Static sealing structure and pressure vessel with static sealing structure

A pressure vessel and static sealing technology, which is applied in the field of static sealing structure and pressure vessel with the static sealing structure, can solve the problems of low operating pressure, low safety of the pressure vessel, and inability to maintain, so as to reduce the use cost and form Process safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following embodiments do not limit the present invention according to the appended claims, and not all combinations of features described in the embodiments are necessary to solve the problems of the present invention.

[0035] [Pressure vessel according to an embodiment of the present invention]

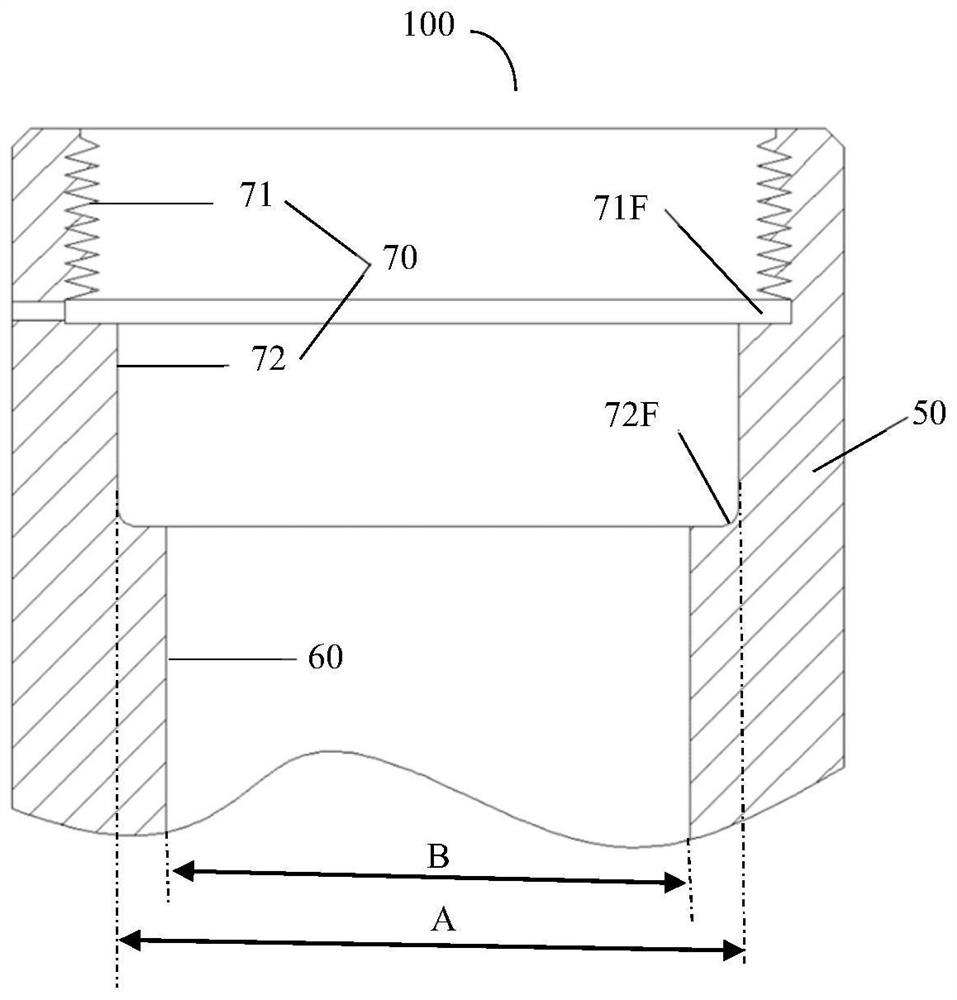

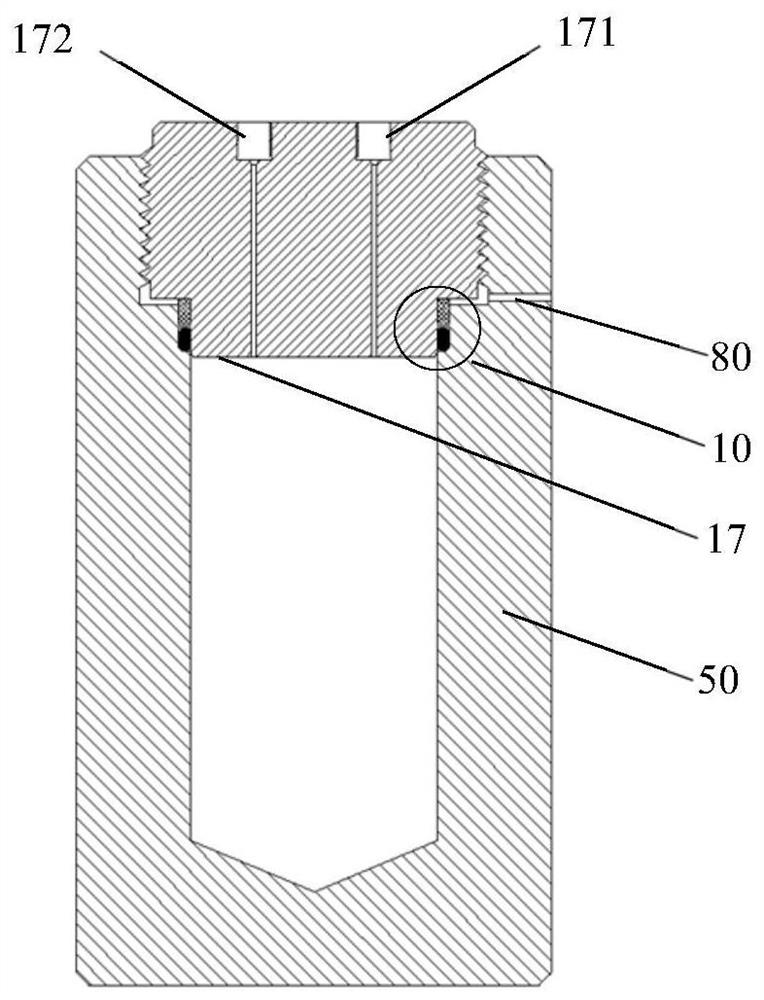

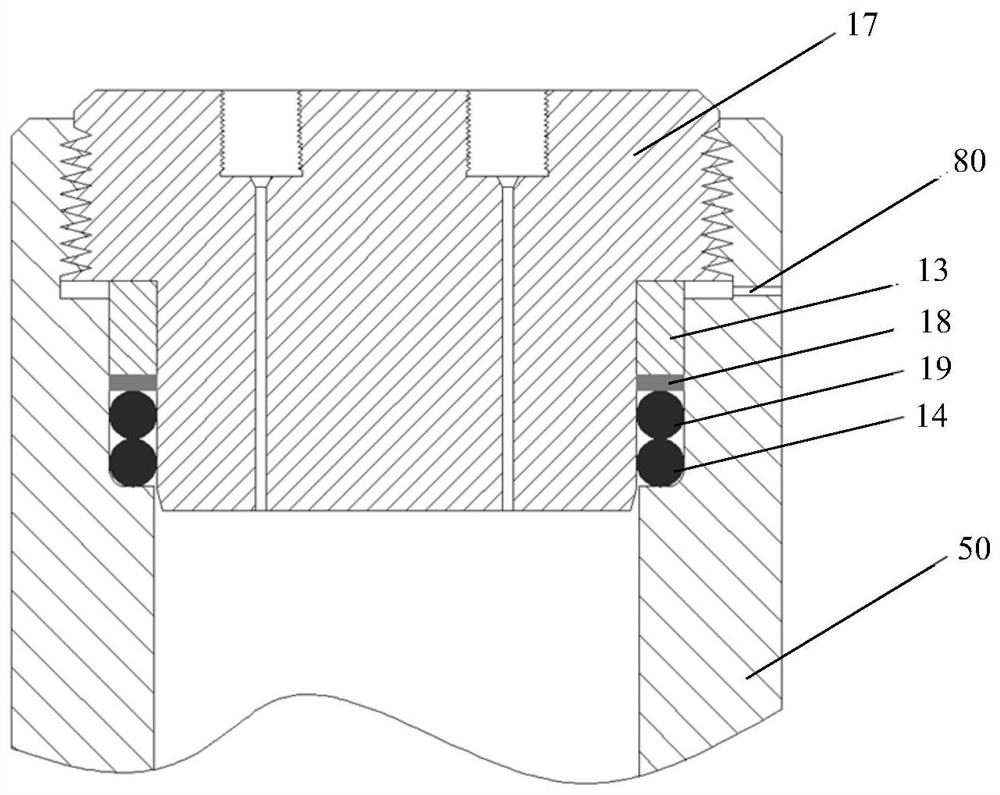

[0036] Below, will refer to figure 1 , the overall structure of the pressure vessel according to the embodiment of the present invention will be described.

[0037] Such as figure 1 As shown, the pressure vessel 100 according to the present invention comprises: a container shell 50; a container cavity 60 formed by the inner cavity of the container shell; a groove structure 70 opening on the top of the container shell, the groove structure and the container cavity through.

[0038] Refer to the following figure 1 , the specific structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com