Patents

Literature

42results about How to "Solve the problem of airtight reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

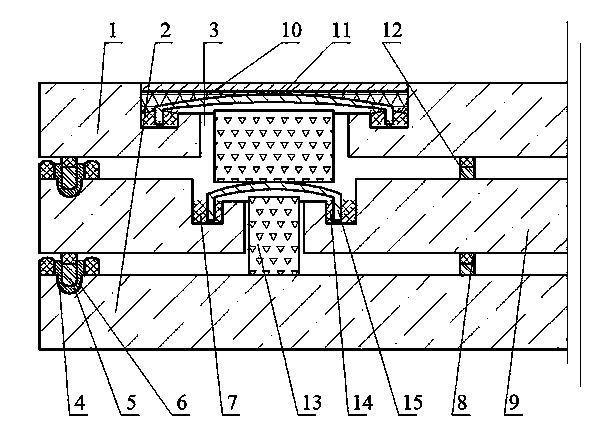

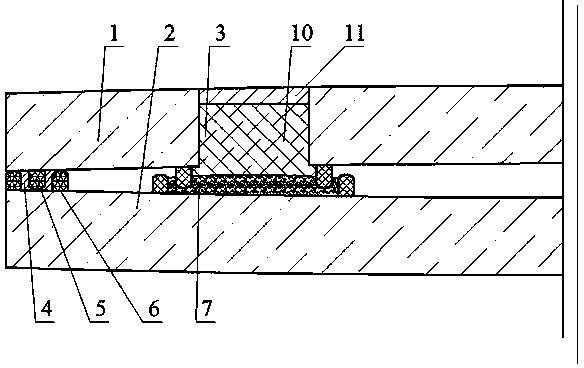

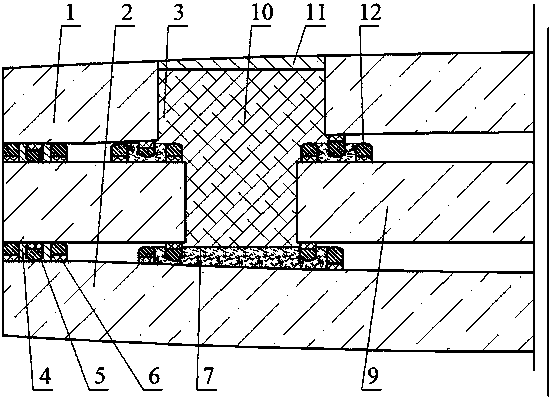

Double-vacuum layer convex glass with sealing strips and mounting holes through metal welding

A piece of double-vacuum layer convex glass with sealing strips and mounting holes through metal welding comprises an upper piece of glass, a lower piece of glass and a middle piece of glass, and is characterized in that the mounting holes are comprised; the upper and the lower piece of glass are convex glass; at least one is respectively arranged at the peripheries of the lower surfaces of the upper glass and the middle glass and of the mounting hole; at least two sealing strips are respectively arranged at the peripheries of the upper surfaces of the lower glass and the middle glass and of the mounting hole; the peripheries of the three pieces of glass are automatically welded together in a vacuum furnace through metal solder; the mounting hole is also automatically sealed through the metal solder. The vacuum glass and the manufacturing method thereof are simple in process. According to the vacuum glass and the toughened vacuum glass prepared, not only are mounting and using convenient, but also the airtightness of the vacuum glass is ensured, and the strength, and heat insulation and acoustic insulation performance are also increased.

Owner:戴长虹

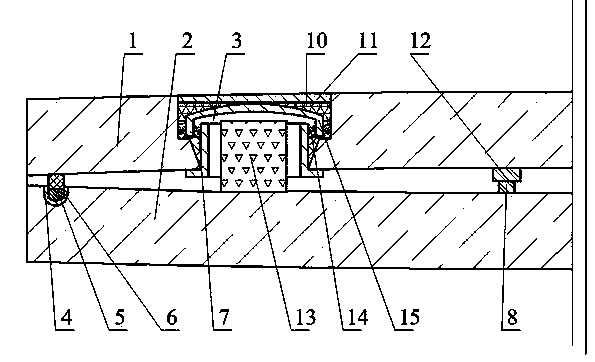

Vacuum convex glass welded with seal grooves and mounting holes

InactiveCN103420587AGuaranteed tightnessHigh strengthGlass reforming apparatusGlass productionEngineeringUltimate tensile strength

A piece of vacuum convex glass welded with seal grooves and mounting holes includes a piece of upper glass and a piece of lower glass, and is characterized in that the mounting holes and extraction openings are integrated; the upper glass and the lower glass are convex glass; seal strips are arranged on the peripheries of the upper glass and the extraction openings; the seal grooves are formed in the peripheries of the lower glass and the extraction openings; the peripheries of the upper glass and the lower glass are welded in an ordinary pressure lower edge sealing furnace through low temperature glass solder; the extraction openings are automatically sealed in a vacuum furnace through metal solder; a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and the manufacture method, provided by the invention, have the advantages that the technology is simple, the manufactured vacuum glass and the toughened vacuum glass facilitate mounting and use, the airtightness of the vacuum glass is guaranteed, and intensity as well as heat and sound insulation performance of the glass can be improved.

