Double-sealed double-outer-ring long-shaft double-row ball bearing with O-shaped ring pre-tightening function

A double row ball bearing, double outer ring technology, applied in the direction of shaft and bearing, bearing in rotating motion, bearing, etc., can solve the problems of difficult to avoid axial movement, difficult to reduce vibration and noise, long lag time, etc. The effect of sloshing response is fast, vibration and noise are reduced, and sealing effect is better.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

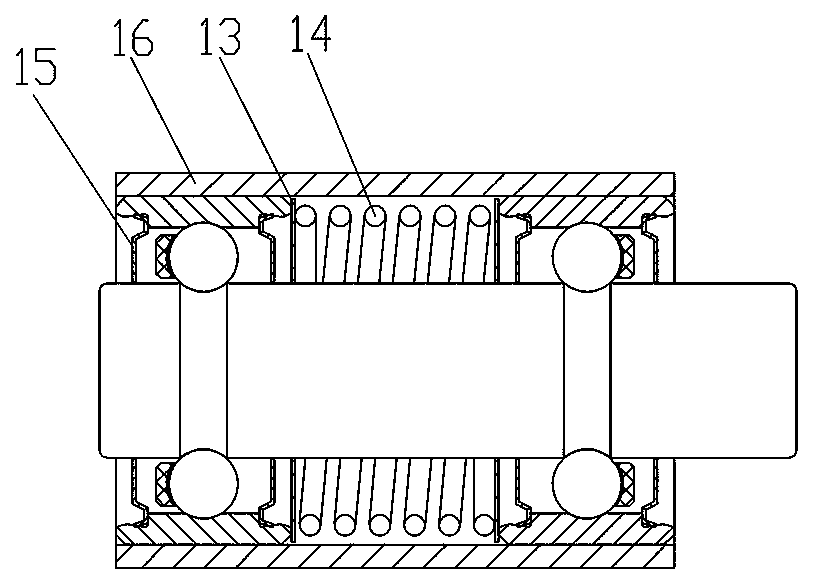

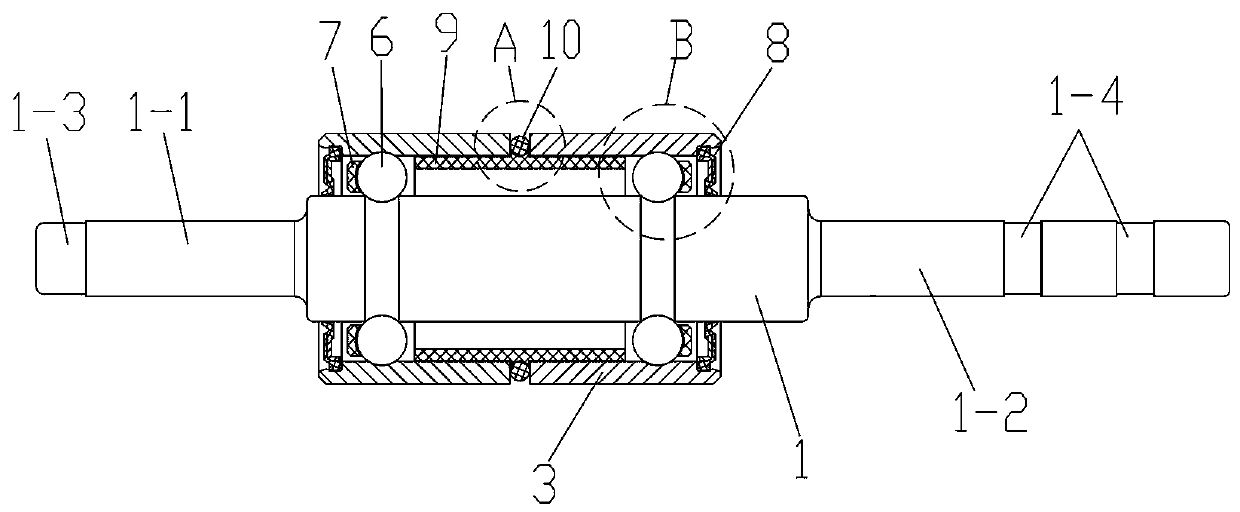

[0020] Such as Figure 2-4 As shown, the present embodiment provides a two-sided sealed double-outer ring long-axis double-row ball bearing with O-ring preload, which includes a long shaft 1, and a pair of first grooves 2 are provided on the surface of the long shaft 1. and distributed at intervals in the axial direction of the major axis 1;

