Double vacuum layer composite vacuum plate with degassers and preparation method of double vacuum layer composite vacuum plate

A getter and double-vacuum technology, which is applied in the field of double-vacuum-layer composite vacuum board and its production, can solve the problems of complex construction process, poor air-tightness of vacuum bags, and falling off of insulation layer tiles, etc., and achieve low puncture resistance , Reliable sealing, and the effect of ensuring the suction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

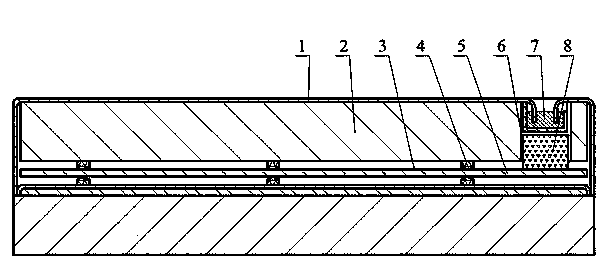

[0046] Referring to the accompanying drawings, the double-vacuum-layer composite vacuum panel with getter is composed of a panel 1, a core panel 2, a vacuum chamber 3, a support 4 and a partition 5, and the panel 1 is a metal panel, a ceramic panel, a glass panel, and a plastic panel Or a composite board, preferably a 3-5mm thick tempered glass board, ceramic board, stone board, artificial stone board or aluminum-plastic composite board, etc., and paste it on the lower surface of the vacuum chamber 3 with a high-temperature adhesive. The high-temperature adhesive can be selected from normal temperature or high temperature Cured high temperature-resistant phenolic resin glue, epoxy resin glue, silicone resin glue, polyimide and other organic adhesives, as well as commonly used inorganic adhesives or organic-inorganic composite adhesives; the core board 2 is a metal plate, ceramic plate, glass plate , plastic plate or composite plate, preferably 3-4mm thick tempered glass plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com