Patents

Literature

42results about How to "Fast response to movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

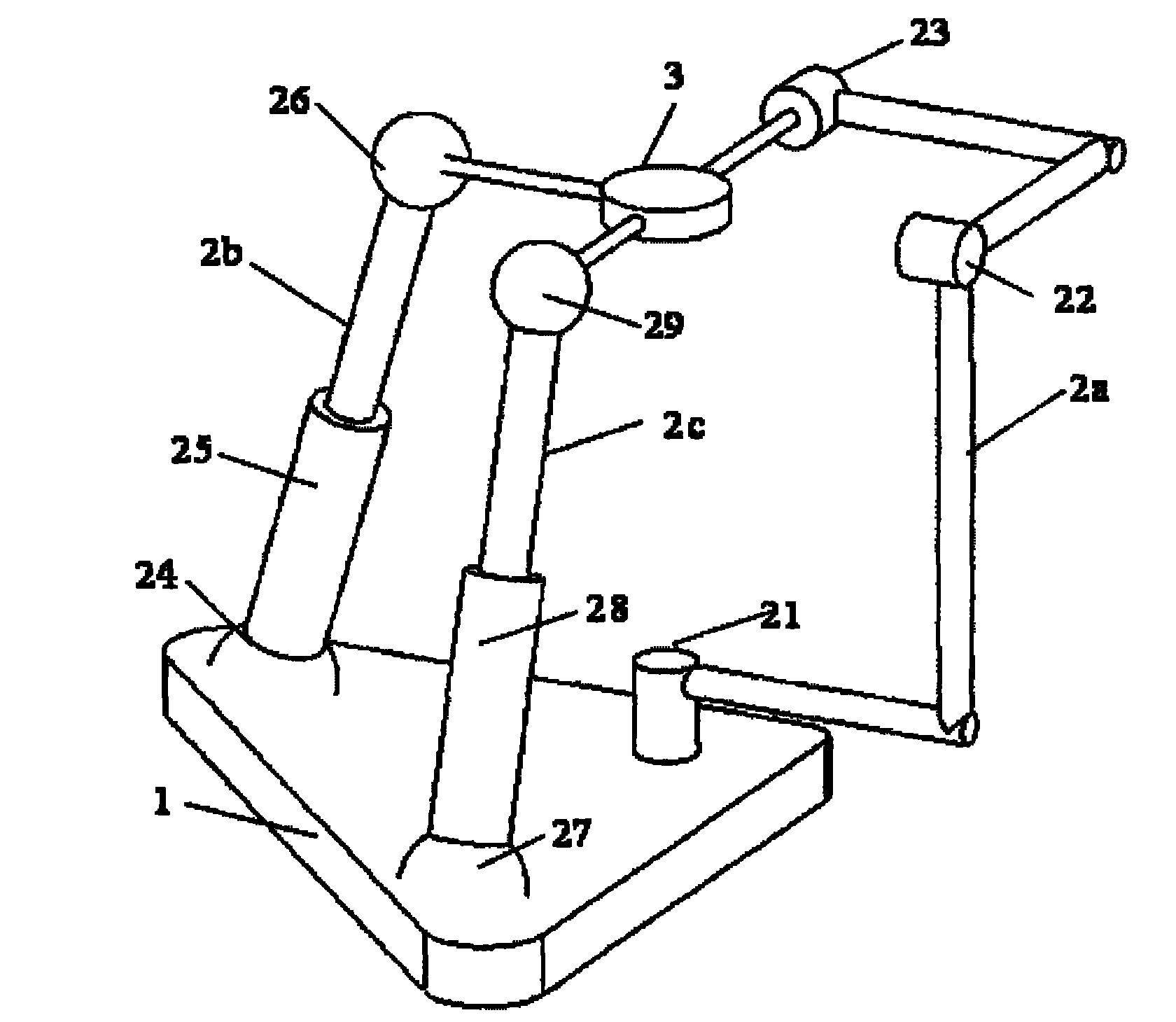

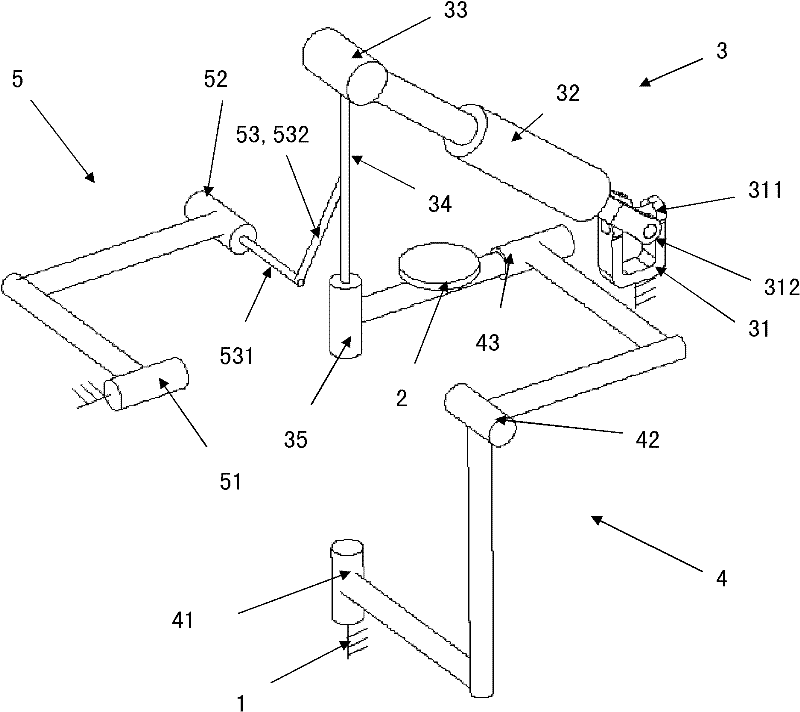

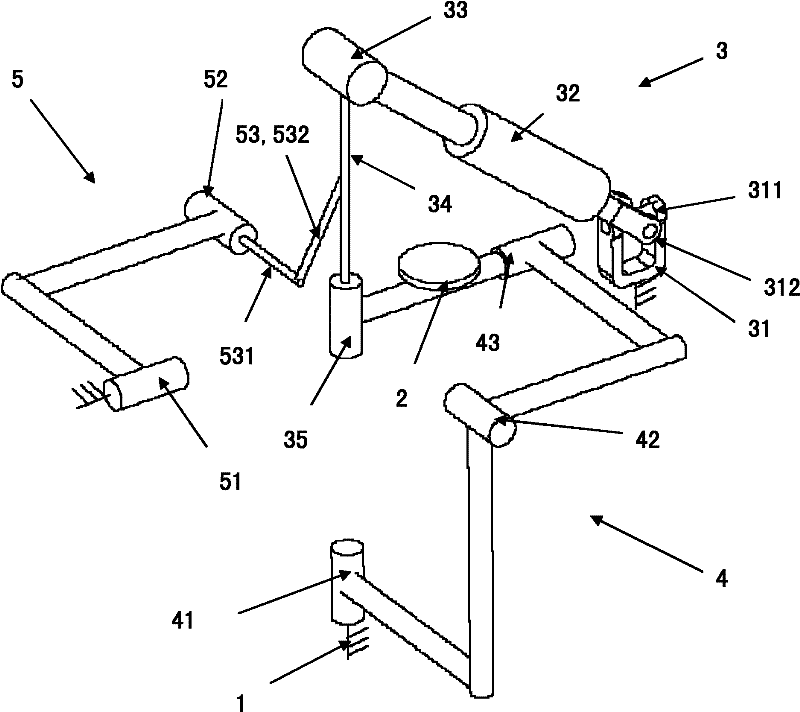

Movement decoupling spherical surface rotating paralleling mechanism can be used as the robot wrist joint

InactiveCN101116971ASimple structureEasy to installProgramme-controlled manipulatorJointsMotor driveKinematic pair

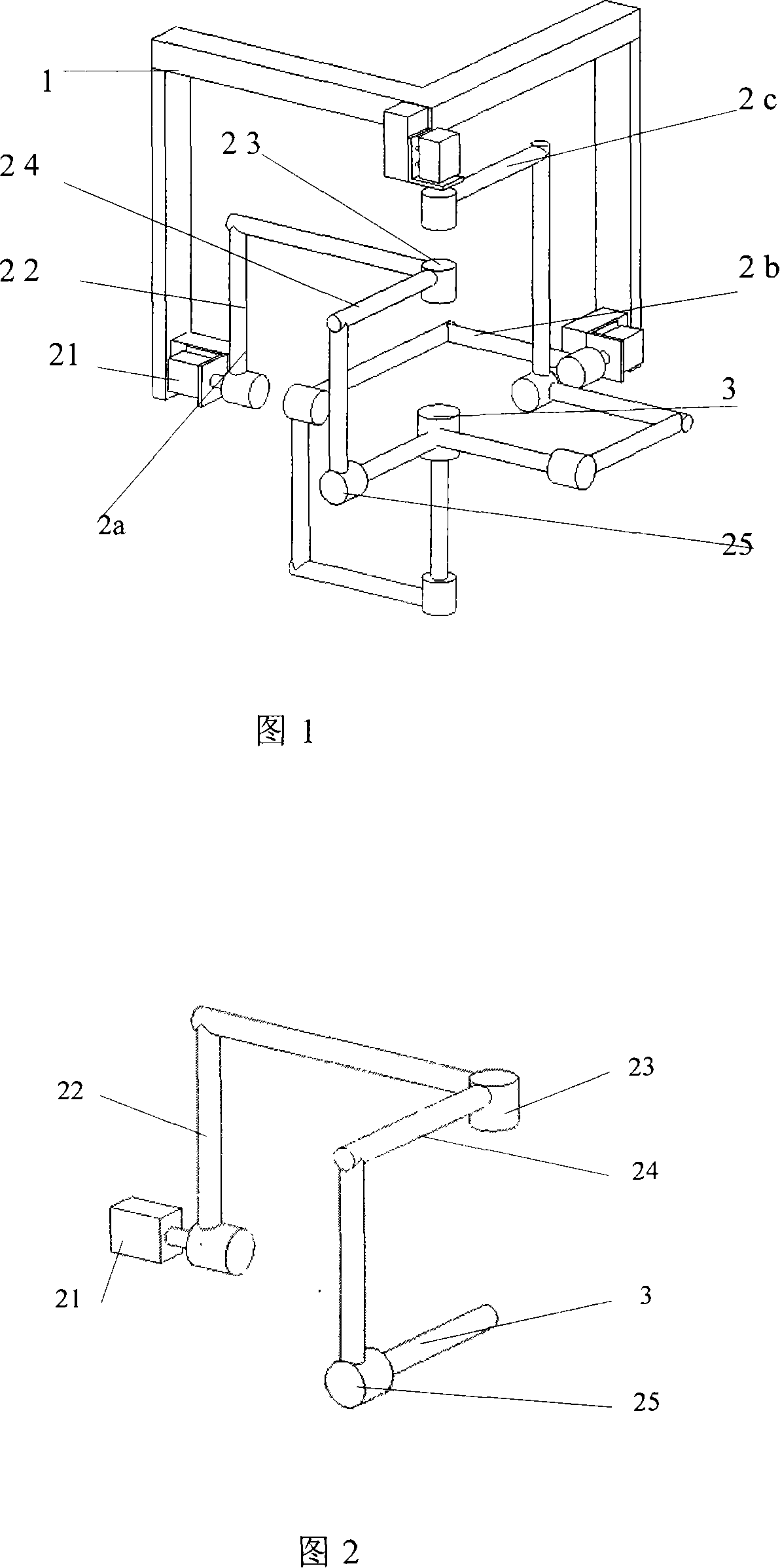

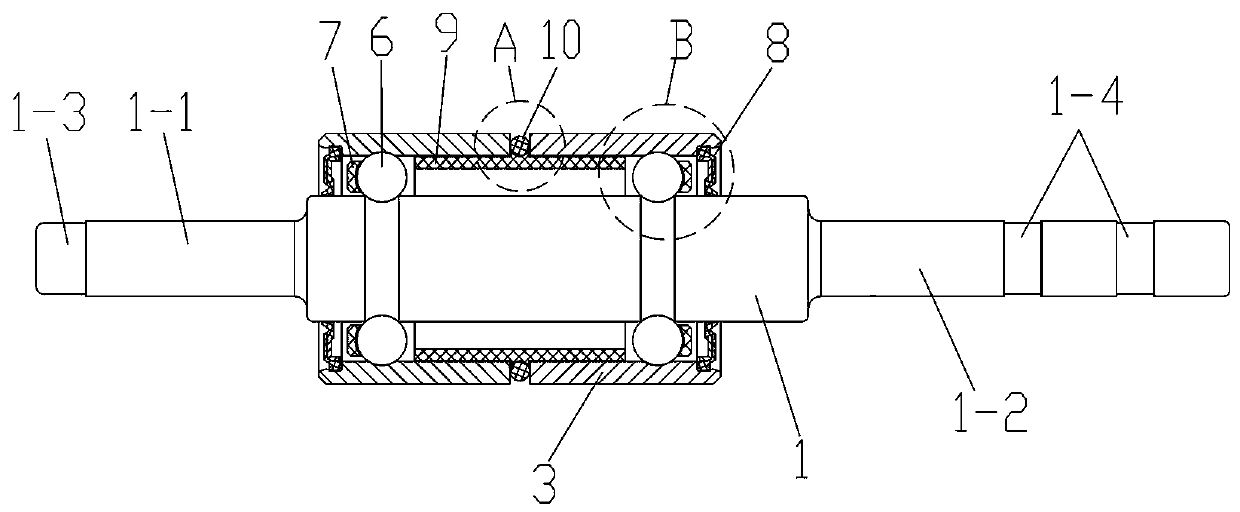

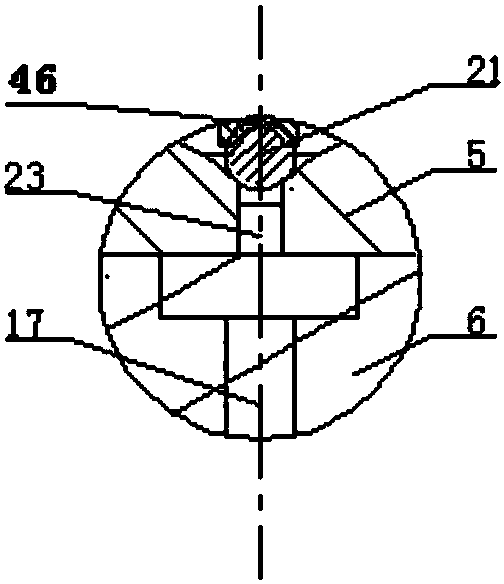

The invention discloses a kinematic decoupling spherical rotation parallel mechanism that can be used as a robot wrist, comprising a rack (1), a movable platform (3) and three kinematic branch chains (2a), (2b) and (2c) which are fixed between the rack and the movable platform and are in the same structural type. Each kinematic branch chain comprises three revolute pairs and rods among the three revolute pairs, primary pairs of the three revolute pairs are distributed via positive crossing and the axes of all kinematic pairs converge to one point. Rotation motors of the three kinematic branch chains drive to realize that the movable platform rotates around the sphere surface of the axes convergence point of the rotation pairs and outputs. The initial end of each kinematic branch chain is motor-driven. The parallel mechanism relating to the invention has the advantages such as kinematic decoupling, simple in structure, easy to control and low in cost, and can be used in the fields such as robot wrist, shoulder joint, satellite positioning and advanced manufacturing.

