Convex tempered vacuum glass provided with getter in edge sealing of sealing strips and preparing method thereof

A technology of vacuum glass and tempered glass ink, which is applied in glass manufacturing equipment, glass production, glass molding, etc., and can solve problems such as affecting the appearance, small space, and difficulty in placing getters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

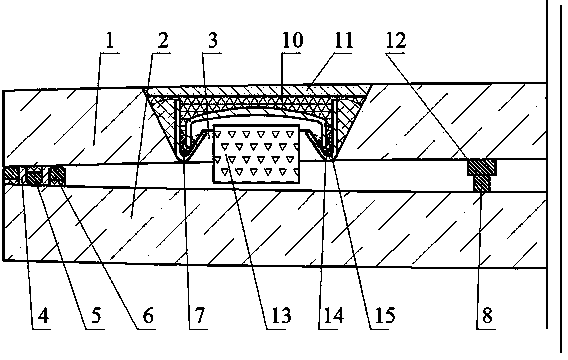

Embodiment 1

[0069] Embodiment 1: see figure 1, the two pieces of tempered vacuum glass are tempered glass or semi-tempered glass, one of which is low-emissivity glass. A tapered through hole is drilled at the corner of the glass 1 to form an air outlet 3, and the upper and lower glasses are ground, chamfered, cleaned and dried, and the sealing strip 5 is prepared by mechanical spraying technology using tempered glass ink on the peripheral welding of the upper and lower glasses and 6; followed by putting two pieces of glass into two forming molds respectively, placing the forming mold with glass in a tempering furnace, raising the temperature to the temperature at which the glass softens, and relying on gravity to make the glass in the forming mold downwardly form a convex surface, Immediately carry out air-cooling and tempering to obtain tempered or semi-tempered glass; the support 8 is made of high polymer 12 alone, and the high polymer 12 is polyimide. First, pyromellitic dianhydride an...

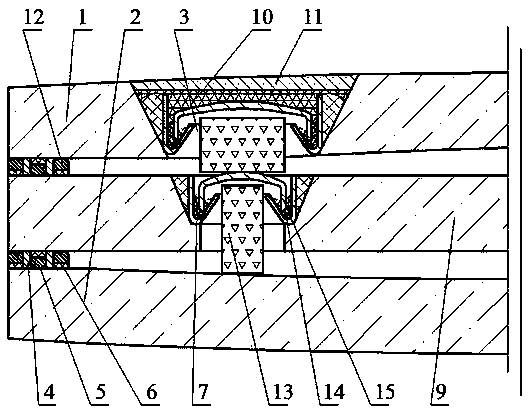

Embodiment 2

[0070] Example 2: see figure 2 , the upper and lower glass of the double vacuum layer tempered vacuum glass is tempered glass or semi-tempered glass, and the middle glass is low-emissivity glass. The production method is as follows: First, cut three planes of the required size according to the shape and size of the vacuum glass to be produced. Glass, respectively drill a through hole on the upper glass 1 and the middle glass 9 to form the suction port 3, wherein the through hole on the upper glass 1 is larger than the through hole on the middle glass 9, and the three pieces of glass are ground, chamfered, cleaned , drying treatment; secondly, the sealing strips 5 and 6 are prepared by tempered glass ink spraying at the peripheral welding places of the upper glass 1, the lower glass 2 and the middle glass 9, and the middle glass 9 is directly sent into a high-temperature furnace for high-temperature treatment, and the upper and lower two Put a piece of glass into the mold, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com