Slide valve type pilot ultra-high pressure pneumatic proportional pressure-reducing valve

A technology of proportional pressure reducing valve and pilot valve, applied in the direction of functional valve type, electric fluid pressure control, valve device, etc., can solve the problems of inconvenient adjustment, low degree of automation, low output pressure of pressure reducing valve, etc., and achieve Improved response speed and control accuracy, simple structure and control, and high output flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

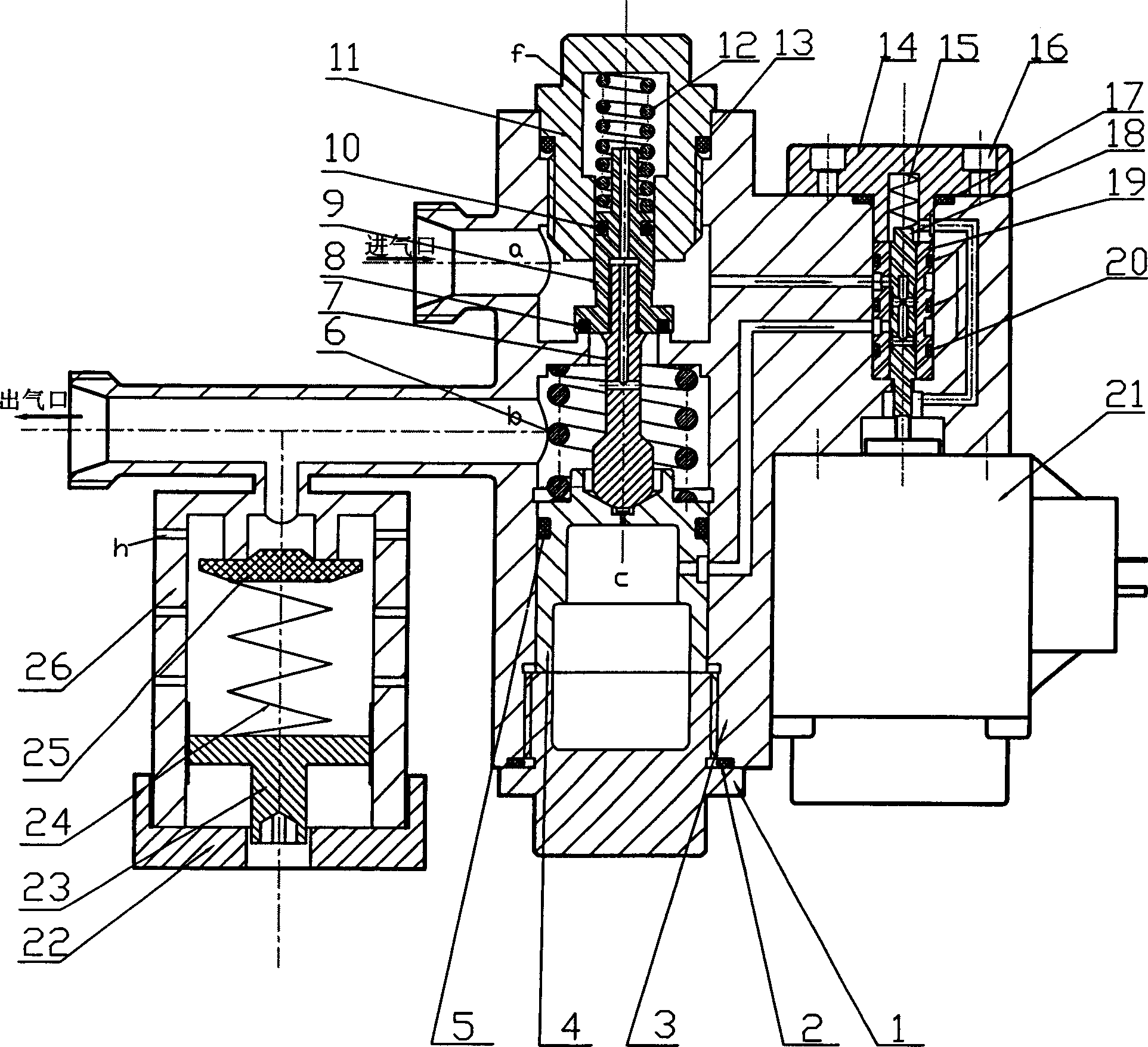

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] As shown in the drawings, the present invention includes a pilot valve and a main valve controlled by proportional solenoids mounted on the same valve body. That is, there is a screw hole at the upper end of the valve body 3 and is firmly connected with the first screw plug 11. The first screw plug 11 and the valve body 3 are sealed with an O rubber sealing ring 13. There is a feedback cavity f inside the first screw plug 11. The main valve spool 9 with the outer main valve spool spring 12 is installed in the feedback cavity f, the main valve spool 9 and the valve body 3 are sealed by the Teflon sealing element 8 pressed in the main valve spool 9, the main valve The valve core 9 and the first screw plug 11 are sealed with an O-shaped rubber sealing ring 10. The main valve core push rod 7 is covered with a piston spring 6. One end of the main valve core push rod 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com