Owner:戴长虹

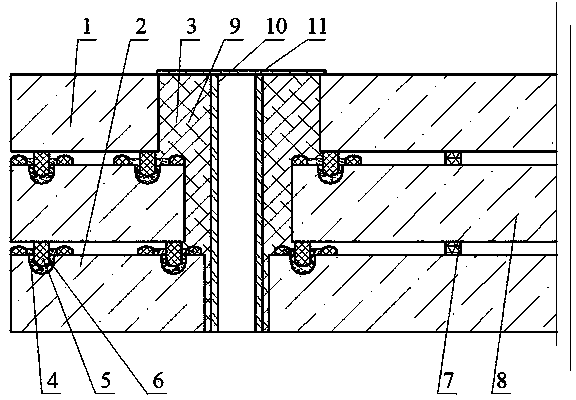

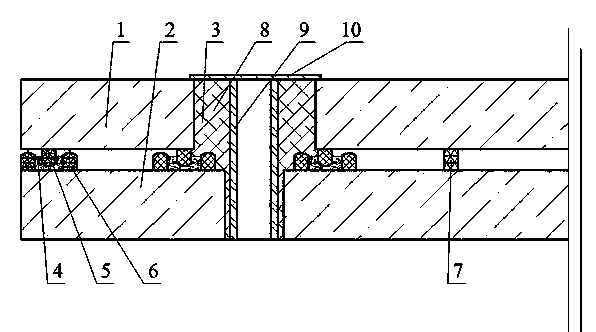

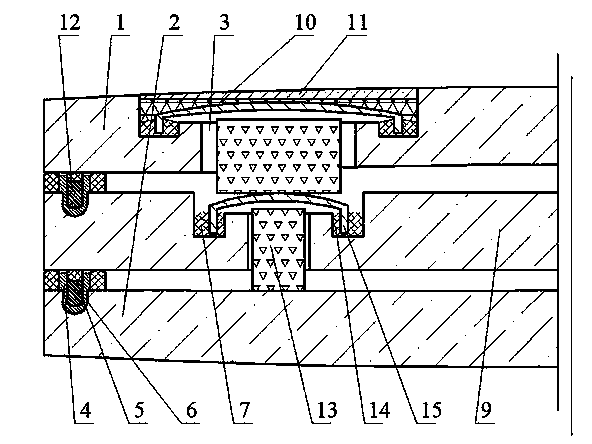

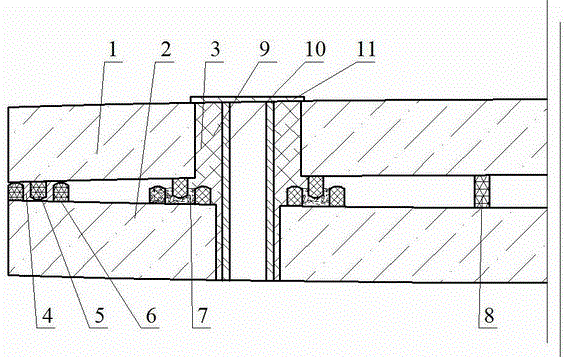

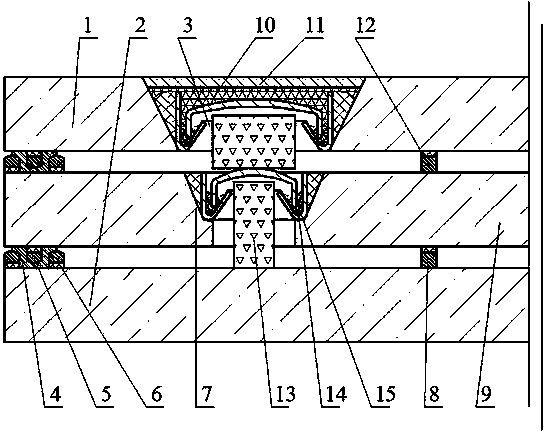

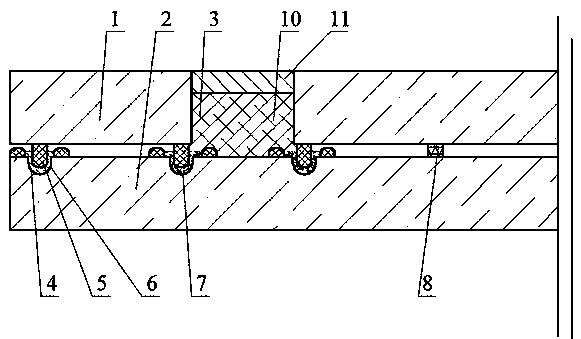

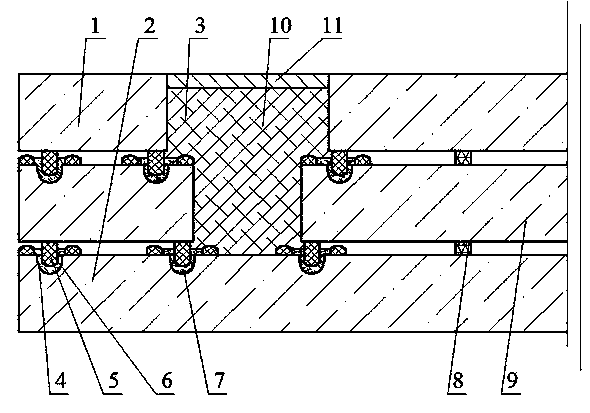

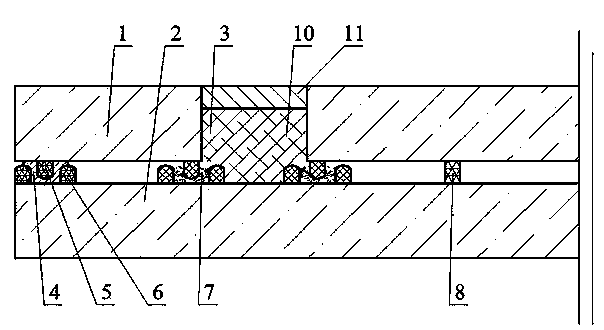

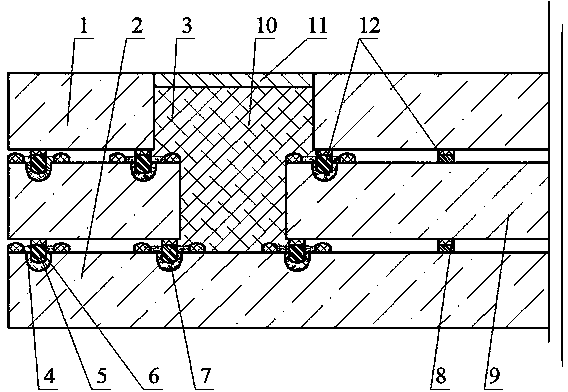

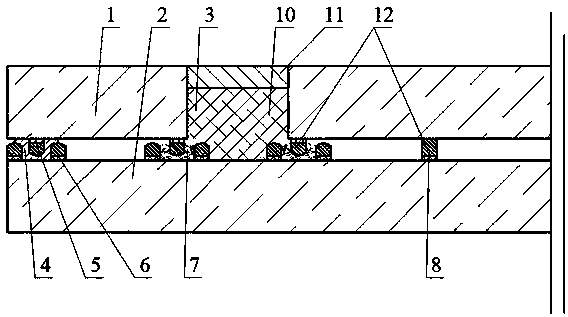

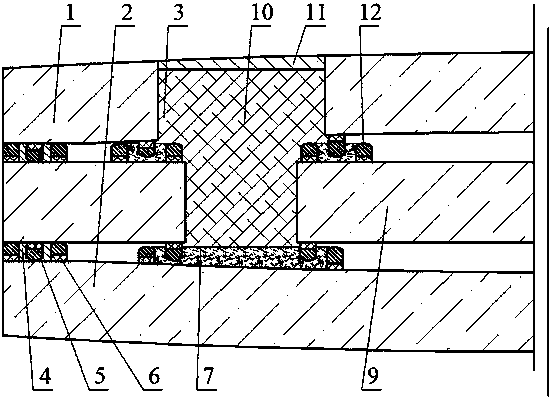

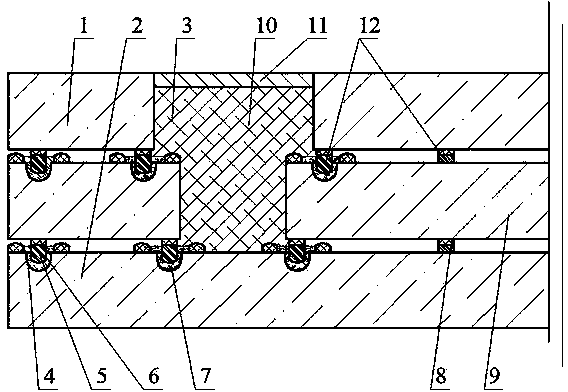

Plane double-vacuum-layer glass with sealing strips and grooves and mounting holes through metal welding

The invention provides plane double-vacuum-layer glass provided with sealing strips and grooves and mounting holes through metal welding. The plane vacuum glass comprises upper glass, lower glass and middle glass, and is characterized in that the plane double-vacuum-layer glass is provided with mounting holes; sealing strips are arranged at the peripheries of lower surfaces of the upper glass and the middle glass, and the mounting holes; sealing strips and sealing grooves are formed in the peripheries of the upper surfaces of the middle glass and the lower glass, and the mounting holes; the peripheries of three blocks of glass are automatically welded together through metal welding material in a vacuum furnace; the mounting holes are sealed automatically by adopting metal welding material; two closed vacuum layers are formed among three blocks of glass; supporting materials arranged in a dot matrix manner are arranged in the vacuum layers. The manufacturing method and technology of the vacuum glass provided by the invention are simple, the vacuum glass and tempered vacuum glass manufactured through the manufacturing method and technology has the advantages that the mounting and use are convenient, the air tightness of the vacuum glass can be guaranteed, and the strength, heat insulation performance and sound insulation performance of the vacuum glass are increased.