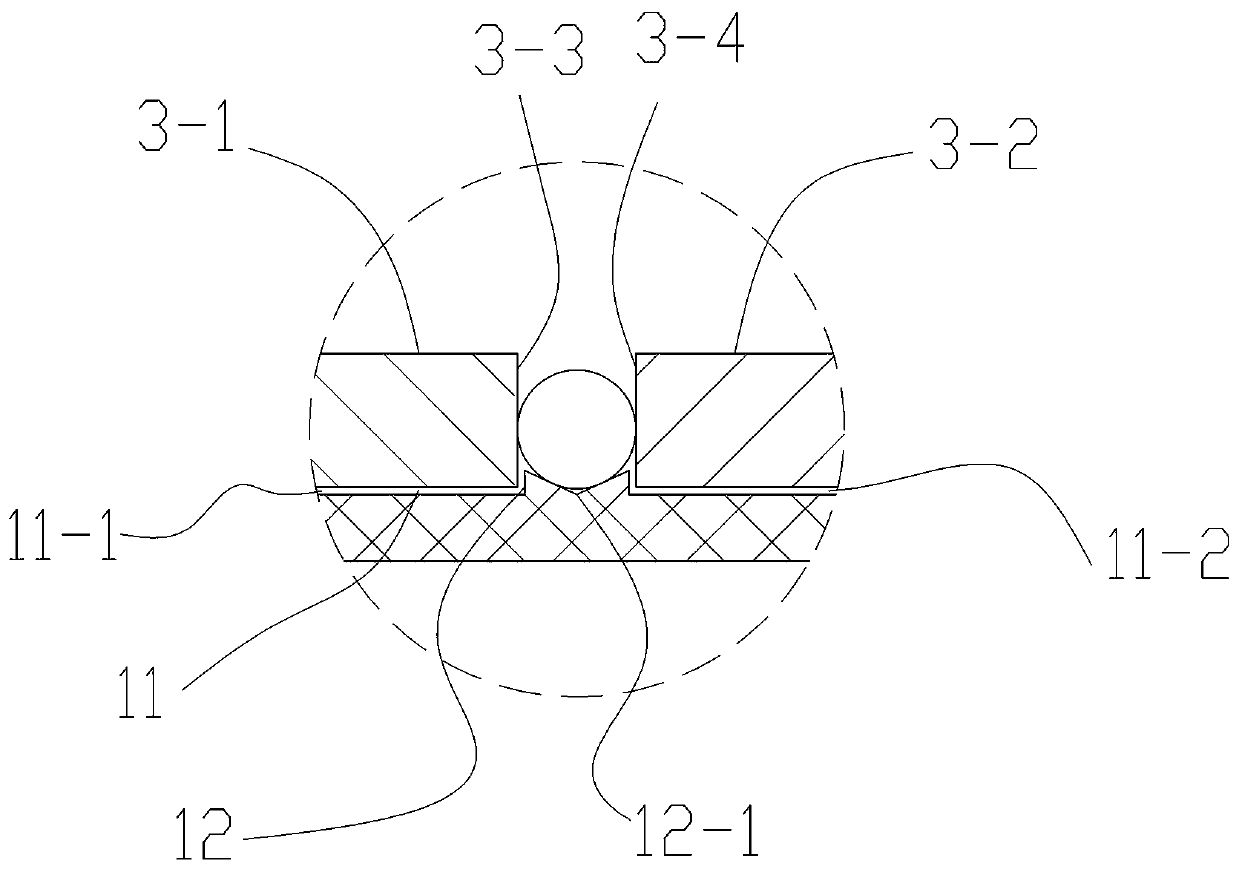

[0021] A pair of bearing outer rings 3, each bearing outer ring 3 is provided with a second channel 4 and a dust-proof groove 5 outside the second channel 4 on the inner surface; the bearing outer ring 3 and the long axis The first grooves 2 on the surface of 1 correspond one by one, and each corresponding set of first grooves 2 and second grooves 4 together form a bearing raceway for the steel ball 6 to run;

[0022] Located in each bearing raceway, the steel balls 6 are separated by the ball pockets 7-1 of the corresponding nylon cages 7;

[0023] Located in each dust-proof groove 5, a sealing ring 8 is installed to prevent internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com