Sealing structure of dual-vacuum-layer glass getter and manufacturing method thereof

A technology of sealing structure and vacuum glass, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve the problems of complex encapsulation and placement of getter, difficulty in placing getter, and small getter dose, etc. problem, to achieve the effect of simple structure, low cost and high degree of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

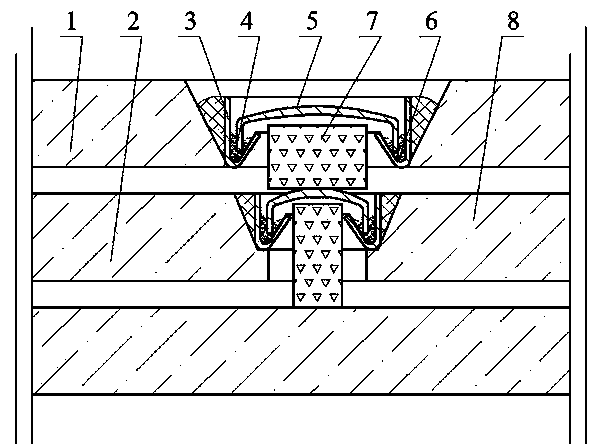

[0044]Embodiment: Referring to the accompanying drawings, the vacuum glass is composed of an upper glass 1, a lower glass 2 and a middle glass 8. A through hole is respectively drilled on the upper glass 1 and the middle glass 8 to form a suction port, wherein the through hole on the upper glass 1 is larger than the middle glass. The through hole on the glass 8; a metal round tube 3 is prepared and inserted into the suction port, the lower end of the round tube 3 is turned up to form a sealing groove 4, and the outer side of the upper part of the round tube 3 and the upper glass 1 and the middle glass 8 pass through the glass solder or metal paste welding together, the top of the round tube 3 is lower than the upper surface of the upper glass 1; according to the size of the sealing groove 4, a sealing cover 5 is made, the edge of the sealing cover 5 can be inserted in the sealing groove 4, and the sealing cover 5 The height is lower than the upper surface of the upper glass 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com