A decoupled three rotational degrees of freedom parallel mechanism for virtual axis machine tools and robots

A robot and three-rotation technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., to achieve the effects of simple control, good decoupling, and fast motion response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

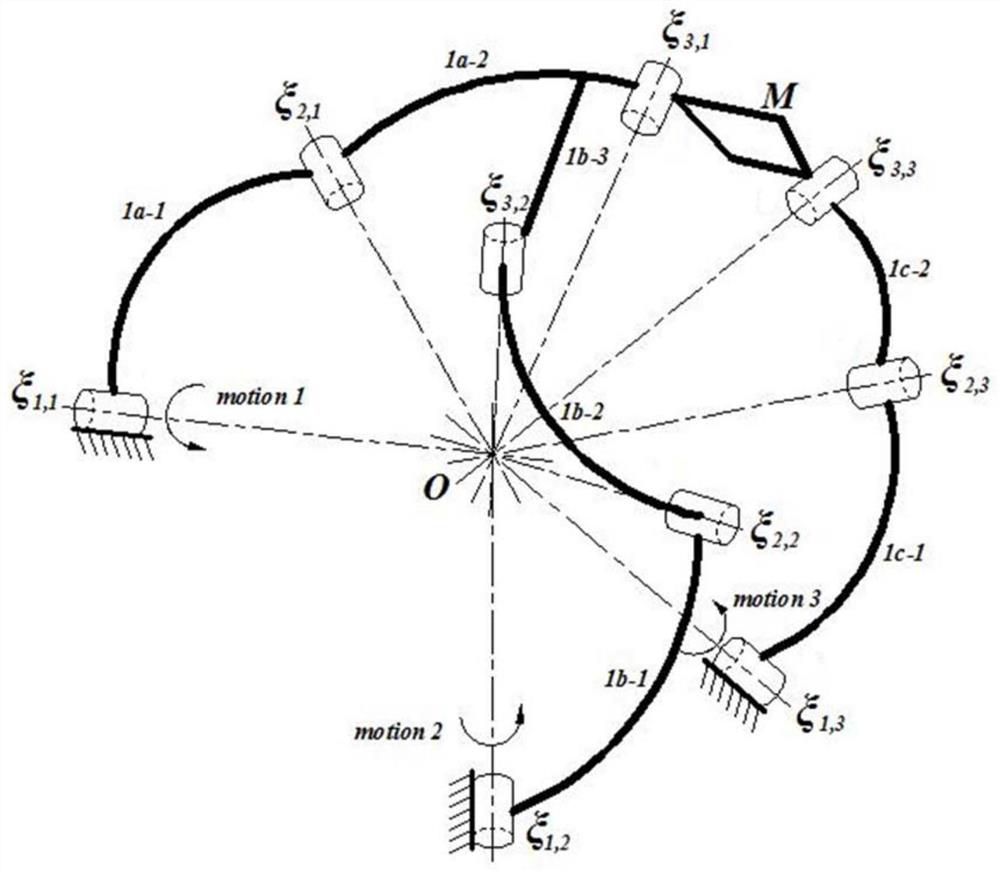

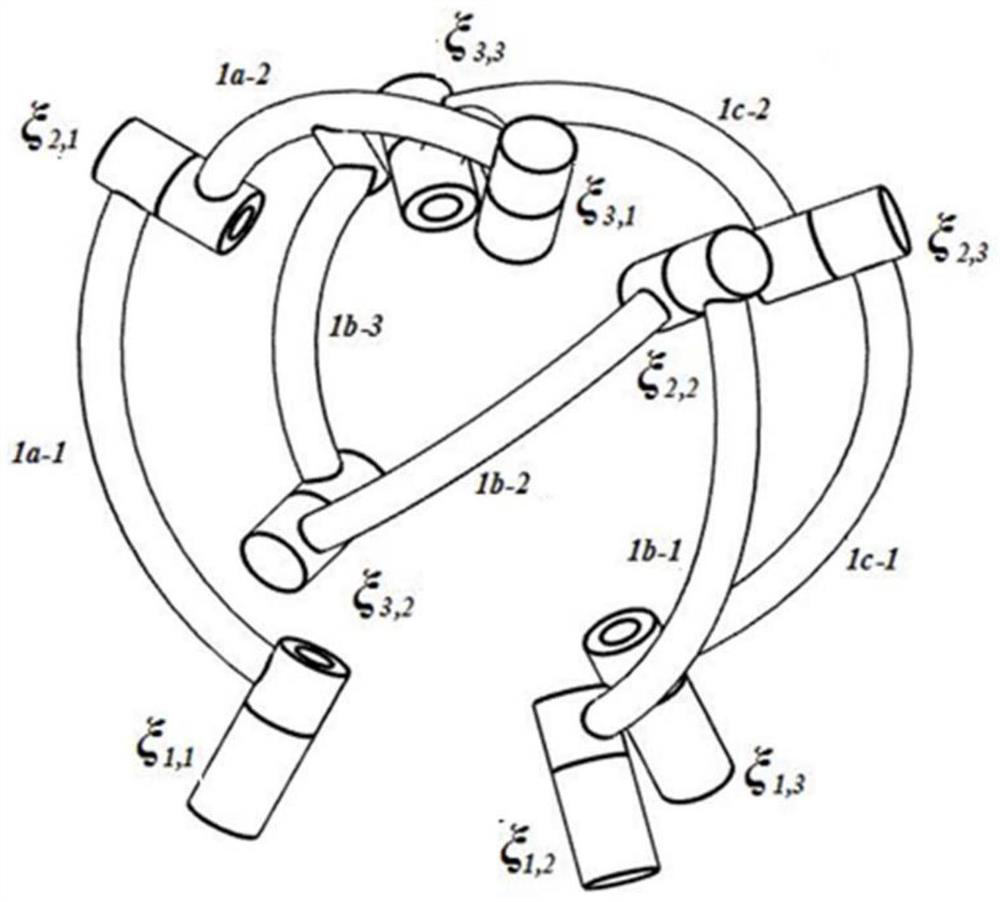

[0023] A decoupled three-rotation-degree-of-freedom parallel mechanism for virtual-axis machine tools and robots, whose structure is as follows Figure 1-2 As shown, it includes the first kinematic branch chain, the second kinematic branch chain, the third kinematic branch chain, the moving platform M, and the static platform. The first kinematic branch chain includes sequentially connected first revolving pairs ξ 1,1 , the second revolving pair ξ 2,1 , the third revolving pair ξ 3,1 , and the first connecting rod 1a-1 and the second connecting rod 1a-2 connected in sequence, where motion1 drives the first rotating pair ξ 1,1 . The second kinematic branch chain includes the fourth rotating pair ξ 1,2 , the fifth revolving pair ξ 2,2 , the sixth rotating pair ξ 3,2 , and the third connecting rod 1b-1, the fourth connecting rod 1b-2, and the fifth connecting rod 1b-3 connected in sequence, where motion2 drives the fourth rotating pair ξ 1,2 . The third kinematic branch c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com