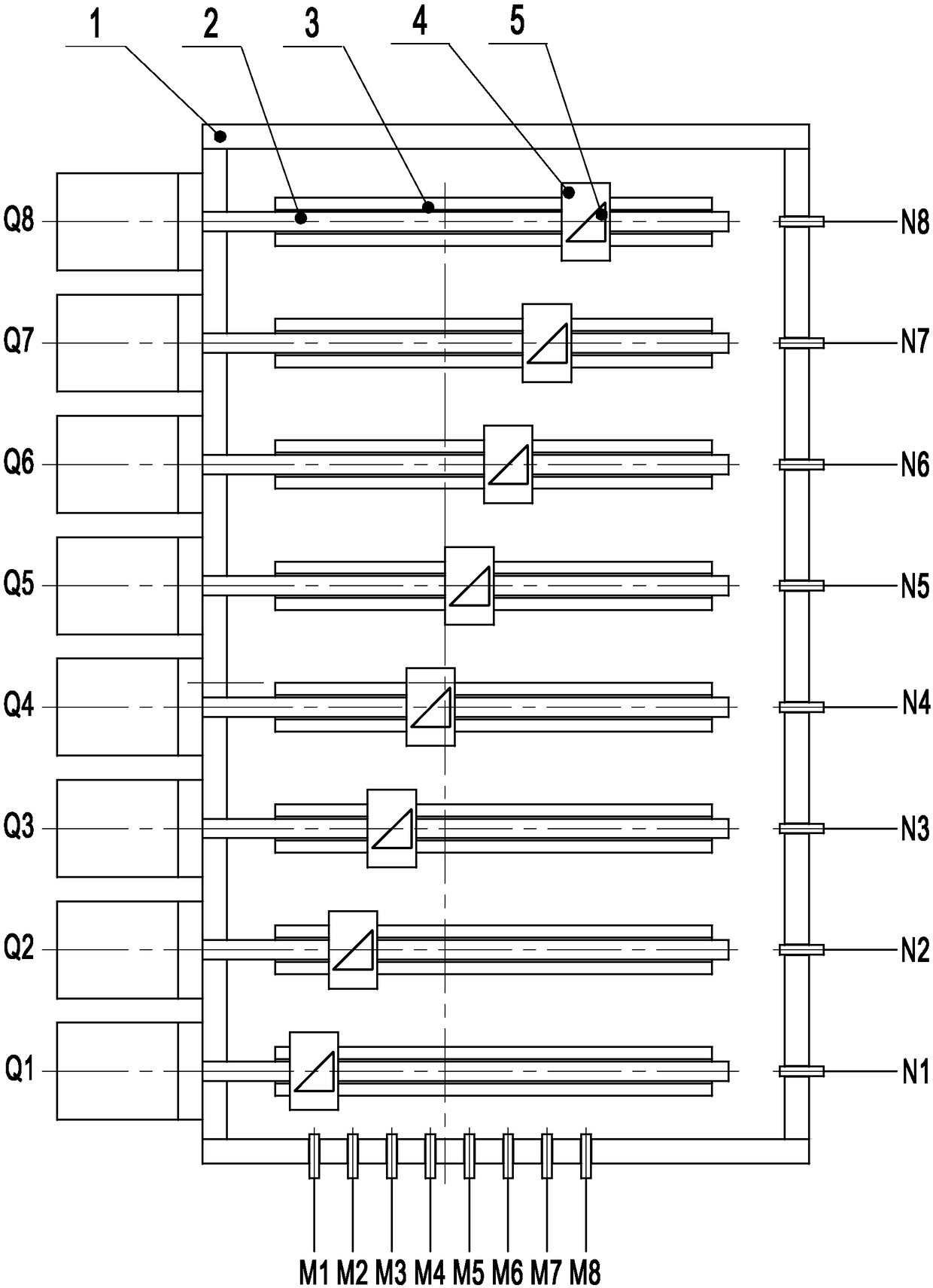

M*N mechanical photoswitch

An optical switch and mechanical technology, applied in the field of optical communication, can solve problems such as difficult to realize optical or photoelectric integration, difficulty in mass production, and large volume of optical switches, and achieve the effects of reduced volume, low cost, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