Owner:戴长虹

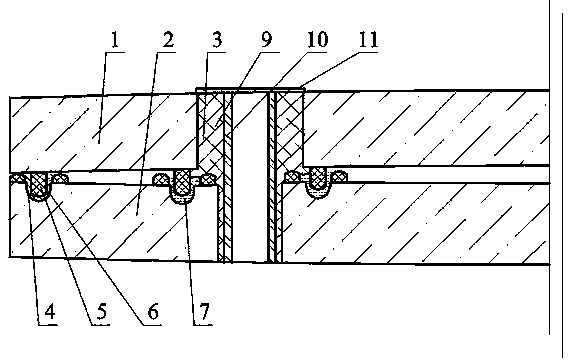

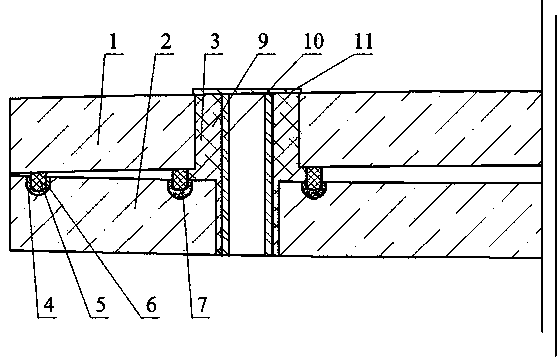

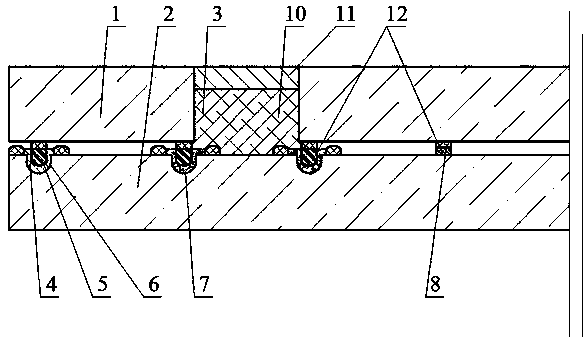

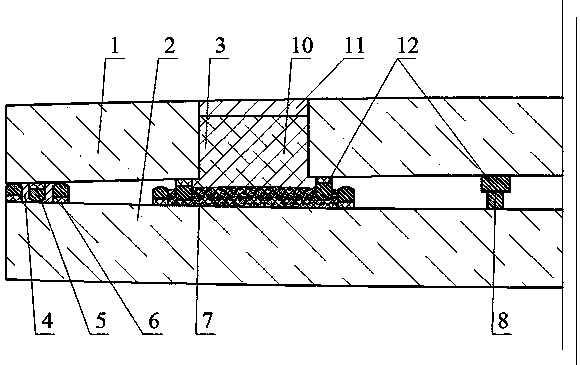

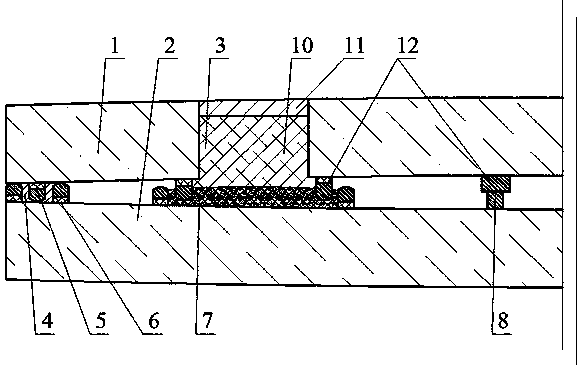

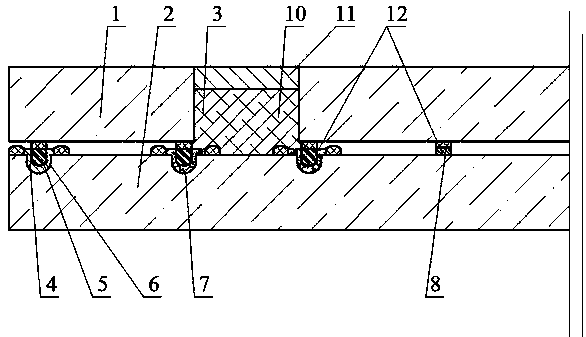

Vacuum plane glass provided with sealing strips and mounting hole through metal welding

A vacuum plane glass provided with sealing strips and a mounting hole through metal welding comprises an upper glass and a lower glass, and is characterized by further comprising the mounting hole, wherein both the upper and the lower glass are plane glasses; at least one sealing strip is respectively arranged at the peripheries of the mounting hole and the upper glass; at least two sealing strips are respectively arranged at the peripheries of the lower glass and the mounting hole; the sealing strips on the upper glass insert among the sealing strips on the lower glass; the peripheries of the lower and the upper glasses are automatically welded together in a vacuum furnace through metal solder; the mounting hole is also automatically sealed through the metal solder. The vacuum glass and the manufacturing method thereof are simple in process. According to the vacuum glass and the toughened vacuum glass prepared, not only are mounting and using convenient, but also the airtightness of the vacuum glass is ensured, and the strength, and heat insulation and acoustic insulation performance are also increased.

Owner:戴长虹

Convex tempered vacuum glass provided with getter in edge sealing of sealing strips and preparing method thereof

InactiveCN104291635ASimple sealing structureLow costGlass reforming apparatusGlass productionElastomerRoom temperature

Convex tempered vacuum glass provided with a getter in edge sealing of sealing strips is disclosed. The convex tempered vacuum glass is characterized in that: upper glass and lower glass are convex tempered glass; the upper glass is provided with an extraction opening; the extraction opening is provided with a sealing cover; the getter is disposed in the extraction opening; the periphery of the upper glass and the periphery of the lower glass are provided with the sealing strips; the periphery of the upper glass and the periphery of the lower glass are welded by adoption of low-temperature glass solder at normal pressure in an edge banding furnace; the extraction opening is automatically sealed by utilization of the sealing cover and metal solder in a vacuum furnace; the getter is automatically activated in a sealing process; a closed vacuum layer is formed between the upper glass and the lower glass; the sealing strips are made of tempered glass printing ink and / or polymer; the polymer is prepared into pre-polymer firstly, and then the prepolymer is prepared onto glass or tempered glass printing ink after glass tempering; the prepolymer cures at the room temperature or high temperature to form an elastomer; the prepolymer or the elastomer can automatically adapt to changes of the height of the vacuum layer; and volatile gas in the elastomer is removed at a high temperature and under high vacuum.

Owner:戴长虹

Convex toughened vacuum glass provided with getter with edges being sealed by sealing strips and sealing grooves and manufacturing method thereof

InactiveCN104291628AGuaranteed suction capacityLow costGlass reforming apparatusGlass productionElastomerRoom temperature

The invention discloses convex toughened vacuum glass provided with a getter with edges being sealed by sealing strips and sealing grooves. The convex toughened vacuum glass is characterized in that upper glass and lower glass are convex toughened glass; the upper glass is provided with an extraction opening; a sealing cover is arranged on the extraction opening; the getter is put into the extraction opening; the upper glass is provided with the sealing strips; the lower glass is provided with the sealing strips and the sealing grooves; the upper glass and the lower glass are welded together in an edge-sealing furnace under a normal pressure by using a glass solder; the extraction opening is automatically enclosed in a vacuum furnace by using the sealing cover and a metal solder; the getter is automatically activated in an edge-sealing process; an enclosed vacuum layer is formed between the upper glass and the lower glass; the sealing strips are made of toughened glass ink or / and a high polymer; the high polymer is prepared into a prepolymer firstly; after the glass is toughened, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a high temperature and in vacuum.

Owner:戴长虹

Microwave-welded flat tempered vacuum glass edge-sealed with sealing groove and having getter

InactiveCN104291647AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

A microwave-welded flat tempered vacuum glass edge-sealed with sealing grooves and having a getter is characterized in that an upper glass and a lower glass are flat tempered glasses. A vacuumizing hole is arranged in the upper glass and a sealing cover is arranged on the vacuumizing hole. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with the sealing groove. The upper glass and the lower glass are welded to each other in a microwave oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and the supporting object are composed of tempered glass printing ink and a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

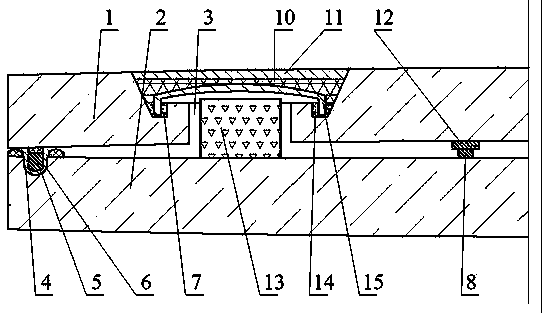

Flat tempered vacuum glass edge-sealed with sealing bars and sealing grooves and having getter and manufacturing method thereof

