Patents

Literature

56results about How to "Guaranteed suction capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

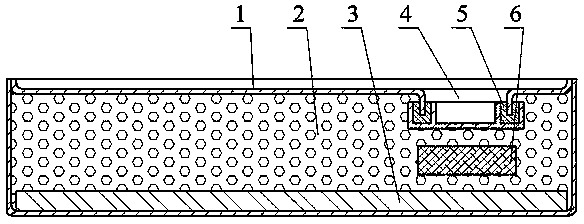

Metal vacuum composite insulation plate with getter and preparation method thereof

InactiveCN104295017ASimple sealing structureReliable sealingCovering/liningsThermal insulationVacuum furnaceGetter

The invention discloses a metal vacuum composite insulation plate with a getter. The metal vacuum composite insulation plate comprises a shell, a core material, a core plate and a vacuum cavity, and is characterized in that the shell is a metal plate or a metal composite plate, wherein the core material is positioned in the vacuum cavity for providing additional strength to the shell and guaranteeing the flatness of the shell under atmospheric pressure; the vacuum cavity is a closed cavity formed by performing the welding edge sealing under normal pressure and the high-temperature opening sealing under vacuum for the shell; the opening sealing is a step that an extraction opening prefabricated in the shell is automatically sealed in a vacuum furnace by using a low-temperature solder according to a liquid sealing principle; and the getter is arranged in the vacuum cavity. A preparation method of the metal vacuum composite insulation plate is simple in process; and the prepared metal vacuum composite insulation plate with the getter can overcome the defects of a traditional insulation plate and a traditional vacuum insulation plate, and can be improved in strength, and heat insulation, sound insulation, fire prevention and decoration functions.

Owner:戴长虹

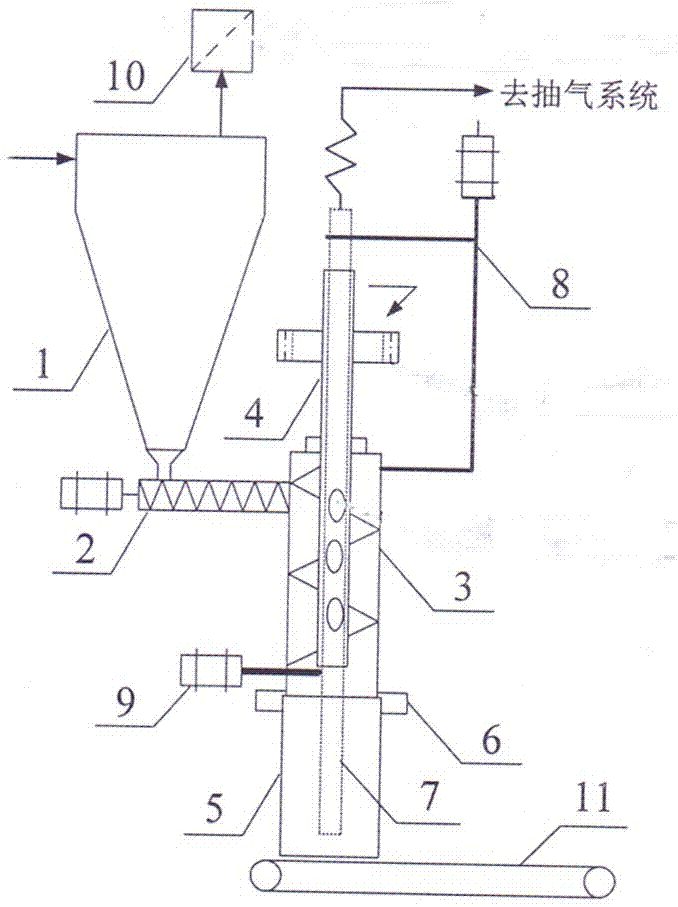

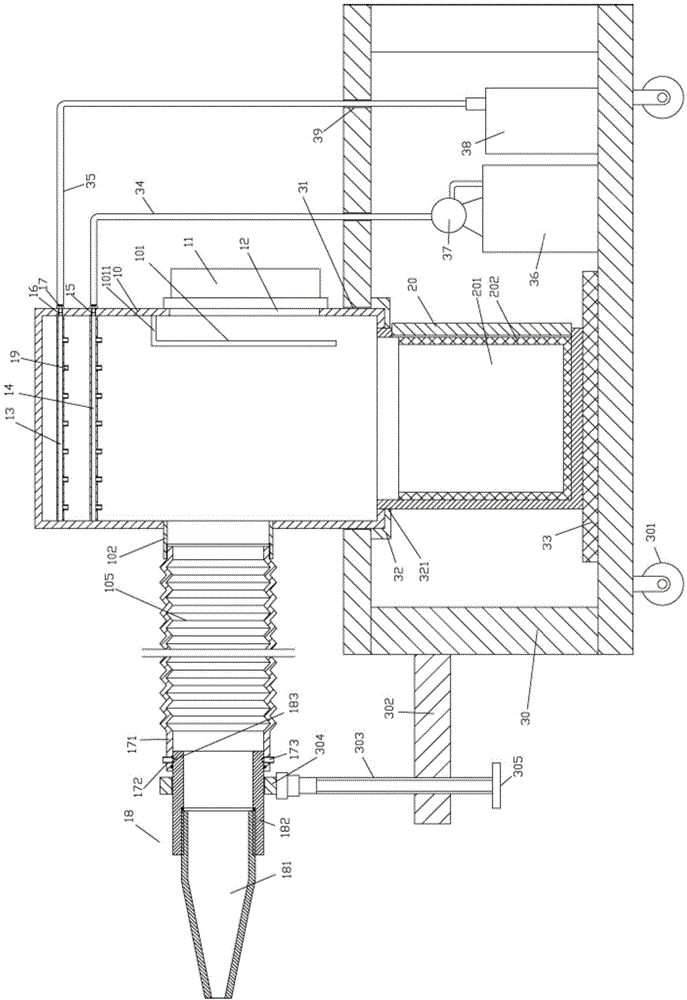

Measurement packing method for powder containing air

InactiveCN107082127ASmooth inhalationBeware of running materialsSolid materialEngineeringScrew conveyor

The invention discloses a measurement packing method for powder containing air. A powder material from an airflow conveying system is temporarily stored in a powder bin; a screw feeder arranged at the bottom of the bin feeds to a middle material cylinder; the material in the middle material cylinder is sent into a packing bag through a hollow stirring shaft; the air contained in the powder is pumped out through a filtering rod arranged inside the hollow stirring shaft in the flow direction; the air pumping process is divided into two levels; according to the first level, air pumping is conducted in a packing material cylinder; according to the second level, deep air pumping is conducted in the packing bag; when the material in the packing bag reaches 99.8% of the rated value, the air pumping filtering rod is quickly removed, and a cut-off valve is turned down; when the weight of the material in the packing bag reaches the set value, the screw conveyor stops feeding, and the cut-off valve is quickly closed; and measurement packing work is completed, and the subsequent working procedures of bag sewing and stacking are executed. According to the measurement packing method, the problem existing in the measurement packing process of the powder containing the air can be effectively solved, and efficient and accurate measurement packing is achieved.

Owner:JIANGSU JIUJIUJIU TECH

Metal vacuum insulation plate with getter and preparation method thereof

InactiveCN104295015AStable and reliable productionEasy to produceCovering/liningsThermal insulationFire preventionGetter

The invention discloses a metal vacuum insulation plate with a getter. The metal vacuum insulation plate comprises a shell, a core material and a vacuum cavity, and is characterized in that the shell is a metal plate or a metal composite plate, wherein the core material is positioned in the vacuum cavity for providing additional strength to the shell and guaranteeing the flatness of the shell under atmospheric pressure; the vacuum cavity is a closed cavity formed by performing the welding edge sealing under normal pressure and the high-temperature opening sealing under vacuum for the shell; the opening sealing is a step that a prefabricated extraction opening in the shell is automatically sealed in a vacuum furnace by using a low-temperature solder according to a liquid sealing principle; and the getter is arranged in the vacuum cavity. A preparation method of the metal vacuum insulation plate is simple; and the prepared metal vacuum insulation plate with the getter can overcome the defects of a traditional insulation plate and a traditional vacuum insulation plate, and can improve the strength, and the heat insulation, sound insulation, fire prevention and decoration functions.