Owner:DONGHUA UNIV

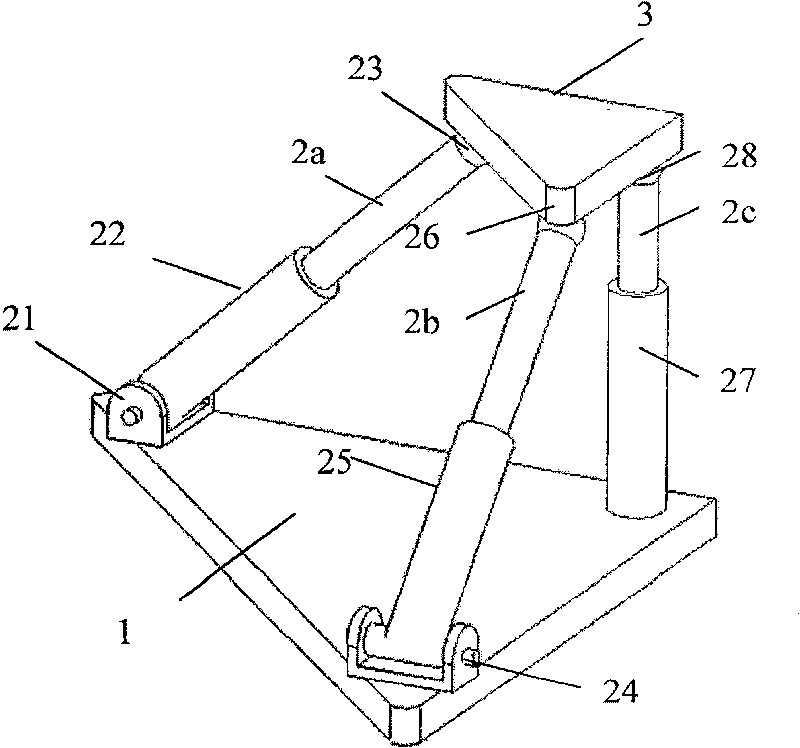

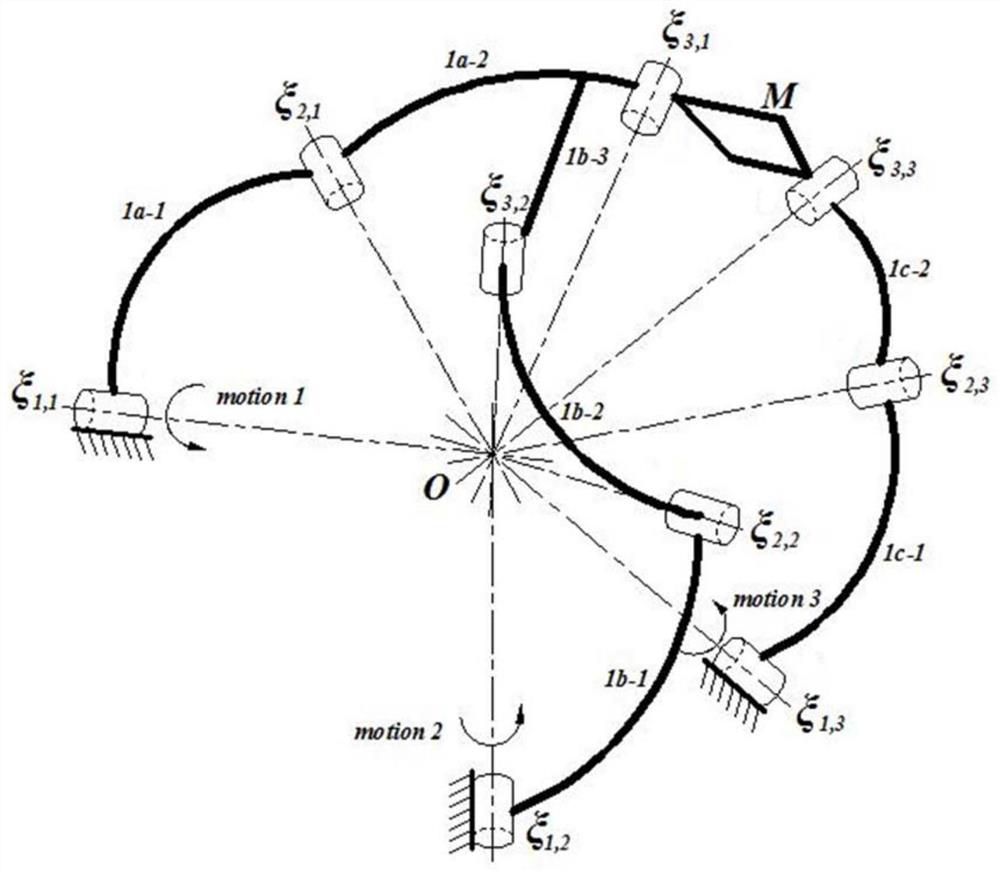

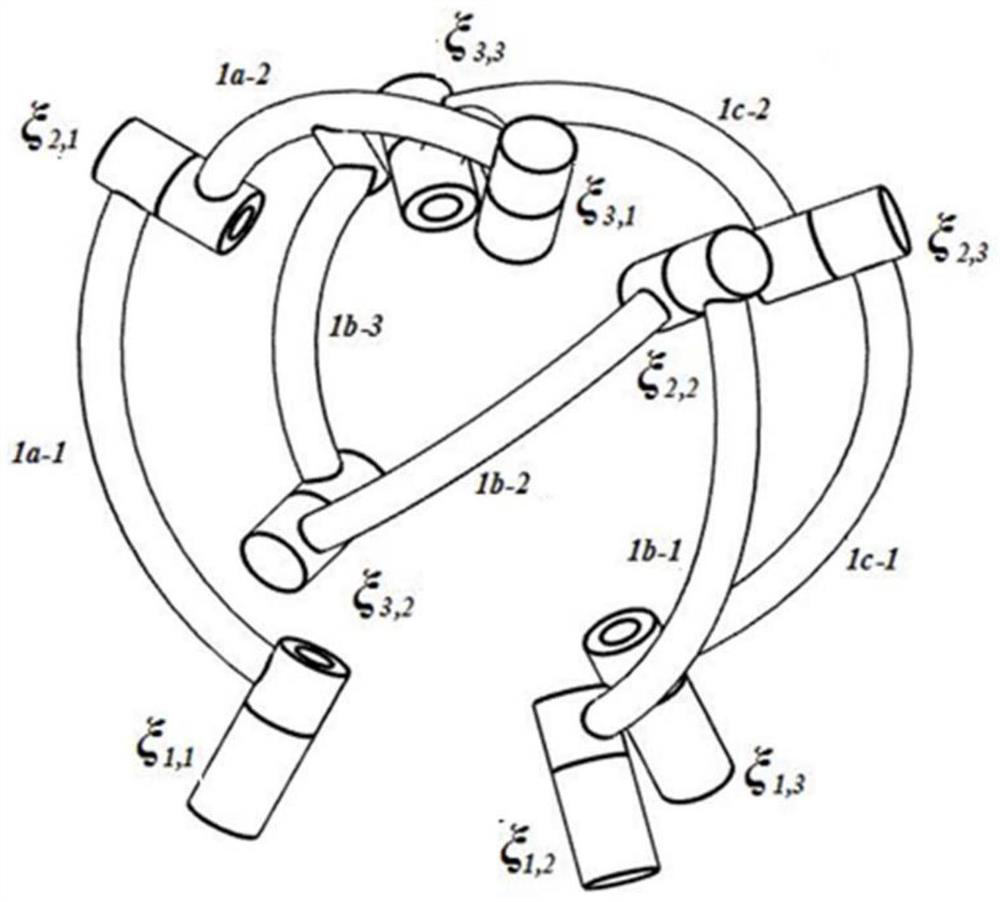

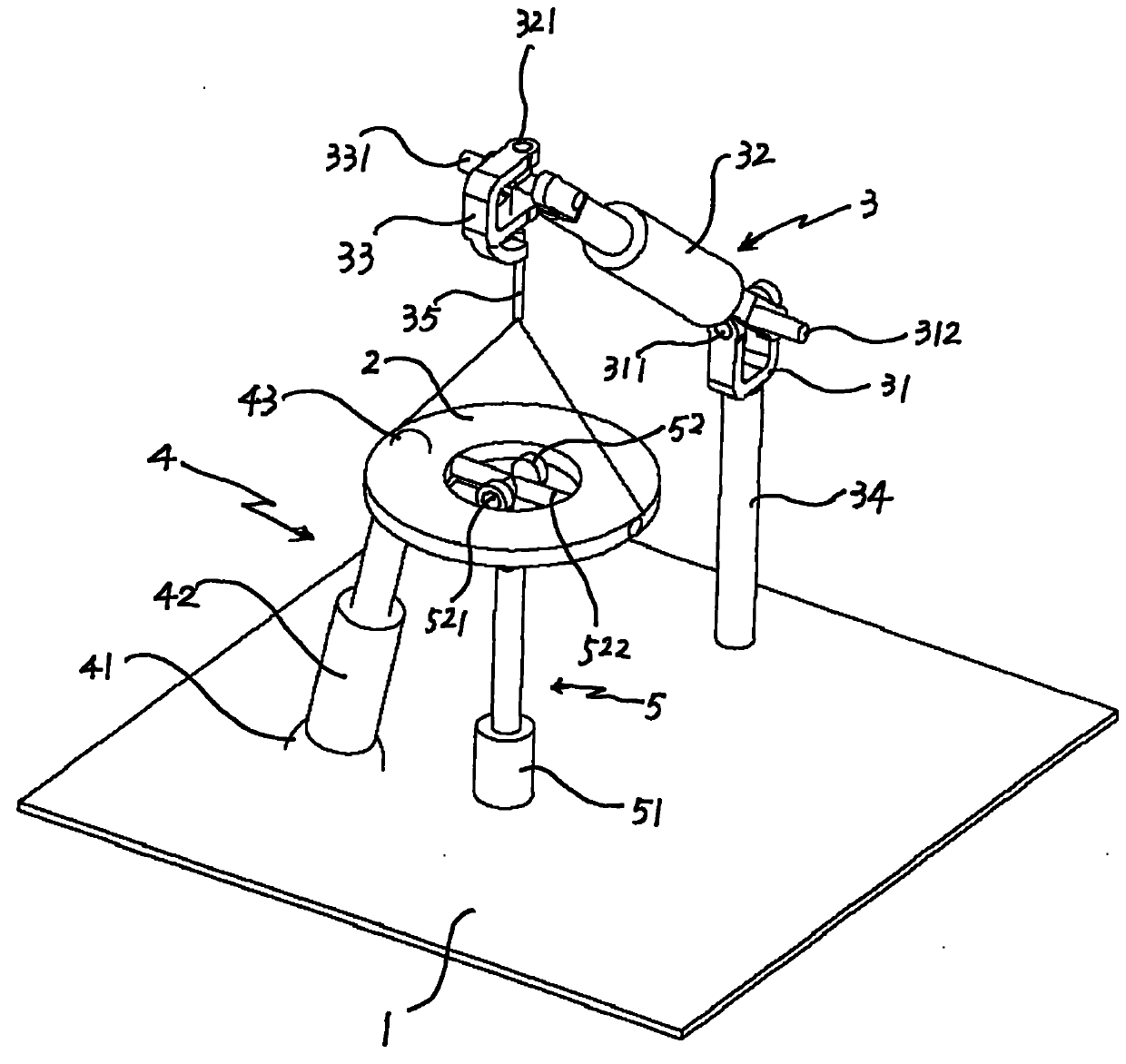

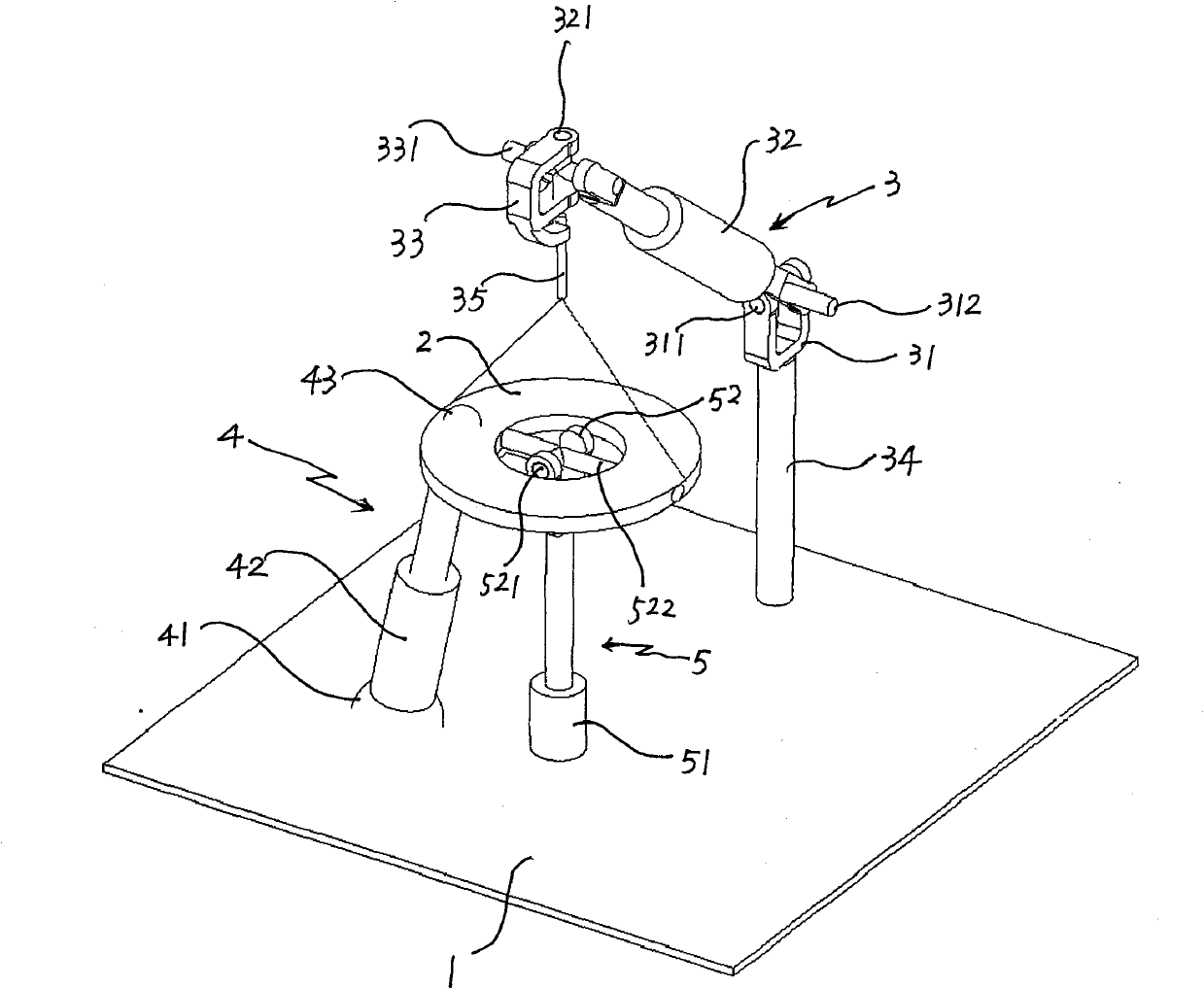

Decoupled three-rotational-degree-of-freedom parallel mechanism

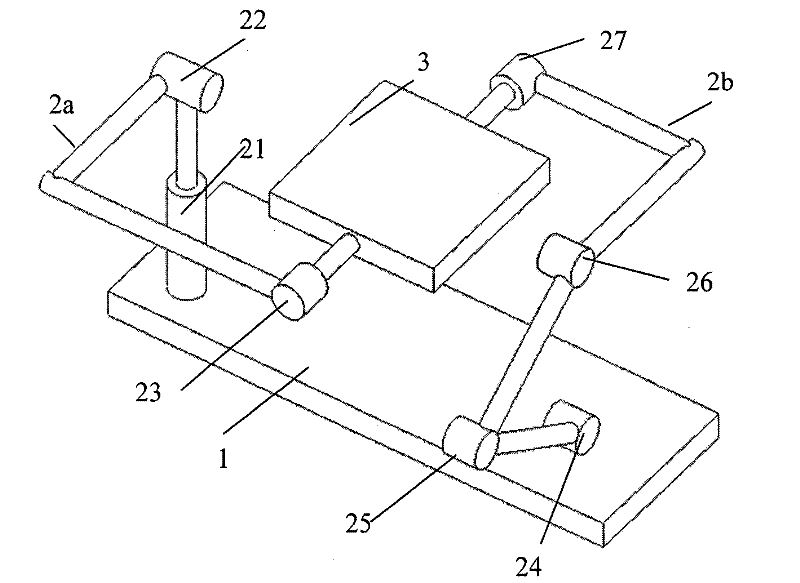

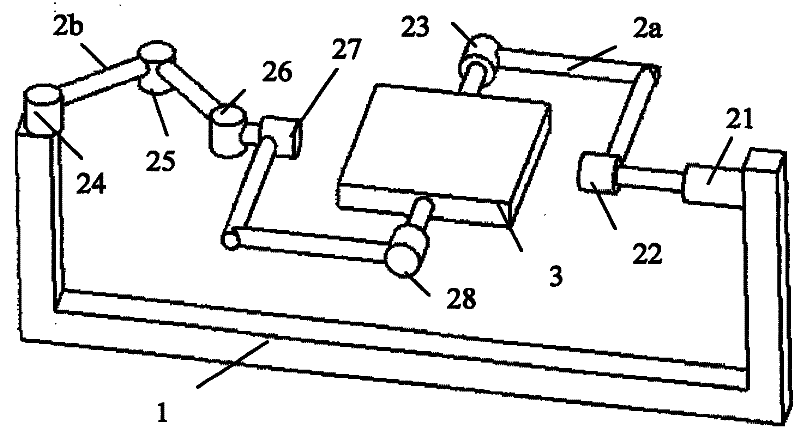

The invention relates to a decoupled three-rotational-degree-of-freedom parallel mechanism, which consists of a machine frame (1), a dynamic platform (3), a first motion branch chain (2a), a second motion branch chain (2b) and a third motion branch chain (2c), wherein the first motion branch chain (2a), the second motion branch chain (2b) and the third motion branch chain (2c) are fixedly connected between the machine frame (1) and the dynamic platform (3); and the axes of three rotation pairs of the first motion branch chain (2a) meet at the central point of the platform (3). As few motion pairs are used and all driving electric motors are arranged on the machine frame, the motion-decoupled spherical rotation parallel mechanism of the invention has the advantages of simple structure, convenient installation, small rotation inertia and quick motion response. In addition, the spherical rotation parallel mechanism of the invention has linear motion decoupling, easy calibration and simple control, thereby reducing development cost.

Owner:DONGHUA UNIV

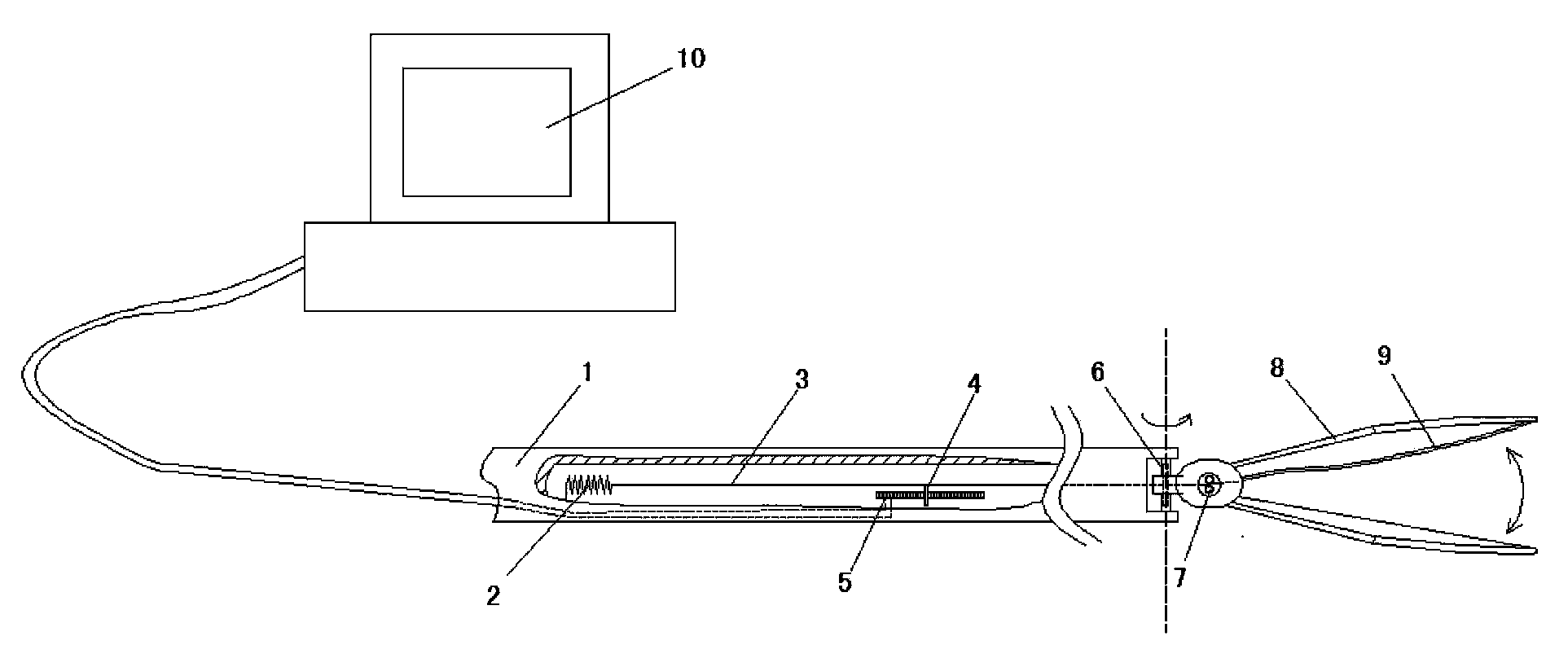

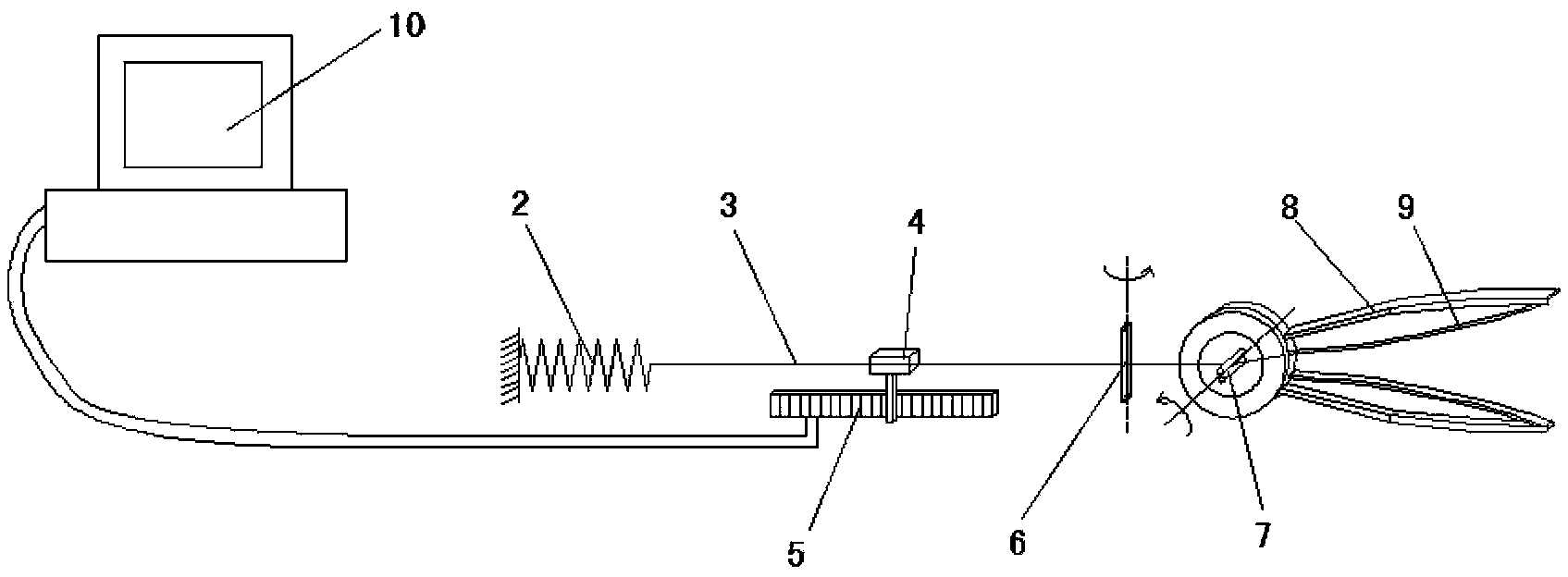

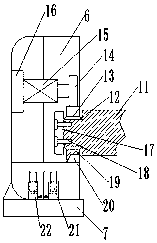

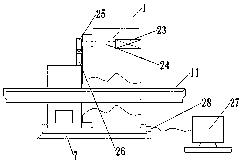

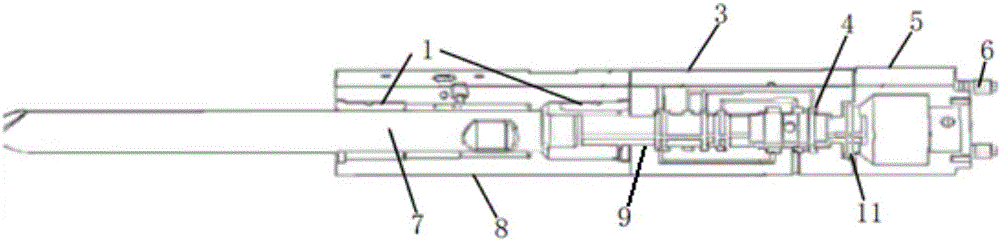

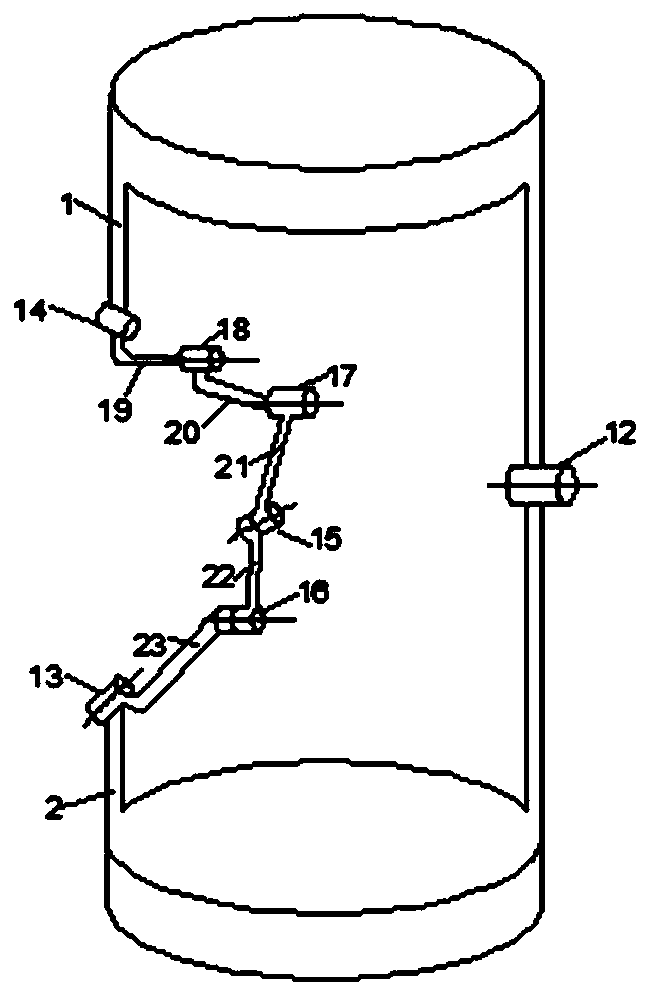

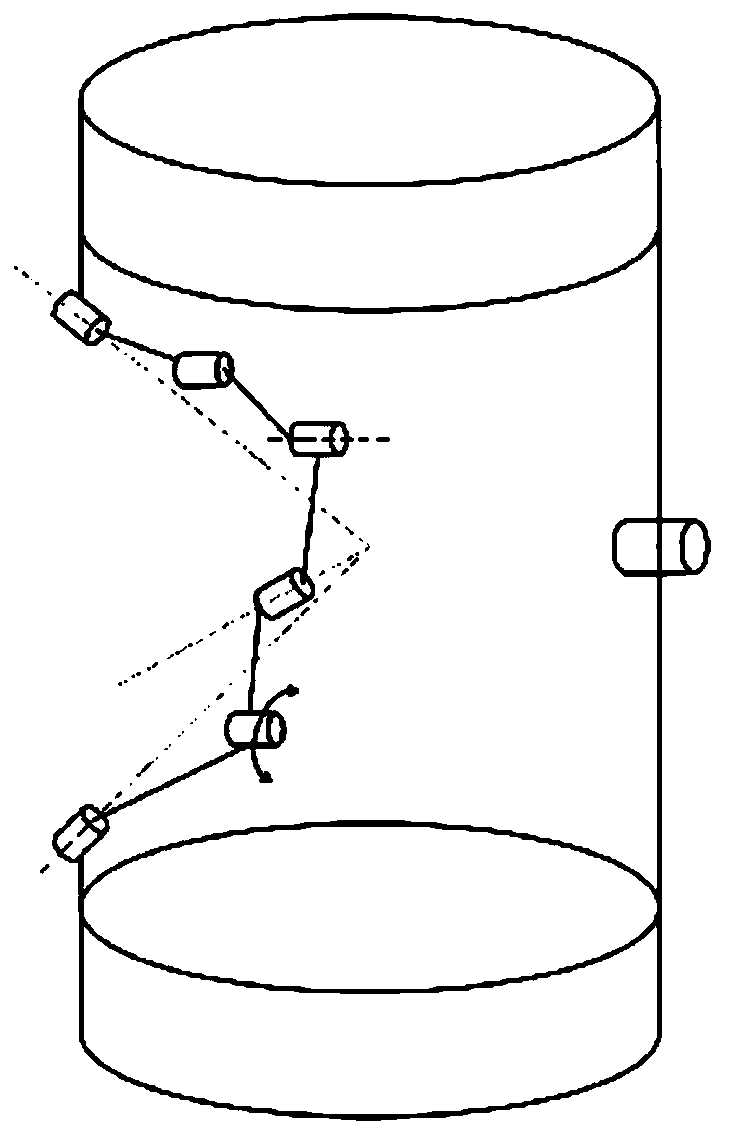

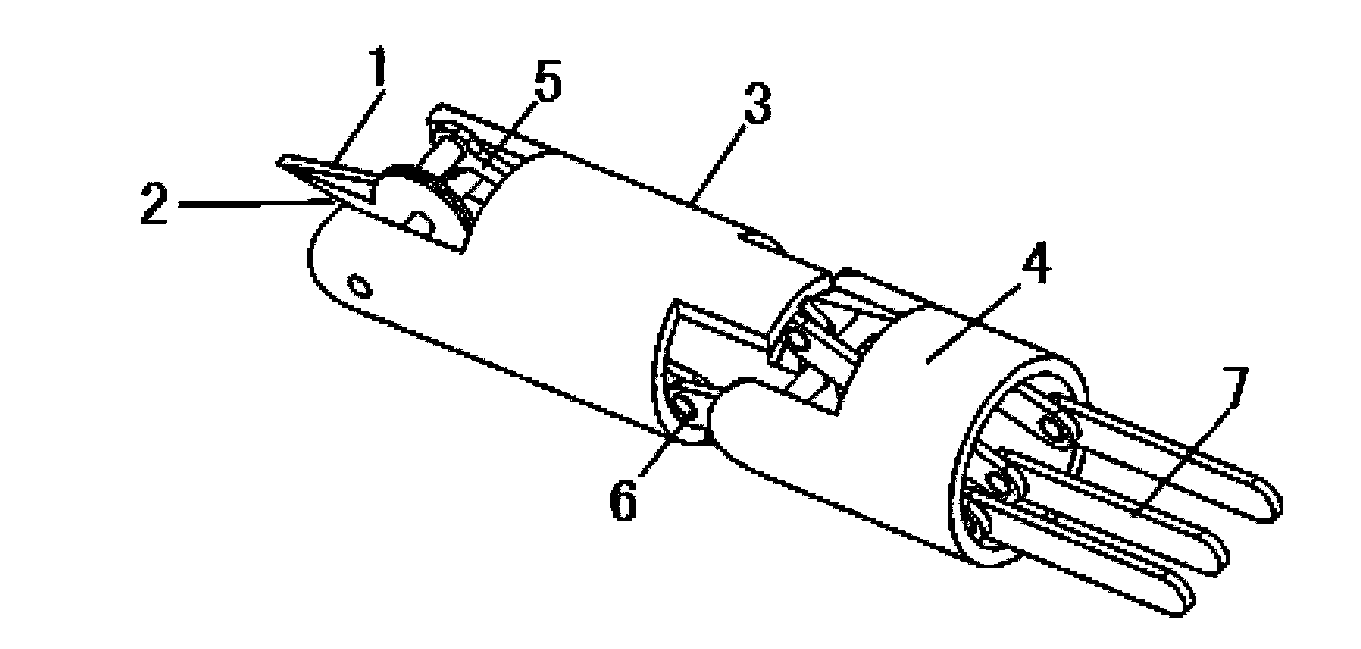

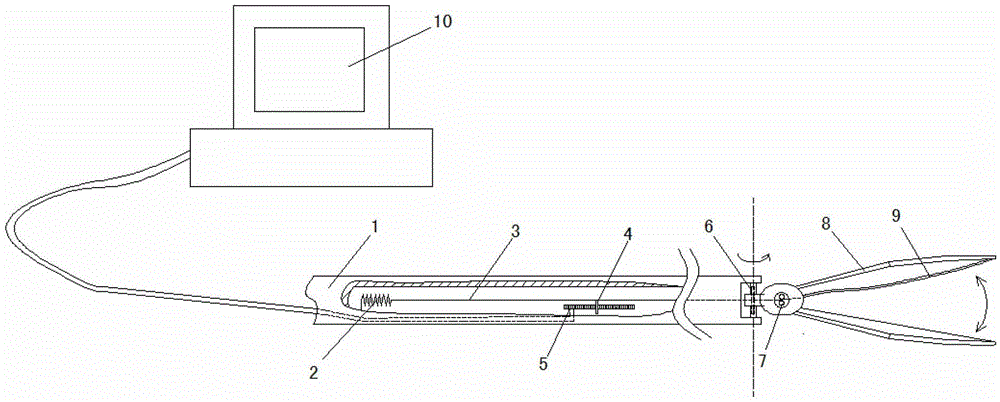

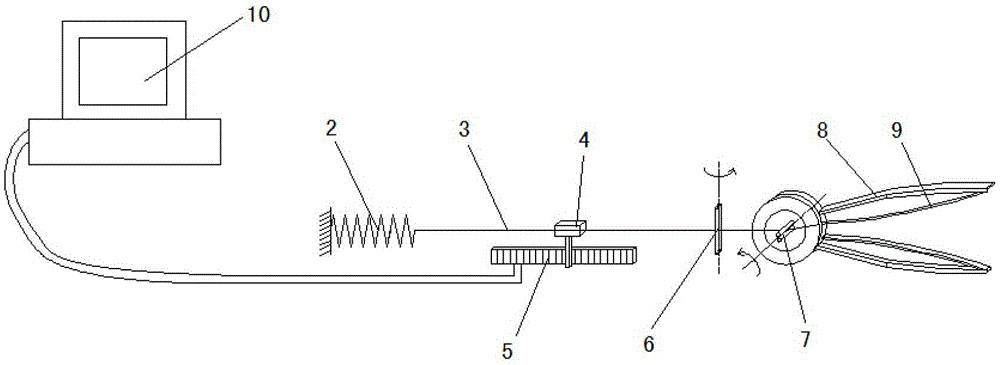

Tactile feedback system of minimally invasive surgery instrument

ActiveCN104274244ASimple structureEasy to installDiagnosticsSurgeryComputer control systemMini invasive surgery