InactiveCN104291646AGuaranteed suction capacityLow costGlass reforming apparatusGlass productionElastomerRoom temperature

A flat tempered vacuum glass edge-sealed with sealing bars and sealing grooves and having a getter is characterized in that an upper glass and a lower glass are flat tempered glasses. A vacuumizing hole is formed in the upper glass and is provided with a seal cover. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with a sealing bar and a sealing groove. The upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and / or the supporting object are composed of tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Microwave-welded convex tempered vacuum glass edge-sealed with sealing groove and having getter

InactiveCN104291656AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

A microwave-welded convex tempered vacuum glass edge-sealed with sealing grooves and having a getter is characterized in that an upper glass and a lower glass are convex tempered glasses. A vacuumizing hole is arranged in the upper glass and a sealing cover is arranged on the vacuumizing hole. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with the sealing groove. Peripheries of the upper glass and the lower glass are welded to each other in a microwave oven at a normal pressure through a glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar is manufactured from tempered glass printing ink and a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Glass-welded convex vacuum glass provided with sealing strips, sealing grooves and mounting holes

InactiveCN104291613AEasy edge banding and sealingHigh bonding strengthGlass reforming apparatusGlass productionVacuum furnaceEngineering

The invention discloses glass-welded planar vacuum glass provided with sealing strips, sealing grooves and mounting holes. The planar vacuum glass comprises upper glass and lower glass, and is characterized in that the mounting holes and extraction openings are combined into one; the upper glass and the lower glass are planar glass; the peripheries of the upper glass and the extraction openings are provided with the sealing strips; the periphery of the lower glass and the peripheries of the extraction openings are provided with the sealing grooves and the sealing strips; the peripheries of the upper glass and the lower glass are welded together in an edge-sealing furnace under the normal pressure through a low-temperature glass solder; the extraction openings are automatically enclosed in a vacuum furnace through a metal solder; and an enclosed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process. The manufactured vacuum glass and toughened vacuum glass are easy to mount and use. Moreover, the air tightness of the vacuum glass can be ensured, and the strength, heat insulation performance and sound insulation performance of the vacuum glass can be enhanced.

Owner:戴长虹

Glass welded convex vacuum glass with sealing strip and mounting holes

ActiveCN103420575BSimple structureQuality improvementGlass reforming apparatusGlass productionManufacturing technologyEngineering

Convex vacuum glass with sealing strip and mounting hole welded in glass comprises upper glass and lower glass, and is characterized in that the mounting hole and an air extracting hole are combined into a whole; the upper glass and the lower glass are both convex glass; at least one sealing strip is arranged on the periphery of the upper glass and the air extracting hole; at least two sealing strips are arranged on the periphery of the lower glass and the air extracting hole; the sealing strip of the upper glass is inserted into the sealing strips of the lower glass; the periphery of the upper glass and the lower glass are welded together under normal pressure in an edge bonding furnace through low temperature glass solder; the air extracting hole is automatically sealed in a vacuum furnace through metal solder. The vacuum glass and the manufacturing technology thereof are simple; the vacuum glass and the toughened glass can facilitate the mounting and the use, and can guarantee the airtightness of the vacuum glass and improve the intensity, heat insulation performance and sound insulation performance of the glass.

Owner:安徽德意达铝业有限公司

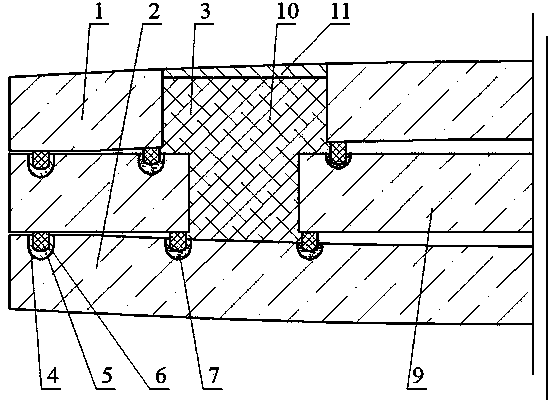

Planar tempered vacuum glass edge-sealed by using sealing strips and with getter, and preparation method thereof

InactiveCN104291604ASimple sealing structureLow costGlass reforming apparatusGlass productionElastomerRoom temperature

The invention relates to planar tempered vacuum glass which is edge-sealed by using sealing strips and which has a getter. The glass is characterized in that upper glass and lower glass are planar tempered glass. An air-exhaust port is provided on the upper glass. A sealing cap is provided on the air-exhaust port. The getter is placed in the air-exhaust port. Sealing strips are provided at the peripheries of the upper glass and the lower glass. The peripheries of the upper and lower glass are welded together by using a glass solder under normal pressure in an edge-sealing furnace. The air-exhaust port is automatically sealed in a vacuum furnace with the sealing cap and with a metal solder. The getter is automatically activated during the sealing process. A vacuum layer is formed between the upper glass and the lower glass. A supporter is provided in the vacuum layer. The sealing strips and / or the supporter is composed of tempered glass ink and / or a high-polymer. The high-polymer is first prepared into a pre-polymer. After the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum.

Owner:戴长虹

Convex low-pressure glass having sealing groove and mounting hole and manufacturing method thereof

InactiveCN104291659AHigh strengthSimple structureGlass reforming apparatusGlass productionManufacturing technologyEngineering

A convex low-pressure glass having sealing grooves and mounting holes includes an upper glass and a lower glass. The convex low-pressure glass is characterized by being provided with the mounting holes. The upper glass and the lower glass are convex glasses. Peripheries of the upper glass and the mounting holes are provided with sealing bars and the peripheries of the lower glass and the mounting holes are provided with the sealing grooves. The peripheries of the upper glass and the lower glass are automatically welded to each other through a low-temperature solder in an edge-sealing oven while the mounting holes are sealed automatically through the low-temperature solder. A sealed low-pressure layer is formed between the upper glass and the lower glass. The low-pressure glass is simple in manufacturing technology. The low-pressure glass and a tempered low-pressure glass are easy to install and use, are ensured in air tightness and are enhanced in strength, heat-insulating performance and sound-insulation performance.