Owner:戴长虹

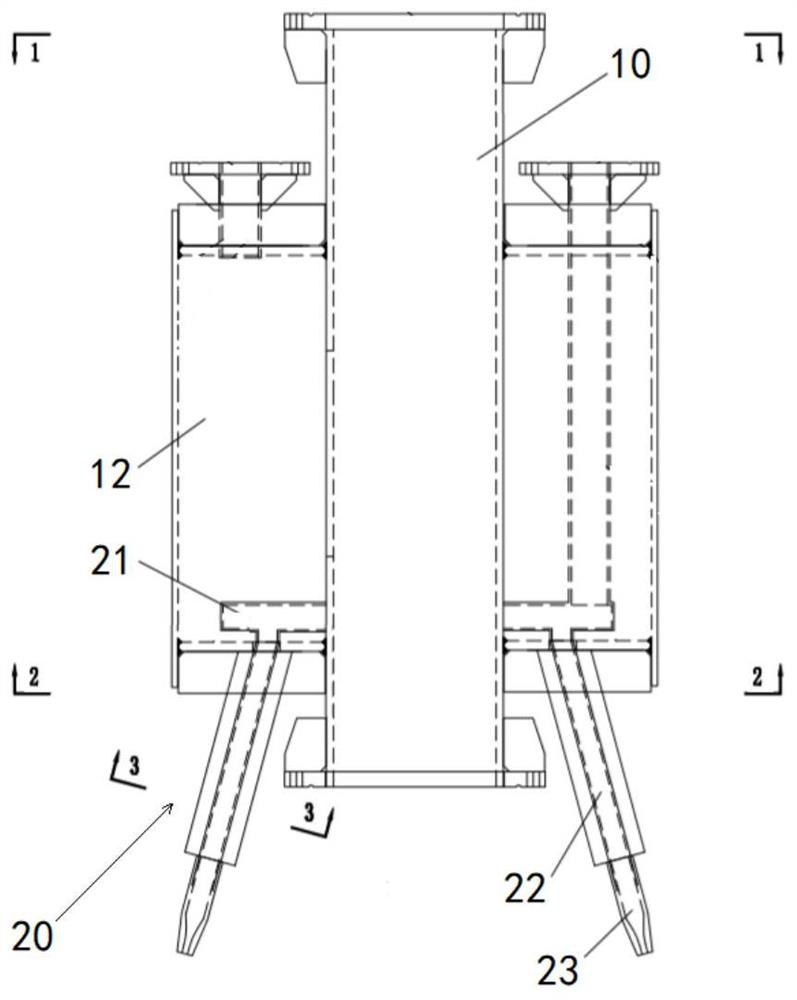

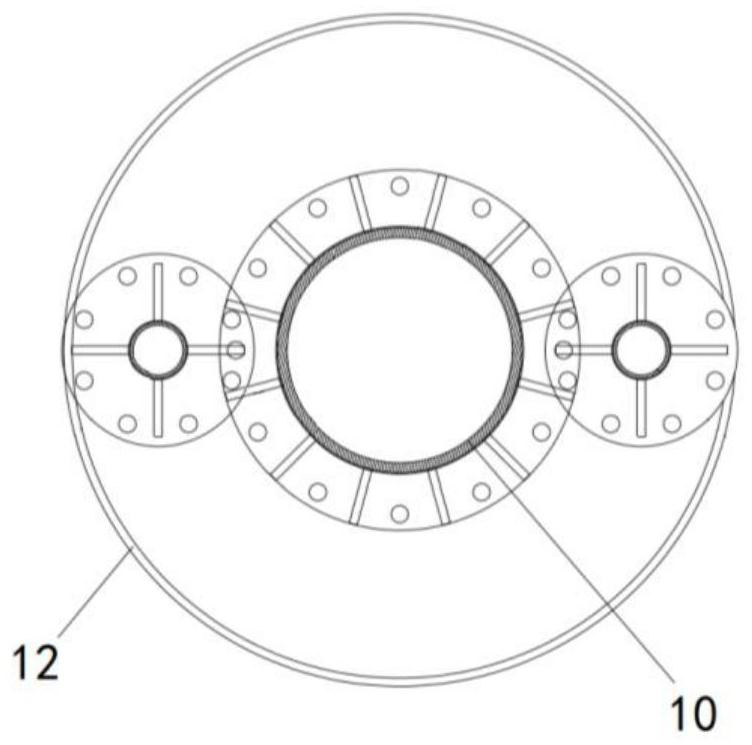

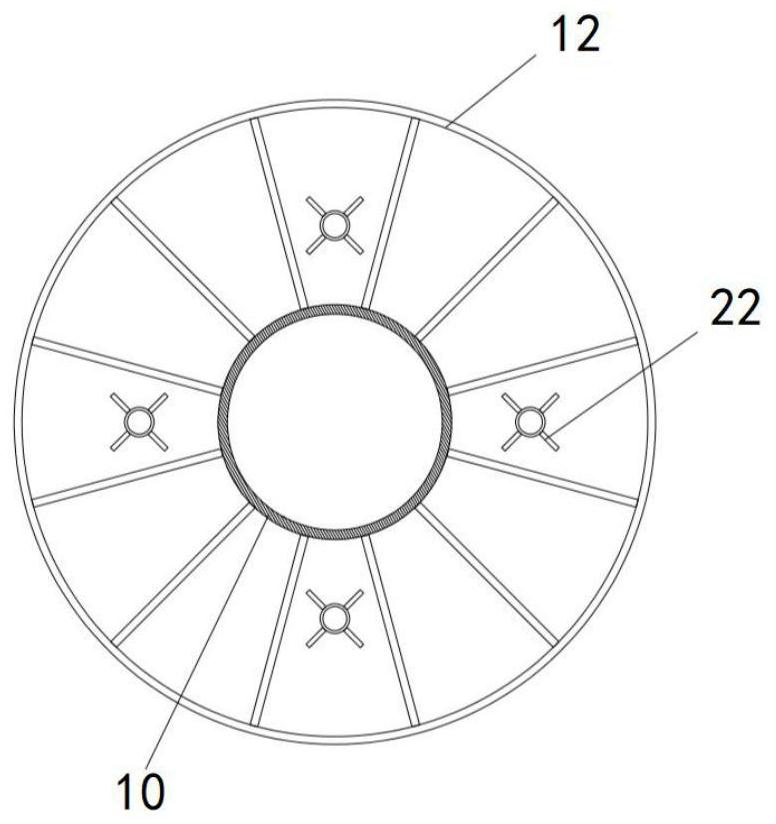

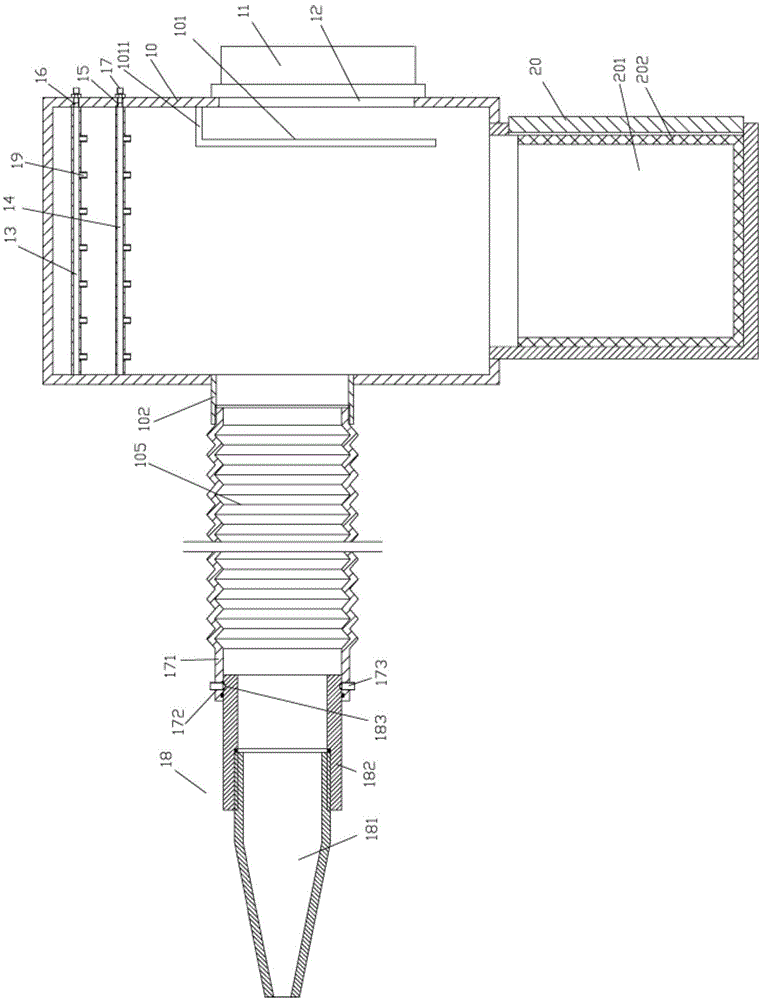

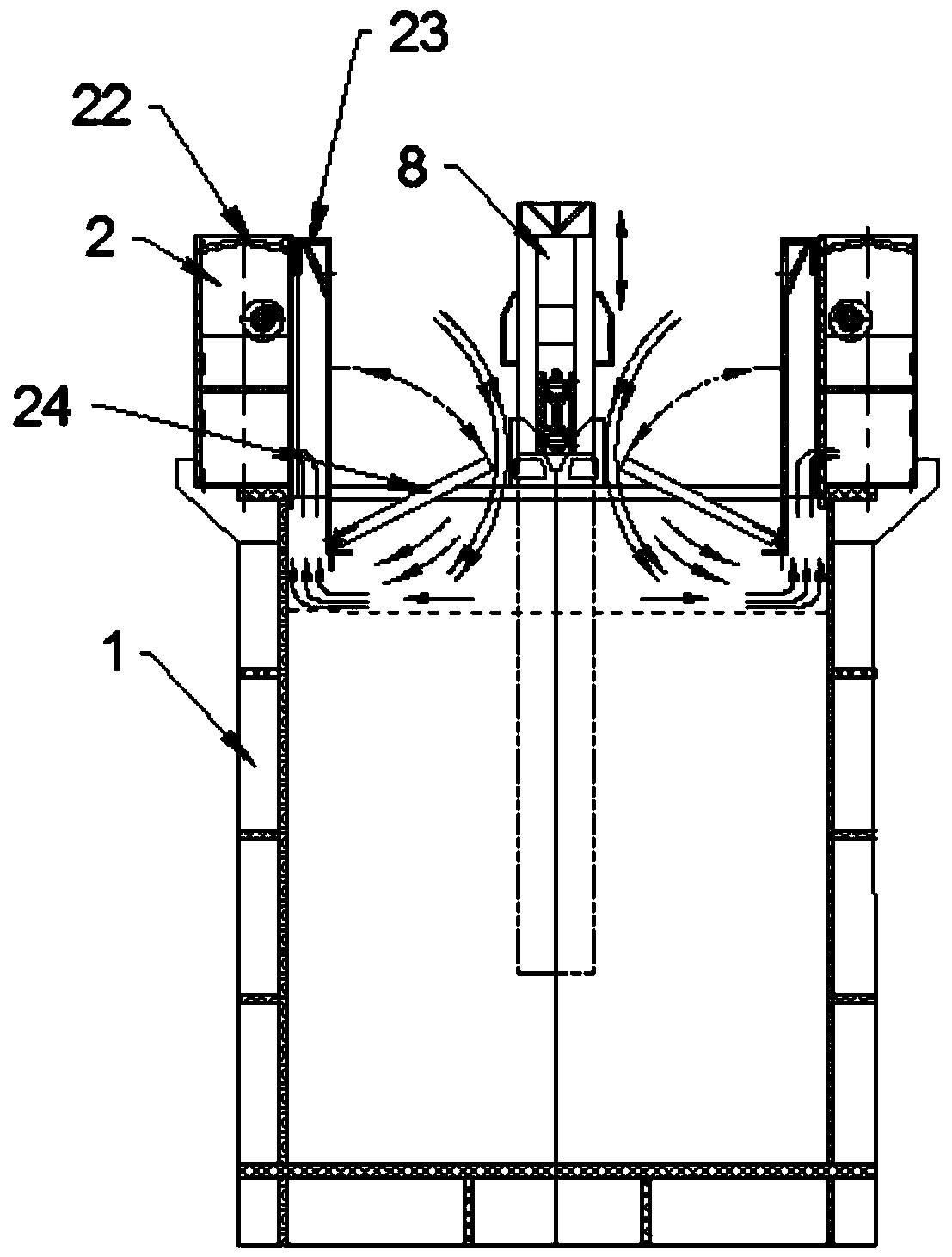

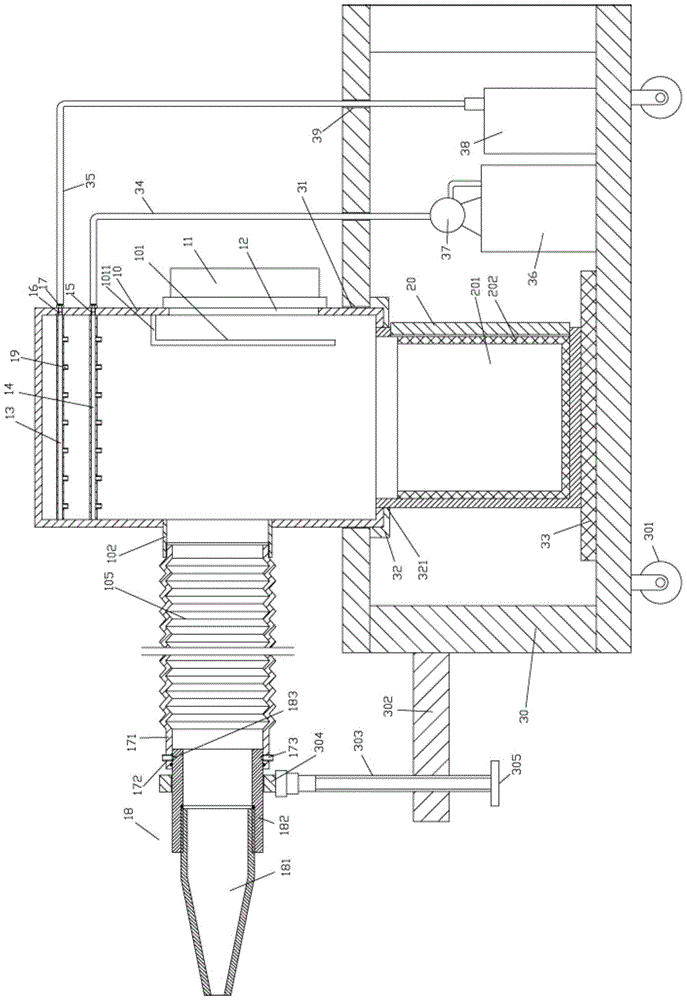

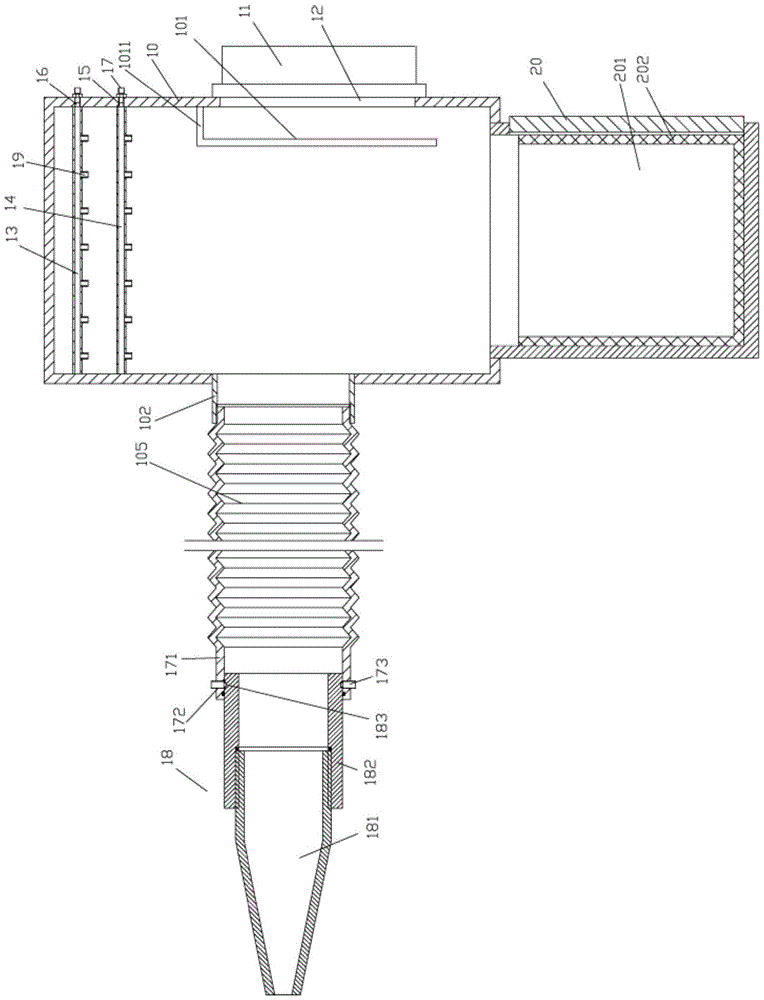

Suction dredge for underwater hard soil layer

PendingCN111691484AAvoid cloggingImprove suction effectMechanical machines/dredgersSoil scienceMechanical engineering

The invention relates to a suction dredge for an underwater hard soil layer, and relates to the field of bridge construction equipment. The suction dredger comprises a mud suction mechanism, a mud crushing mechanism and an anti-blocking assembly, wherein the mud suction mechanism comprises a pressurizing assembly and a mud suction pipe, the mud suction pipe penetrates through the pressurizing assembly, at least part of the two ends of the mud suction pipe extend out of the pressurizing assembly, a plurality of pressurizing holes inclining upwards in the direction from the outer wall to the inner wall are formed in the side wall of the pipe section of the mud suction pipe in the pressurizing assembly, and the pressurizing assembly is used for forming a low-pressure in the mud suction pipe through the pressurizing holes; the mud crushing mechanism comprises at least two mud crushing assemblies, the mud crushing assemblies are arranged at the bottom of the mud suction mechanism, and the mud crushing assemblies are used for crushing the underwater hard soil layer to assist the mud suction of the mud suction pipe; and the anti-blocking assembly is arranged at the bottom of the mud suction pipe, the anti-blocking assembly is used for preventing the mud suction pipe from being blocked in the mud suction process. According to the suction dredger for the underwater hard soil layer, theproblems that in the prior art, when the suction dredger works in the underwater hard soil layer, the suction dredger is poor in mud suction effect and prone to being blocked are solved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

