Decoupled three-rotational-degree-of-freedom parallel mechanism

A technology with three rotations and degrees of freedom, applied to manipulators, manufacturing tools, joints, etc., can solve problems such as complex control of parallel mechanisms, weak coupling of pose parameters, and changes in pose parameters, and achieve fast motion response, simple control, and low moment of inertia. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

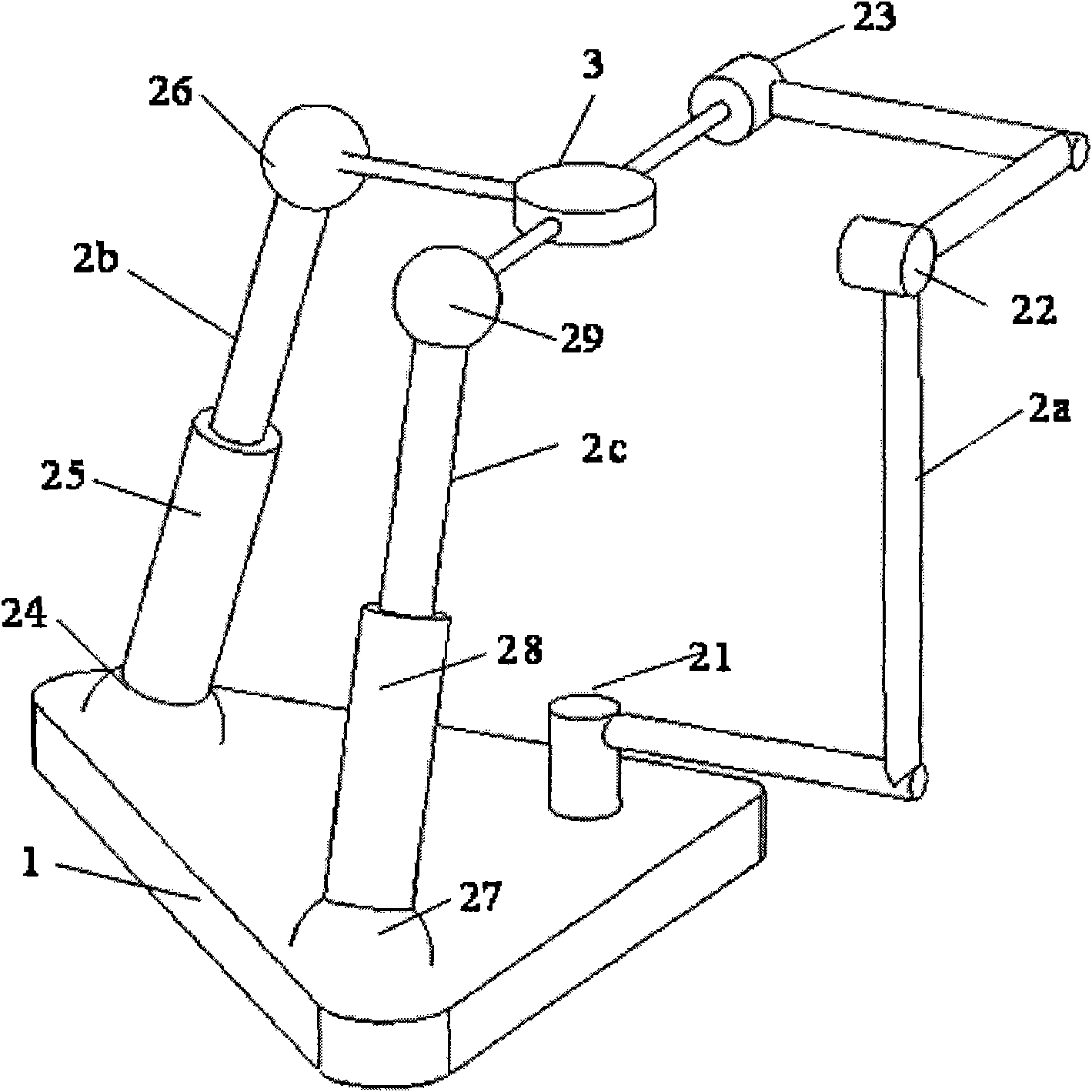

[0012] A decoupled three-rotation-degree-of-freedom parallel mechanism consists of a frame 1, a moving platform 3, and a first kinematic branch chain 2a, a second kinematic branch chain 2b, and a third kinematic branch chain fixedly connected between the frame and the moving platform. The first motion branch chain 2a includes a Z-axis rotation pair 21, an X-axis rotation pair 22, and a Y-axis rotation pair 23. The second motion branch chain 2b includes a first ball joint 24, a first movement pair 25. The second ball joint 26, the third motion branch chain 2c includes the third ball joint 27, the second moving joint 28, the fourth ball joint 29, the Z-axis rotating joint 21, the first ball joint 24, The 3rd ball hinge 27 is installed on the frame 1, and the three rotary axes of the first kinematic branch chain 2a meet at the central point of the platform 3, and the ball hinges (26), (29) link to each other with the moving platform (3), The ball center of the ball hinge (26), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com