Safety monitoring system and method for small fuel gas storage tank and intelligent terminal

A safety monitoring system and control terminal technology, applied in the field of combustible gas safety monitoring, can solve problems such as low maintenance efficiency and increased workload of staff, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

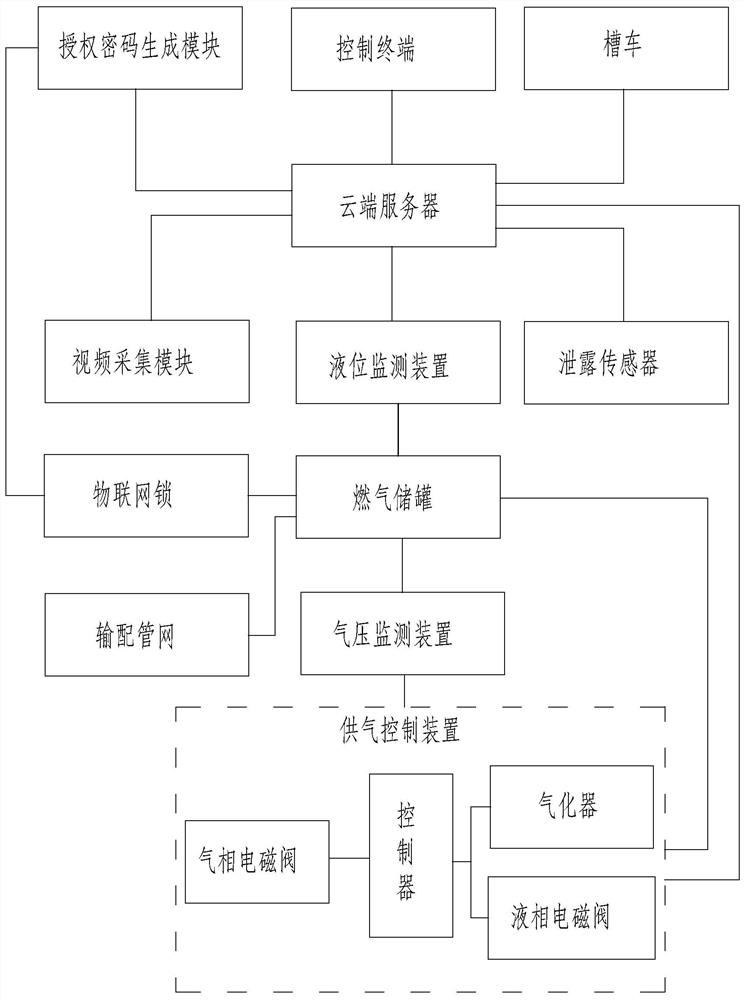

[0043] Embodiment one: refer to figure 1 , the embodiment of the present application discloses a safety monitoring system for a small gas storage tank, which is used to monitor the usage of the gas storage tank, reduce the workload of staff, and thus improve maintenance efficiency. refer to figure 1 , the safety monitoring system for small gas storage tanks includes a liquid level monitoring device, a cloud server and a control terminal. The gas storage tank adopts LPG storage tank, and the filling gas can be propane. The liquid level monitoring device is used to monitor the liquid level of the liquid gas in the gas storage tank and generate liquid level information. The cloud server is connected to the liquid level monitoring device to send the liquid level information to the control terminal. The control terminal can use a computer, which is connected to the tank trucks in the designated area to generate scheduling instructions based on the liquid level information, and se...

Embodiment 2

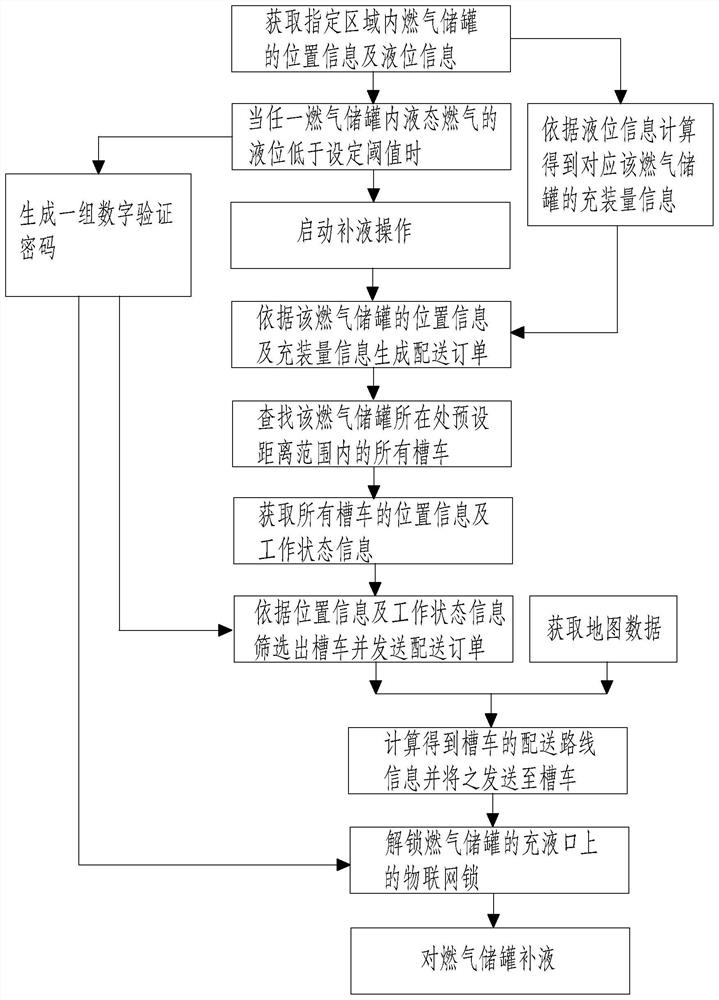

[0055] Embodiment two: refer to figure 2 , the application of the safety monitoring system of the above-mentioned small gas storage tank can realize the safety monitoring method of the small gas storage tank, which includes the following steps,

[0056] The control terminal first obtains the location information and liquid level information of the gas storage tank in the designated area. The location information can be obtained by installing a GPS locator on each gas storage tank, and the GPS locator is connected to the control terminal through the cloud server to facilitate the transmission of location information. The liquid level information can be collected by an electronic liquid level gauge pre-installed on the gas storage tank. When the liquid gas level in any gas storage tank is lower than the set threshold, the replenishment operation is started.

[0057] Liquid replenishment operation: The control terminal first calculates the filling amount information correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com