Self-propelled working machine and method for braking working machine of this type

A technology for working machines and mechanical brakes, which can be used in motor vehicles, electric braking systems, earthmovers/shovels, etc., and can solve problems such as complex control systems for electric motor braking power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

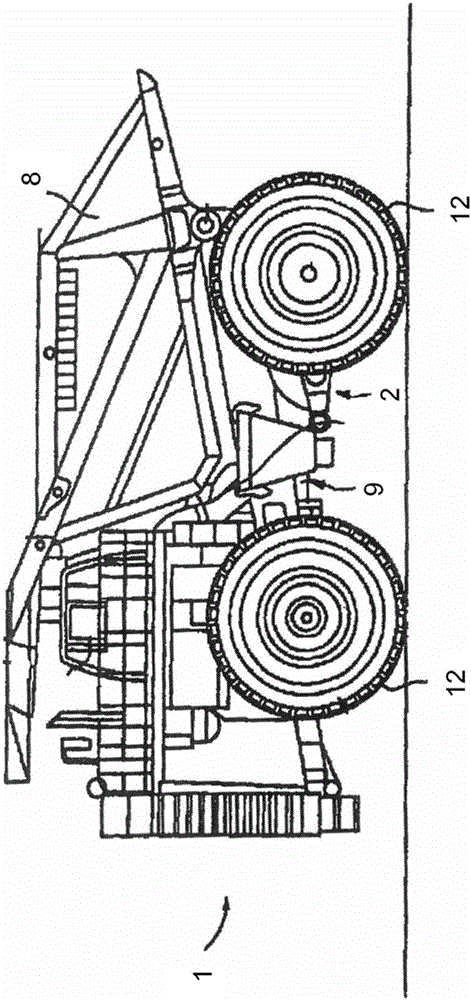

[0023] Such as figure 1 As shown, the self-propelled work machine 1 can be constructed, for example, in the form of an off-road truck and in particular a dump truck, which can include a running gear 2 and a plurality of wheels 12, which are distributed on several axles and carry the chassis or machine body of the work machine 1. shelf. However, it should be understood that the work machine can generally also be configured in other forms, such as other construction machines or mining machines with wheeled or chain-type running gear.

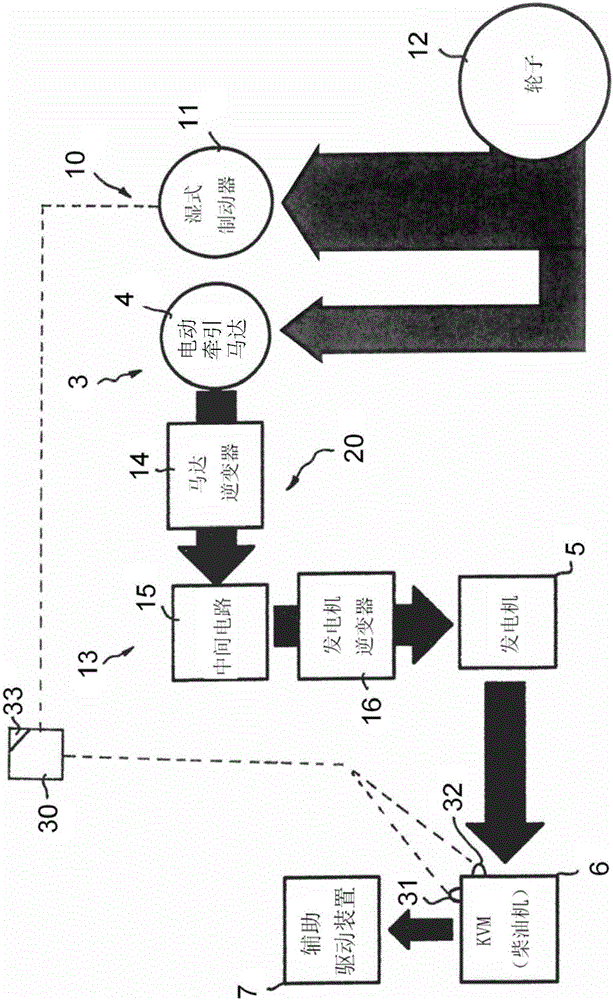

[0024] The drive system of the work machine 1 includes at least one electric drive 3 with at least one electric motor 4 , which can serve as a traction drive and can drive wheels 12 . Here, perhaps by means of a power split drive or a differential, one electric motor 4 can simultaneously drive several wheels 12 , for example wheels 12 of one axle. Alternatively, a single-wheel drive can also be provided, in which each driven wheel 12 is assigned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com