Piezo-stack pump capable of driving double-piston in tandem connection

A piezoelectric stack and series drive technology, which is applied to pumps, pumps, machines/engines with flexible working elements, etc., can solve the problems of small output flow of piezoelectric stack pumps, and achieve high electromechanical energy conversion efficiency and improve The effect of high output flow and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

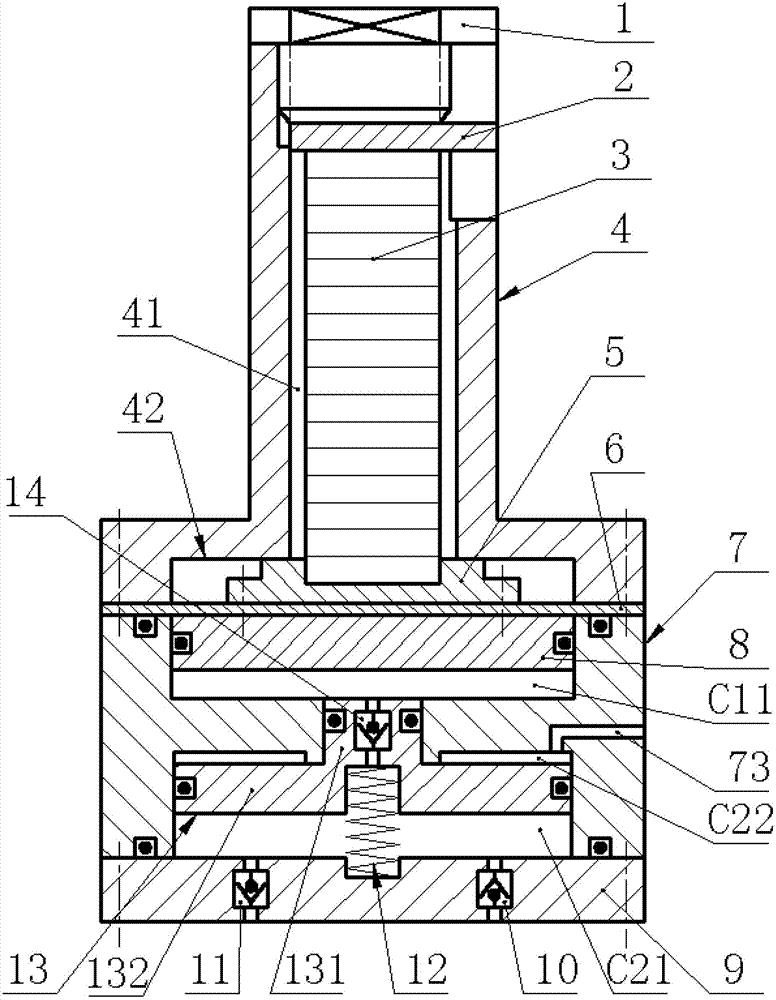

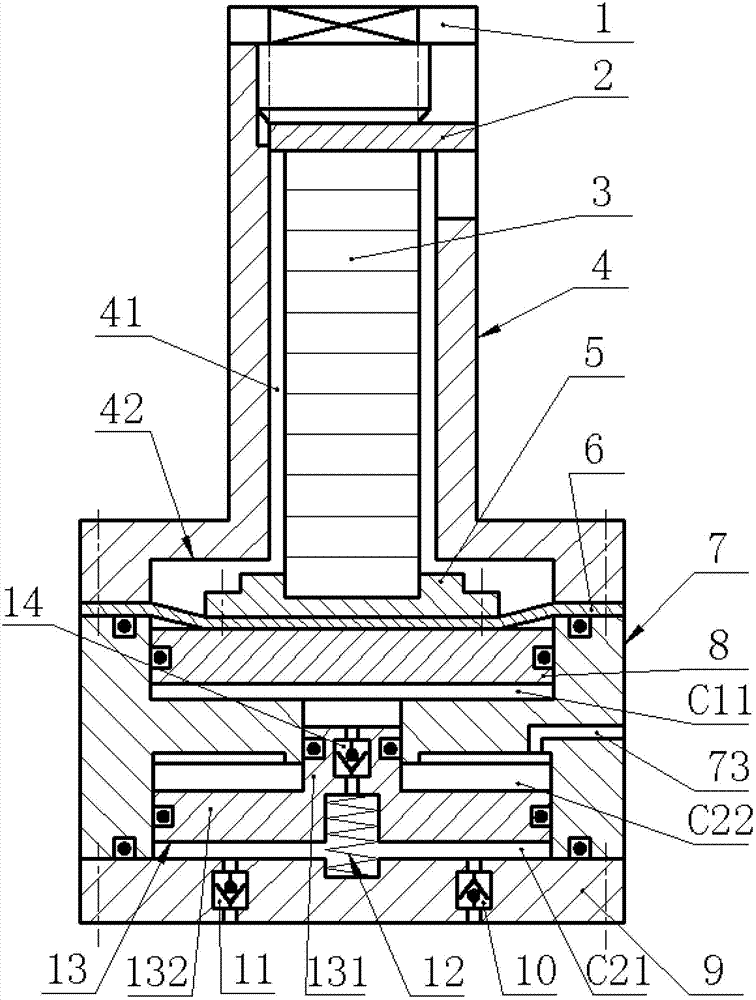

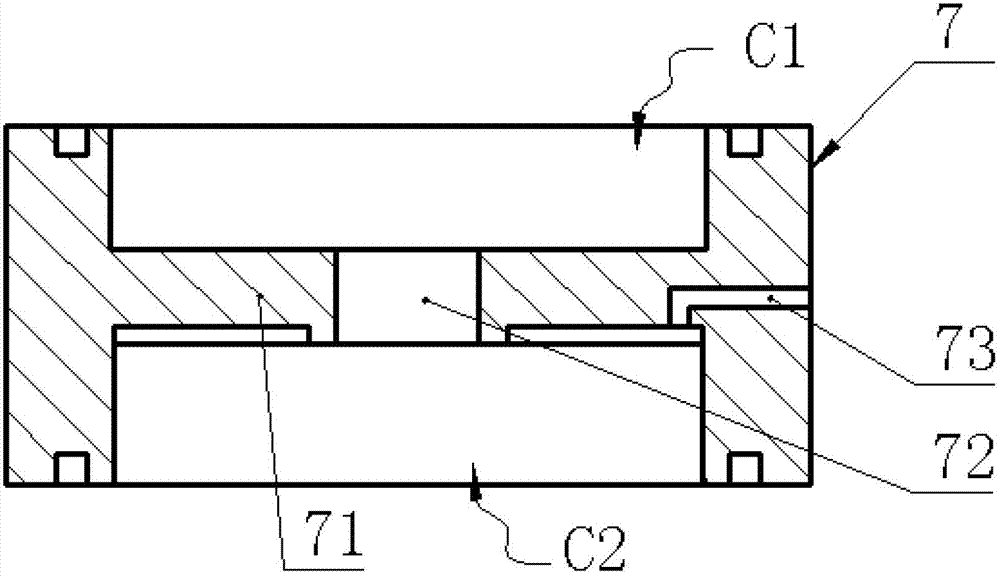

[0012] The upper and lower ends of the pump body 7 are respectively fixed with an upper casing 4 and a lower end cover 9 by screws. The pump body 7 is provided with an upper chamber C1 and a lower chamber C2 separated by a partition 71. The upper chamber C1 and the lower chamber The chamber C2 communicates with the piston hole 72 on the partition 71; the elastic diaphragm 6 is crimped between the pump body 7 and the upper casing 4; It is connected with the elastic diaphragm 6 and the top block 5, the upper surface of the top block 5 leans against the inner wall 42 of the upper case 4; the adjusting screw 1 is fixed on the upper case 4, and the upper The piezoelectric stack 3 in the inner cavity 41 of the housing 4 is squeezed on the top block 5; the small end 131 and the large end 132 of the stepped pump chamber piston 13 are respectively placed in the piston hole 72 on the partition 71 and the pump body In the lower chamber C2 of 7, the small end 131 of the pump chamber pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com