Owner:戴长虹

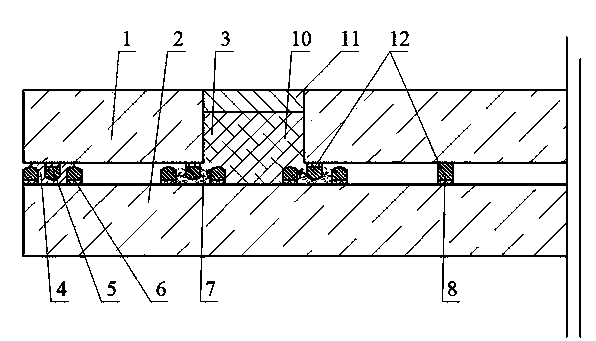

Microwave-heated planar double-vacuum-layer glass edge-sealed and port-sealed by using sealing grooves, and preparation method thereof

InactiveCN104291573AAchieving tightnessHigh bonding strengthGlass reforming apparatusGlass productionMicrowave ovenThermal insulation

The invention relates to microwave-heated planar double-vacuum-layer glass which is edge-sealed and port-sealed by using sealing grooves. The glass comprises upper glass, lower glass, and intermediate glass. Air-exhaust ports are provided on the upper glass and on the intermediate glass. Sealing strips are provided on the peripheries of the lower surfaces of the upper glass and the intermediate glass, and on the peripheries of the air-exhaust ports. Sealing strips are provided on the peripheries of the upper surfaces of the intermediate glass and the lower glass, and at the places corresponding to the air-exhaust ports. The peripheries of the upper glass, the lower glass and the intermediate glass are welded together by using a low-temperature glass solder under normal pressure in a microwave oven. The air-exhaust port is automatically sealed by using a metal solder in a vacuum furnace. Two sealed vacuum layers are formed between the upper glass and the intermediate glass, and between the intermediate glass and the lower glass. The planar double-vacuum-layer glass and the preparation method thereof have simple process. The prepared vacuum glass and tempered vacuum glass can overcome defects of prior arts. Air-tightness of vacuum glass can be effectively ensured. Strength, thermal insulation performance and sound insulation performance of the glass can be enhanced.

