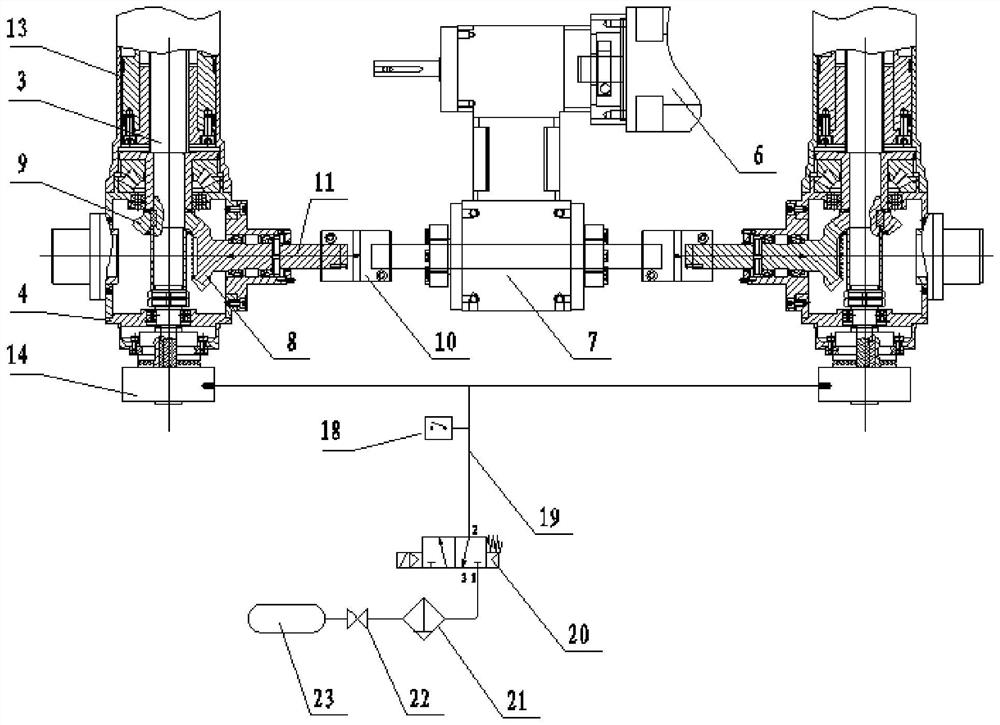

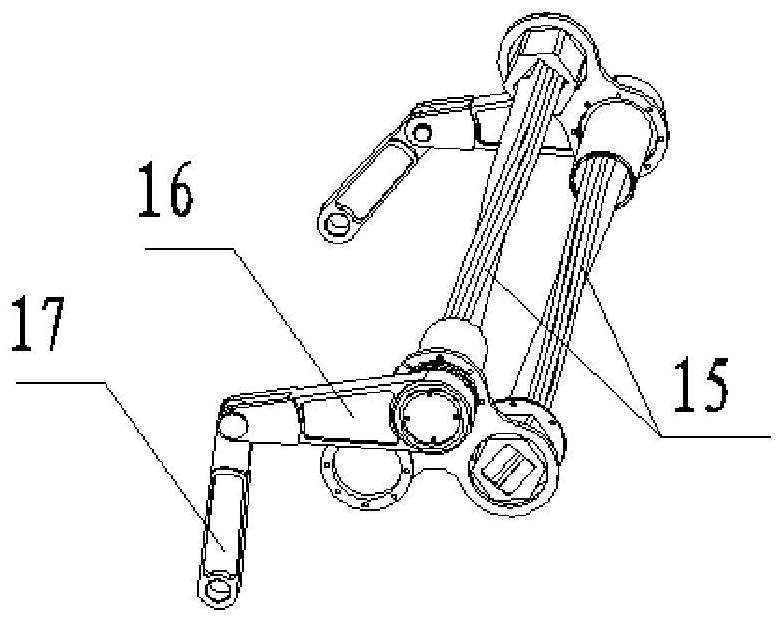

[0025] This embodiment provides a lifting device, such as figure 1 As shown, it includes a base 1, a lifting frame 2, a lifting assembly and a driving assembly; the lifting frame 2 is rotatably connected to the base 1; one end of the lifting assembly is rotatably connected to the lifting frame 2, and the other One end is rotationally connected with the end of the base 1 away from the lifting frame 2; the driving assembly is arranged on the base 1, and the driving assembly is arranged away from the lifting frame 2, and the driving assembly is used to drive the elevating assembly to elongate or shorten; The lifting assembly includes a ball screw pair 3, a positioning sleeve 4 and a support rod 5, the positioning sleeve 4 is sleeved on the end of the screw of the ball screw pair 3, the positioning sleeve 4 is connected to the base 1 in rotation, the One end of the support rod 5 is rotatably connected with the lifting frame 2, and the other end of the support rod 5 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com