Provided is a tactile feedback system of a minimally invasive surgery instrument. The tactile feedback system of the minimally invasive surgery instrument comprises a long and thin rod of the minimally invasive surgery instrument, an end effector connected with the long and thin rod, a first elastic device, a connecting piece with flexible deformability, a second elastic device, a first pair of rolling wheels, a second pair of rolling wheels, an indicating piece, a measuring element and a computer control system. The position of the indicating piece can be read through the measuring element in the long and thin rod mounted in the minimally invasive surgery instrument. The computer control system reads the reading of the measuring element, converts the reading, and judges the magnitude of the force applied to the inner side of the end effector. The tactile feedback system of the minimally invasive surgery instrument has the advantages of being simple in structure, high in sensitivity and low in cost.

Owner:SHANGHAI UNIV OF ENG SCI

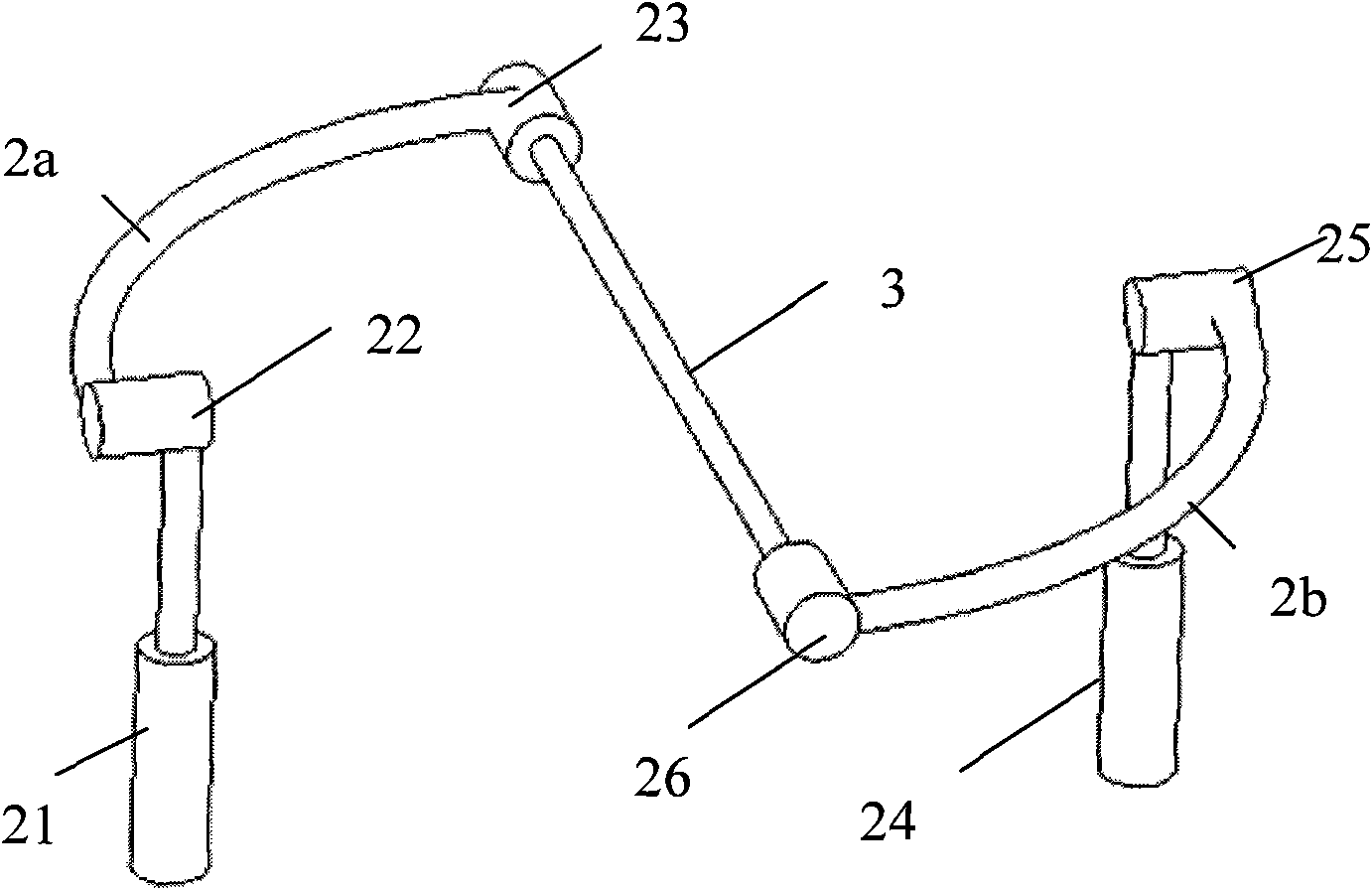

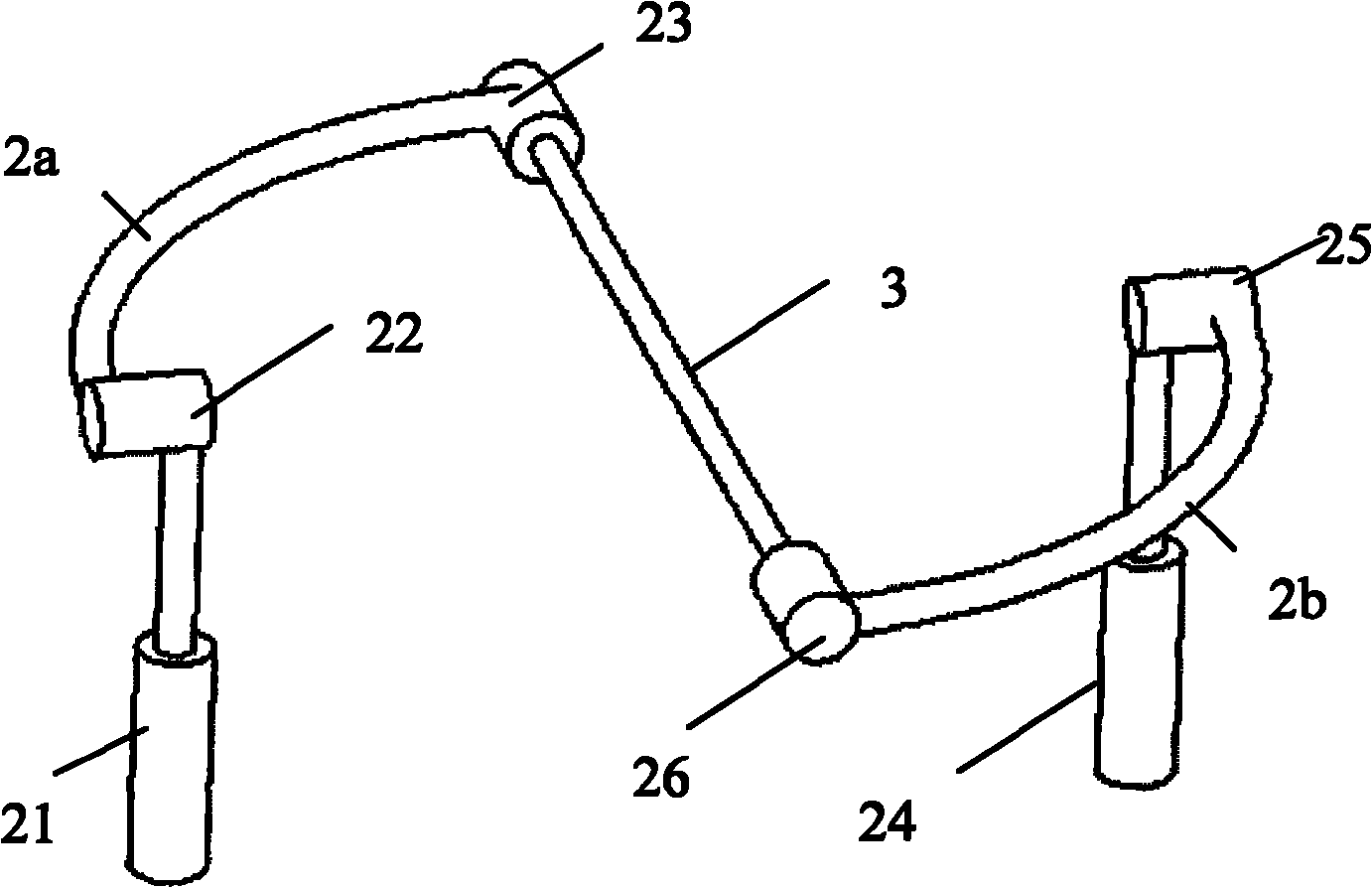

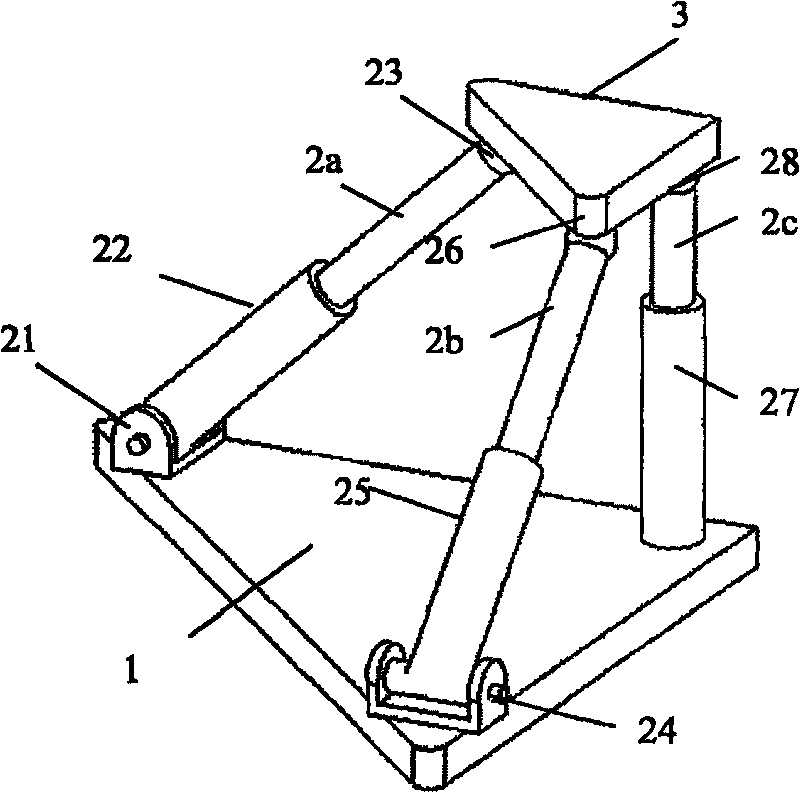

Decoupling parallel mechanism

InactiveCN101780671ASimple structureEasy to installProgramme-controlled manipulatorLarge fixed membersEngineeringMechanical engineering

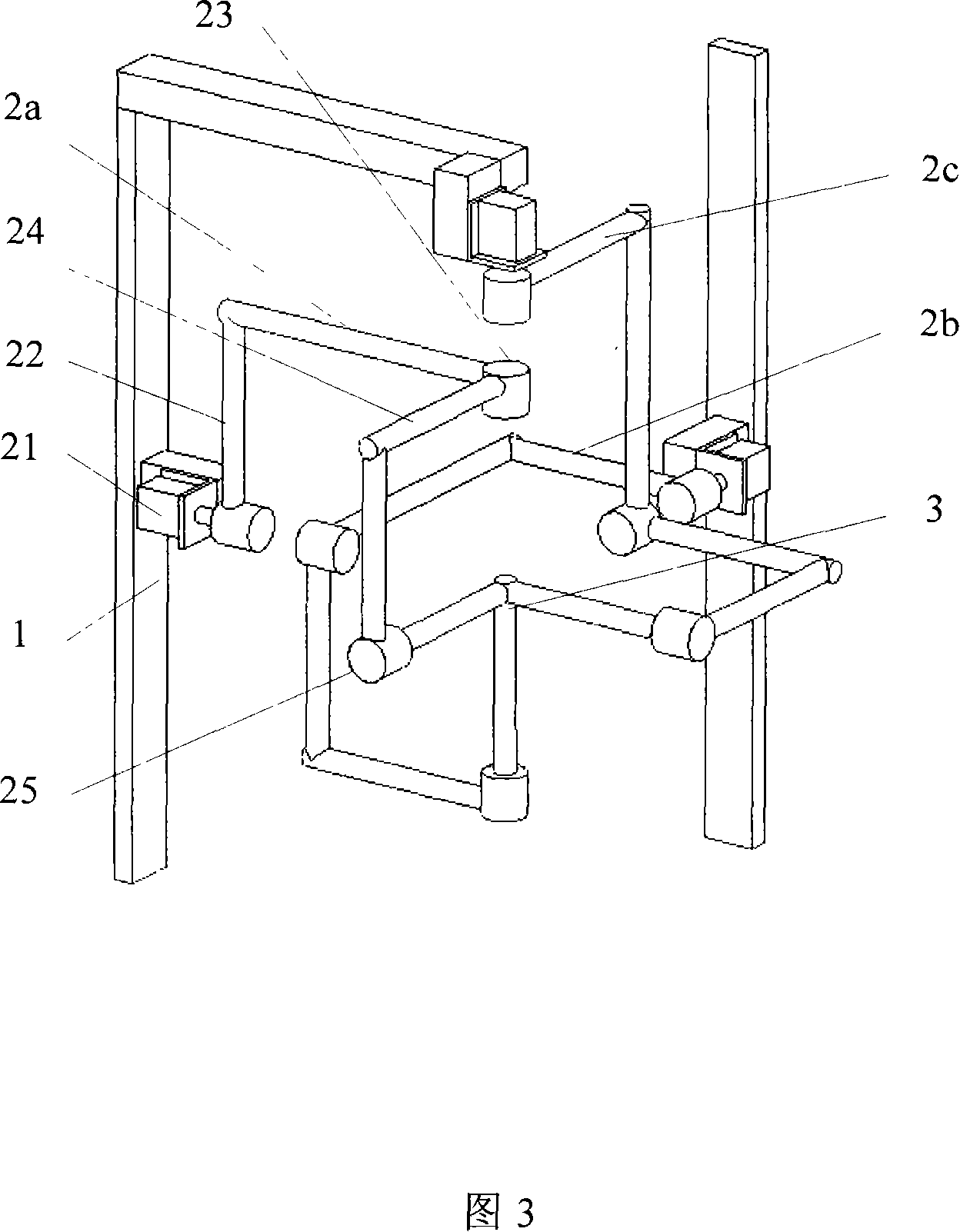

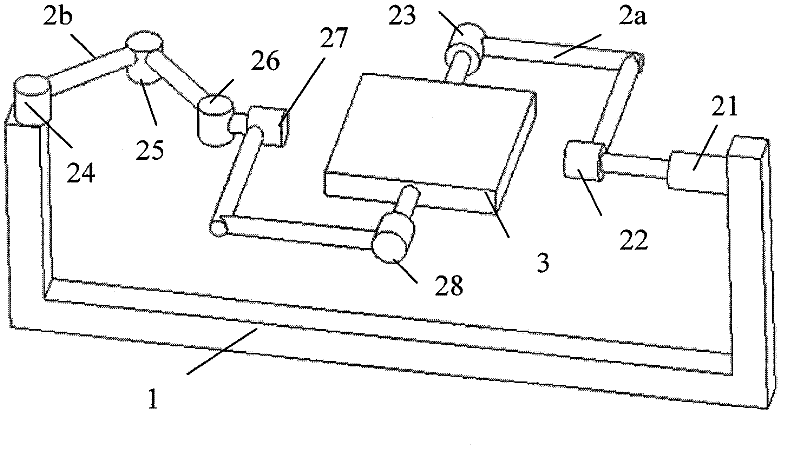

The invention relates to a decoupling parallel mechanism, which comprises a stand, a mobile platform (3), a mobile branched chain (2a) and a mobile branched chain (2b), wherein the mobile branched chain (2a) and the mobile branched chain (2b) are connected with the stand and the mobile platform (3); the mobile branched chain (2a) comprises a sliding pair (21), a revolute pair (22), a revolute pair (23) and a rod piece; the mobile branched chain (2b) comprises a sliding pair (24), a revolute pair (25), a revolute pair (26) and a rod piece; and the axial lines of the sliding pair (21) and the sliding pair (24) are parallel, the revolute pair (22) and the revolute pair (25) are coaxial, and the revolute pair (23) and the revolute pair (26) are coaxial. Compared with the prior art, the invention improves the rigidity of the mechanism through the parallel mechanism, the carrying capacity of the mechanism in unit volume is higher, and a motor is close to a base, thus the movement inertia of the mechanism is reduced, and higher response speed can be obtained.

Owner:SHANGHAI UNIV OF ENG SCI

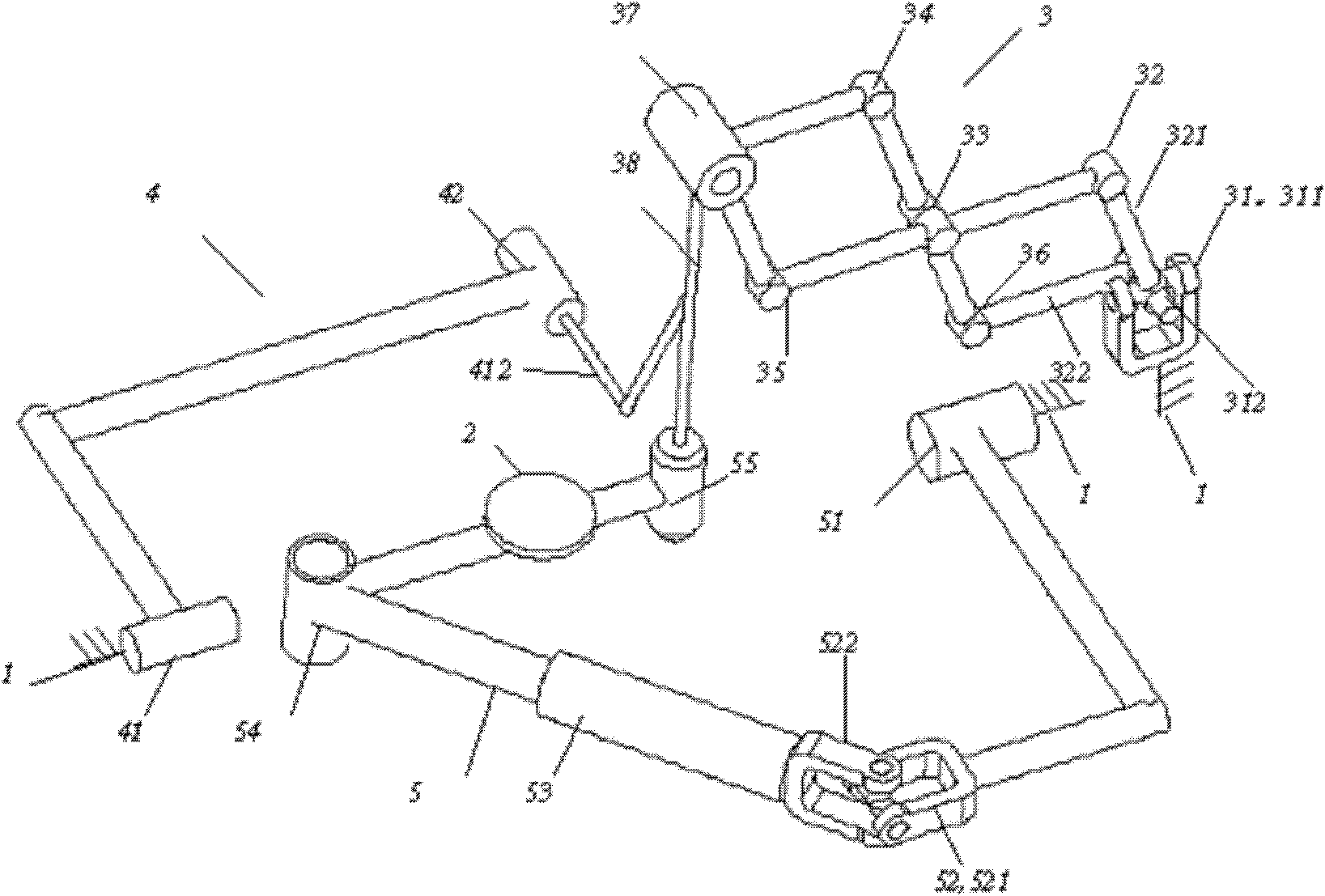

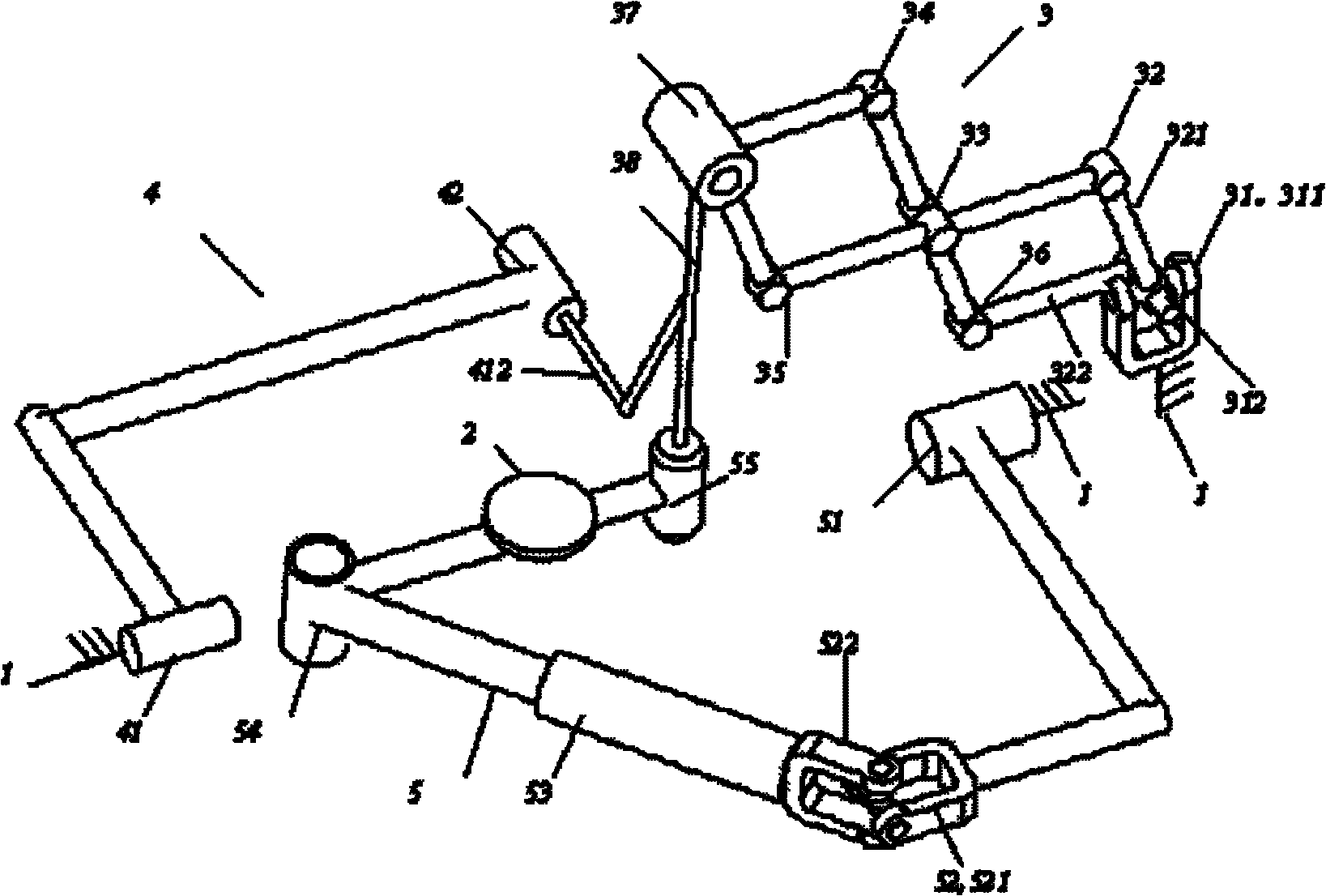

Decoupled three-rotation parallel mechanism

InactiveCN102120299AThe realization principle is simpleGood linear relationshipProgramme-controlled manipulatorLarge fixed membersMoment of inertiaEngineering

