Uprighting and sand preventing integrated pipe column and operating method thereof

An operation method and sand control technology, applied in the direction of drill pipe, casing, production fluid, etc., can solve the problems of sand control construction strings not being centered, sand control ineffective, not sealed, etc., to prevent wellbore collapse and sand production, and avoid scrapping , long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

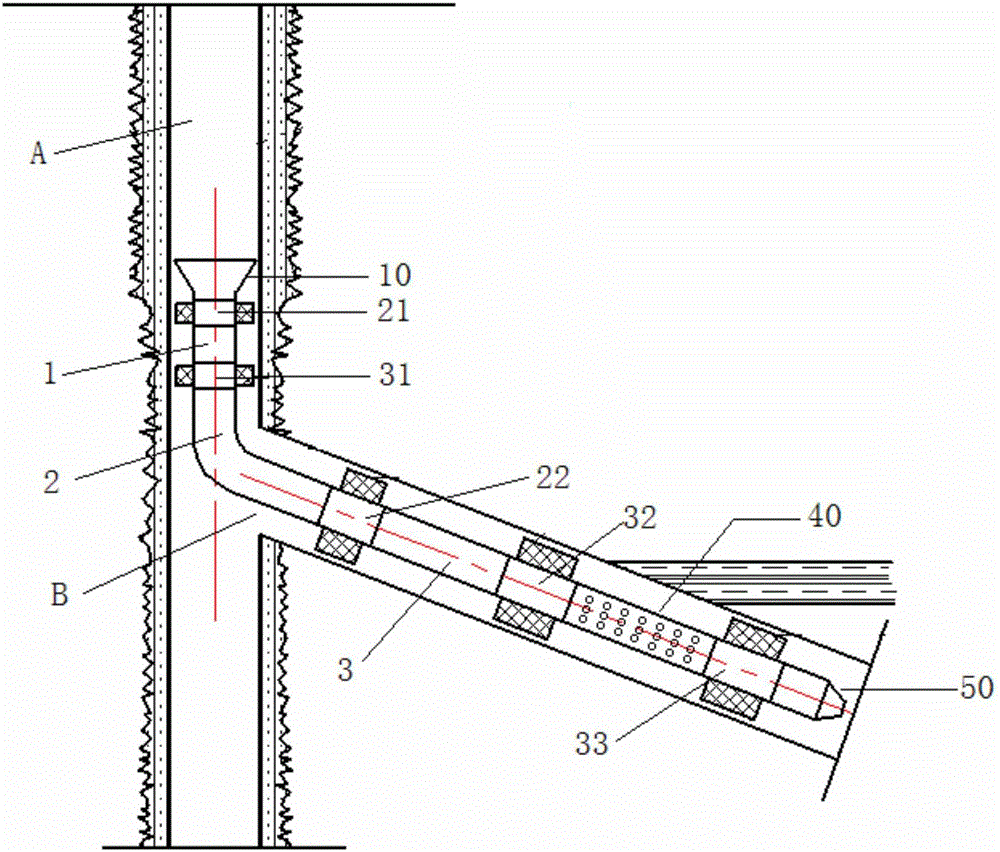

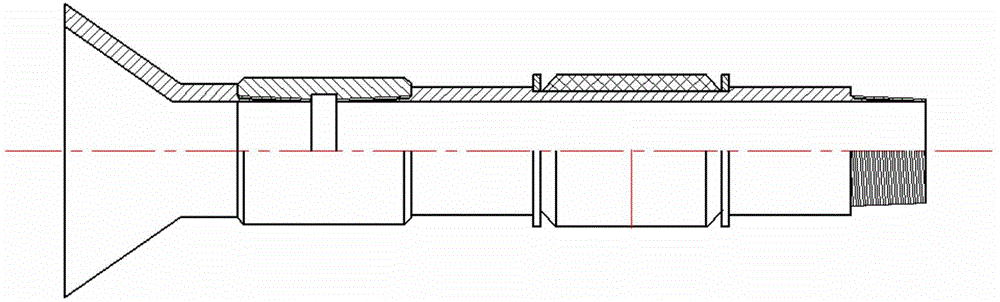

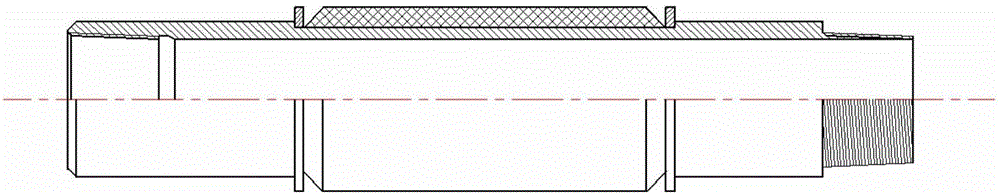

[0025] like Figure 1 to Figure 6 As shown, a centralizing and sand control integrated pipe string is mainly composed of suspension head, self-expanding and sealing centralizing sub-joint, self-expanding and sealing centralizing sub-joint, screen pipe and guide cone, one self-expanding and sealing centralizing sub-joint and one self-expanding and sealing centralizing sub-joint There is a sleeve connection between the sections.

[0026] The suspension head is an inverted cone structure, the inner wall of one end is turned with a square connecting box for connecting the pin of the drill pipe body; the outer wall of the other end is turned with a pin for connecting the self-expanding and centralizing pup, and the inverted cone Then it is beneficial for the sand-washing pipe string to enter into the erecting sand-control integrated pipe string. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com