Bendable miniature wrist

A miniature, wrist-based technology, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of easy deformation of ropes, easy wear of gear transmission, and difficult application, and achieve the effect of compact structure, small moment of inertia, and fast motion response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

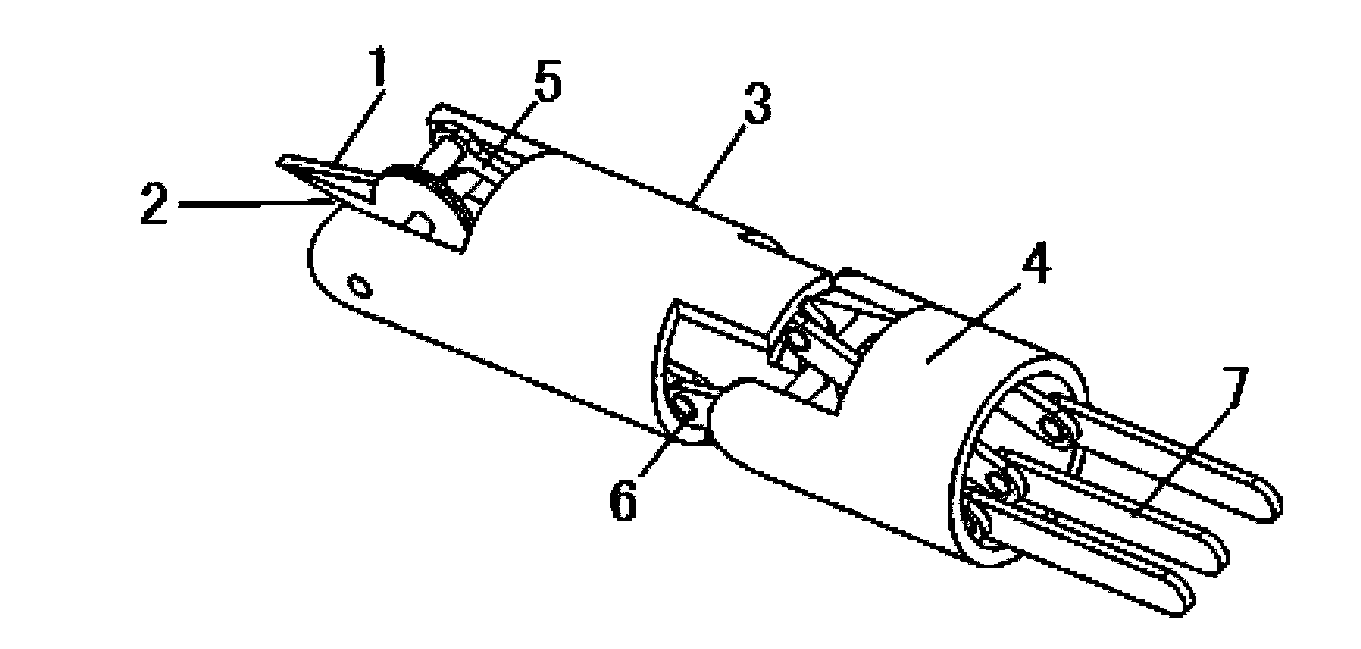

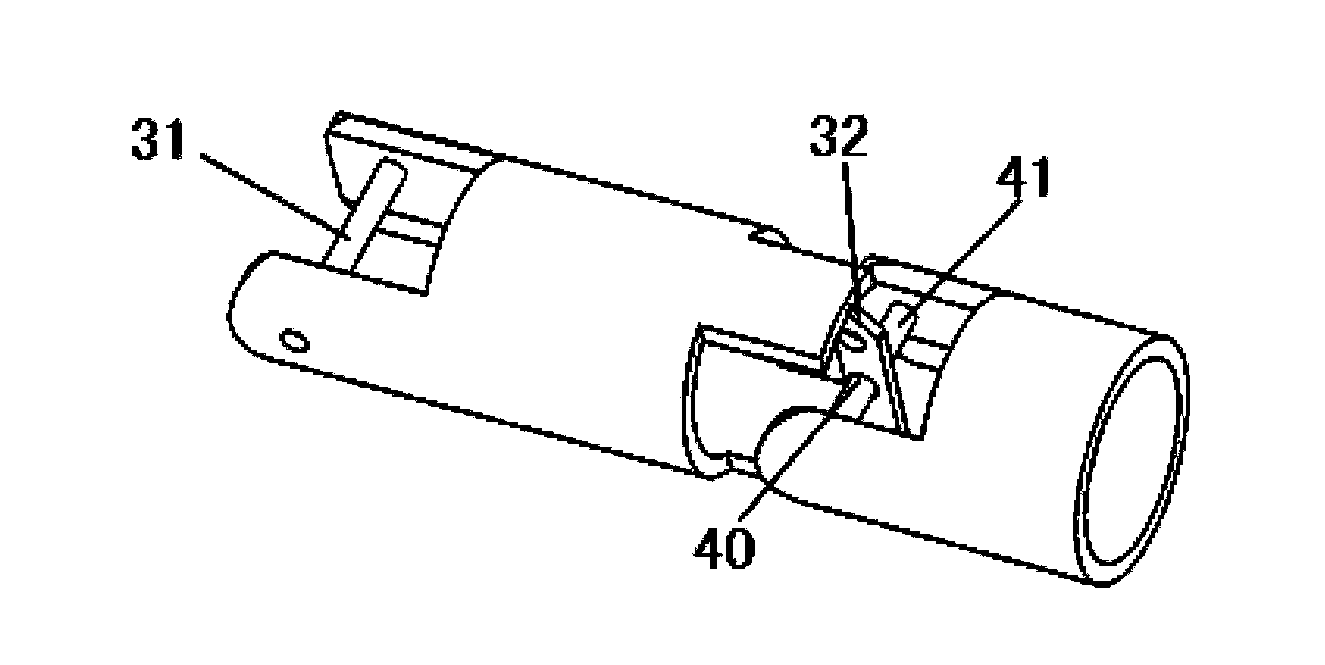

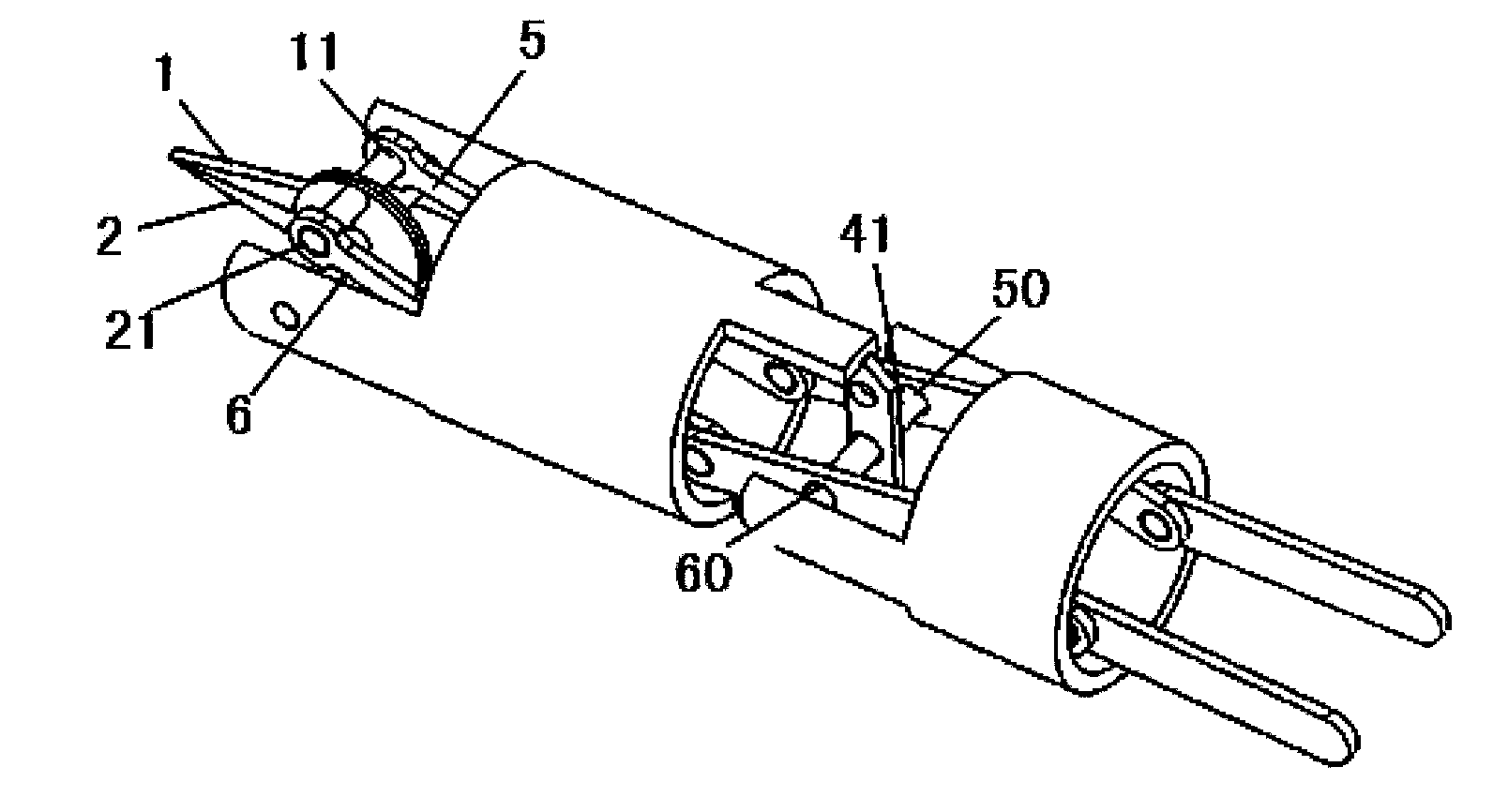

[0019] see figure 1 , with reference to figure 2 , image 3 , Figure 4 , Figure 5 , the flexible micro-wrist of the present invention includes a first end effector 1, a second end effector 2, a first-level sleeve 3, a second-level sleeve 4, a first kinematic branch chain 5, and a second kinematic branch chain 6 and the third kinematic branch 7 . Wherein, the first end effector 1 and the second end effector 2 are combined into clamps or grippers and are respectively rotatably connected with the first-level sleeve 3 (through a rotating pair); the second-level sleeve 4 is connected with the first-level The sleeve 3 is rotatably connected; the first kinematic branch chain 5 is rotatably connected to the first end effector 1, the second kinematic branch chain 6 is rotatably connected to the second end effector 2, and the third kinematic branch chain 7 is rotatably connected to the first end effector 2. The stage sleeve 3 is rotatably connected; the combined movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com