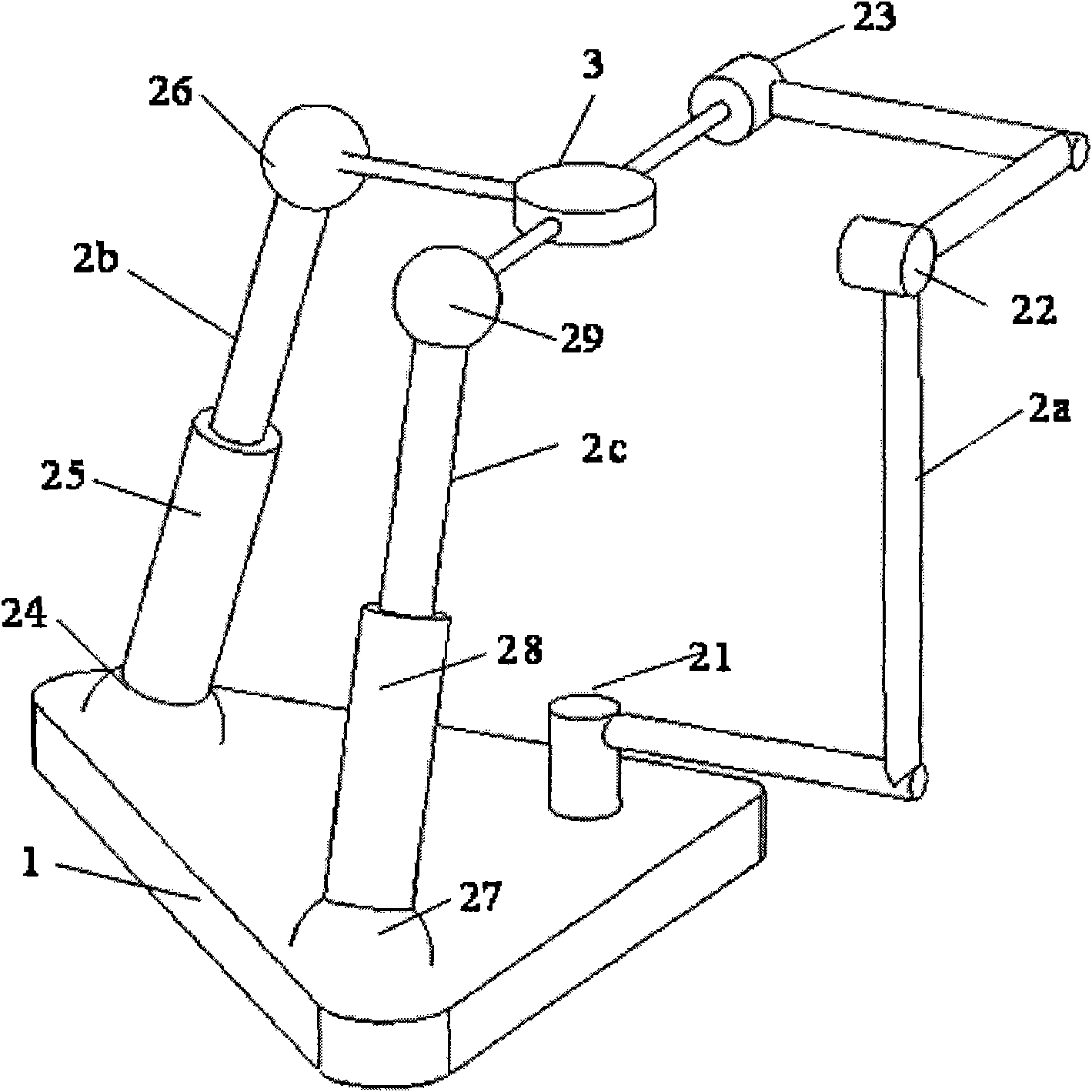

The invention relates to a decoupled three-rotation parallel mechanism, which comprises a base, a dynamic platform, a first moving branch chain, a second moving branch chain and a third moving branch chain, wherein the first, second and third moving branch chains are connected between the base and the dynamic platform; the first moving branch chain comprises a first universal hinge, a first rotating pair, a second rotating pair, a third rotating pair, a fourth rotating pair, a fifth rotating pair, a sixth rotating pair and a seventy rotating pair, which are connected in turn; the second moving chain comprises a tenth rotating pair, an eleventh rotating pair and a second rotating rod, which are connected in turn; and the third moving branch chain comprises a second universal hinge, a moving pair, a twelfth rotating pair and a thirteenth rotating pair, which are connected in turn, and one end of the twelfth rotating pair is connected with the seventh rotating pair through the dynamic rotating platform. In the invention, fewer moving pairs are adopted, the structure is simple, the installation is convenient, the rotation inertia is small, and the motion response is quick; and the motion decoupling and control are simple, so the development cost is reduced.

Owner:DONGHUA UNIV

Decoupled three-rotation parallel mechanism

InactiveCN102120299BThe realization principle is simpleGood linear relationshipProgramme-controlled manipulatorLarge fixed membersEngineeringMoment of inertia

The invention relates to a decoupled three-rotation parallel mechanism, which comprises a base, a dynamic platform, a first moving branch chain, a second moving branch chain and a third moving branch chain, wherein the first, second and third moving branch chains are connected between the base and the dynamic platform; the first moving branch chain comprises a first universal hinge, a first rotating pair, a second rotating pair, a third rotating pair, a fourth rotating pair, a fifth rotating pair, a sixth rotating pair and a seventy rotating pair, which are connected in turn; the second moving chain comprises a tenth rotating pair, an eleventh rotating pair and a second rotating rod, which are connected in turn; and the third moving branch chain comprises a second universal hinge, a moving pair, a twelfth rotating pair and a thirteenth rotating pair, which are connected in turn, and one end of the twelfth rotating pair is connected with the seventh rotating pair through the dynamic rotating platform. In the invention, fewer moving pairs are adopted, the structure is simple, the installation is convenient, the rotation inertia is small, and the motion response is quick; and the motion decoupling and control are simple, so the development cost is reduced.

Owner:DONGHUA UNIV

Decoupled three-rotational-degree-of-freedom parallel mechanism

The invention relates to a decoupled three-rotational-degree-of-freedom parallel mechanism, which consists of a machine frame (1), a dynamic platform (3), a first motion branch chain (2a), a second motion branch chain (2b) and a third motion branch chain (2c), wherein the first motion branch chain (2a), the second motion branch chain (2b) and the third motion branch chain (2c) are fixedly connected between the machine frame (1) and the dynamic platform (3); and the axes of three rotation pairs of the first motion branch chain (2a) meet at the central point of the platform (3). As few motion pairs are used and all driving electric motors are arranged on the machine frame, the motion-decoupled spherical rotation parallel mechanism of the invention has the advantages of simple structure, convenient installation, small rotation inertia and quick motion response. In addition, the spherical rotation parallel mechanism of the invention has linear motion decoupling, easy calibration and simple control, thereby reducing development cost.

Owner:DONGHUA UNIV

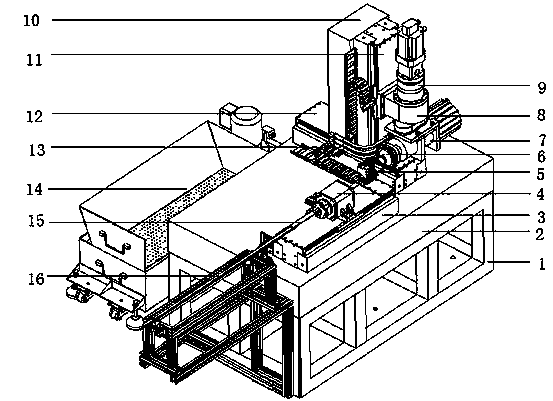

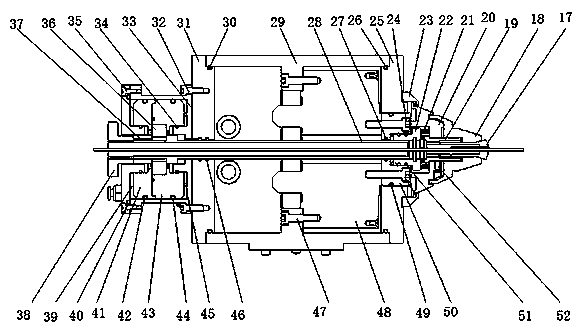

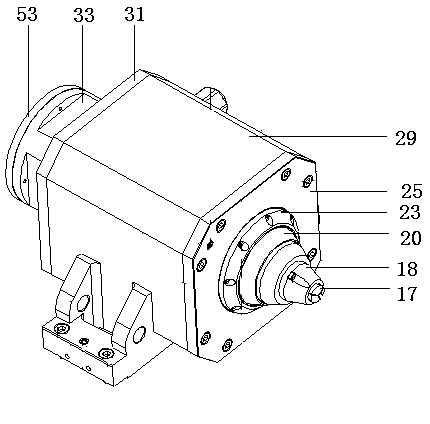

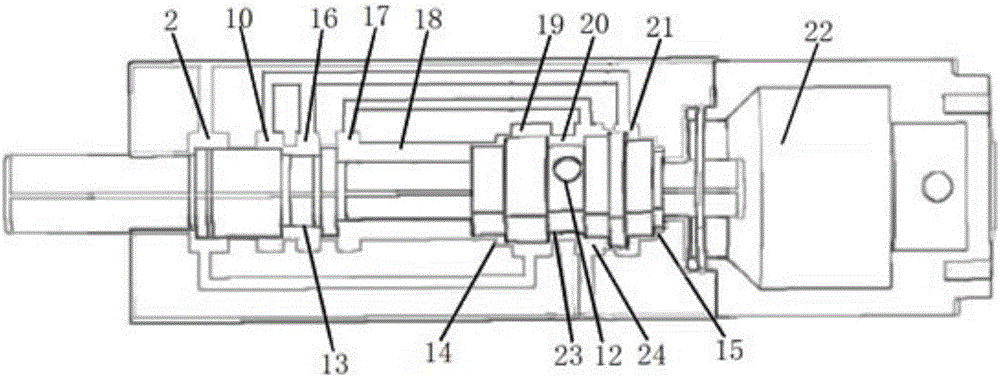

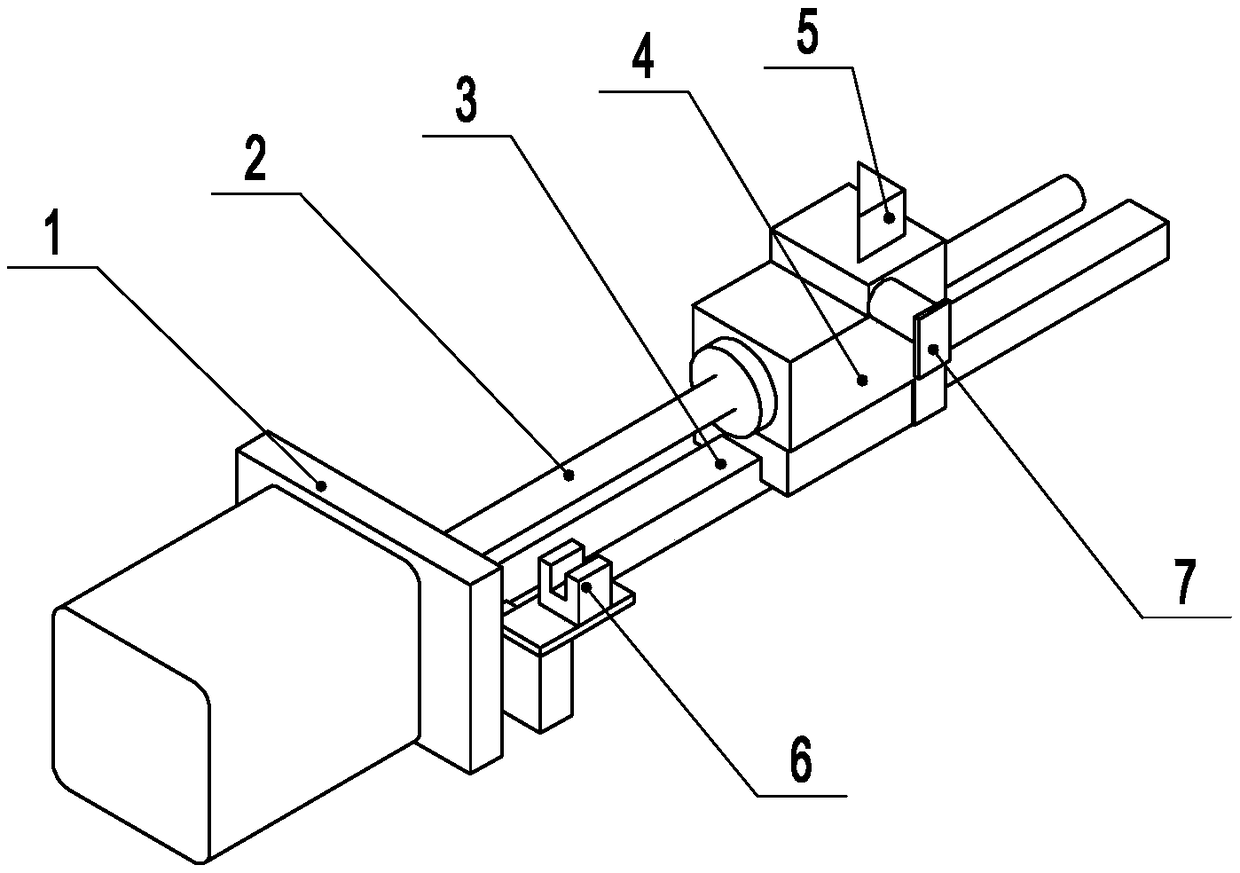

Five-shaft cutter grinding machine

InactiveCN103419099AEliminate backlashMove fastOther manufacturing equipments/toolsElectric machineEngineering

A five-shaft cutter grinding machine comprises a steel frame base, a filtering water tank, a platform, an X shaft, a precision rotary shaft, a cutter bar stock supporting frame, a Y shaft, a main shaft, a grinding wheel set, a rotary shaft, a stand column, a Z shaft, a bar stock far-end supporting module and a nozzle. Compared with most products of the same type abroad where the technologies like servomotor driving and worm and gear drive are adopted, the precise rotary shaft adopted in the five-shaft cutter grinding machine is driven by a direct driving type motor, does not need the intermediate transmission link, and has higher movement speed. Particularly, the intermediate transmission link does need to be used for transmitting movement, so that rotation gaps generated by a worm and gear transmission mechanism and other transmission mechanisms are completely eliminated. The five-shaft cutter grinding machine has the advantages that the rotation speed is high, waterproof sealing is achieved, the cutter bar stock automatic clamping function is achieved, precision is high, the structure is compact, and the grinding machine is modularized. Therefore, a comprehensive optimized solution is provided for cutter precise machining.

Owner:KUNSHAN YUNCO PRECISION IND TECH

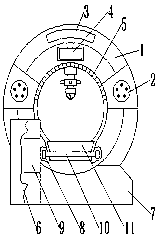

Radiotherapy device with magnetic resonance imaging (MRI) guidance

PendingCN108236761AFast response to movementHigh movement precisionDiagnostic recording/measuringSensorsResonanceEngineering

The invention belongs to the technical field of medical instruments, in particular to a radiotherapy device with magnetic resonance imaging (MRI) guidance. For the problems that an existing radiotherapy device cannot accurately image and the movement of an imaging device is unreasonable, the invention proposes the following scheme, including a magnetic resonance circular ring body having a groovein the outer wall on one side thereof, a control panel is clamped on the inner wall of the groove, a curved plate is welded at an intermediate position of the outer wall on one side of the magnetic resonance circular ring body, a warning name plate is connected onto the outer wall on one side of the curved plate by a bolt, and a square groove is formed in the outer wall on one side of the magneticresonance circular ring body. According to the invention, the radiotherapy device enables a patient to obtain an all-round detection inside the magnetic resonance circular ring body, avoids the medical staff being subjected to different degrees of radiation, plays a good role in protecting the medical staff, allows the detected data to be timely observed by the medical staff and the patient, andmeanwhile, enables the storage and transmission of data.