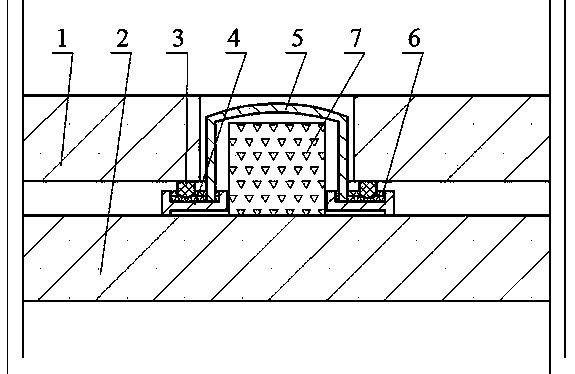

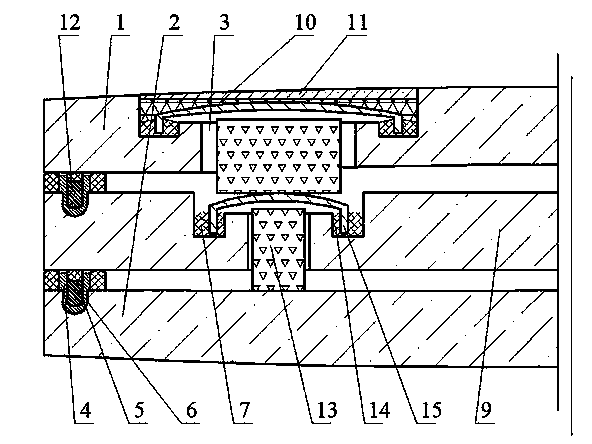

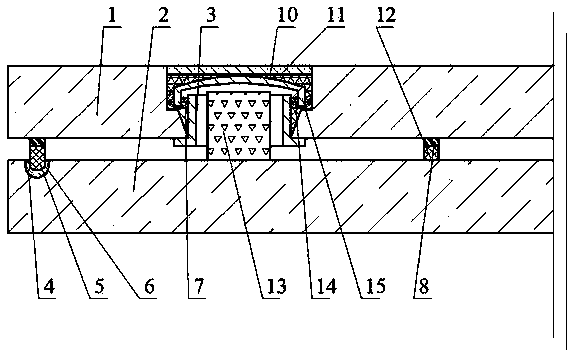

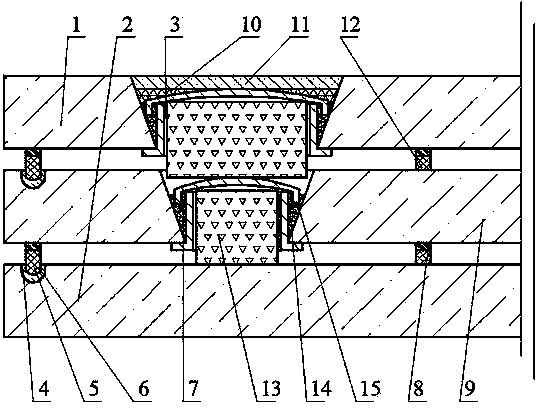

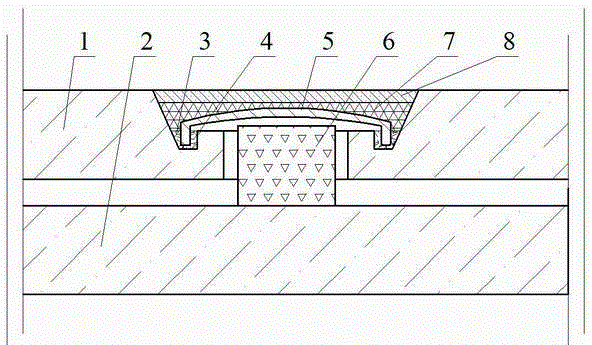

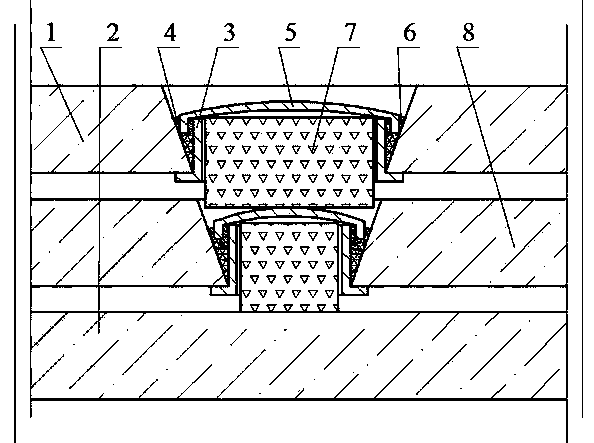

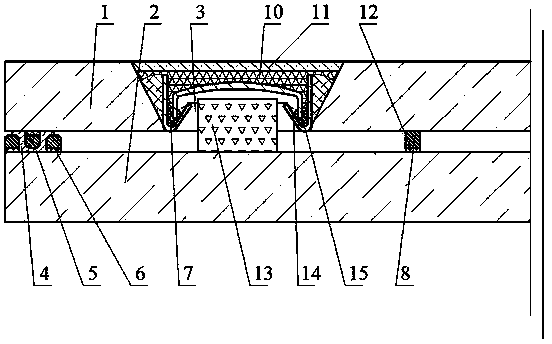

Double-vacuum-layer ceramic composite vacuum plate with getters and preparation method of double-vacuum-layer ceramic composite vacuum plate

InactiveCN103422633ASimple sealing structureImprove sealingCovering/liningsThermal insulationCeramic compositeVacuum chamber

A double-vacuum-layer ceramic composite vacuum plate with getters comprises face plates, connecting layers and a vacuum chamber and is characterized in that the face plates are made of ceramic plates or ceramic tiles; the face plates and / or the connecting layers provide additional strength for the vacuum chamber, so that smoothness of the vacuum chamber under atmosphere is guaranteed; the vacuum chamber is a sealed cavity which is formed in the mode that the edges of metal plates are sealed in a welding mode under normal pressure and the openings of the metal plates are sealed by high temperature under vacuum; the opening sealing operation is conducted as follows: an extraction opening preformed in the vacuum chamber is automatically sealed in a vacuum furnace by low-temperature welding fluxes on the basis of the liquid sealing principle; a partition plate is arranged in the vacuum chamber and divides the vacuum chamber into double vacuum layers; upholders are arranged in the vacuum layers. A method for manufacturing the double-vacuum-layer ceramic composite vacuum plate with the getters is simple in process, the prepared double-vacuum-layer ceramic composite vacuum plate with the getters can overcome the defects of an existing heat preservation plate and an existing vacuum heat insulation plate, and strength, heat and sound insulation performance and fireproof performance of the double-vacuum-layer ceramic composite vacuum plate with the getters can be improved.