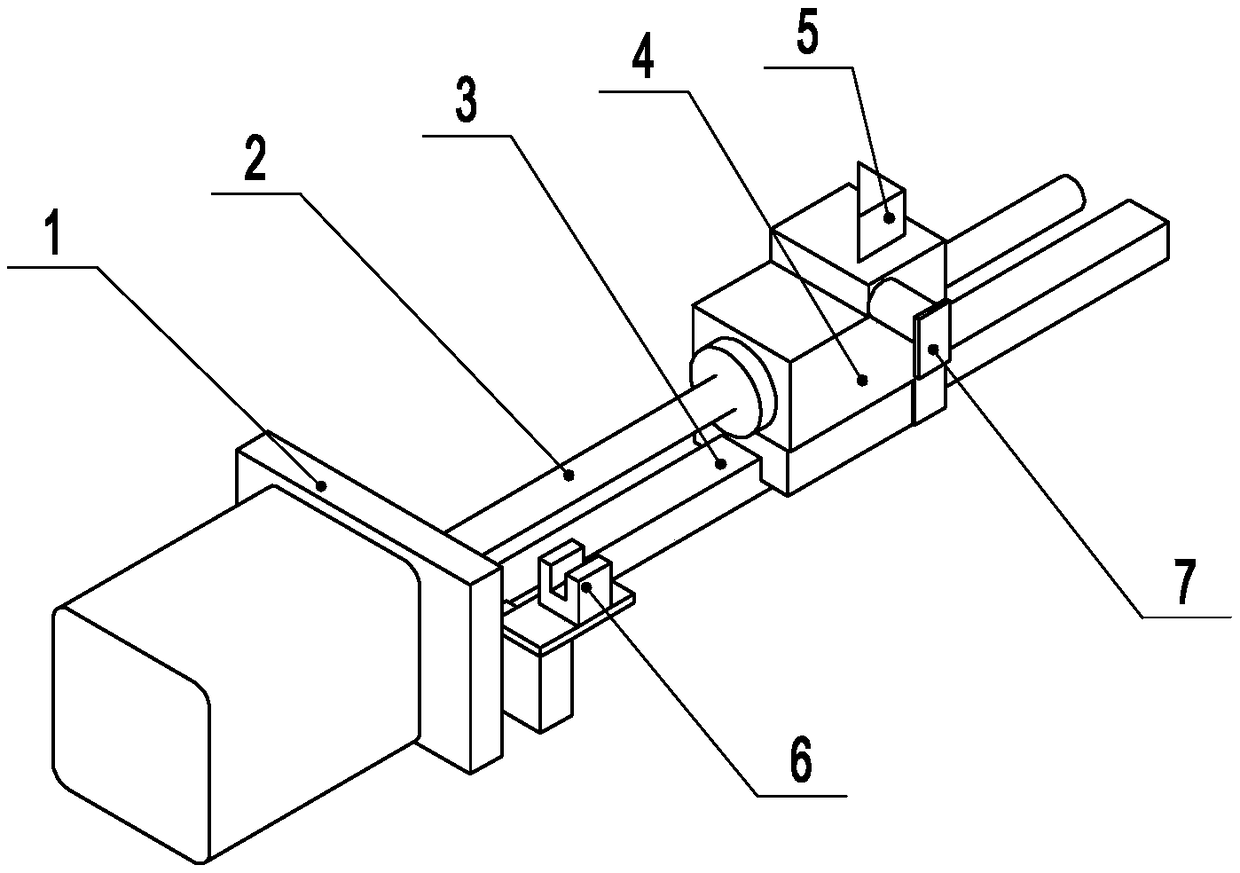

Method used

Image

Examples

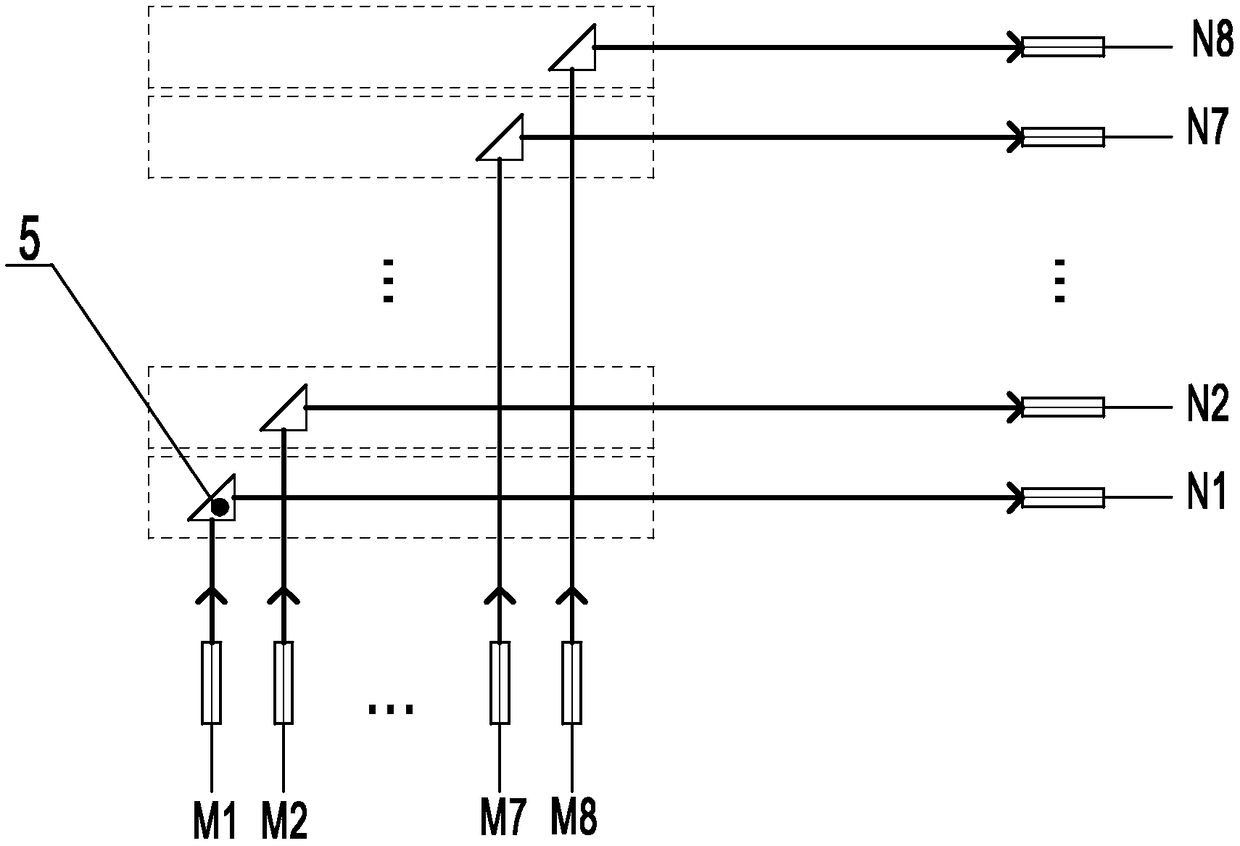

Embodiment 2

[0030] M=4, N=6 in the second embodiment of the M×N mechanical optical switch, which is a 4×6 mechanical optical switch, including a 4-core array collimator, a 6-core array collimator and a control center, and its bottom box The structure of 1 is the same as that of Embodiment 1. The 4-core array collimator is four identical collimators M arranged on the side of the bottom box A and in the same plane. 1 ,M 2 , M 3 , M M , their output optical paths are parallel to each other, and the intersection angle with the A side of the bottom box is α=80°. Similarly, the 6-core array collimator is 6 identical collimators N arranged on the side of the bottom box B in the same plane 1 ,N 2 …N 6 , their input optical paths are parallel to each other, and the intersection angle with the B side of the bottom box is also 80°. The optical path directions of the 4-core array collimator and the 6-core array collimator are in the same plane.

[0031] The light path in this example is as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com