Owner:宋俊韬

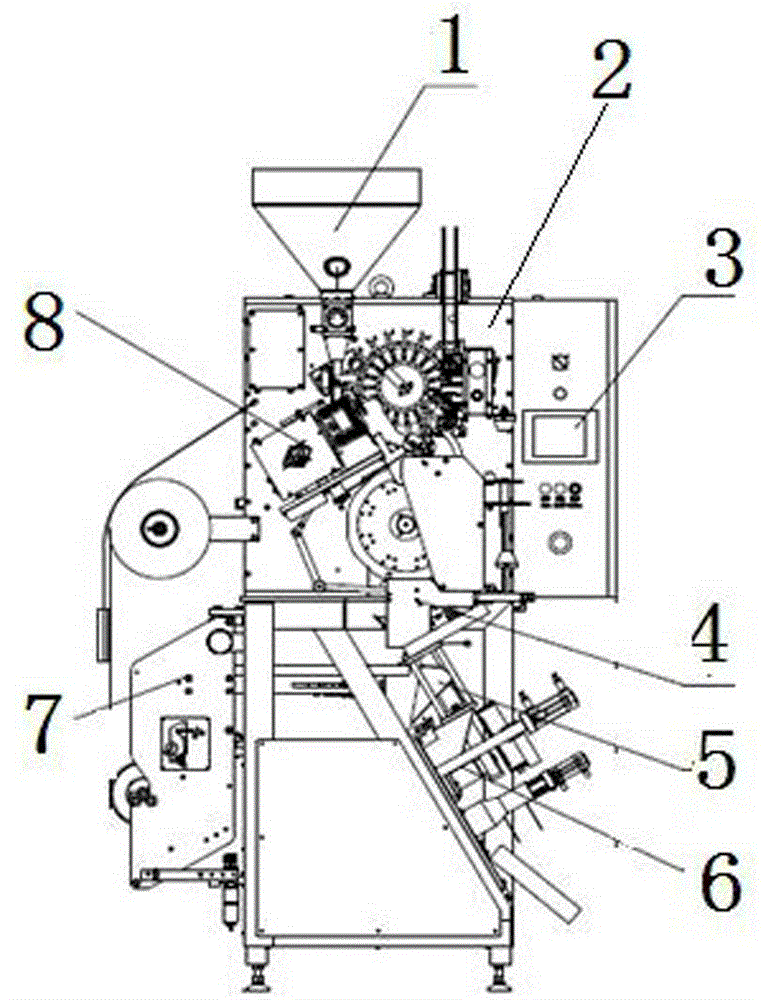

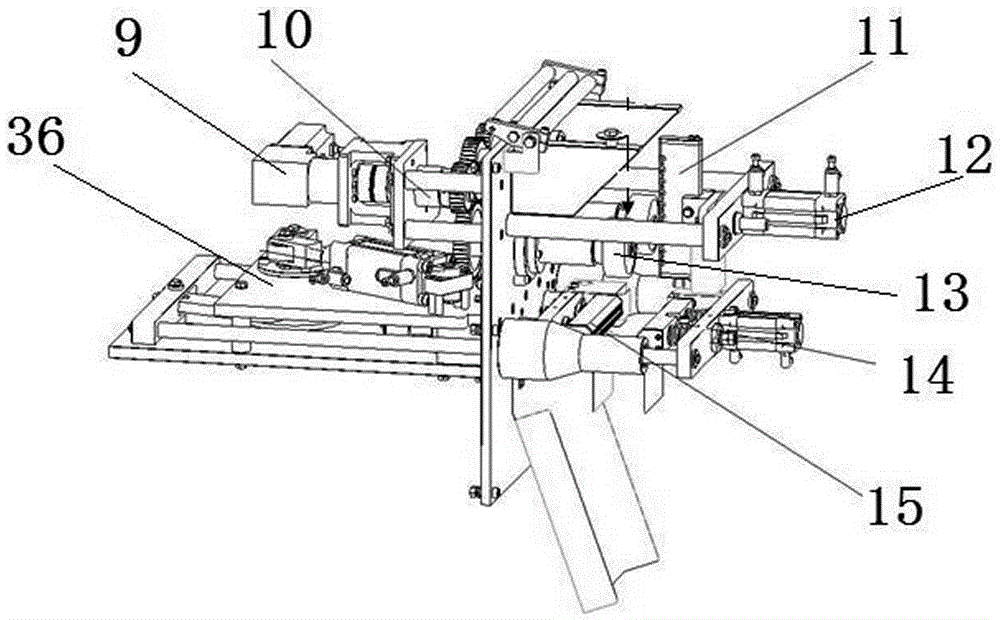

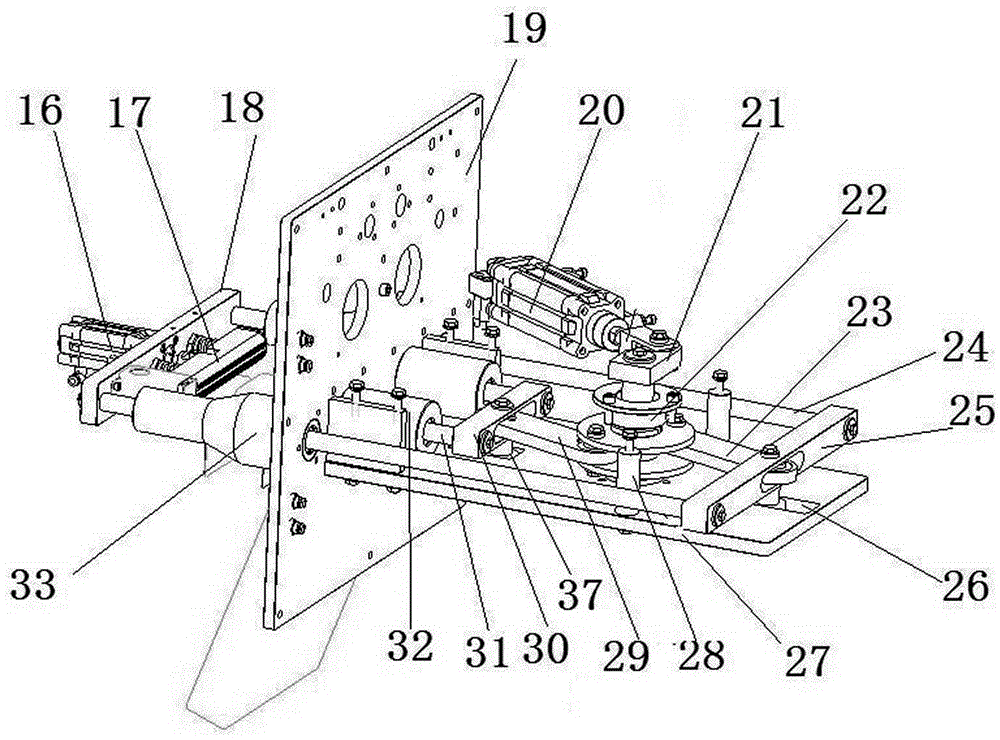

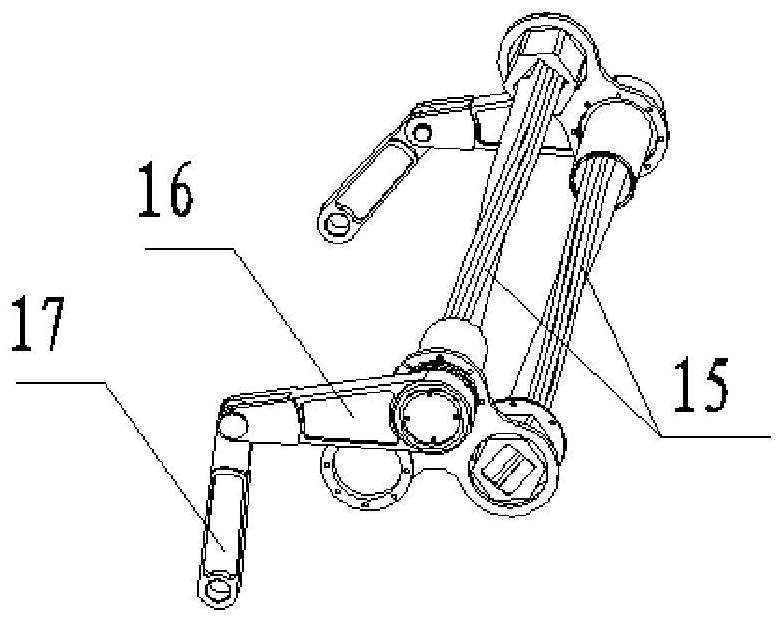

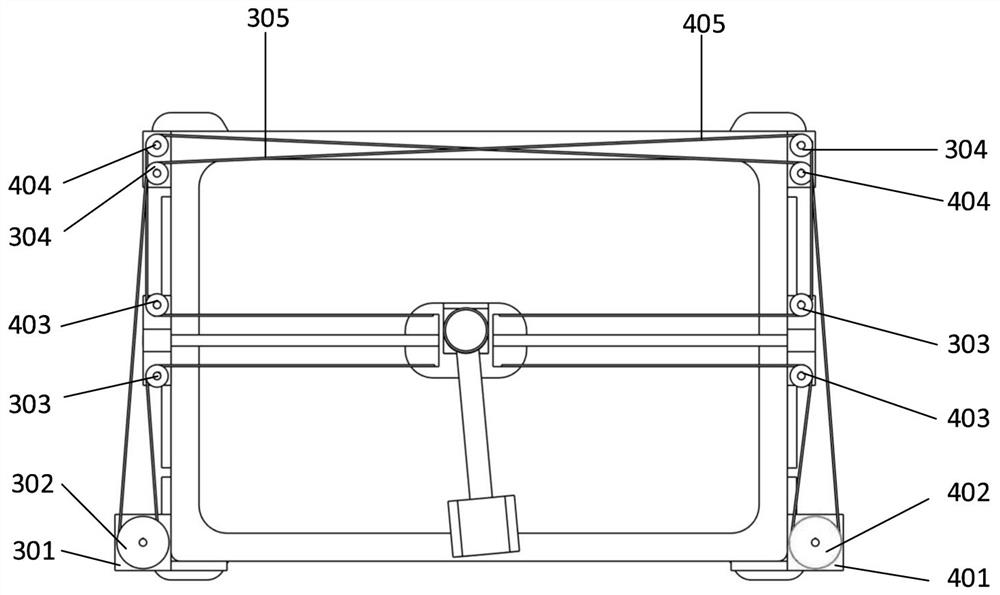

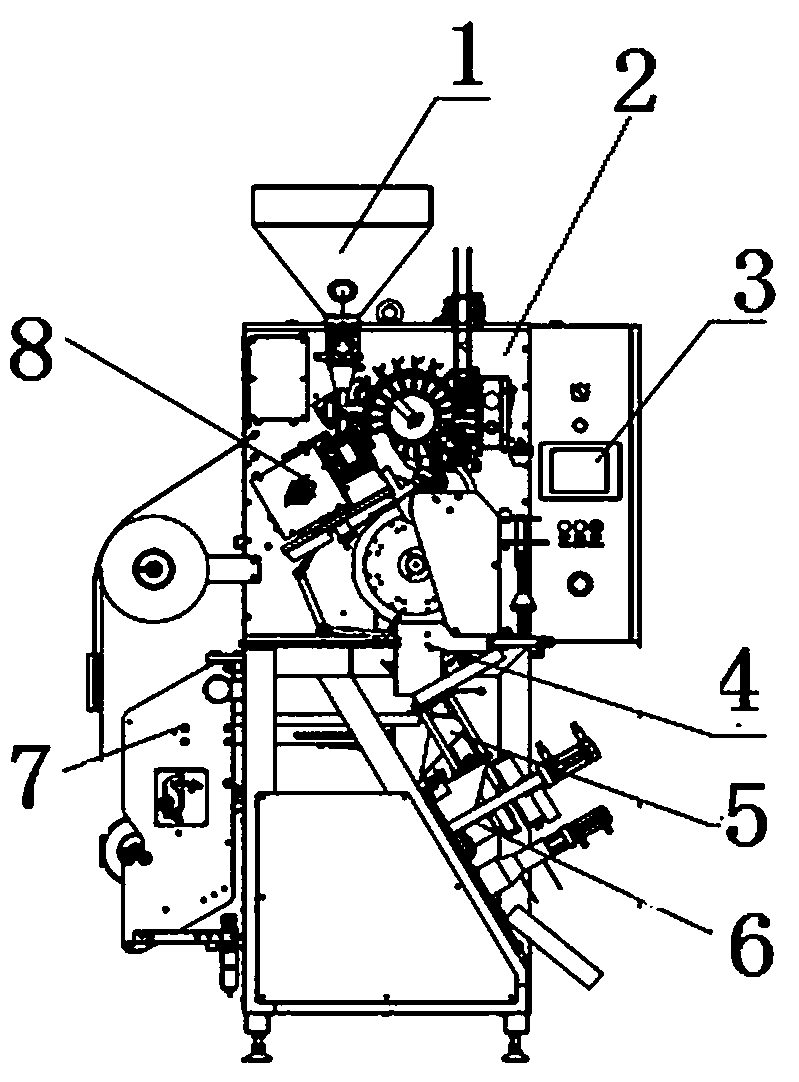

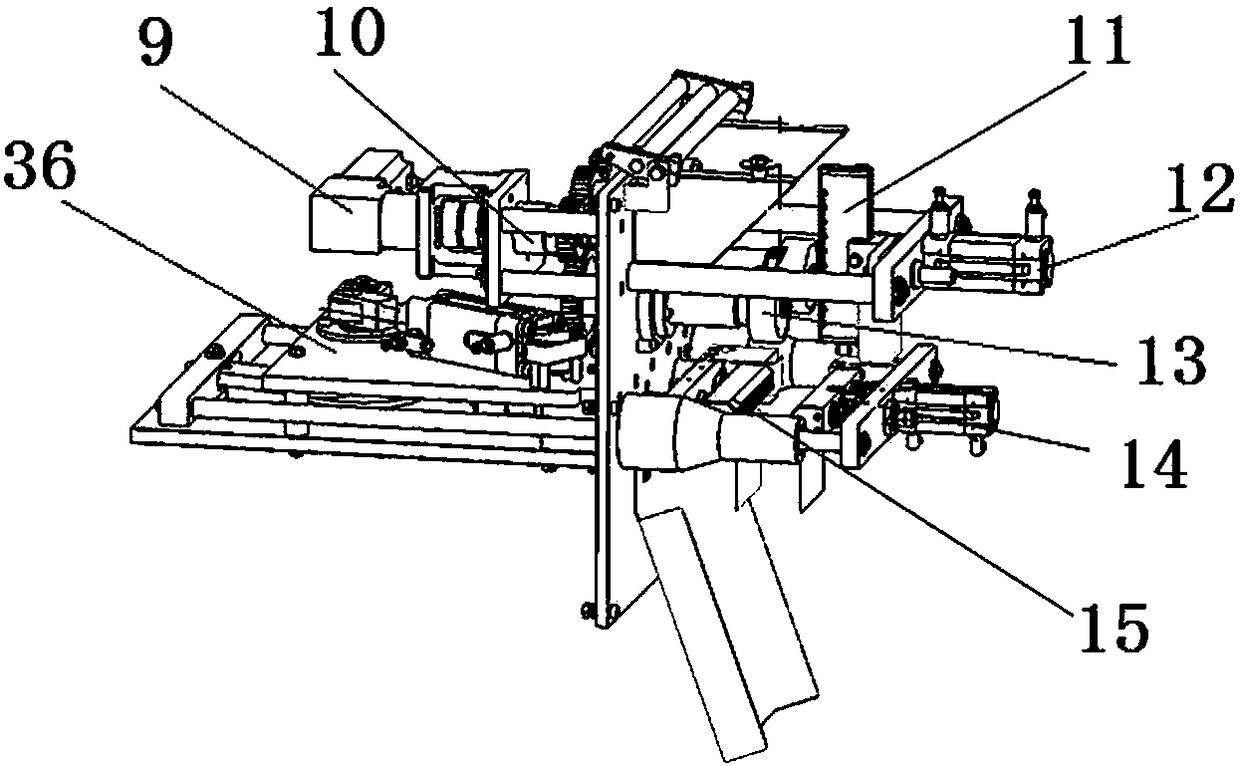

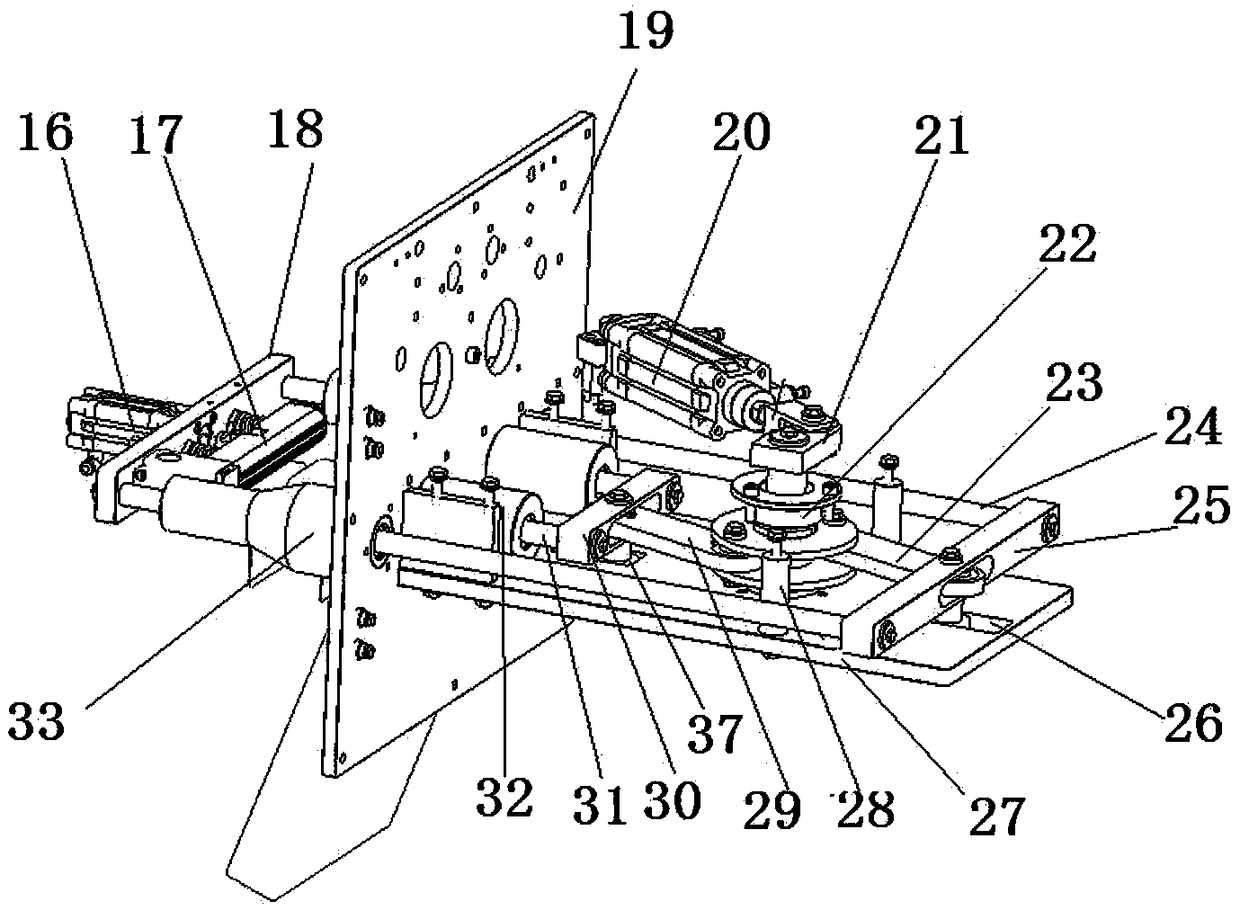

Teabag packing machine and outer bag heat-sealing assembly thereof

ActiveCN105416710AFast response to movementGood synchronizationWrapper twisting/gatheringPackaging foodstuffsEngineeringMechanical engineering

The invention discloses a teabag packing machine and an outer bag heat-sealing assembly thereof. The outer bag heat-sealing assembly comprises an installing bracket, a driving mechanism, a first heat-sealing plate and a second heat-sealing plate. The driving mechanism comprises a rotating driving piece, a first connecting component and a second connecting component. One end of the first connecting component is connected to the rotating driving piece, and the other end of the first connecting component is connected to the first heat-sealing plate. One end of the second connecting component is connected to the rotating driving piece, and the other end of the second connecting component is connected to the second heat-sealing plate. The movement direction of the first heat-sealing plate and the movement direction of the second heat-sealing plate are opposite under the drive of the rotating driving piece. The movement of the first heat-sealing plate and the movement of the second heat-sealing plate are both driven by the same driving mechanism. The first heat-sealing plate, the second heat-sealing plate and the driving mechanism are linked together to form an integral structure. The first heat-sealing plate and the second heat-sealing plate are not mutually independent but associated. Compared with a heat-sealing assembly of the prior art, other intermediate driving pieces are no longer depended on, and the movement is stable and reliable.

Owner:CAMALUOYANGELECTROMECHANIC

Sleeving valve type hydraulic breaking hammer

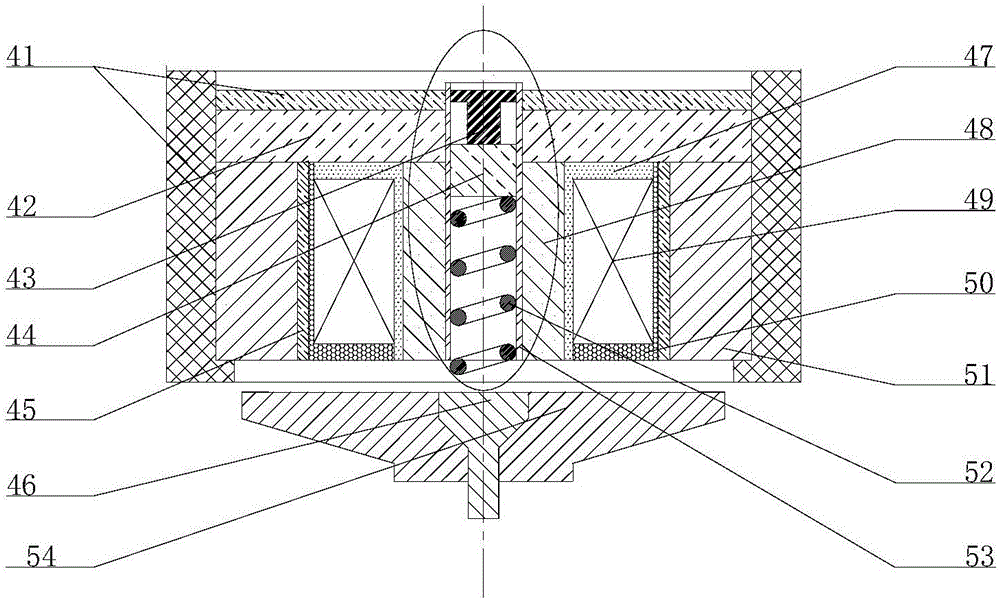

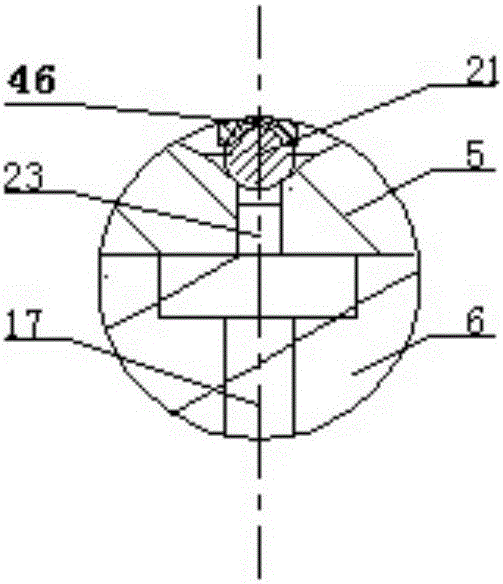

InactiveCN106120925ASimple structureCompact structureMechanical machines/dredgersReciprocating motionSleeve valve

The invention relates to a sleeving valve type hydraulic breaking hammer. The sleeving valve type hydraulic breaking hammer comprises a front body, a middle cylinder and a nitrogen chamber which are sequentially arranged from front to back. A drill rod is arranged inside the front body in the axial direction. The middle cylinder is internally provided with a piston, a sleeving valve and a hydraulic oil path system, wherein the piston is in transmission connection with the drill rod; the sleeving valve is arranged outside the piston in a sleeving mode and matched with the inner wall of the middle cylinder; and the hydraulic oil path system drives the piston and the sleeving valve to move back and forth in the axial direction of the middle cylinder. In the working state, the piston drives the drill rod to move back and forth in the axial direction of the middle cylinder under driving of the hydraulic oil path system, and accordingly hard objects are broken. Compared with the prior art, the sleeving valve type hydraulic breaking hammer is simple in structure, the sleeving valve is directly arranged on the piston in the sleeving mode, a valve element is omitted, the structure is more compact, and structure manufacturability is good; and since the travel stroke of the sleeving valve is short, the working efficiency is remarkably improved, and the demands of engineering application can be met.

Owner:SHANGHAI UNIV OF ENG SCI

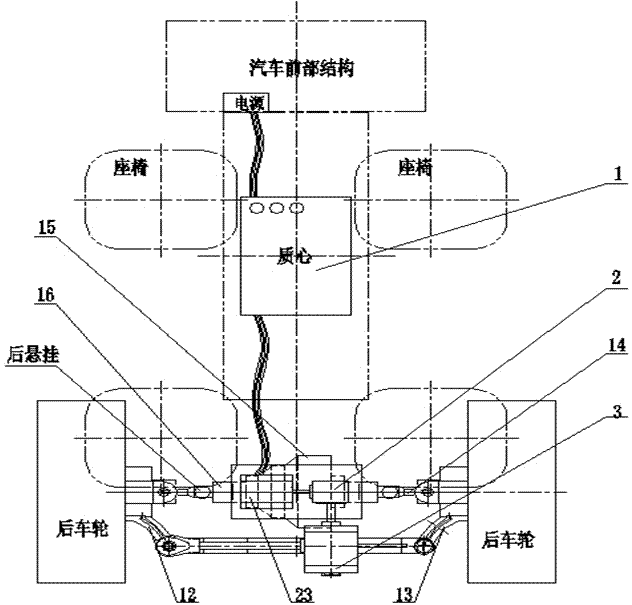

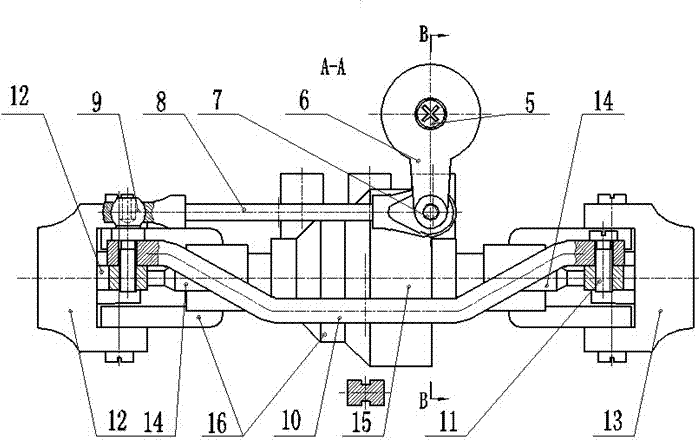

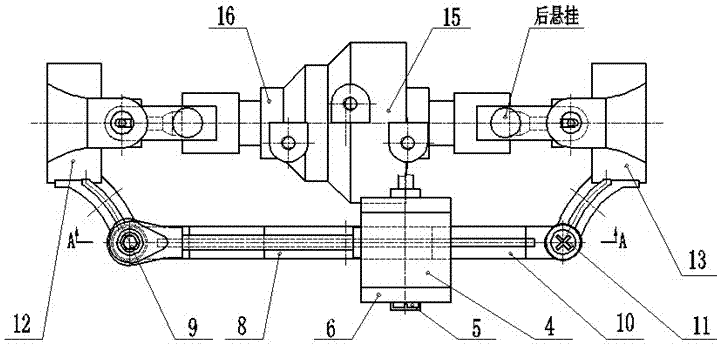

Driving rear wheel steering mechanism based on crank connecting rod mechanism

InactiveCN107235073AFast response to movementReduce volumeSteering linkagesElectrical steeringStability coefficientElectricity

Disclosed is a driving rear wheel steering mechanism based on a crank connecting rod mechanism. A steering mechanism controller is additionally arranged at the mass center of a vehicle, one end of the steering mechanism controller is connected with an electricity supply of the vehicle through a circuit to lead out a control signal, and the other end of the steering mechanism controller is connected with a steering electromotor through a circuit to transmit the control signal. A speed regulating mechanism supporting plate is additionally arranged on a rear axle shell of the vehicle, a steering electromotor and a steering speed regulating mechanism are arranged, and a worm wheel spline shaft of the steering speed regulating mechanism outputs power. A steering connecting rod mechanism is hinged to two rear wheel vertical columns of the vehicle, one end of the steering connecting rod mechanism is driven through the worm wheel spline shaft, and the other end of the steering connecting rod mechanism outputs power to the rear wheel columns to drive rear wheels to rotate. The crank connecting rod structure is adopted, the movement response is rapid, the size is small, the weight is small, and energy consumption is low; the turning radius of the vehicle is effectively decreased, the high-speed stability of the vehicle is strengthened, and the safety stability coefficient of the vehicle is promoted; and particularly, the instable condition, caused by high-speed tire bursting and similar incidents, of the vehicle with a rear wheel steering function is reduced, and the accidental loss is reduced.