Owner:盐城市洲和新型建材有限公司

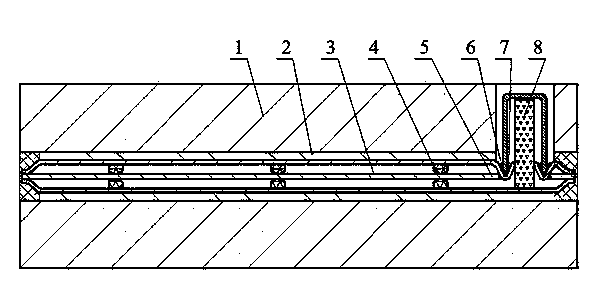

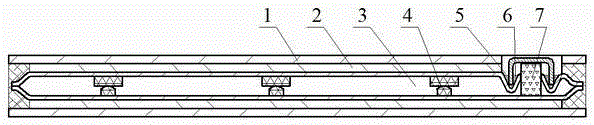

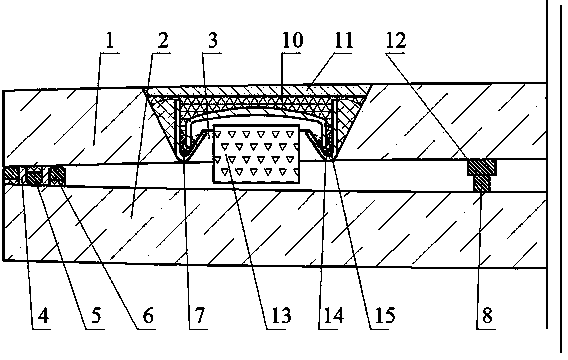

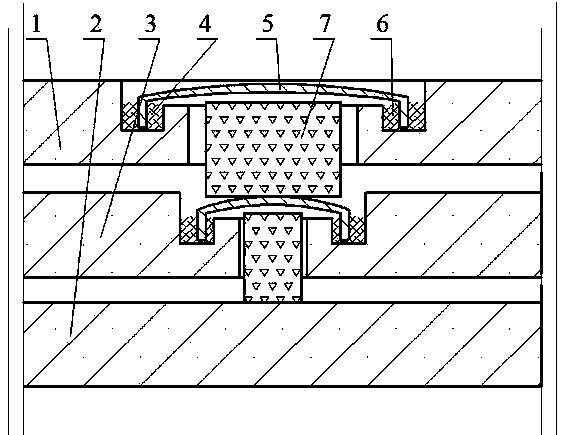

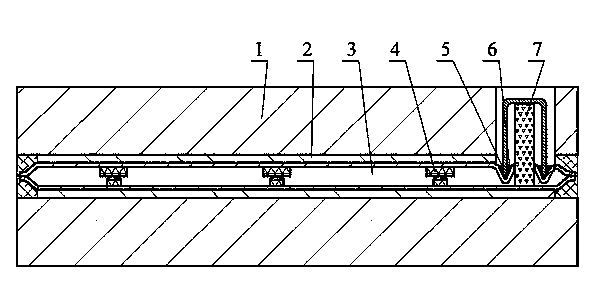

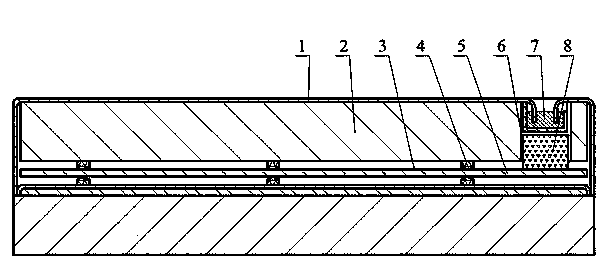

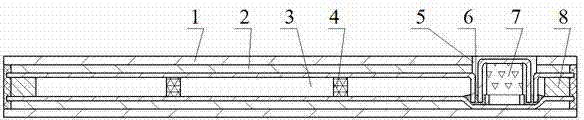

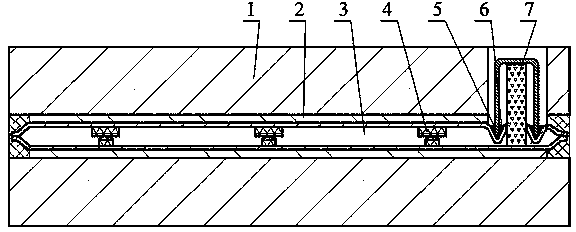

Metal composite vacuum panel with getter and preparation method thereof

ActiveCN103422634BGuaranteed suction capacitySimple sealing structureCovering/liningsThermal insulationComposite plateAir tightness

A metal composite vacuum plate with getters comprises face plates, connecting layers and a vacuum chamber and is characterized in that the face plates are made of metal plates or metal composite plates; the face plates and / or the connecting layers provide additional strength for the vacuum chamber, so that smoothness of the vacuum chamber under atmosphere is guaranteed; the vacuum chamber is a sealed cavity which is formed in the mode that the edges of metal plates are sealed in a welding mode under normal pressure and the openings of the metal plates are sealed by high temperature under vacuum; the opening sealing operation is conducted as follows: an extraction opening preformed in the vacuum chamber is automatically sealed in a vacuum furnace by low-temperature welding fluxes on the basis of the liquid sealing principle; upholders and the getters are arranged in the vacuum chamber. A method for manufacturing the metal composite vacuum plate with the getters is simple in process, the prepared metal composite vacuum plate with the getters can overcome the defects of an existing heat preservation plate and an existing vacuum heat insulation plate, the air tightness of the vacuum chamber of the metal composite vacuum plate with the getters can be effectively guaranteed, the service life of the metal composite vacuum plate with the getters is prolonged, and strength, heat and sound insulation performance and fireproof performance of the metal composite vacuum plate with the getters can be improved.

Owner:江苏富盈汇林达建筑科技有限公司

Convex tempered vacuum glass provided with getter in edge sealing of sealing strips and preparing method thereof

InactiveCN104291635ASimple sealing structureLow costGlass reforming apparatusGlass productionElastomerRoom temperature

Convex tempered vacuum glass provided with a getter in edge sealing of sealing strips is disclosed. The convex tempered vacuum glass is characterized in that: upper glass and lower glass are convex tempered glass; the upper glass is provided with an extraction opening; the extraction opening is provided with a sealing cover; the getter is disposed in the extraction opening; the periphery of the upper glass and the periphery of the lower glass are provided with the sealing strips; the periphery of the upper glass and the periphery of the lower glass are welded by adoption of low-temperature glass solder at normal pressure in an edge banding furnace; the extraction opening is automatically sealed by utilization of the sealing cover and metal solder in a vacuum furnace; the getter is automatically activated in a sealing process; a closed vacuum layer is formed between the upper glass and the lower glass; the sealing strips are made of tempered glass printing ink and / or polymer; the polymer is prepared into pre-polymer firstly, and then the prepolymer is prepared onto glass or tempered glass printing ink after glass tempering; the prepolymer cures at the room temperature or high temperature to form an elastomer; the prepolymer or the elastomer can automatically adapt to changes of the height of the vacuum layer; and volatile gas in the elastomer is removed at a high temperature and under high vacuum.

Owner:戴长虹

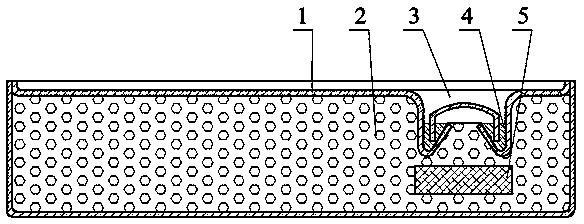

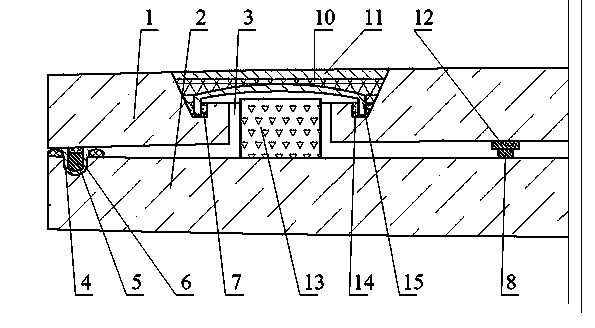

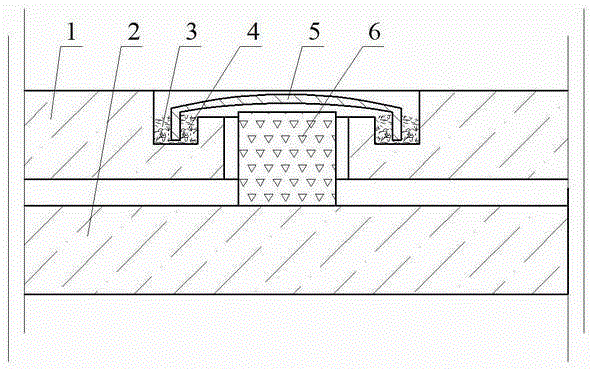

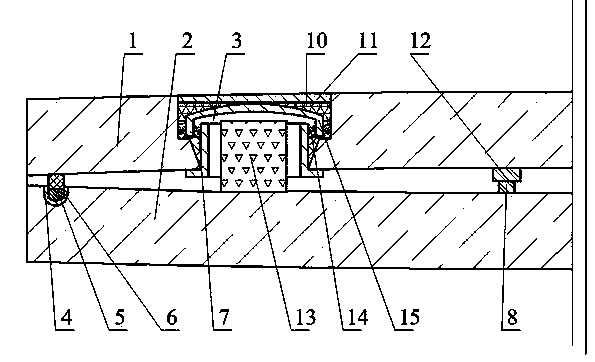

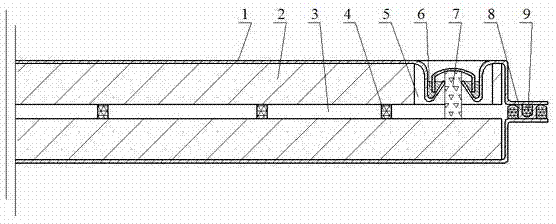

Vacuum glass getter placement structure and manufacturing method thereof

InactiveCN103420590ADoes not affect appearanceImprove heat insulationGlass reforming apparatusGlass productionPunchingAir tightness

The invention provides a vacuum glass getter placement structure which is characterized in that punching is performed on an upper piece of glass of vacuum glass to form an extraction opening, a sealing ring is prepared at the periphery of the extraction opening and the lower surface of the upper piece of glass, an annular sealing box is placed on a lower piece of glass, and a sealing cover is further arranged on the annular sealing box; after edges of the upper piece of glass and the lower piece of glass are sealed, the getter is placed into the extraction opening, the extraction opening is covered with the sealing cover, then metal solder is placed into the annular sealing box or on the sealing cover, the extraction opening is vacuumized and heated, the getter is automatically activated at high temperature and under high vacuum, meanwhile metal solder is melted into liquid at high temperature, the liquid is retained in the annular sealing box, edge parts of the sealing ring and the sealing cover are submerged into the liquid, the extraction opening is in self sealing by utilizing the liquid sealing principle and the getter is further sealed in the vacuum layer, and after cooling, the liquid is solidified, and air tightness seal is realized. According to the method provided by the invention, mass production can be realized, production efficiency and qualified rate of the vacuum glass are greatly improved, and production cost is reduced.

