A tea bag packaging machine and its outer bag heat sealing assembly

A technology of components and heat-sealing plates, applied in special packaging objects, packaging sealing/fastening, packaging, etc., can solve the problems of unstable operation and low efficiency of outer bag heat-sealing components, and achieve stable movement, good synchronization, Motion-response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

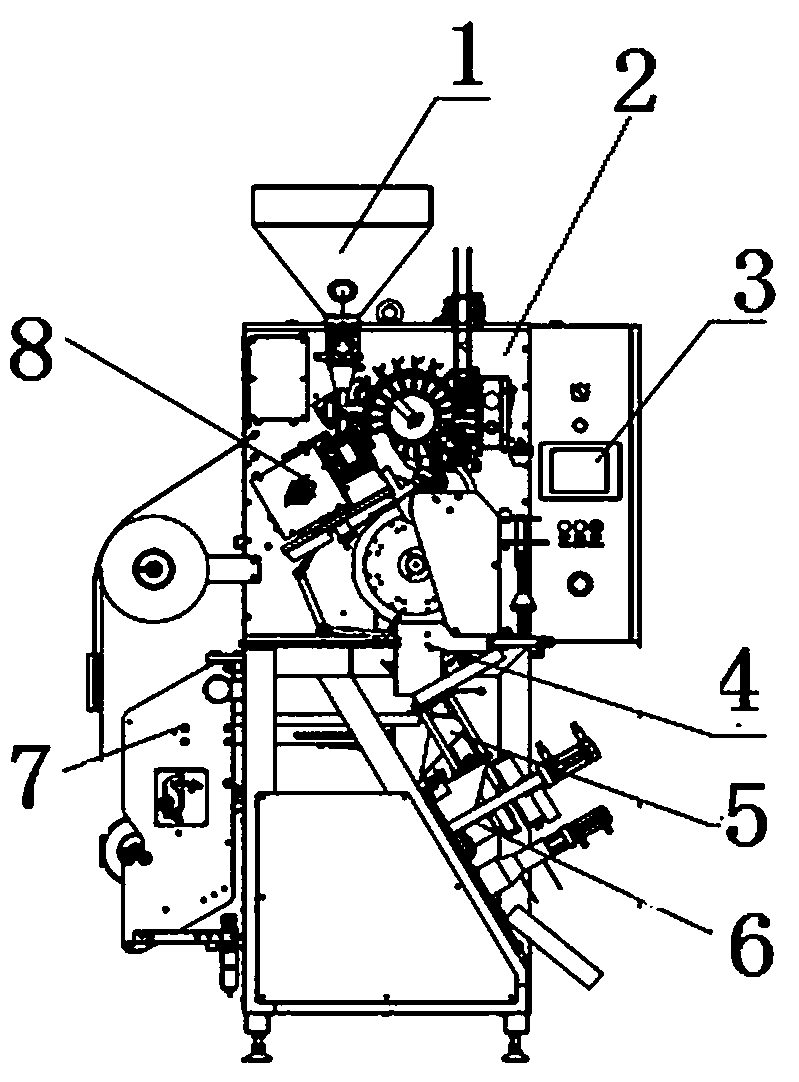

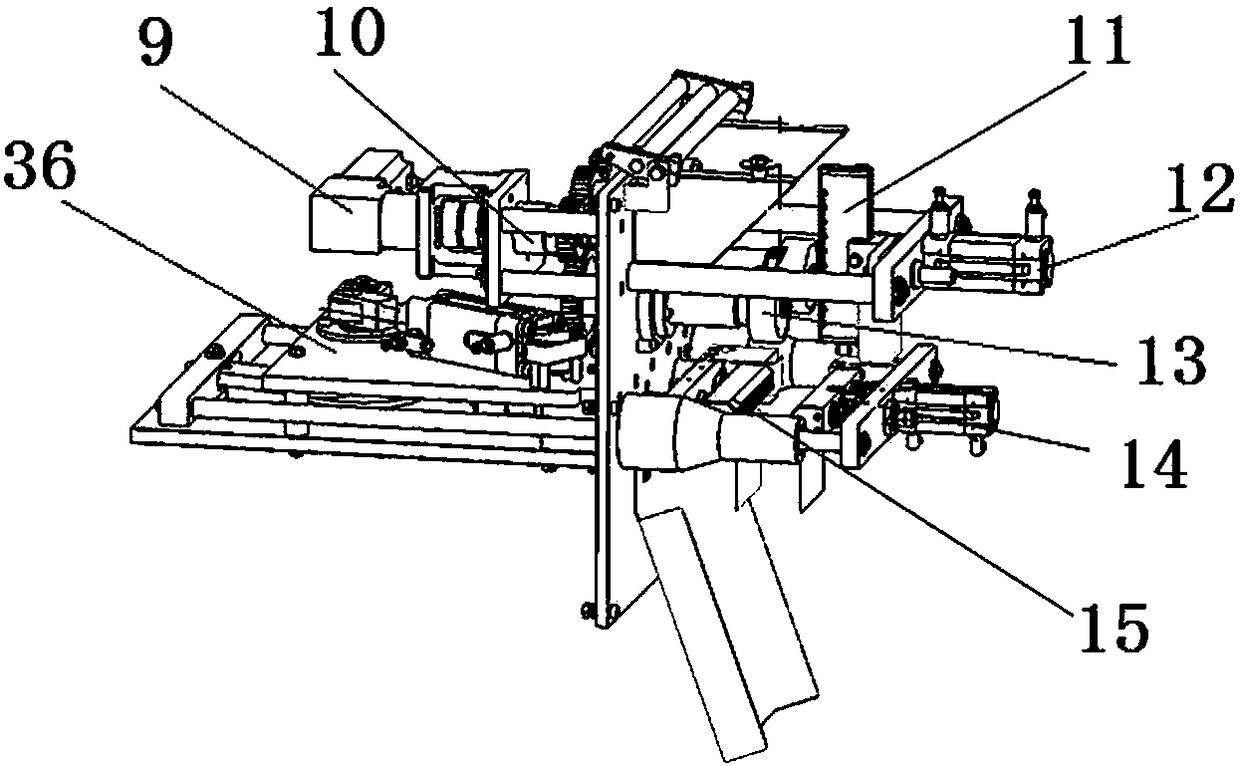

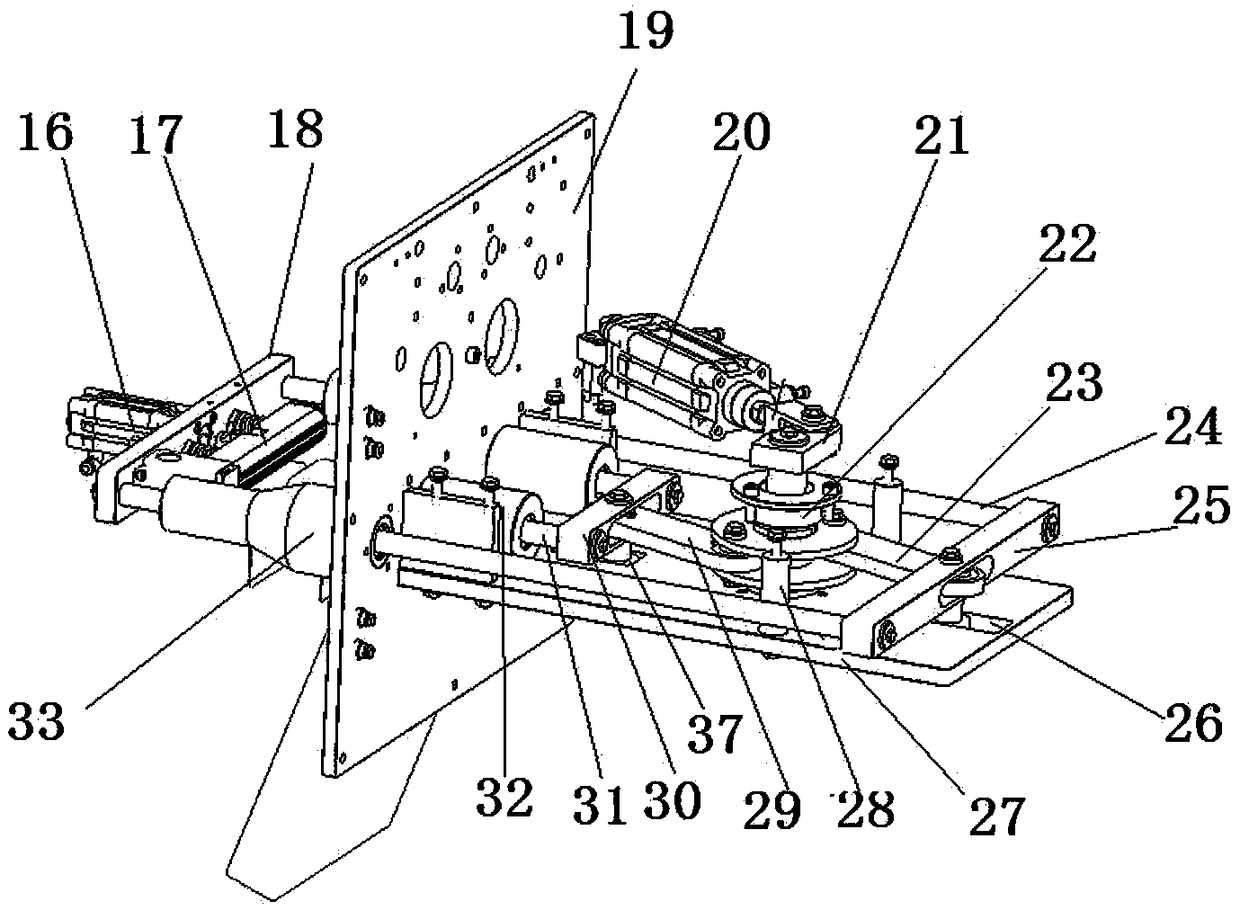

[0020] The embodiment of tea bag packaging machine of the present invention: as Figure 1-4 As shown, the tea bag packaging machine includes a quantitative feeding component 1, a heat-sealing label conveying component 2, an electric control component 3, an inner bag output component 4, an inner bag heat-sealing component 8, an outer bag paper supply component 7, an outer bag Paper tube former assembly 5 and outer bag heat sealing assembly 6. The outer bag heat-sealing component includes a mounting bracket, a vertical sealing component and a horizontal sealing component, and the mounting bracket includes a longitudinal mounting plate 27 and a transverse mounting plate 19 perpendicular to each other. A fixed mounting plate 36 parallel to the longitudinal mounting plate 27 is also provided. The horizontal sealing assembly includes a driving mechanism, a first heat-sealing plate 34 , and a second heat-sealing plate 17 opposite to the first heat-sealing plate 34 and spaced left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com