Owner:TAIYUAN UNIV OF TECH

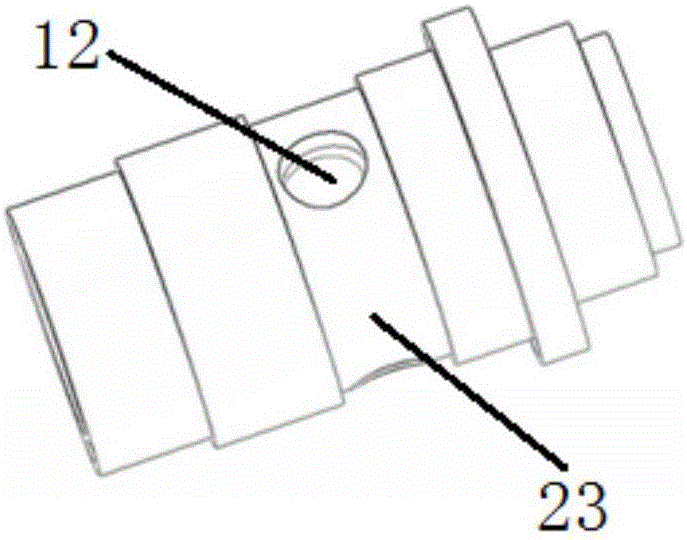

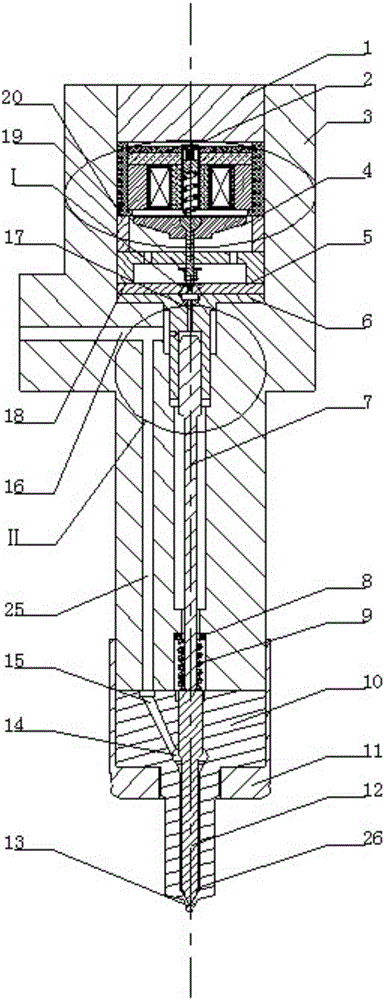

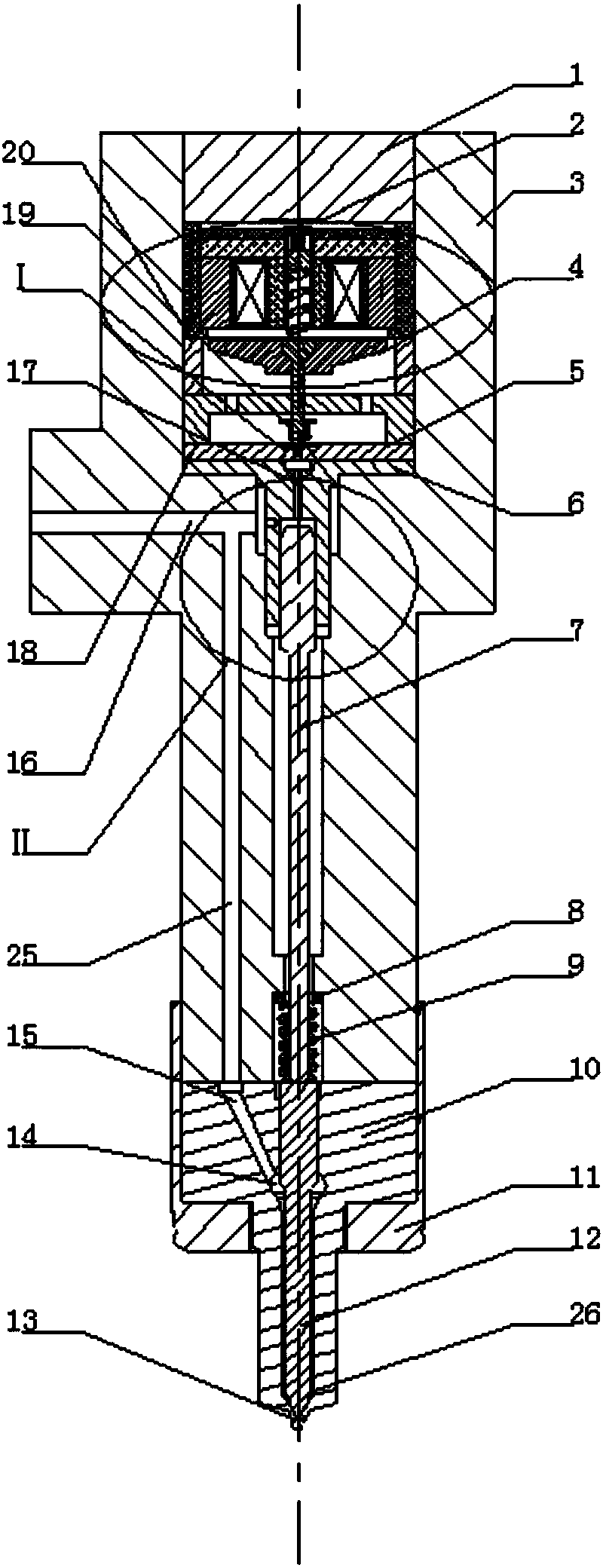

Amorphous alloy electromagnetic control oil injector with combined iron core

ActiveCN105888904AQuick responseIncreased long-term operating lifeFuel injection apparatusMachines/enginesMagnetic polesAlloy

The invention aims to provide an amorphous alloy electromagnetic control oil injector with a combined iron core. An amorphous alloy electromagnet assembly, a pilot ball valve seat, a control piston body and a needle valve ejector rod are installed in an oil injector body in sequence from top to bottom, a nozzle is fixedly arranged at the bottom of the oil injector body through a nozzle clamp nut, and a needle valve is installed in the nozzle. Compared with a conventional silicon steel sheet magnetic pole, the amorphous alloy electromagnetic control oil injector with the combined iron core has the advantage that the loss of the iron core is greatly reduced. In addition, due to the facts that a copper ring is arranged between an auxiliary magnetic pole and coils in the amorphous alloy electromagnet assembly, copper has good electrical conductivity, and the constantly-enhanced magnetic field can generate high induced current in the copper ring to delay the increase of the magnetic flux, the effective inductance of the coils in the working process is greatly reduced, the increase speed of the driving current of the coils is increased, the movement response of a valve rod is quickened, the response speed of the amorphous alloy electromagnetic control oil injector with the combined iron core can be conveniently increased, and the loss is reduced.

Owner:HARBIN ENG UNIV

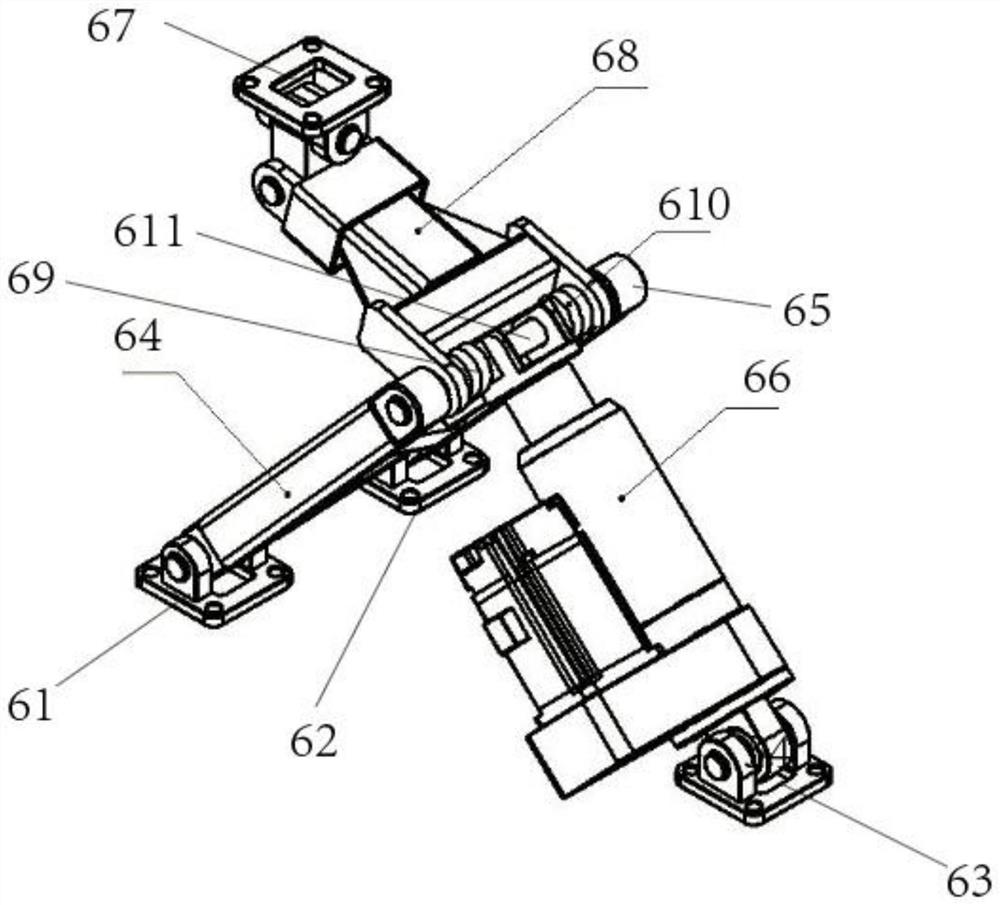

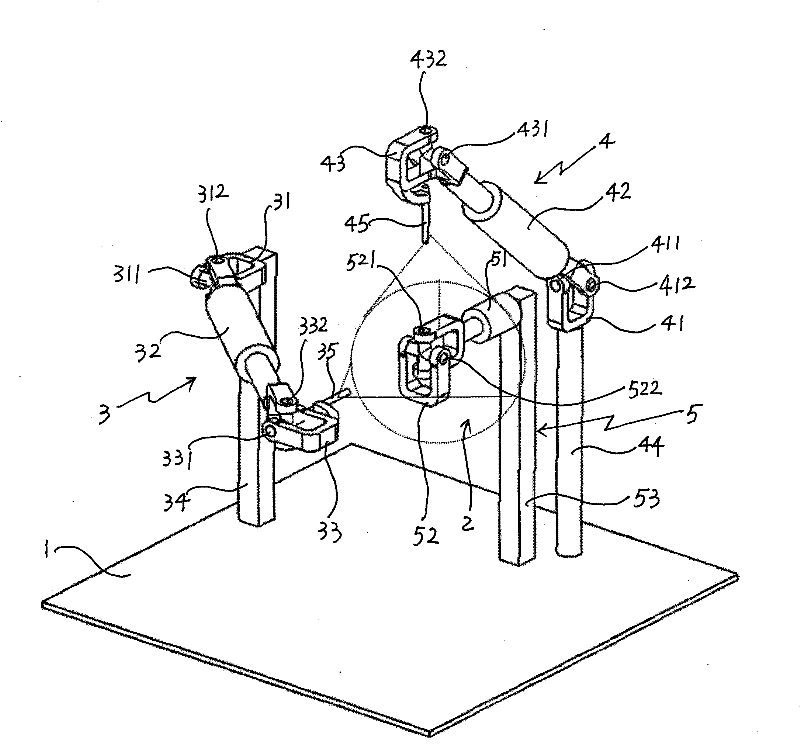

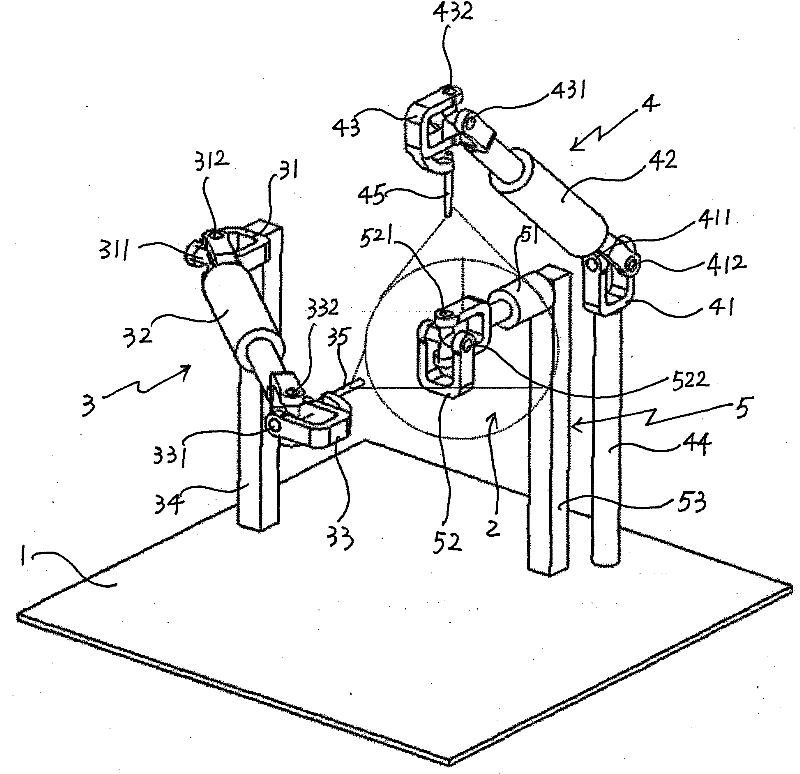

Mechanical arm joint with controllable rigidity

ActiveCN109849047AStiffness controllableIncrease stiffnessProgramme-controlled manipulatorJointsEngineeringSacroiliac joint

The invention provides a mechanical arm joint with controllable rigidity. The mechanical arm joint comprises an upper platform, a lower platform, and a first motion branched chain and a second motionbranched chain connected between the platforms. The first motion branched chain comprises six rotating pairs; a sixth rotating pair and a seventh rotating pair are connected with the upper platform; afirst rotating pair is connected with a second rotating pair through a connecting rod; the second rotating pair is connected with a third rotating pair through a connecting rod; the third rotating pair is connected with a fourth rotating pair through a connecting rod; the fourth rotating pair is connected with a fifth rotating pair through a connecting rod; the fifth rotating pair is connected with the sixth rotating pair through a connecting rod; the second motion branched chain comprises the seventh rotating pair; and the seventh rotating pair is connected with the upper platform and the lower platform. The second rotating pair is driven to change the axis position of the third rotating pair, so that the position of an intersecting point of the axis of the first rotating pair, the axisof the third rotating pair and the axis of the sixth rotating pair in movement of the first branched chain is changed, rotating conditions are destructed, and the rigidity controllability of the mechanism and the locking in any position are achieved.

Owner:SHANGHAI UNIV OF ENG SCI

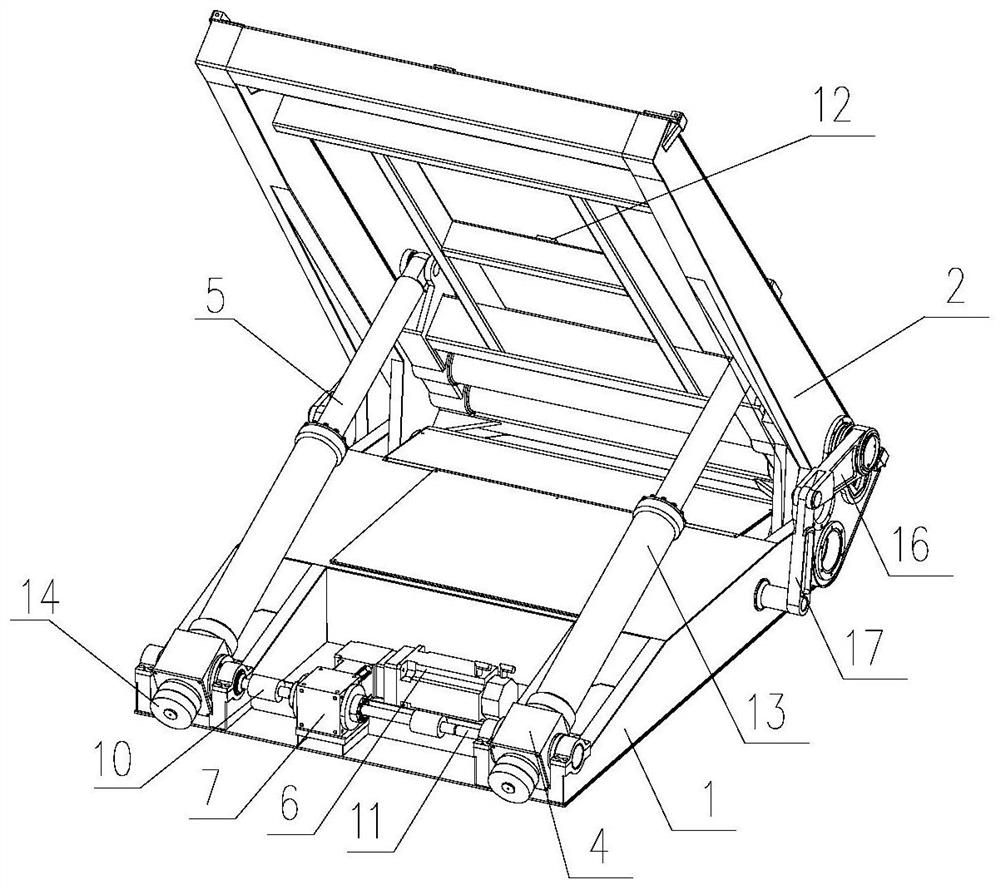

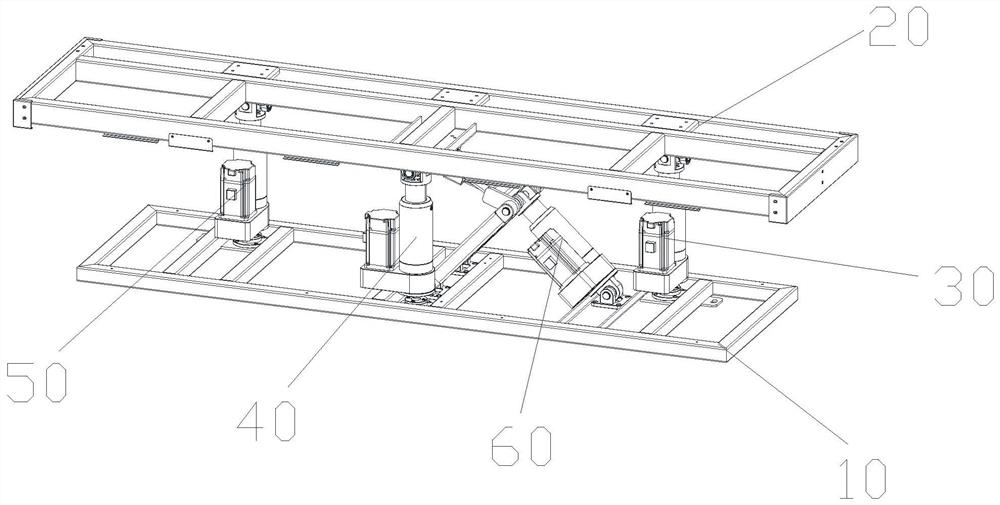

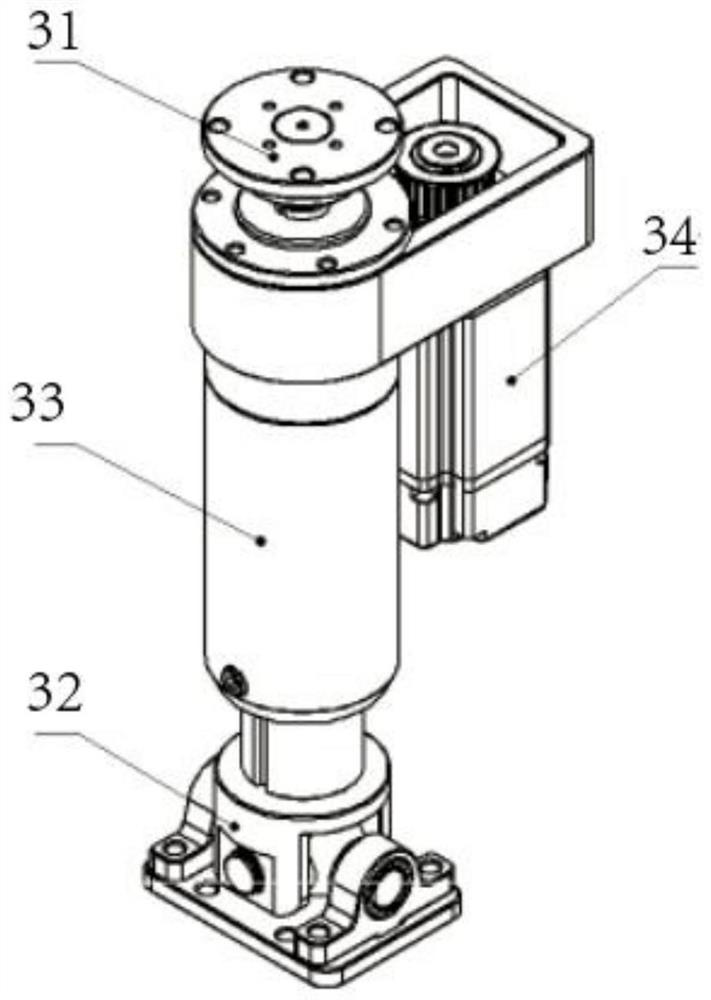

Lifting device

PendingCN114476897AGood synchronizationImprove securityLifting framesElevatorsBall screwControl engineering

The invention relates to the technical field of vehicle auxiliary instruments, and aims to provide a lifting device. According to the technical scheme, the lifting device comprises a base, a lifting frame, a lifting assembly and a driving assembly; the lifting frame is rotationally connected with the base; one end of the lifting assembly is rotationally connected with the lifting frame, and the other end of the lifting assembly is rotationally connected with the end, away from the lifting frame, of the base. The driving assembly is arranged on the base and used for driving the lifting assembly to stretch or retract. The lifting assembly comprises a ball screw pair, a positioning sleeve and a supporting rod, the end of a screw of the ball screw pair is sleeved with the positioning sleeve, the positioning sleeve is rotationally connected with the base, one end of the supporting rod is rotationally connected with the lifting frame, and the other end of the supporting rod is connected with a nut of the ball screw pair; the driving assembly comprises a servo motor, and the output end of the servo motor is in transmission connection with a screw of the ball screw pair. The device is high in positioning precision, fast in motion response, small in transmission gap, compact in structure and applicable to special vehicles.