Owner:戴长虹

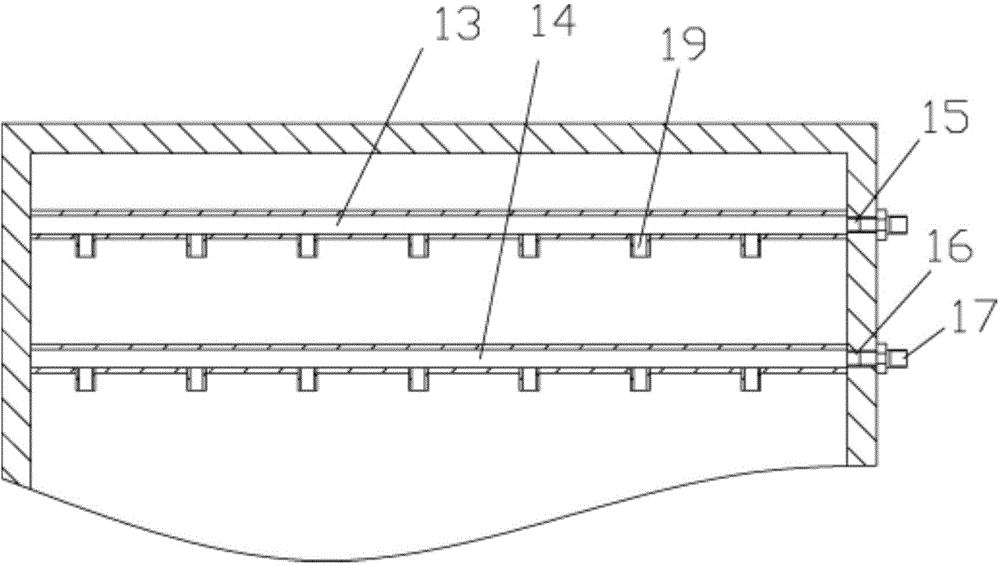

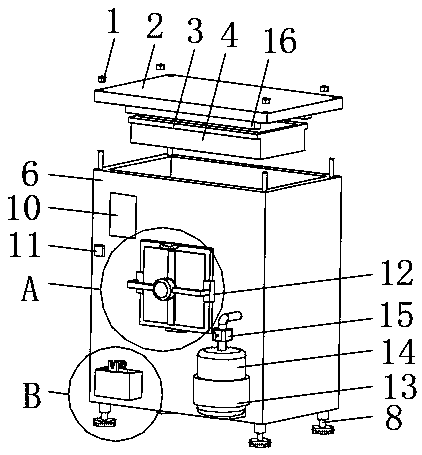

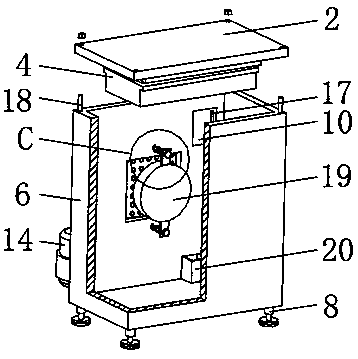

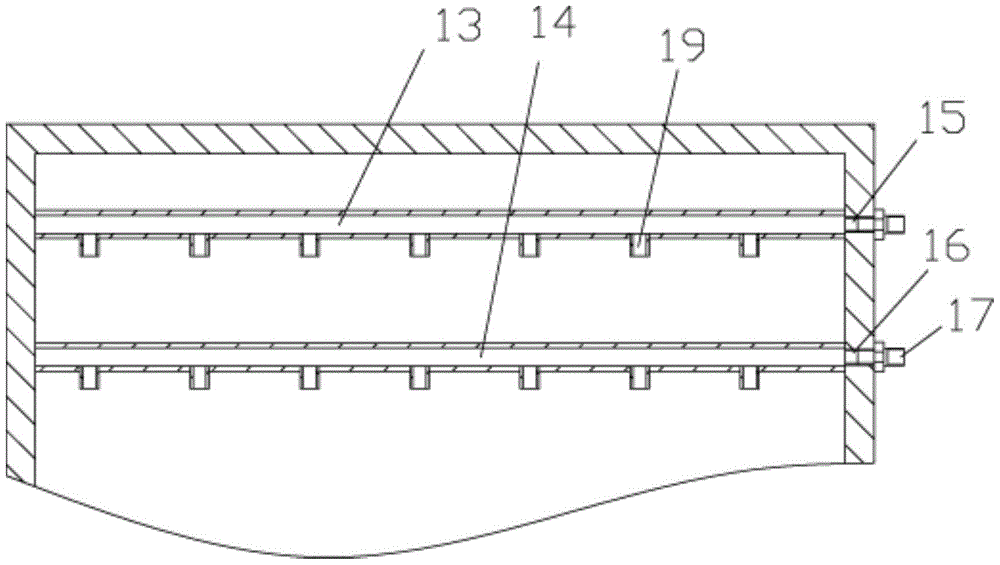

Dust collection cart for spinning

ActiveCN104856608AReduce harmReduces inhalation of fibrous shorthairSuction filtersEngineeringBobbin

The invention discloses a dust collection cart for spinning. The dust collection cart comprises a transition box, a bottom collecting box and a cart frame. The upper end of the bottom collecting box is in through connection with the bottom of the transition box, the transition box is sleeved with a placing through hole formed in a top plate of the cart frame, the bottom end face of the transition box abuts against the upper end face of a base plate of a supporting sleeve fixedly arranged on the bottom surface of the top plate of the cart frame, and the bottom collecting box penetrates a central through hole of the base plate of the supporting sleeve and abuts against a buffer cushion fixedly positioned on the upper portion of the base plate of the cart frame. A ventilator is fixed on an outer wall of a rear side plate of the transition box, the air suction end of the ventilator is communicated with a through hole formed in the rear side plate of the transition box, and at least one air spraying pipe and at least one water spraying pipe are fixed on the upper portion of the transition box. The dust collection cart can move near spinning devices, such as the front of a bobbin winder and the front of a twisting machine; air in front of the devices is absorbed through an air suction head, accordingly air with impurities such as fibers and short hair is sucked in and filtered.

Owner:威海高新园区运营管理有限公司

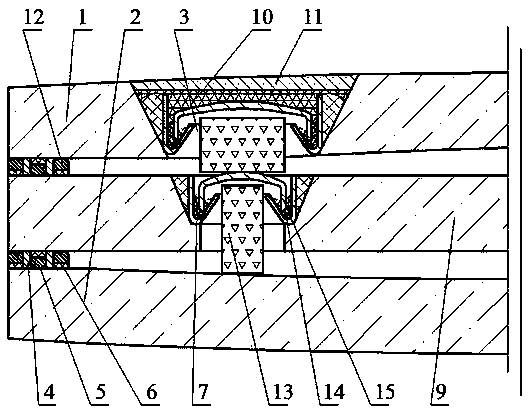

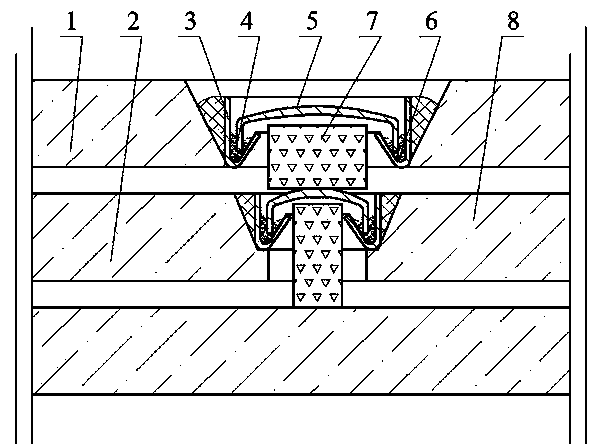

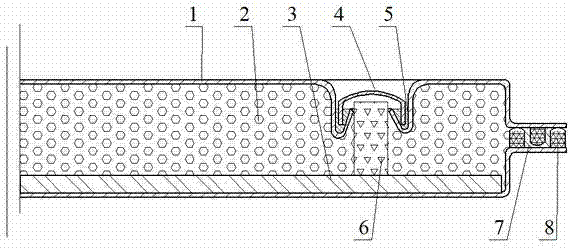

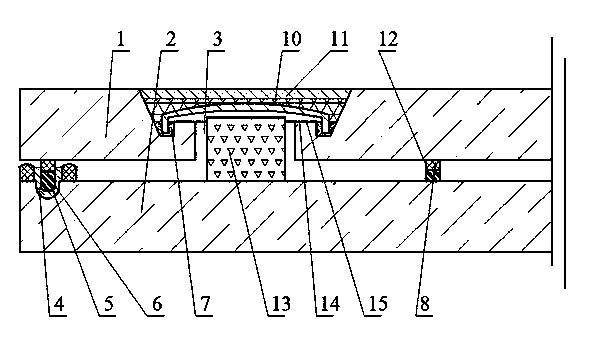

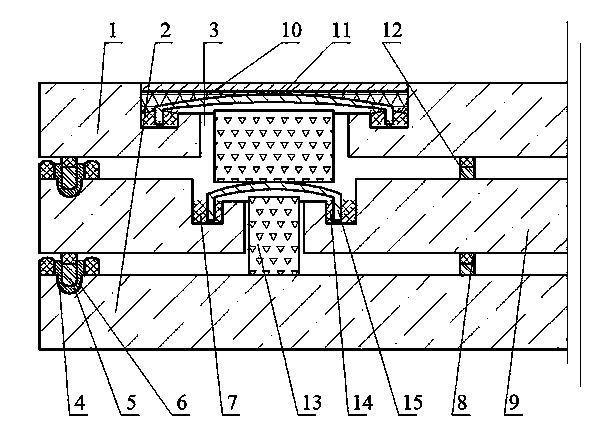

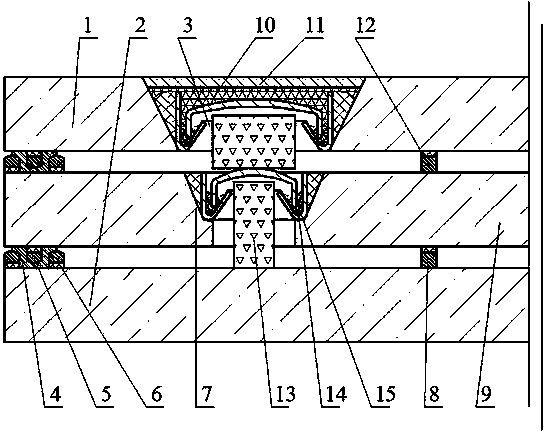

Placement structure for getter of double-vacuum layer glass and manufacturing method of placement structure

