Amorphous Alloy Composite Iron Core Electromagnetic Control Injector

An amorphous alloy, electromagnetic control technology, used in machines/engines, fuel injection devices, engine components, etc., can solve the problems of reducing long-term operating life, energy waste, shortening the life of electronically controlled injectors, etc., to improve long-term operation. The effect of life, core loss reduction, and valve stem movement response speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

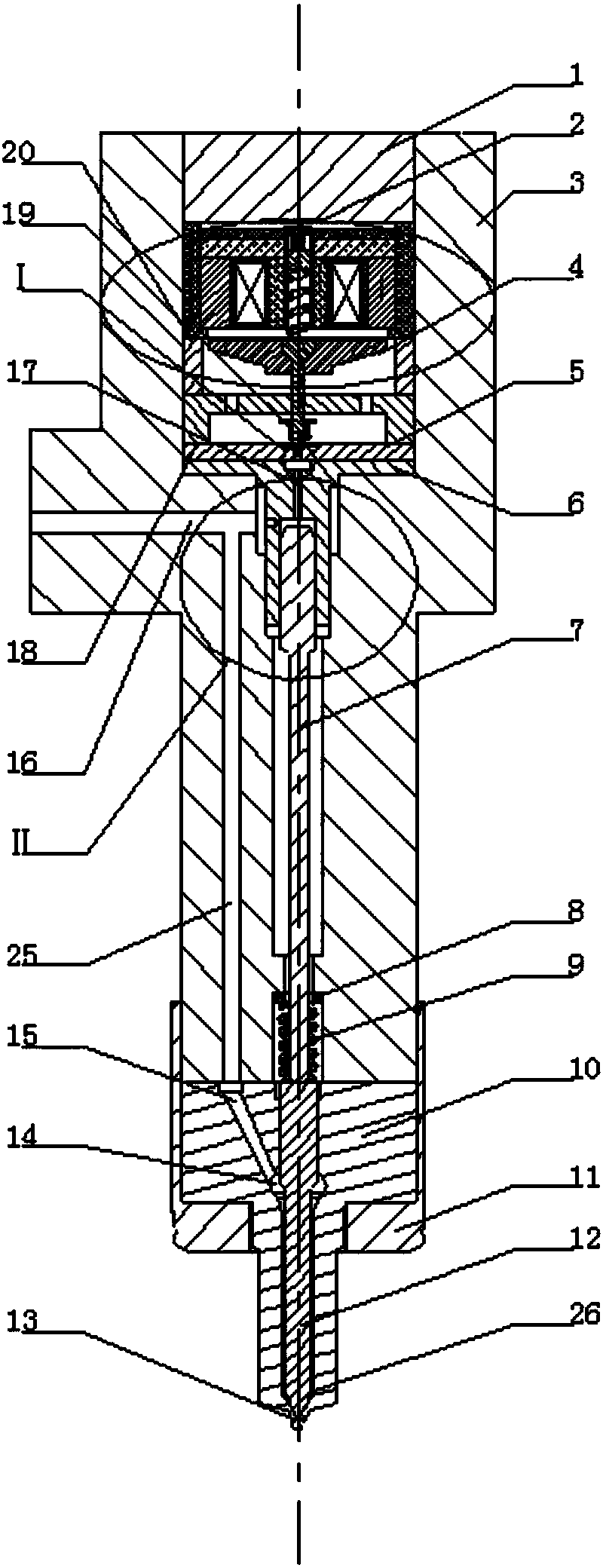

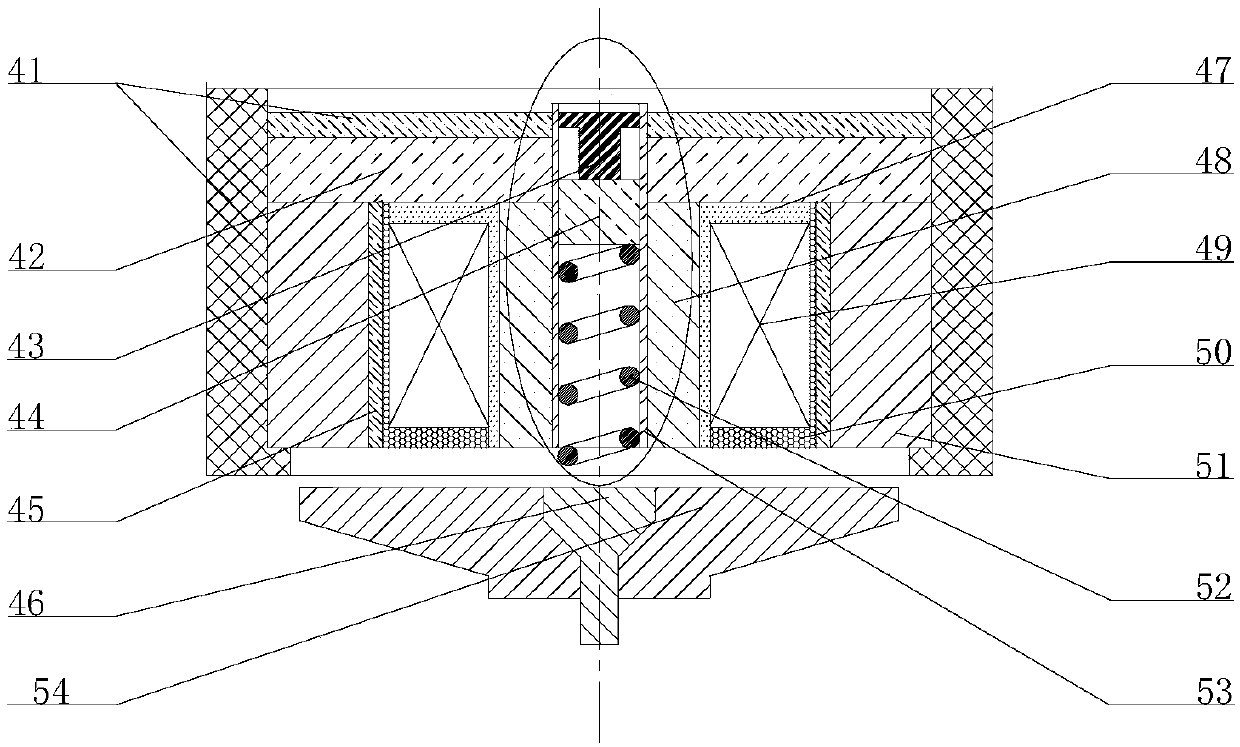

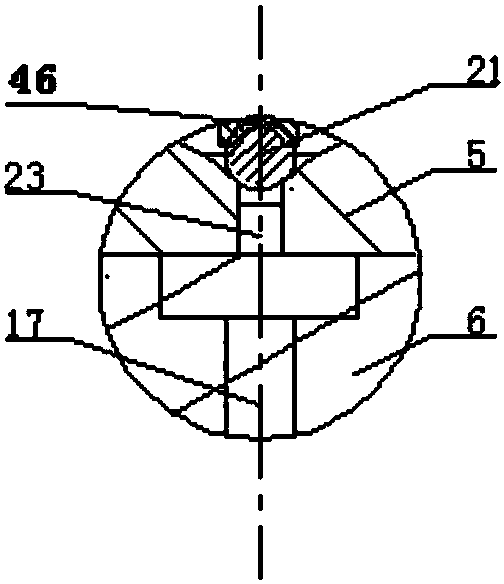

[0024] combine figure 1 -7. The composition of this embodiment includes injector head fastening nut 1, amorphous alloy electromagnet assembly 2, injector body 3, electromagnet assembly chamber 4, pilot ball valve seat 5, control piston body 6, needle valve Push rod 7, needle valve return spring seat 8, needle valve return spring 9, nozzle 10, nozzle fastening nut 11, needle valve 12, dividing plate 18, stop ring 19, cushion block 20 these components. The needle valve ejector rod 7 and the control piston body 6 are sequentially installed from the upper part of the injector body 3, and the amorphous alloy electromagnet assembly 2, the electromagnetic pilot ball valve, the partition plate 18, the stop ring 19, the cushion block 20 and the pilot ball valve seat 5 After being assembled together in a reasonable order, they are finally placed on the control piston body 6, and are fixed by the uppermost injector head fastening nut 1, and the needle valve return spring 9 is combined wi...

Embodiment approach 2

[0028] This embodiment is to change the structural combination of the flange extending from the lower part of the casing 41 of the amorphous alloy electromagnet assembly 2 in the first embodiment 2 along the side near the coil, and the flange is changed from a complete ring flange to an equal ring flange. The evenly spaced circular arc flanges also play a role in fixing the amorphous alloy electromagnet assembly, which can save flange materials and relatively increase the bond between the composite iron core and the lower temperature fuel in the amorphous alloy electromagnet assembly. contact area to enhance heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com