Owner:四川中陆嘉诚科技有限公司

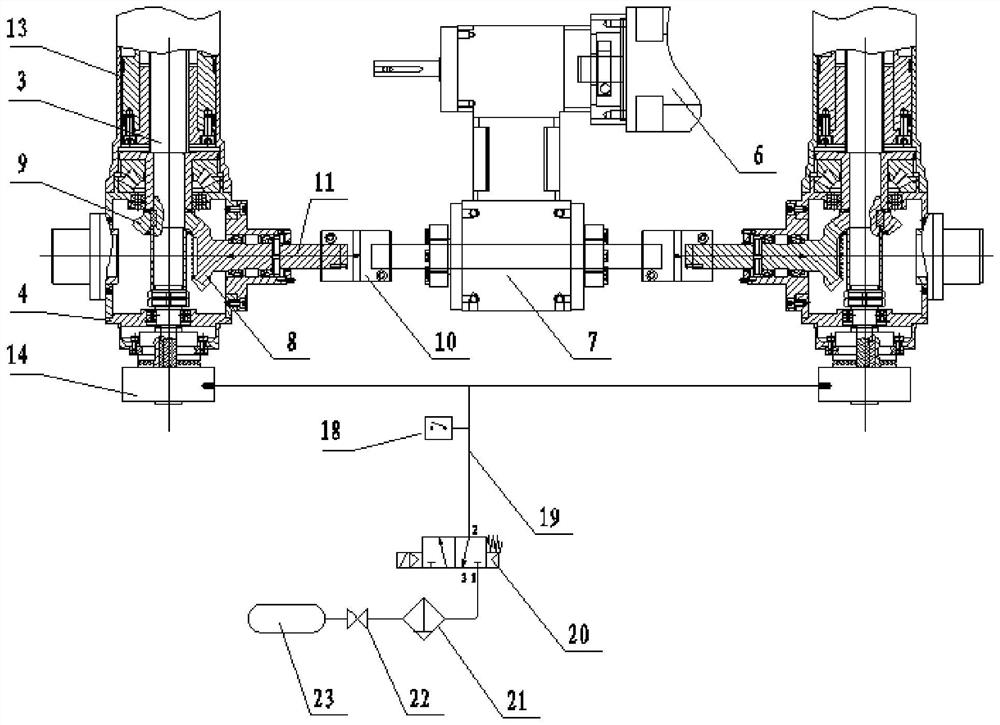

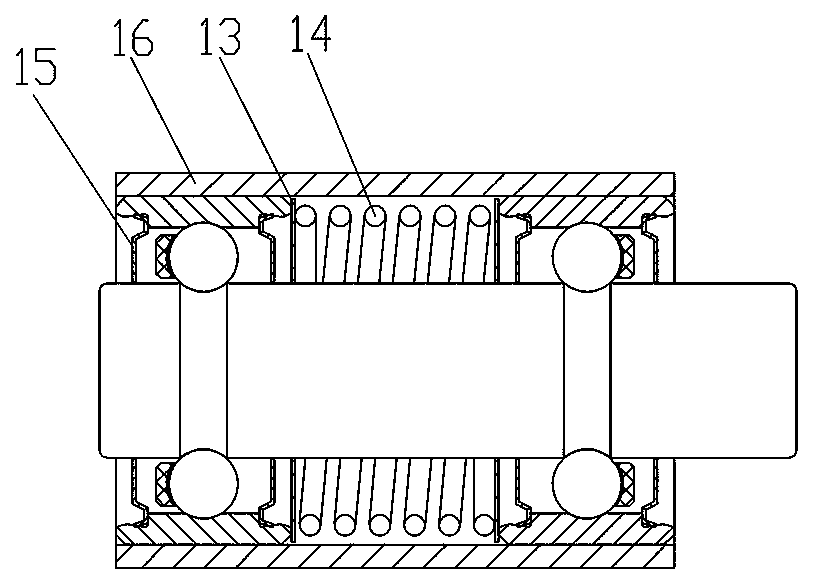

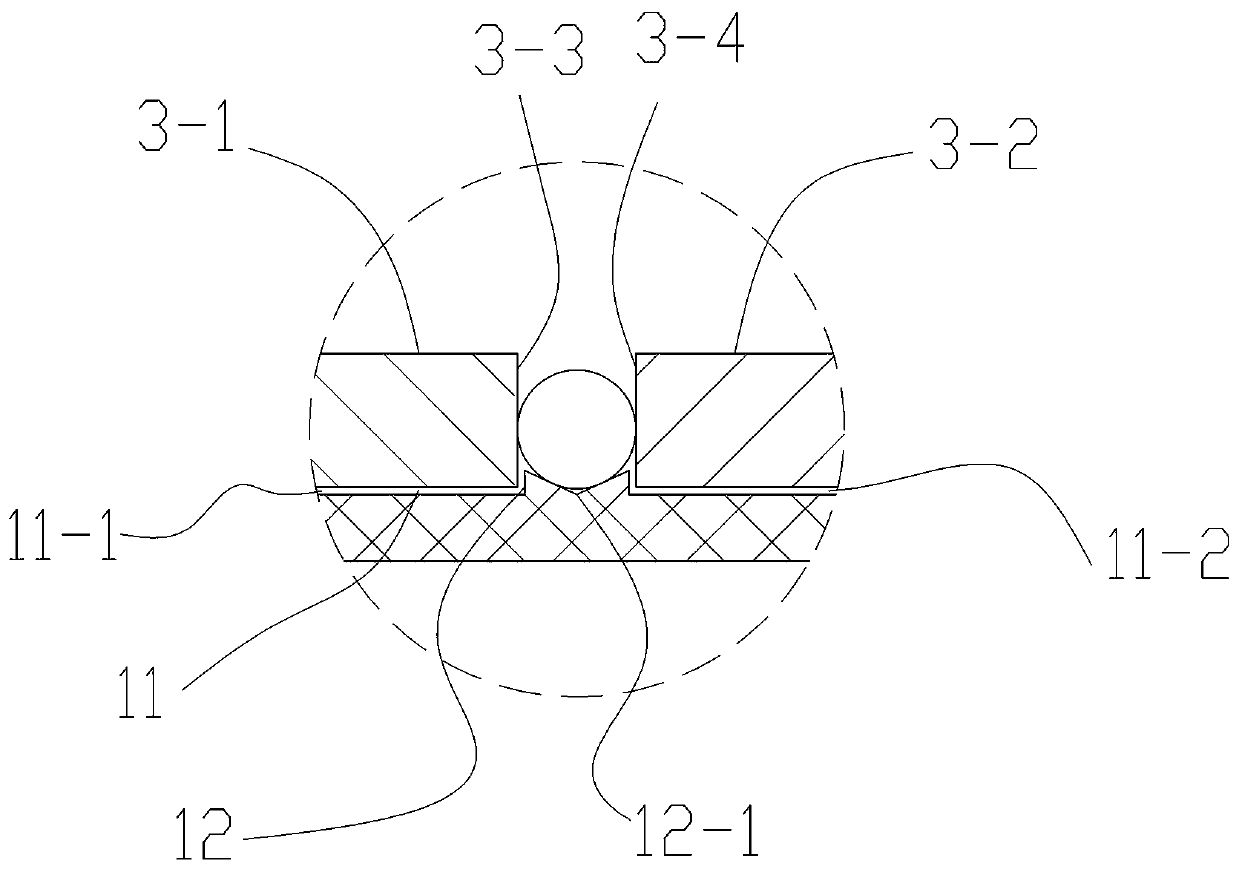

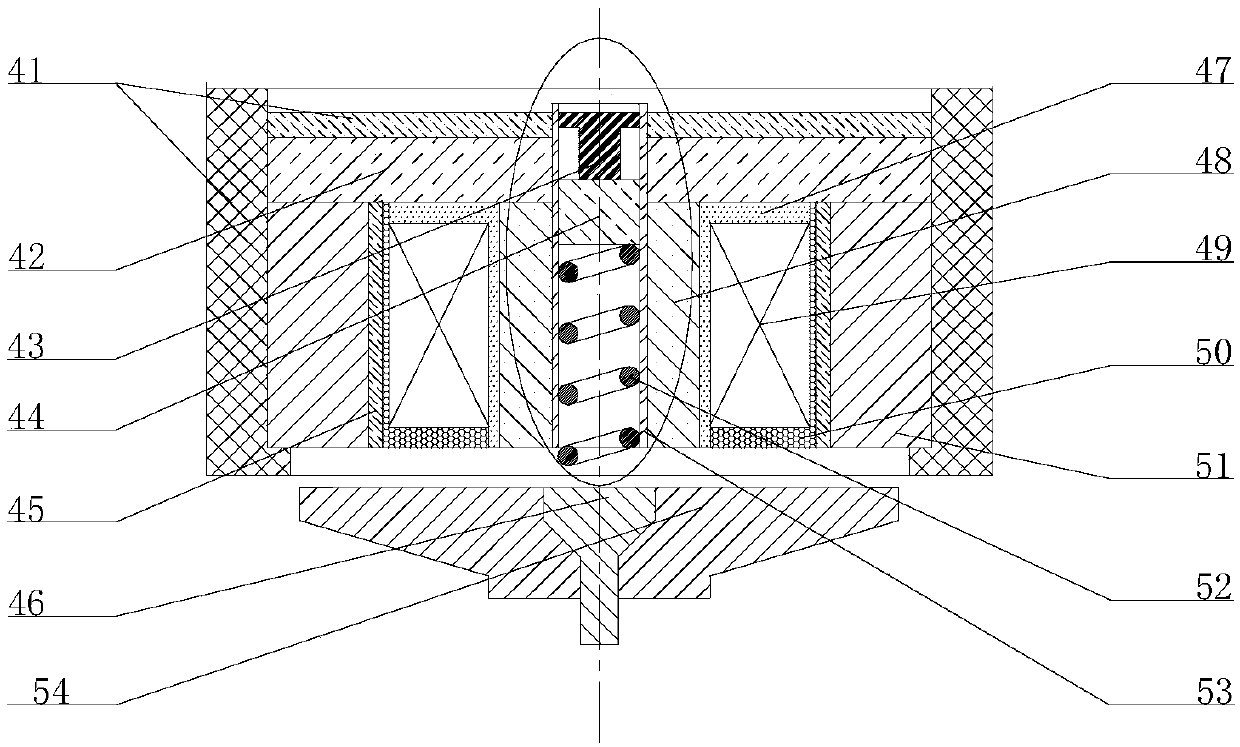

Double-sealed double-outer-ring long-shaft double-row ball bearing with O-shaped ring pre-tightening function

PendingCN110513391AReduce deflectionFast response to movementRolling contact bearingsBearing componentsBall bearingLong axis

The invention discloses a double-sealed double-outer-ring long-shaft double-row ball bearing with an O-shaped ring pre-tightening function. The bearing comprises a long shaft and a pair of bearing outer rings, wherein a pair of first channels is formed in the surface of the long shaft; the inner surface of each bearing outer ring is provided with a second channel and a dustproof groove located outside each second channel; the bearing outer rings corresponds to the first channels on the surface of the long shaft one by one; a sealing ring is arranged in each dustproof groove; an isolation sleeve with two ends located in the middle of the inner diameter of the two bearing outer rings is installed outside the long shaft; and an O-shaped ring for axially pre-tightening the bearing outer ringson the two sides is arranged in the middle of the bearing outer rings. According to the double-sealed double-outer-ring long-shaft double-row ball bearing with the O-shaped ring pre-tightening function, by using the O-shaped ring instead of two plain washers and one compression spring for pre-tightening, the outer diameter of the two bearing outer rings is increased and the axial spacing distancebetween the two bearing outer rings is reduced; and the structure is simple, lower vibration and noise are generated in the working process, and the bearing with longer service life and better reliability can meet the requirements of people.

Owner:NINGBO ZHENHAI SILVER BALL BEARING CO LTD

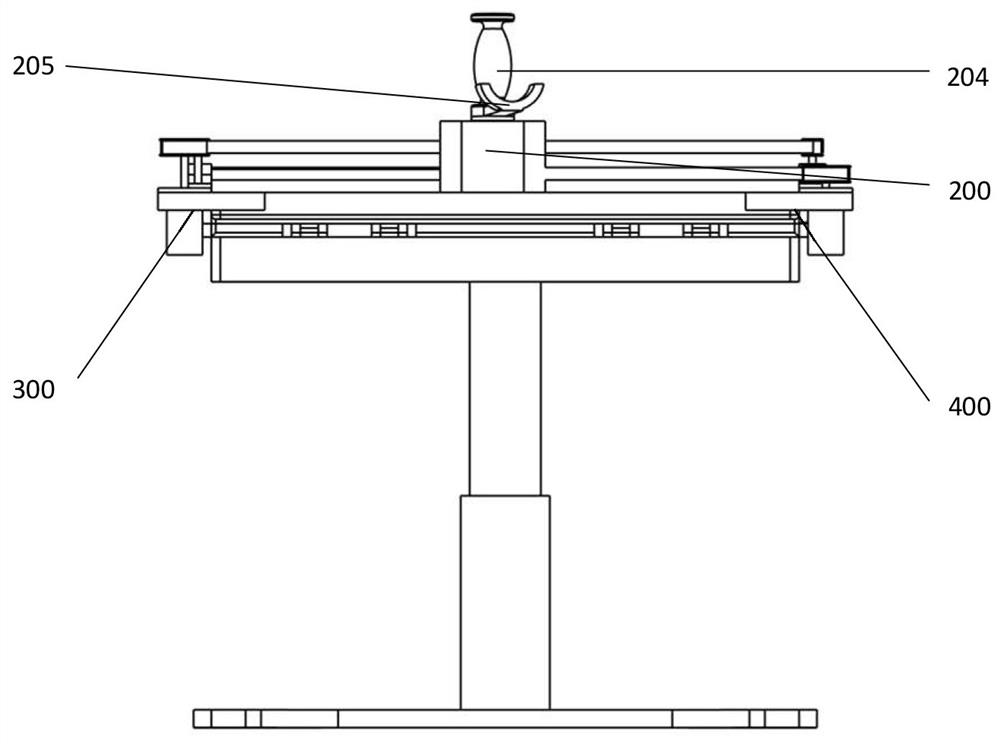

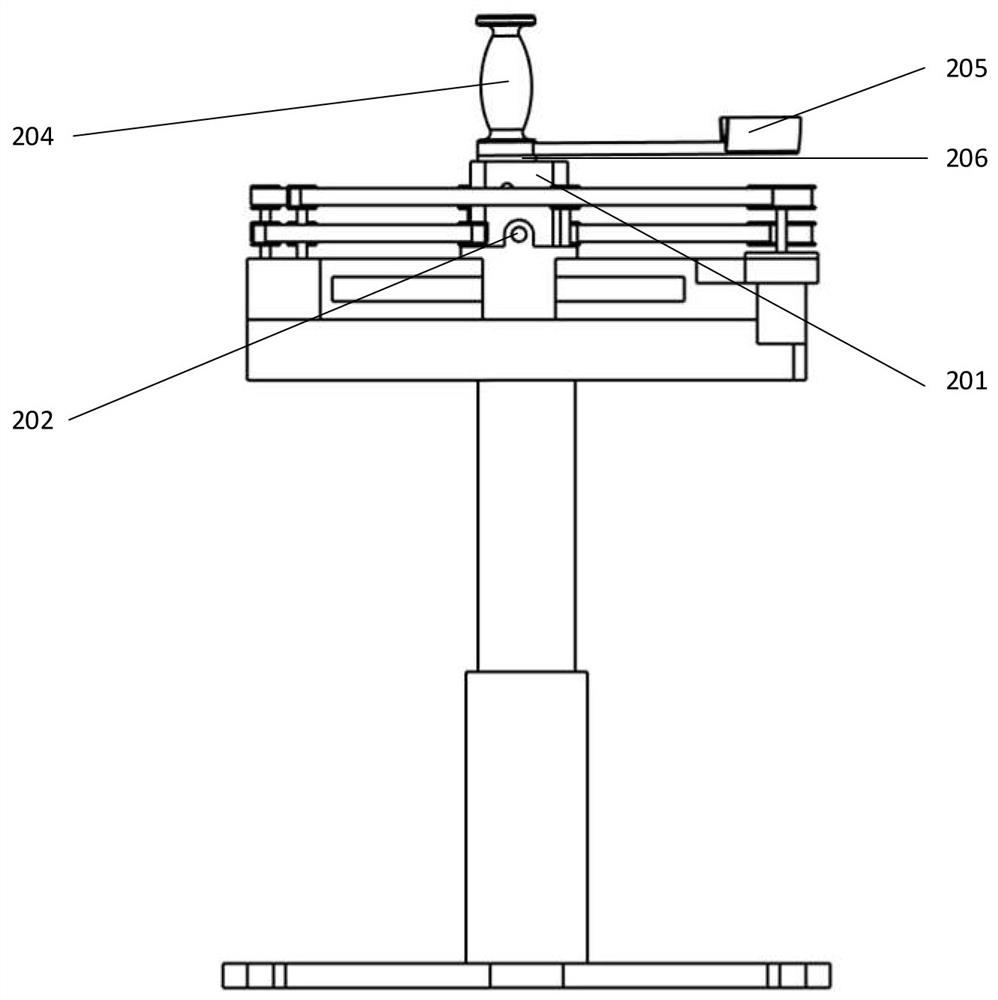

Planar two-dimensional upper limb rehabilitation training robot and training method

ActiveCN114504769AEasy to adjust the training angleAvoid complex structuresChiropractic devicesMovement coordination devicesMedizinische rehabilitationUpper limb rehabilitation

The invention belongs to the field of medical rehabilitation robots, and relates to the field of cerebral apoplexy rehabilitation robots, in particular to a planar two-dimensional upper limb rehabilitation training robot which comprises a liftable table assembly, a quick-change tail end platform is arranged on the liftable table assembly, and the quick-change tail end platform is connected with a driving system; the planar two-dimensional upper limb rehabilitation training robot is wide in application range, simple in structure and rapid in response.

Owner:SHANGHAI UNIV

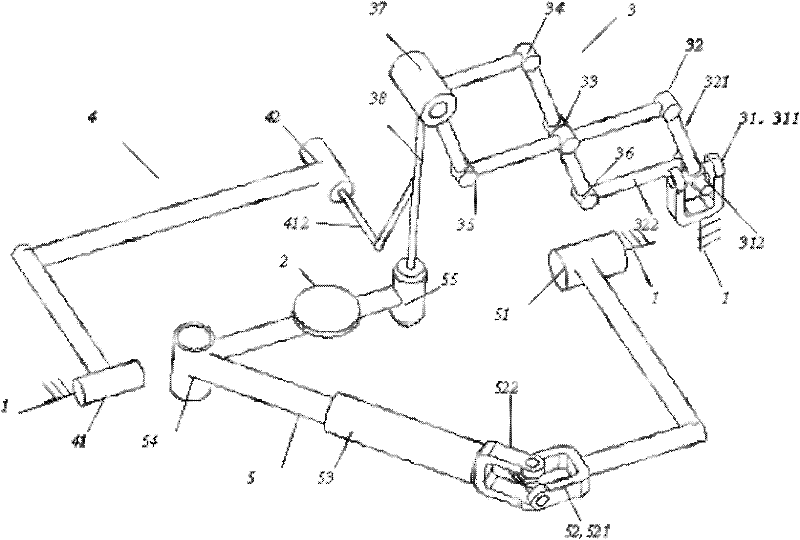

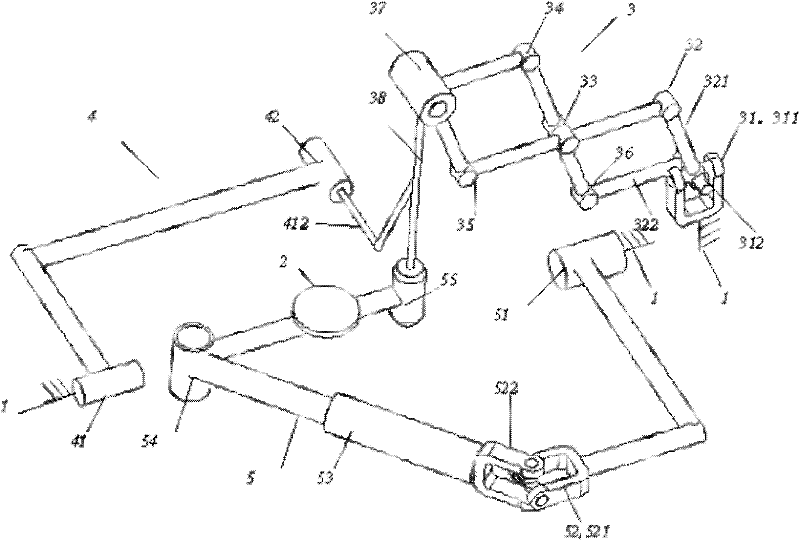

Decoupling three-rotation parallel mechanism for imaginary axis lathe and robot

InactiveCN102114599BThe realization principle is simpleGood linear relationshipProgramme-controlled manipulatorLarge fixed membersRotational freedomEngineering

The invention provides a decoupling three-rotation parallel mechanism for an imaginary axis lathe and a robot, which comprises a static platform, a movable platform, a first movement branch chain, a second movement branch chain and a third movement branch chain, wherein the first movement branch chain, the second movement branch chain and the third movement branch chain are connected between the static platform and the movable platform; the first movement branch chain comprises a universal hinge, a movable pair, a first rotating pair, a first connecting rod and a second rotating pair which are sequentially connected; the second movement branch chain comprises a third rotating pair, a fourth rotating pair and a fifth rotating pair which are sequentially connected; and the third movement branch chain comprises a sixth rotating pair, a seventh rotating pair and a second connecting rod which are sequentially connected. The decoupling three-rotation parallel mechanism has three rotational freedom degrees of decoupling, which are linearly controlled by depending on the movable pairs of the branch chains only, and the decoupling three-rotation parallel mechanism is very simple in a realizing principle, and has a good linear relation.

Owner:SHANGHAI UNIV OF ENG SCI

Four-degree-of-freedom motion platform with left-right transverse movement function

PendingCN112604313ASimple structureEasy maintenanceCinema apparatusEngineeringMechanical engineering

A four-degree-of-freedom motion platform with a left-right transverse movement function comprises: a lower platform used for mounting all parts; an upper platform used for mounting bearing equipment, wherein the upper platform is arranged above the lower platform; a first driving assembly used for driving the upper platform to move, wherein first driving assembly is arranged on the lower platform and is connected with the upper platform; a second driving assembly used for driving the upper platform to move, wherein the second driving assembly is arranged on the lower platform and is connected with the upper platform; a third driving assembly used for driving the upper platform to move, wherein the third driving assembly is arranged on the lower platform and is connected with the upper platform; and a left-right transverse moving anti-torsion assembly used for driving the upper platform to move, wherein the left-right transverse moving anti-torsion assembly is arranged on the lower platform and connected with the upper platform. The four-degree-of-freedom motion platform is simple in structure, convenient to maintain, small in size, low in height and convenient to use in a limited space environment.

Owner:HUBEI SIDI TELEVISION & TECH

Amorphous Alloy Composite Iron Core Electromagnetic Control Injector

ActiveCN105888904BQuick responseIncreased long-term operating lifeFuel injection apparatusMachines/enginesMagnetic polesEngineering

Owner:HARBIN ENG UNIV

Two-rotation one-movement-freedom-degree decoupling parallel mechanism

InactiveCN101780670BSimple structureEasy to installProgramme-controlled manipulatorLarge fixed membersKinematic pairDegrees of freedom

The invention relates to a two-rotation one-movement-freedom-degree decoupling parallel mechanism, which is composed of a rack (1), a moving platform (3) and two moving branch chains (2a), (2b) which connect the rack (1) and the moving platform (3), the axis of the sliding pair of the moving branch chain (2a) is vertical to the axis of a rotation pair which is parallel to three axes of the movingbranch chain (2b), and the moving branch chain (2a) and the moving branch chain (2b) comprise two coaxial rotation pairs. Compared with the prior art, the mechanism has less kinematic pair, the structure is simple, the rotary inertia is low, the movement response is fast, a single driving unit is only controlled by a single output freedom degree basically, the calibration is easy, the control is simple, the movement is controlled more accurately, and the development cost and the development cycle are greatly reduced.