Owner:戴长虹

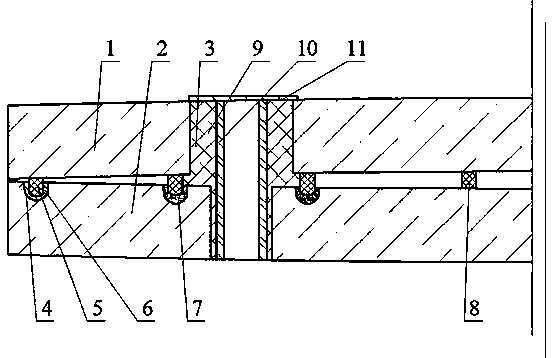

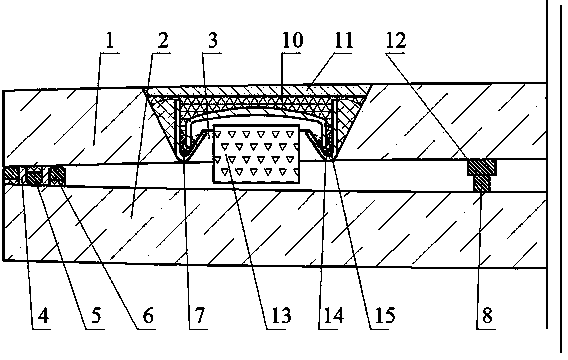

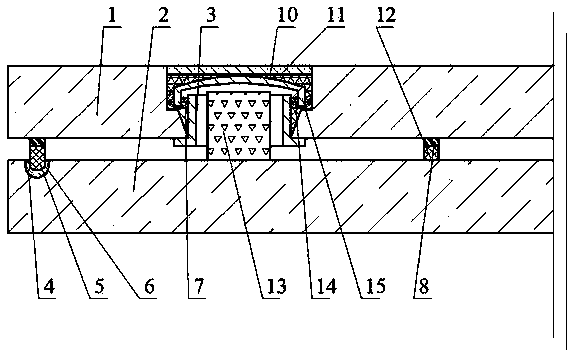

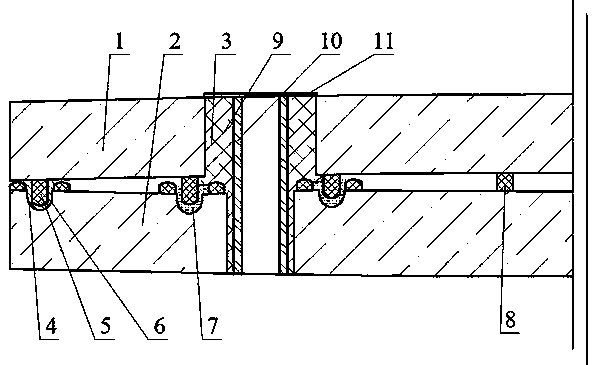

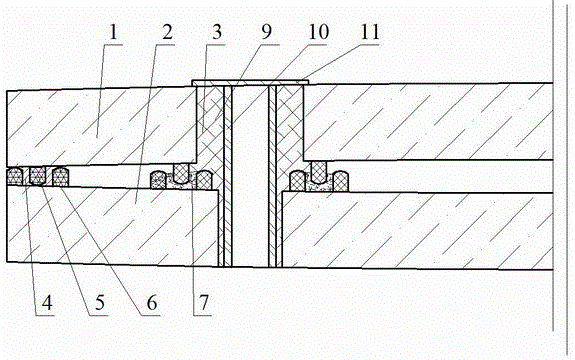

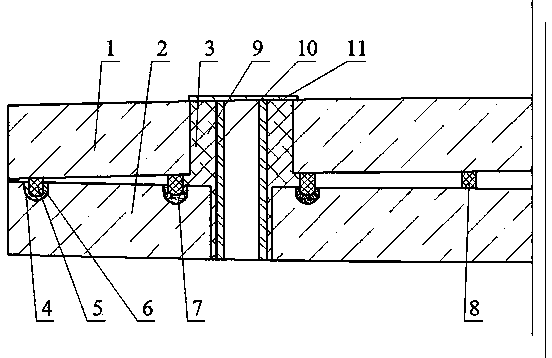

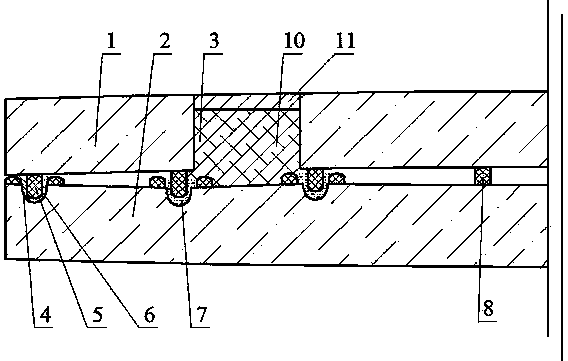

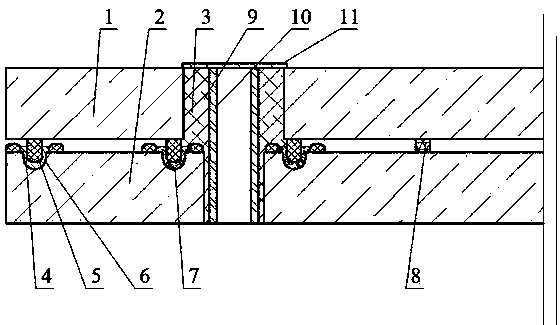

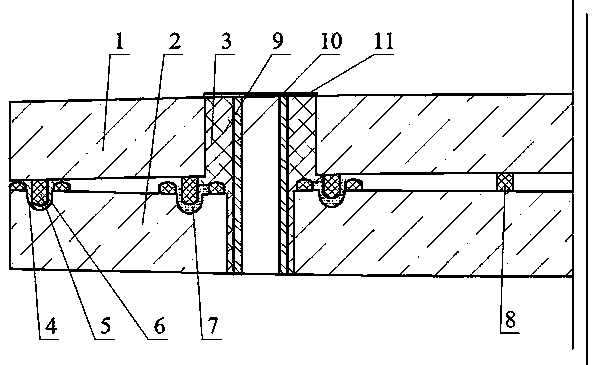

Planar vacuum glass edge-sealed and port-sealed by using sealing strips and sealing grooves, and preparation method thereof

InactiveCN104291615AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionThermal insulationEngineering

The invention relates to planar vacuum glass edge-sealed and port-sealed by using sealing strips and sealing grooves. The vacuum glass comprises upper glass and lower glass which are planar glass. An air-exhaust port is provided on the upper glass. Sealing strips are provided on the periphery of the upper glass and on the periphery of the air-exhaust port. Sealing grooves and sealing strips are provided on the periphery of the lower glass and at the place corresponding to the air-exhaust port. The peripheries of the upper glass and the lower glass are welded together by using a low-temperature glass solder under normal pressure in an edge-sealing furnace. The air-exhaust port is automatically sealed by using a metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. Supporters arranged in a lattice pattern is provided in the vacuum layer. The vacuum glass and the preparation method thereof have simple process. The prepared vacuum glass and tempered vacuum glass can overcome defects of prior arts. Air-tightness of vacuum glass can be effectively endured. Strength, thermal insulation performance and sound insulation performance of the vacuum glass can be enhanced.

Owner:戴长虹

Microwave-welded planar tempered vacuum glass edge-sealed by using sealing strips and a sealing groove and provided with getter

InactiveCN104291620AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

The invention relates to microwave-welded planar tempered vacuum glass which is edge-sealed by using sealing strips and a sealing groove and which is provided with a getter. The glass is characterized in that upper glass and lower glass are planar tempered glass. An air-exhaust port is provided on the upper glass. A sealing cap is provided on the air-exhaust port. The getter is placed in the air-exhaust port. A sealing strip is provided on the upper glass, and sealing strips and a sealing groove are provided on the lower glass. The upper glass and the lower glass are welded together by using a glass solder under normal pressure in a microwave oven. The air-exhaust port is automatically sealed by using the sealing cap and with a metal solder in a vacuum furnace. The getter is automatically activated during the port-sealing process. A vacuum layer is formed between the upper glass and the lower glass. Supporters are provided in the vacuum layer. The sealing strips and the supporters are prepared by using tempered glass ink or a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum.

Owner:戴长虹

Microwave-heated planar vacuum glass edge-sealed and port-sealed by using sealing strips, and preparation method thereof

InactiveCN104291562AHigh bonding strengthIncrease the sealing areaGlass reforming apparatusGlass productionMicrowave ovenThermal insulation

The invention relates to microwave-heated planar vacuum glass which is edge-sealed and port-sealed by using sealing strips. The glass comprises upper glass and lower glass which are planar glass. An air-exhaust port is provided on the upper glass. At least one sealing strip is provided at each of the peripheries of the upper glass and of the air-exhaust port. At least two sealing strips are provided at the periphery of the lower glass. At least one sealing strip is provided on the lower glass at the place corresponding to the air-exhaust port. The sealing strips on the upper glass are inserted between or in the sealing strips on the lower glass. The peripheries of the upper and lower glass are welded together by using a low-temperature glass solder under normal pressure in a microwave oven. The air-exhaust port is automatically sealed by using a metal solder in a vacuum furnace. The vacuum glass and the preparation method thereof have simple process. The prepared vacuum glass and tempered vacuum glass can overcome defects of prior arts. Air-tightness of vacuum glass can be effectively ensured. Strength, thermal insulation performance and sound insulation performance of the glass can be enhanced.