InactiveCN103420580AIncrease vacuumGuaranteed suction capacityGlass reforming apparatusGlass productionHeating furnaceAir tightness

A placement structure for getter of double-vacuum layer glass is characterized in that openings are formed in upper glass and middle glass of vacuum glass to serve as exhaust openings, two seal grooves are formed in the upper surfaces of the upper glass and the middle glass respectively, and surround the respective exhaust openings; seal covers are arranged on the seal grooves, and the edges of the seal covers are inserted into the seal grooves respectively; after edge sealing for the glass, the getter is placed into the exhaust openings, the exhaust openings are covered with the seal covers, and metal solder is placed inside the seal grooves or on the seal covers; then vacuumizing and heating are performed on a vacuum heating furnace, so that the getter can be activated automatically under the high-temperature and high-vacuum condition, and meanwhile, the metal solder is molten to be liquid due to the high temperature; the liquid is stored in the seal grooves, and the edges of the seal covers are immersed in the liquid, so that the exhaust openings are automatically sealed and the getter is sealed in the vacuum layers by utilizing the liquid sealing principle; after the liquid is solidified due to temperature drop, the airtight sealing is realized. With adoption of the method disclosed by the invention, batch production can be realized, production efficiency and qualification rate of the vacuum glass can be greatly improved, and production cost is lowered.

Owner:戴长虹

Convex toughened vacuum glass provided with getter with edges being sealed by sealing strips and sealing grooves and manufacturing method thereof

InactiveCN104291628AGuaranteed suction capacityLow costGlass reforming apparatusGlass productionElastomerRoom temperature

The invention discloses convex toughened vacuum glass provided with a getter with edges being sealed by sealing strips and sealing grooves. The convex toughened vacuum glass is characterized in that upper glass and lower glass are convex toughened glass; the upper glass is provided with an extraction opening; a sealing cover is arranged on the extraction opening; the getter is put into the extraction opening; the upper glass is provided with the sealing strips; the lower glass is provided with the sealing strips and the sealing grooves; the upper glass and the lower glass are welded together in an edge-sealing furnace under a normal pressure by using a glass solder; the extraction opening is automatically enclosed in a vacuum furnace by using the sealing cover and a metal solder; the getter is automatically activated in an edge-sealing process; an enclosed vacuum layer is formed between the upper glass and the lower glass; the sealing strips are made of toughened glass ink or / and a high polymer; the high polymer is prepared into a prepolymer firstly; after the glass is toughened, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a high temperature and in vacuum.

Owner:戴长虹

Sealing structure of dual-vacuum-layer glass getter and manufacturing method thereof

InactiveCN104291583AIncrease vacuumGuaranteed suction capacityGlass reforming apparatusGlass productionEngineeringMetal

The invention discloses a sealing structure of a dual-vacuum-layer glass getter. The sealing structure is characterized in that upper glass and middle glass of vacuum glass are drilled with a circular hole for serving as an extraction opening; a circular tube is inserted into each extraction opening respectively; the upper parts of the circular tubes are welded together with the glass; the lower parts of the circular tubes are turned up, thereby forming sealing grooves; sealing covers are arranged on the upper parts of the sealing grooves; the edges of the sealing covers are inserted into the sealing grooves; after the edges of the glass are sealed, the getter is put into the extraction openings, and the sealing covers are covered; a metal solder is put into the sealing grooves or on the sealing covers; the extraction openings are vacuumized and heated; the getter is automatically activated at a high temperature in vacuum; meanwhile, the metal solder is molten into liquid at a high temperature, and the liquid is left in the sealing grooves; the edges of the sealing covers are submerged in the liquid; the extraction openings are automatically sealed by using a liquid sealing principle; and the getter is sealed in vacuum layers. Through adoption of a method for manufacturing the sealing structure, mass production can be realized; the production efficiency and yield of the vacuum glass can be increased greatly; and the production cost is reduced.

Owner:戴长虹

Computer main case capable of improving dustproof effect

ActiveCN108845629AImprove dustproof effectEasy to storeDispersed particle filtrationTransportation and packagingControl valvesComputer engineering

The invention discloses a computer main case capable of improving dustproof effect. The computer main case capable of improving dustproof effect comprises a case, wherein an upper end of the case is opening, a rectangular cover board is arranged over the case, four first threaded rods are respectively fixed on four top ends at the upper end of the case, the upper ends of the four first threaded rods respectively pass through four round fixing holes on the cover board, the upper ends of the four first threaded rods are respectively in threaded connection with the four first nuts, the four firstnuts are all located above the cover board, four support devices are evenly fixed at the lower surface of the case, a dust filtering device prevents dust from entering into the case, when temperaturein the case is always too high, a user makes a control value be conducted, compressed air in a compressed air tank enters into the case via the control valve, the compressed air expands and absorbs heat, thus, temperature in the case is reduced, a draught fan blows air to realize heat dissipation and the compressed air in the compressed air tank expands and absorbs heat, thus, heat dissipation effect of the case is guaranteed.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Stone composite vacuum plate with getters and preparation method of stone composite vacuum plate

ActiveCN103422632ASimple sealing structureImprove sealingCovering/liningsEngineeringArtificial stone

A stone composite vacuum plate with getters comprises face plates, connecting layers and a vacuum chamber and is characterized in that the face plates are made of natural stones or artificial stones; the face plates and / or the connecting layers provide additional strength for the vacuum chamber, so that smoothness of the vacuum chamber under atmosphere is guaranteed; the vacuum chamber is a sealed cavity which is formed in the mode that the edges of metal plates are sealed in a welding mode under normal pressure and the openings of the metal plates are sealed by high temperature under vacuum; the opening sealing operation is conducted as follows: an extraction opening preformed in the vacuum chamber is automatically sealed in a vacuum furnace by low-temperature welding fluxes on the basis of the liquid sealing principle; upholders and the getters are arranged in the vacuum chamber. A method for manufacturing the stone composite vacuum plate with the getters is simple in process, the prepared stone composite vacuum plate with the getters can overcome the defects of an existing heat preservation plate and an existing vacuum heat insulation plate, the air tightness of the vacuum chamber of the stone composite vacuum plate with the getters can be effectively guaranteed, the service life of the stone composite vacuum plate with the getters is prolonged, and strength, heat and sound insulation performance and fireproof performance of the stone composite vacuum plate with the getters can be improved.