Owner:SHANGHAI UNIV OF ENG SCI

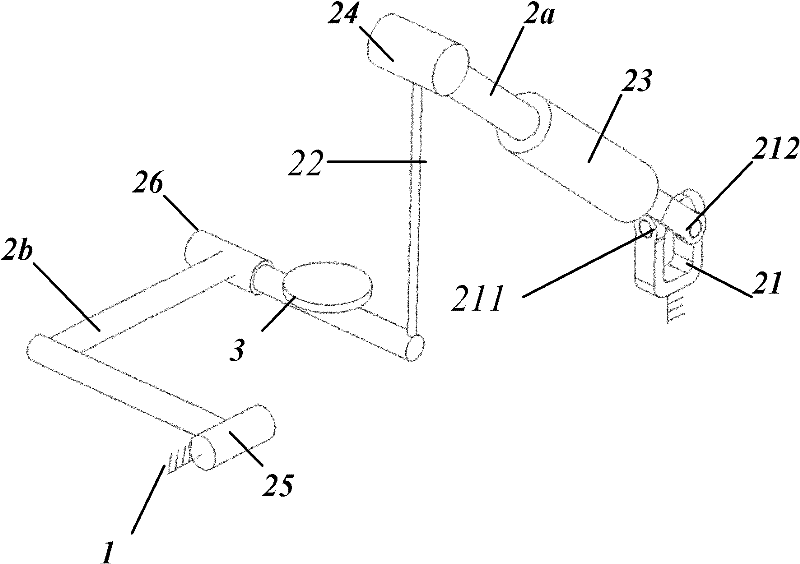

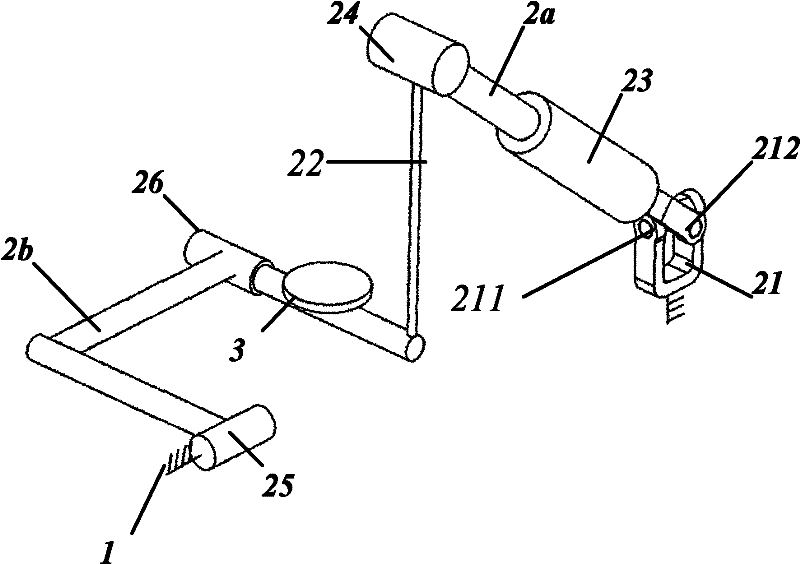

Decoupled false shaft machine tool and two-rotary and one-moving parallel connection mechanism

InactiveCN101249651BSimple structureEasy to installProgramme-controlled manipulatorKinematic pairSpherical joint

The invention relates to a two-rotation and one-movement parallel mechanism which is used in the decoupling of the virtual axis machine and robot, consisting of a frame (1), a moving platform (3) andthree motion branch chains which connect the frame (1) and the moving platform (3). The motion branch chains (2a) and (2b) have the same structure which comprises revolute joint (21),(24), shifting pair (22),(25), spherical joint (23),(26) and the member, wherein junction of the motion branch chain(2c) and the frame is a vertex of a right angle. With only a few kinematic pairs, the mechanism has the advantages of simple structure, easy installation, small moment of inertia and fast motion response. Basically, single output degree of freedom only needs to control single driving unit. With easycalibration and control, not only the movement control is more precise but also the development cost and cycle is greatly lowered.

Owner:DONGHUA UNIV

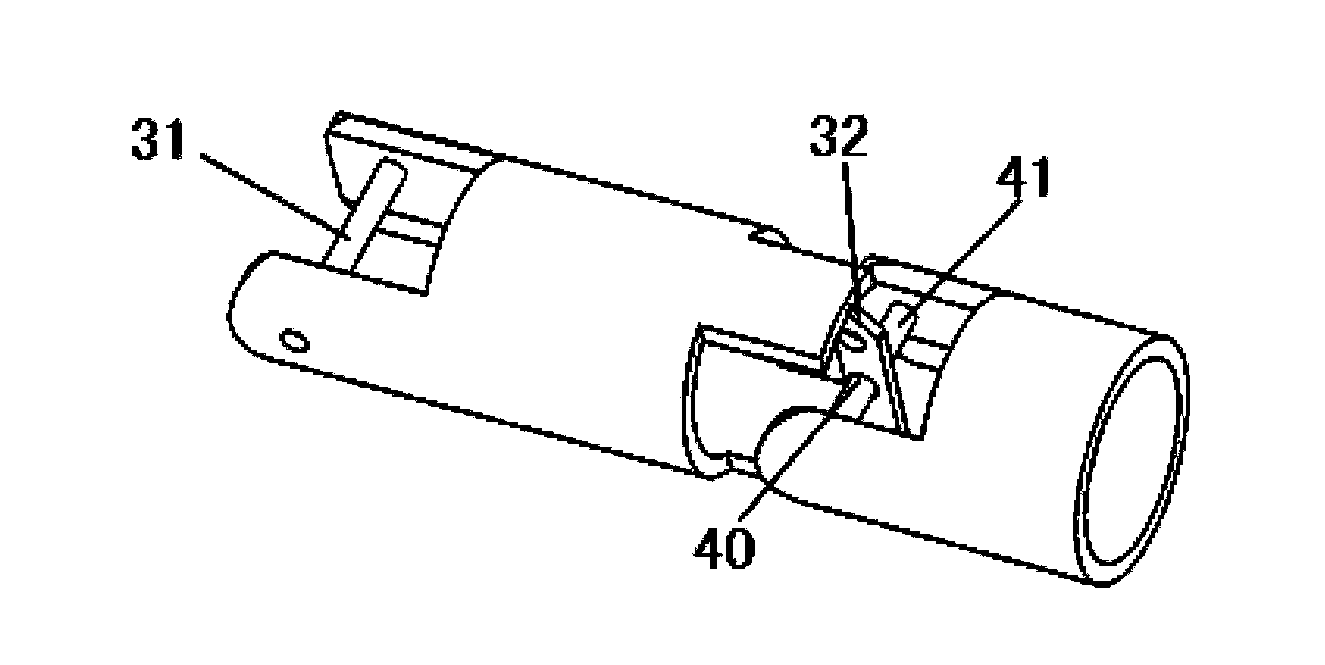

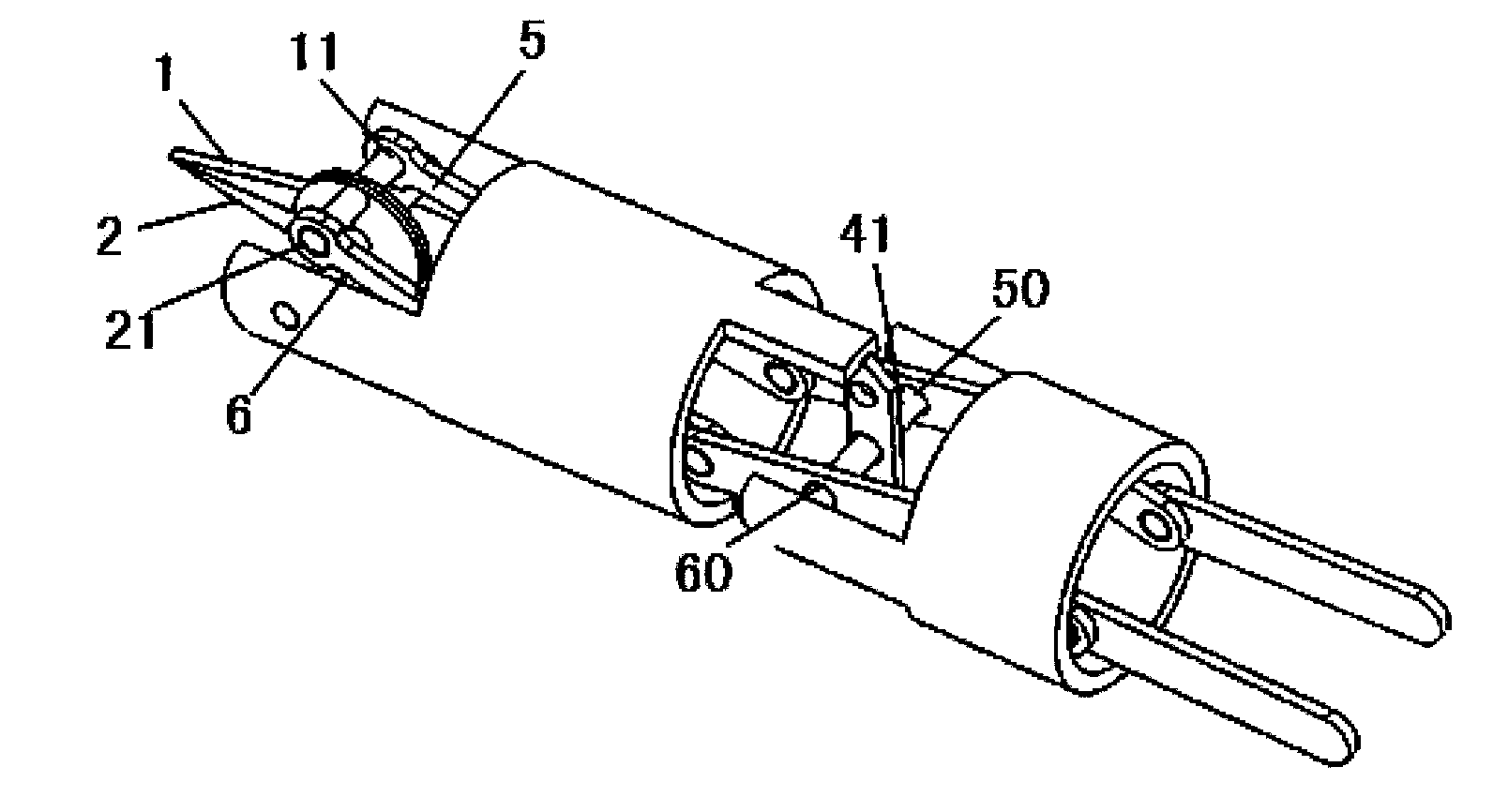

Bendable miniature wrist

A bendable miniature wrist comprises a first end effector, a second end effector, a primary sleeve, a secondary sleeve, a first motion support chain, a second motion support chain and a third motion support chain, wherein the first end effector and the second end effector are combined to form a clamp or a gripper and respectively rotationally connected with the primary sleeve which is rotationally connected with the secondary sleeve; the first motion support chain is in drive connection with the first end effector, the second motion support chain is in drive connection with the second end effector, and the third motion support chain is in drive connection with the primary sleeve; the clamp or the gripper is opened or closed under driving of combined motion of the first motion support chain and the second motion support chain; and the third motion support chain moves to drive primary sleeve to perform pitching swing . The bendable miniature wrist has opening and bending freedom degree, can imitate a human hand to achieve flexible actions, and is simple in structure and high in bearing capacity.

Owner:SHANGHAI UNIV OF ENG SCI

A decoupled three rotational degrees of freedom parallel mechanism for virtual axis machine tools and robots

ActiveCN109848969BEasy to decoupleGood motion precisionProgramme-controlled manipulatorControl engineeringMachine

Owner:SHANGHAI UNIV OF ENG SCI

Haptic Feedback System for Minimally Invasive Surgical Instruments

ActiveCN104274244BSimple structureEasy to installSurgical robotsComputer control systemLess invasive surgery

A tactile feedback system for a minimally invasive surgical instrument, comprising a slender rod of the minimally invasive surgical instrument and an end effector connected thereto, a first elastic device, a connecting piece with flexible deformation capability, a second elastic device, a first A pair of rollers, a second pair of rollers, an indicator, a measuring element and a computer control system. The position of the indicator can be read from the measuring element installed in the slender rod of the minimally invasive surgical instrument, and the computer control system reads the reading of the measuring element, converts and judges the magnitude of the force applied to the inner side of the end effector. The invention has the advantages of simple structure, high sensitivity and low cost.

Owner:SHANGHAI UNIV OF ENG SCI

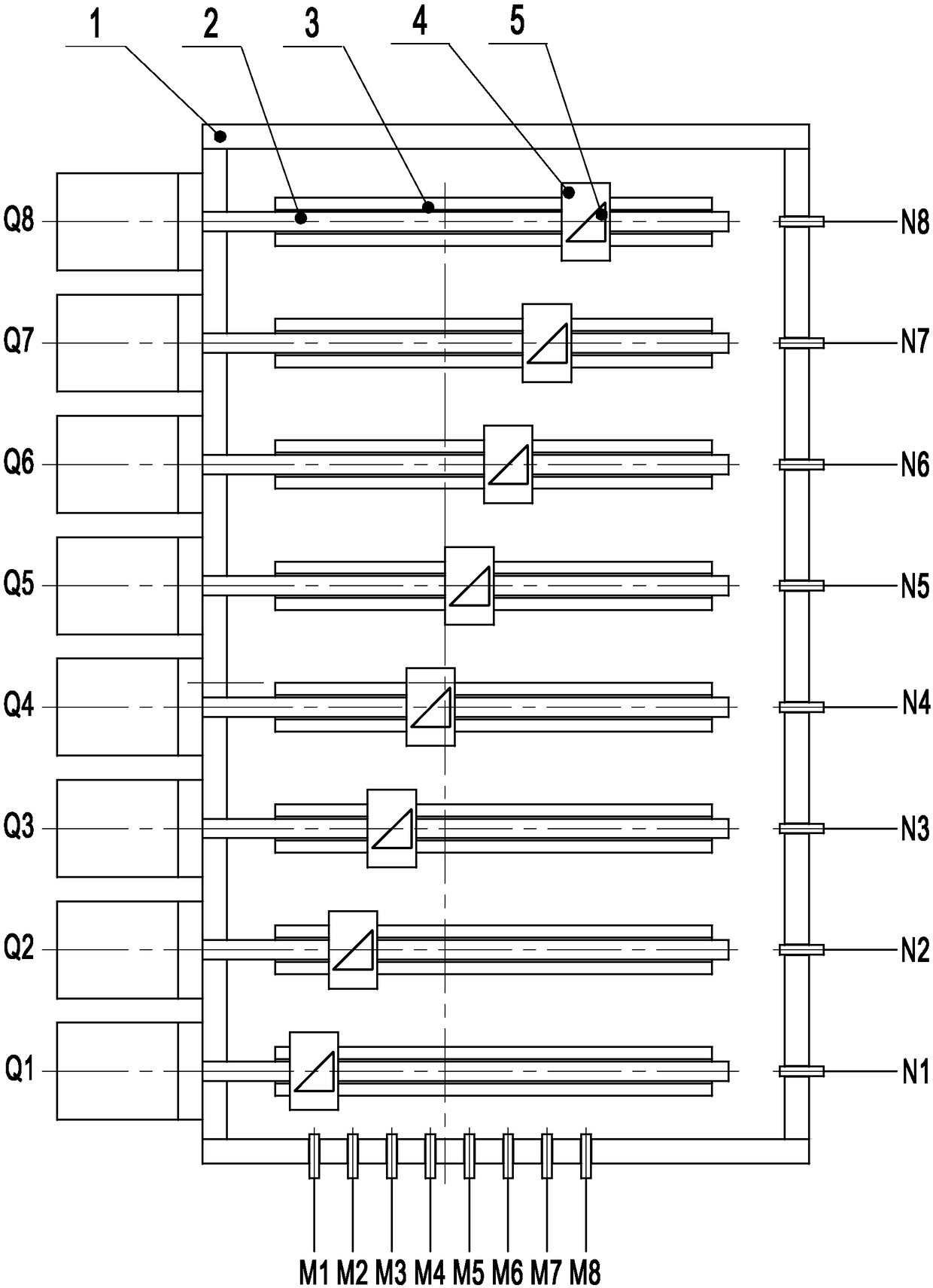

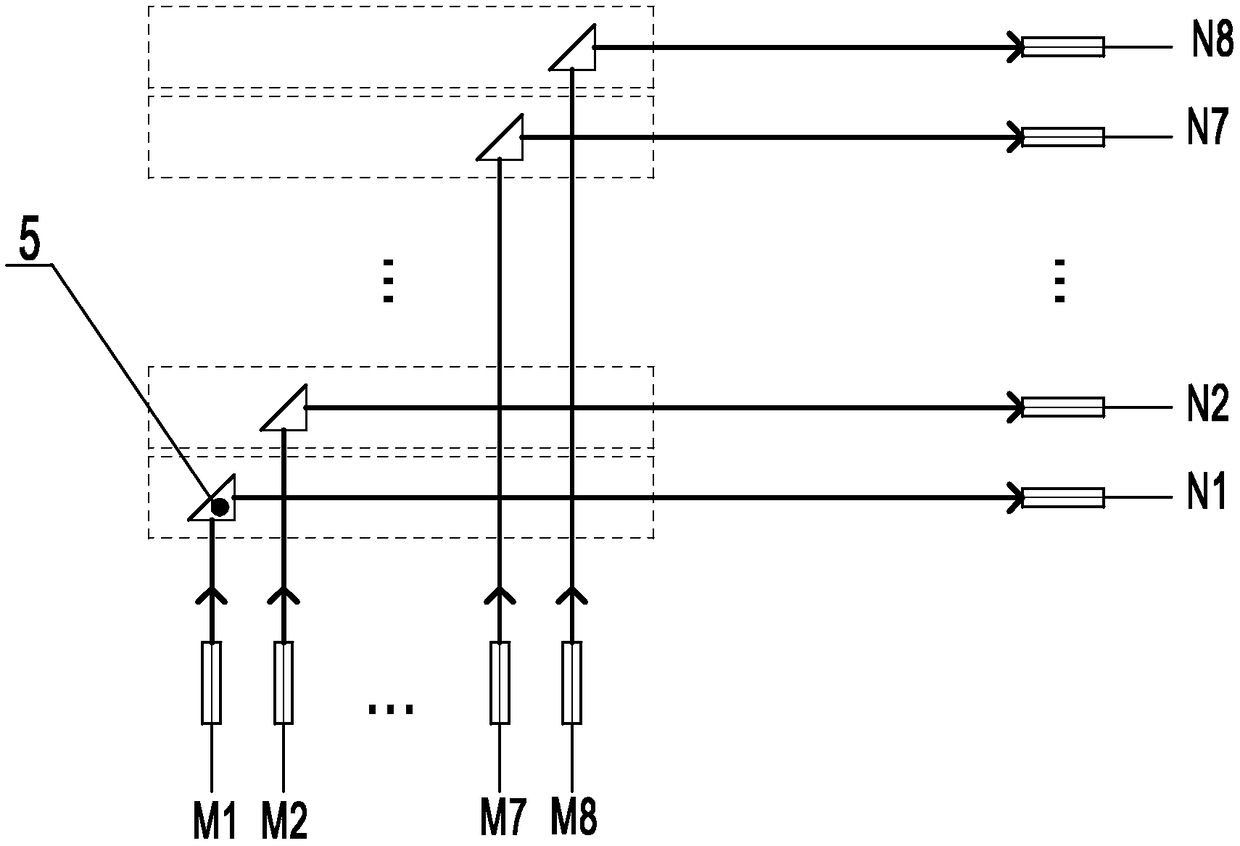

M*N mechanical photoswitch

PendingCN109375367AFast switching speedFast response to movementOptical elementsPhotoswitchReduced size

The invention relates to an M*N mechanical photoswitch, which comprises a bottom box, wherein an M-core array collimator is fixedly installed on the A side surface of the bottom box, M identical collimated output optical paths are parallel to each other, an N-core array collimator is fixedly installed on the B side surface adjacent to the A side surface, N is greater than or equal to M, and inputoptical paths of N identical collimators are parallel to one another; N motors are fixedly installed on the B' side surface of the bottom box, N guide rails are installed between the two side surfacesB and B', each guide rail is perpendicular to the side surfaces B and B', each guide rail is provided with a sliding block, and a reflector is fixedly installed on each sliding block to be opposite to the corresponding optical path; lead screws connected with motors are parallel to the guide rails, the lead screws are threaded in corresponding sliding block threaded holes, and the sliding blocksmove along the guide rails linearly when one motor starts to rotate the lead screws; electromagnetic switches of the motors are connected with a control center; and the reflectors are arranged in different positions, so that the M paths of input light can select N paths for output. The M*N mechanical photoswitch has the advantages of reduced size, low insertion loss, high isolation, low cost and good repeatability. The photoswitch has a high switching speed.

Owner:NO 34 RES INST OF CHINA ELECTRONICS TECH GRP

Triple rotating parallel mechanism for virtual axis machine tool and robot

InactiveCN101954593BThe realization principle is simpleGood linear relationshipProgramme-controlled manipulatorLarge fixed membersLinear controlLinear relationship

The invention provides a triple rotating parallel mechanism for a virtual axis machine tool and a robot. The triple rotating parallel mechanism for the virtual axis machine tool and the robot consists of a machine frame, a moveable platform, and a first motion branched chain, a second motion branched chain and a third motion branched chain which are connected between the machine frame and the moveable platform, wherein the first motion branched chain comprises a first universal hinge, a first moveable pair and a second universal hinge which are connected with one another sequentially; the second motion branched chain comprises a third universal hinge, a second moveable pair and a fourth universal hinge which are connected with one another sequentially; and the third motion branched chain comprises a rotating pair and a fifth universal hinge which are connected with each other sequentially. The triple rotating parallel mechanism for the virtual axis machine tool and the robot has threedecoupled rotational degrees of freedom which only depend on the linear control of the motion pairs of the motion branched chains, wherein the implementing principle is very simple and the linear relationship is very good.

Owner:SHANGHAI UNIV OF ENG SCI

Two-rotational degree-of-freedom parallel mechanism for imaginary axis machine tool and robot

InactiveCN102069392BThe realization principle is simpleGood linear relationshipProgramme-controlled manipulatorLarge fixed membersLinear controlLinear relationship

The invention provides a two-rotational degree-of-freedom parallel mechanism for an imaginary axis machine tool and a robot. The two-rotational degree-of-freedom parallel mechanism comprises a static platform, a movable platform, a first movable branched chain and a second movable branched chain, wherein the first movable branched chain and the second movable branched chain are connected between the static platform and the movable platform; the first movable branched chain comprises a universal hinge, a moving pair and a first revolute pair which are connected in sequence; the universal hingeis also connected with the static platform; the first revolute pair is also connected with the movable platform through a connecting rod; the second movable branched chain comprises a second revolutepair and a third revolute pair which are connected in sequence; the second revolute pair is also connected with the static platform; and the third revolute pair is also connected with the movable platform. The two-rotational degree-of-freedom parallel mechanism has two decoupled rotational degrees of freedom which only depend on the linear control of kinematic pairs of the movable branched chains, and has an extremely simple implementation principle and an extremely good linear relationship.

Owner:SHANGHAI UNIV OF ENG SCI

Decoupled tri-rotation parallel mechanism

InactiveCN101934521BThe realization principle is simpleGood linear relationshipProgramme-controlled manipulatorLarge fixed membersRotational freedomLinear control

The invention provides a decoupled tri-rotation parallel mechanism, which comprises a stand, a moving platform, a first moving branch chain, a second moving branch chain and a third moving branch chain, wherein the first moving branch chain, the second moving branch chain and the third moving branch chain are connected between the stand and the moving platform. The first moving branch chain comprises a first universal hinge, a first moving pair and a second universal hinge which are sequentially connected; the second moving branch chain comprises a first spherical hinge, a second moving pair and a second spherical hinge which are sequentially connected; and the third moving branch comprises a rotation pair and a third universal hinge which are sequentially connected. The invention has three decouple rotational degrees of freedom, and the rotational freedom degree of freedom only depends on the linear control of the moving pair of the moving branch chains, therefore, the implementationprinciple is very simple and the mechanism has quite good linear relation.

Owner:SHANGHAI UNIV OF ENG SCI

A tea bag packaging machine and its outer bag heat sealing assembly

ActiveCN105416710BFast response to movementGood synchronizationWrapper twisting/gatheringPackaging foodstuffsEngineeringPackaging machine

The invention discloses a teabag packing machine and an outer bag heat-sealing assembly thereof. The outer bag heat-sealing assembly comprises an installing bracket, a driving mechanism, a first heat-sealing plate and a second heat-sealing plate. The driving mechanism comprises a rotating driving piece, a first connecting component and a second connecting component. One end of the first connecting component is connected to the rotating driving piece, and the other end of the first connecting component is connected to the first heat-sealing plate. One end of the second connecting component is connected to the rotating driving piece, and the other end of the second connecting component is connected to the second heat-sealing plate. The movement direction of the first heat-sealing plate and the movement direction of the second heat-sealing plate are opposite under the drive of the rotating driving piece. The movement of the first heat-sealing plate and the movement of the second heat-sealing plate are both driven by the same driving mechanism. The first heat-sealing plate, the second heat-sealing plate and the driving mechanism are linked together to form an integral structure. The first heat-sealing plate and the second heat-sealing plate are not mutually independent but associated. Compared with a heat-sealing assembly of the prior art, other intermediate driving pieces are no longer depended on, and the movement is stable and reliable.

Owner:CAMALUOYANGELECTROMECHANIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com