Owner:福建省南安市弘一石业有限公司

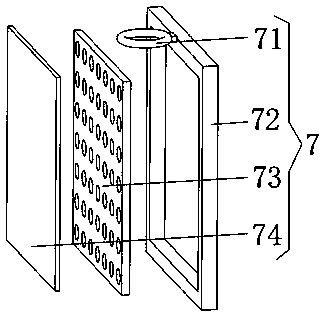

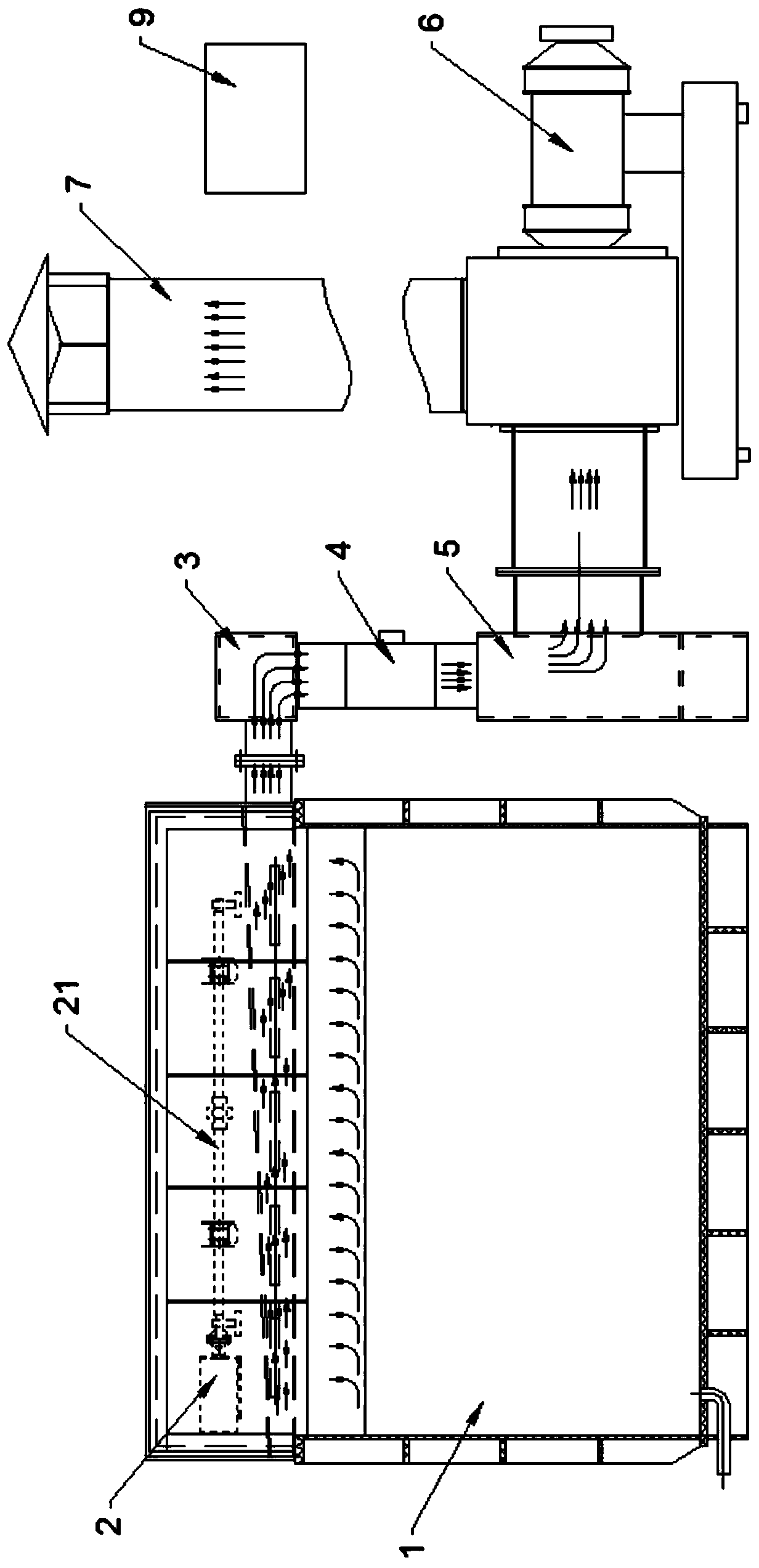

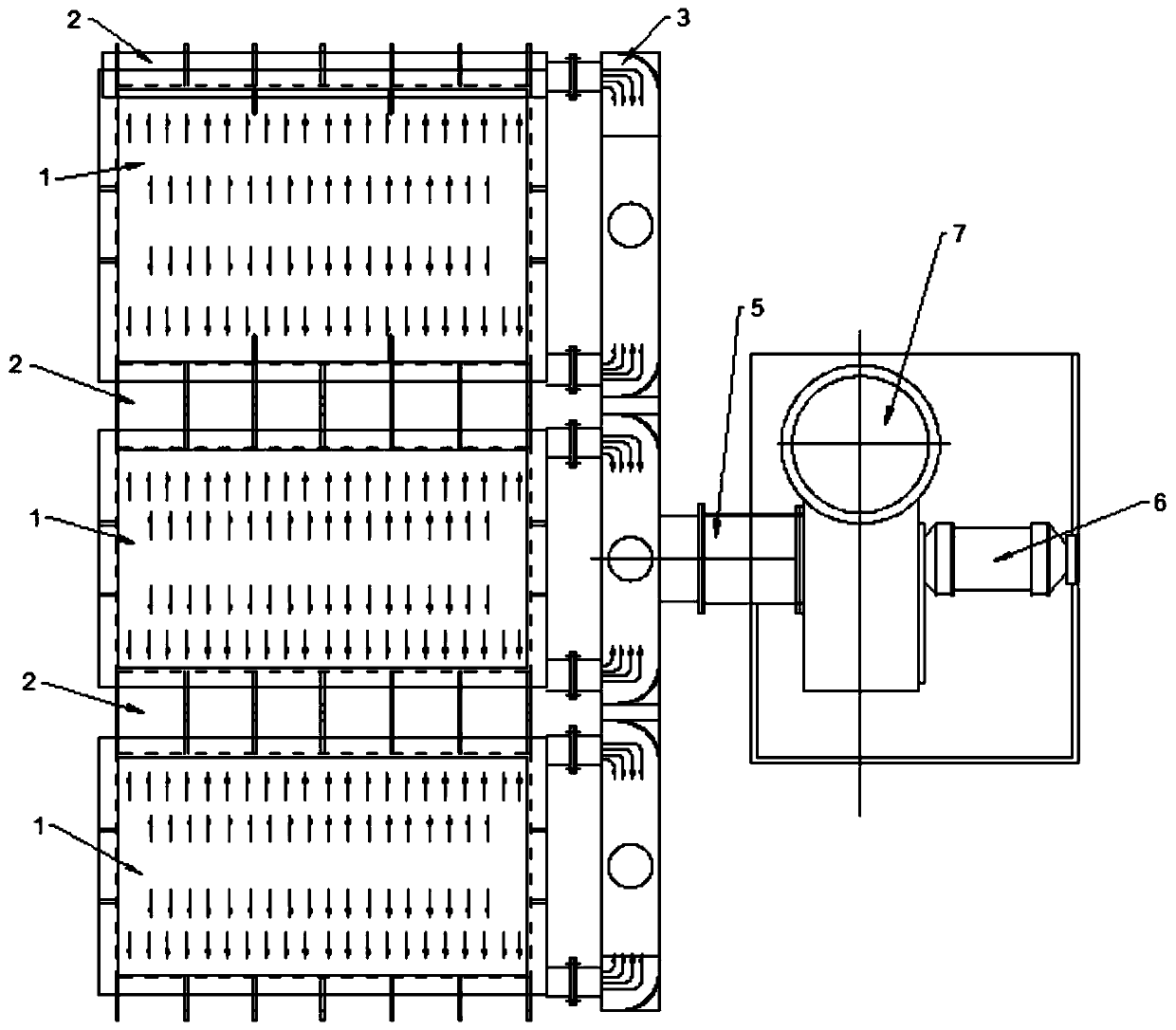

Electroplating automatic line exhaust mechanism

The invention provides an electroplating automatic line exhaust mechanism, and belongs to the field of electroplating equipment. The electroplating automatic line exhaust mechanism comprises exhaust assemblies, single-groove air flues, main air flues and fans, wherein the exhaust assemblies, the single-groove air flues, the main air flues and the fans are arranged on the two sides of the upper ends of solution tanks; each exhaust assembly is arranged corresponding to one single-groove air flue and comprises an air cover, a door cover, an air cover air cavity and an air sucking opening; the airsucking openings communicate with the interiors of the air cavities and the interiors of the solution tanks; one ends of the air cavities communicate with the single-groove air flues which communicate with the main air flues; the fans are arranged at the ends, away from the single-groove air flues, of the main air flues; and the door covers are arranged at the ends, close to the solution tanks, of the air covers, and the height of the lower end faces of the door covers is smaller than that of the air sucking openings. The electroplating automatic line exhaust mechanism is simple in structure,good in air sucking effect, free of leakage, and capable of achieving energy saving and environmental protection.

Owner:万向新元绿柱石(天津)科技有限公司

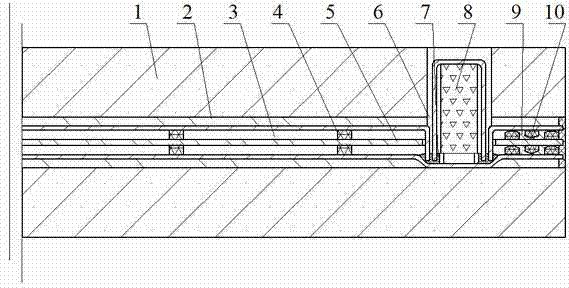

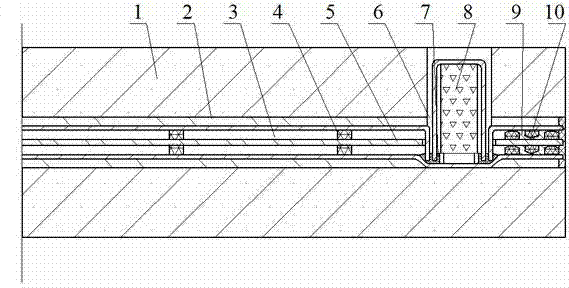

Double vacuum layer composite vacuum plate with degassers and preparation method of double vacuum layer composite vacuum plate

InactiveCN104294927AReduce thicknessSimple sealing structureClimate change adaptationInsulation improvementDegasserFire resistance

A double vacuum layer composite vacuum plate with degassers comprises a panel, a core plate and a vacuum cavity, and is characterized in that the panel is fixed on the upper surface at the outer part of the vacuum cavity; the core plate is placed at the bottom in the vacuum cavity; the panel and / or the core plate provide (s) additional strength for the vacuum cavity, and ensure (s) the smoothness of the vacuum cavity under the atmospheric pressure; the vacuum cavity is a closed cavity formed in such a way that a metal plate is subjected to welding and edge sealing under the normal pressure and sealing at a high temperature in vacuum; the sealing is achieved through automatically sealing an extraction opening, prefabricated in the vacuum cavity, in a vacuum furnace by low-temperature solder according to a liquid sealing principle; a clapboard is arranged in the vacuum cavity, and divides the interior of the vacuum cavity into double vacuum layers; and struts are arranged in the vacuum layers. The double vacuum layer composite vacuum plate has the advantages that the preparation method is simple in process, the prepared double vacuum layer composite vacuum plate with the degassers can overcome defects of a conventional insulation board and a conventional vacuum insulation board, and the strength, the heat insulation performance, the sound insulation performance, and the fire resistance and the decoration performance can be enhanced.

Owner:戴长虹

Double-vacuum-layer glass composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746710AIncrease vacuumImprove air tightnessCovering/liningsHeat proofingGlass sheetVacuum chamber

A double-vacuum-layer glass composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is a glass plate, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, a separation plate separating the vacuum chamber into two to form double vacuum layers is arranged in the vacuum chamber, and supporting members are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer glass composite vacuum panel with the sealing strips and the getter is simple in process. The manufactured double-vacuum-layer glass composite vacuum panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

Metal vacuum composite insulation panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746762ASimple sealing structureReliable sealingCovering/liningsHeat proofingVacuum furnaceClosed cavity

A metal vacuum composite insulation panel with sealing strips and a getter comprises a housing, a core material, a core plate and a vacuum chamber and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core material is arranged in the vacuum chamber to provide the housing with additional strength to ensure the smoothness of the housing at atmospheric pressure, the vacuum chamber is a closed chamber formed by the housing subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of glass solder, the opening sealing is the automatic sealing of pumping holes preformed in the housing with low-temperature solder in a vacuum furnace according to the principle of liquid seal, and the getter is arranged in the vacuum chamber. A manufacturing method of the metal vacuum composite insulation panel with the sealing strips and the getter is simple in process. The manufactured metal vacuum composite insulation panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength, thermal insulation, sound insulation and fireproof performance and decorative functions can be improved.

Owner:戴长虹

Microwave-welded flat tempered vacuum glass edge-sealed with sealing groove and having getter

InactiveCN104291647AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

A microwave-welded flat tempered vacuum glass edge-sealed with sealing grooves and having a getter is characterized in that an upper glass and a lower glass are flat tempered glasses. A vacuumizing hole is arranged in the upper glass and a sealing cover is arranged on the vacuumizing hole. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with the sealing groove. The upper glass and the lower glass are welded to each other in a microwave oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and the supporting object are composed of tempered glass printing ink and a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Glass welded composite vacuum plate with getter and production method thereof

InactiveCN104746723AIncrease vacuumExtension of timeCovering/liningsHeat proofingAir tightnessCarbon steel

The invention discloses a glass welded composite vacuum plate with a getter. The composite vacuum plate comprises a panel, a connecting layer and a vacuum cavity, and is characterized in that the panel is made from either a metal plate or a metal composite plate, the panel and / or the connecting layer are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, and the vacuum cavity is a closed cavity formed by carrying out glass welding at normal pressure and high temperature and sealing at high pressure to a low carbon steel plate; the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and a support and a getter are arranged in the vacuum cavity. A production method of the composite vacuum plate with the getter provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

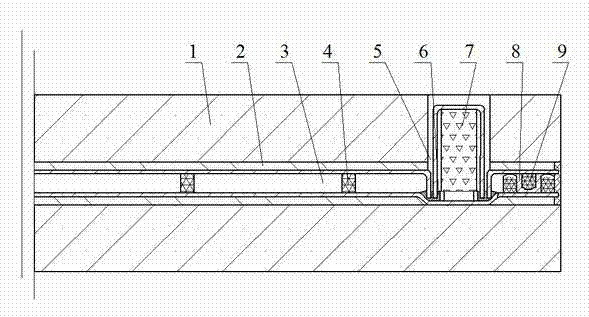

Placement structure of vacuum glass getter and method of making the same

An accommodating structure of vacuum glass getter is characterized in that a hole is formed in the upper glass of vacuum glass so as to form an extraction opening; a sealed groove is formed in the upper surface of the upper glass and in a position at the periphery of the extraction opening; a sealing cover is arranged on the sealed groove; the edge part of the sealing cover is inserted into the sealed groove; after the edges of the upper glass and lower glass are sealed, the vacuum glass getter is put into the extraction opening; the sealing cover is closed; metal solder is put into the sealed groove or onto the sealing cover; vacuum pumping and heating are perform at the extraction opening; the vacuum glass getter is activated automatically under the conditions of high temperature and high vacuum while the metal solder is molten into liquid due to high temperature; the liquid is kept in the sealed groove; the edge part of the sealing cover is immersed in the liquid; the extraction opening is sealed automatically according to the liquid seal principle; the vacuum glass getter is sealed in a vacuum layer; after temperature reduction, the liquid freezes, so as to realize airtightness sealing. According to the manufacture method provided by the invention, mass production can be realized, the production efficiency and qualification rates of vacuum glass can be greatly improved, and the manufacturing cost of the vacuum glass is lowered.

Owner:戴长虹

Ceramic composite vacuum plate with getters and preparation method of ceramic composite vacuum plate

InactiveCN103422635ASimple sealing structureImprove sealingCovering/liningsThermal insulationCeramic compositeAir tightness

A ceramic composite vacuum plate with getters comprises face plates, connecting layers and a vacuum chamber and is characterized in that the face plates are made of ceramic plates or ceramic tiles; the face plates and / or the connecting layers provide additional strength for the vacuum chamber, so that smoothness of the vacuum chamber under atmosphere is guaranteed; the vacuum chamber is a sealed cavity which is formed in the mode that the edges of metal plates are sealed in a welding mode under normal pressure and the openings of the metal plates are sealed by high temperature under vacuum; the opening sealing operation is conducted as follows: an extraction opening preformed in the vacuum chamber is automatically sealed in a vacuum furnace by low-temperature welding fluxes on the basis of the liquid sealing principle; upholders and the getters are arranged in the vacuum chamber. A method for manufacturing the ceramic composite vacuum plate with the getters is simple in process, the prepared ceramic composite vacuum plate with the getters can overcome the defects of an existing heat preservation plate and an existing vacuum heat insulation plate, the air tightness of the vacuum chamber of the ceramic composite vacuum plate with the getters can be effectively guaranteed, the service life of the ceramic composite vacuum plate with the getters is prolonged, and strength, heat and sound insulation performance and fireproof performance of the ceramic composite vacuum plate with the getters can be improved.

Owner:戴长虹

Double-vacuum-layer ceramic composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746683AIncrease vacuumImprove air tightnessCovering/liningsHeat proofingCeramic compositeVacuum chamber

A double-vacuum-layer ceramic composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is a ceramic plate or tile, the surface plate and / or the connecting layer provide / provides the vacuum chamber with additional strength to ensure the smoothness of the vacuum chamber at atmospheric pressure, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, a separation plate separating the vacuum chamber into two to form double vacuum layers is arranged in the vacuum chamber, and supporting members are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer ceramic composite vacuum panel with the sealing strips and the getter is simple in process. The manufactured double-vacuum-layer ceramic composite vacuum panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

Flat tempered vacuum glass edge-sealed with sealing bars and sealing grooves and having getter and manufacturing method thereof

InactiveCN104291646AGuaranteed suction capacityLow costGlass reforming apparatusGlass productionElastomerRoom temperature

A flat tempered vacuum glass edge-sealed with sealing bars and sealing grooves and having a getter is characterized in that an upper glass and a lower glass are flat tempered glasses. A vacuumizing hole is formed in the upper glass and is provided with a seal cover. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with a sealing bar and a sealing groove. The upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and / or the supporting object are composed of tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Microwave-welded convex tempered vacuum glass edge-sealed with sealing groove and having getter

InactiveCN104291656AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

A microwave-welded convex tempered vacuum glass edge-sealed with sealing grooves and having a getter is characterized in that an upper glass and a lower glass are convex tempered glasses. A vacuumizing hole is arranged in the upper glass and a sealing cover is arranged on the vacuumizing hole. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with the sealing groove. Peripheries of the upper glass and the lower glass are welded to each other in a microwave oven at a normal pressure through a glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar is manufactured from tempered glass printing ink and a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Glass composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746705AIncrease vacuumImprove air tightnessCovering/liningsHeat proofingThermal insulationAir tightness

A glass composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is a glass plate, the connecting layer connects the surface plate and the vacuum chamber as a whole, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, and supporting members and the getter are arranged in the vacuum chamber. A manufacturing method of the glass composite vacuum panel with the sealing strips and the getter is simple in process. The glass composite vacuum panel with the getter can effectively ensure the gas tightness of the vacuum chamber, the service life can be prolonged, and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

A vacuum cart for textiles

The invention discloses a dust collection cart for spinning. The dust collection cart comprises a transition box, a bottom collecting box and a cart frame. The upper end of the bottom collecting box is in through connection with the bottom of the transition box, the transition box is sleeved with a placing through hole formed in a top plate of the cart frame, the bottom end face of the transition box abuts against the upper end face of a base plate of a supporting sleeve fixedly arranged on the bottom surface of the top plate of the cart frame, and the bottom collecting box penetrates a central through hole of the base plate of the supporting sleeve and abuts against a buffer cushion fixedly positioned on the upper portion of the base plate of the cart frame. A ventilator is fixed on an outer wall of a rear side plate of the transition box, the air suction end of the ventilator is communicated with a through hole formed in the rear side plate of the transition box, and at least one air spraying pipe and at least one water spraying pipe are fixed on the upper portion of the transition box. The dust collection cart can move near spinning devices, such as the front of a bobbin winder and the front of a twisting machine; air in front of the devices is absorbed through an air suction head, accordingly air with impurities such as fibers and short hair is sucked in and filtered.

Owner:威海高新园区运营管理有限公司

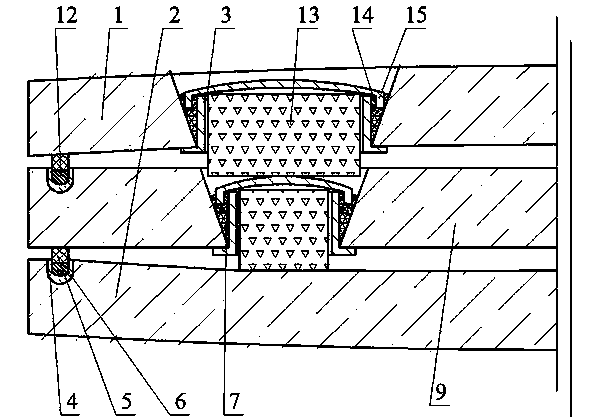

Double-vacuum-layer glass getter sealed placement structure and manufacturing method thereof

InactiveCN104291599AIncrease vacuumEfficient removalGlass reforming apparatusGlass productionEngineeringMetal

The invention relates to a double-vacuum-layer glass getter sealed placement structure. The structure has the following characteristics: one round hole is drilled on each of the upper glass and the intermediate glass of vacuum glass, such that air-exhaust ports are prepared; one round pipe is prepared and is inserted in each of the air-exhaust ports; the lower parts of the round pipes are welded with glass, and the upper parts of the round pipes form sealing grooves with the air-exhaust ports; sealing caps are provided on the upper parts of the sealing grooves; the edges of the sealing caps are inserted into the sealing grooves; when the glass is edge-sealed; a getter is placed into the air-exhaust ports, and the ports are covered by using the sealing caps; a metal solder is placed in the sealing grooves or on the sealing caps; the air-exhaust ports are vacuumed and heated, such that the getter is automatically activated under high temperature and high vacuum, and also the metal solder is molten into liquid under the high temperature; the liquid is retained in the sealing grooves, and the edges of the sealing caps are immersed in the liquid; the air-exhaust ports are automatically sealed with a liquid sealing principle, and the getter is sealed in the vacuum layers. The method provided by the invention is suitable for mass productions. With the method, vacuum glass production efficiency and qualification rate can be greatly improved, and production cost can be reduced.

Owner:戴长虹

Planar tempered vacuum glass edge-sealed by using sealing strips and with getter, and preparation method thereof

InactiveCN104291604ASimple sealing structureLow costGlass reforming apparatusGlass productionElastomerRoom temperature

The invention relates to planar tempered vacuum glass which is edge-sealed by using sealing strips and which has a getter. The glass is characterized in that upper glass and lower glass are planar tempered glass. An air-exhaust port is provided on the upper glass. A sealing cap is provided on the air-exhaust port. The getter is placed in the air-exhaust port. Sealing strips are provided at the peripheries of the upper glass and the lower glass. The peripheries of the upper and lower glass are welded together by using a glass solder under normal pressure in an edge-sealing furnace. The air-exhaust port is automatically sealed in a vacuum furnace with the sealing cap and with a metal solder. The getter is automatically activated during the sealing process. A vacuum layer is formed between the upper glass and the lower glass. A supporter is provided in the vacuum layer. The sealing strips and / or the supporter is composed of tempered glass ink and / or a high-polymer. The high-polymer is first prepared into a pre-polymer. After the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum.

Owner:戴长虹

Metal vacuum composite panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746682ASimple sealing structureReliable sealingCovering/liningsHeat proofingVacuum furnaceClosed cavity

A metal vacuum composite panel with sealing strips and a getter comprises a housing, at least two core plates and a vacuum chamber and is characterized in that the housing is a low-carbon steel plate, the core plate is arranged in the vacuum chamber to provide the housing with additional strength to ensure the smoothness of the housing at atmospheric pressure, the vacuum chamber is a closed chamber formed by the housing subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of glass solder, the opening sealing is the automatic sealing of pumping holes preformed in the housing with low-temperature solder in a vacuum furnace according to the principle of liquid seal, the getter is arranged in the vacuum chamber, and supporting members are arranged between the core plates. A manufacturing method of the metal vacuum composite panel with the sealing strips and the getter is simple in process. The manufactured metal vacuum composite panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength, thermal insulation, sound insulation and fireproof performance and decorative functions can be improved.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com