Owner:戴长虹

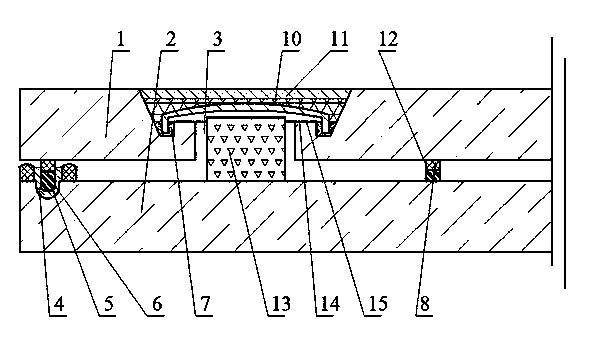

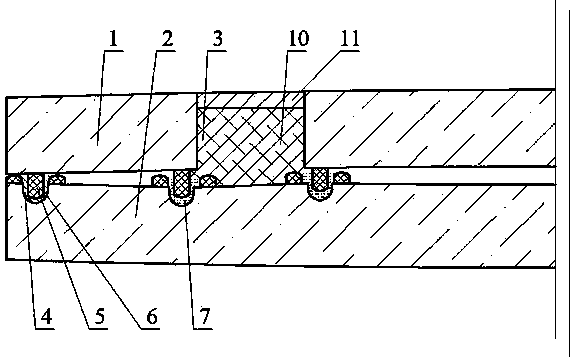

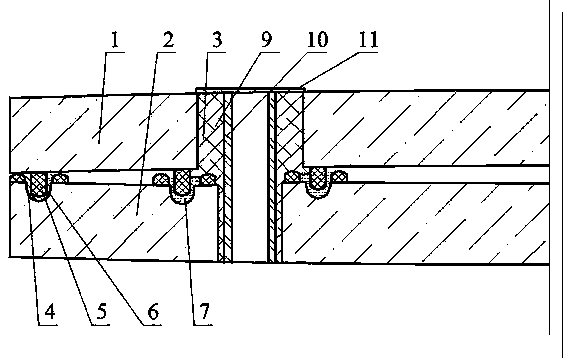

Vacuum glass with edge and port sealed by using sealing strips and sealing grooves, and preparation method thereof

InactiveCN104291619AExtend your lifeImprove productivityGlass reforming apparatusGlass productionThermal insulationEngineering

The invention relates to vacuum glass with edge and port sealed by using sealing strips and sealing grooves. The vacuum glass comprises upper glass and lower glass which are convex glass or planar glass. An air-exhaust port is provided on the upper glass. Sealing strips are provided on the periphery of the upper glass and on the periphery of the air-exhaust port. Sealing grooves and sealing strips are provided on the periphery of the lower glass and at places corresponding to the air-exhaust port. The peripheries of the upper and lower glass are automatically welded together in an edge-sealing furnace under normal pressure by using a low-temperature glass solder. The air-exhaust port is automatically sealed by using a metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum layer is provided with or without supporters in a lattice arrangement. The vacuum glass and the preparation method thereof provided by the invention have a simple process. Prepared vacuum glass and tempered vacuum glass can overcome defects of prior arts. Air-tightness of the vacuum glass can be ensured. Strength, thermal insulation performance and sound insulation performance of the glass can be effectively ensured.

Owner:戴长虹

Microwave-welded planar tempered vacuum glass edge-sealed by using sealing strips and sealing grooves and provided with air-exhaust port

InactiveCN104291590AAchieving tightnessGuaranteed tightnessGlass reforming apparatusGlass productionElastomerMicrowave oven

The invention relates to microwave-welded planar tempered vacuum glass which is edge-sealed by using sealing strips and sealing grooves and which is provided with an air-exhaust port. The glass is characterized in that upper glass and lower glass are planar tempered glass. The air-exhaust is provided on the upper glass. Sealing strips are provided at the periphery of the upper glass and at the periphery of the air-exhaust port. Sealing strips and sealing grooves are provided at the periphery of the lower glass and at the place corresponding to the air-exhaust port. The peripheries of the upper glass and lower glass are welded together by using a glass solder under normal pressure in a microwave oven. The air-exhaust port is automatically sealed by using a metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. One or two layers of supporters are provided in the vacuum layer. The sealing strips and the supporters are composed of tempered glass ink or a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapt to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum.

Owner:戴长虹

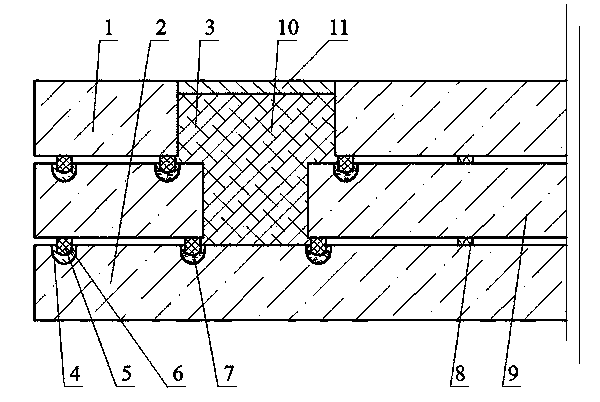

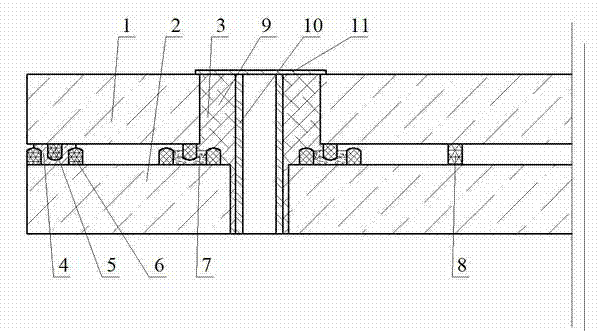

Flat low-pressure glass having sealing bars, sealing grooves and mounting holes and manufacturing method thereof

InactiveCN104291652AGuaranteed tightnessHigh strengthGlass reforming apparatusGlass productionFlat glassManufacturing technology

A flat low-pressure glass having sealing bars, sealing grooves and mounting holes includes an upper glass and a lower glass. The flat low-pressure glass is characterized by being provided with the mounting holes. The upper glass and the lower glass are flat glasses. Peripheries of the upper glass and the mounting holes are provided with sealing bars and the peripheries of the lower glass and the mounting holes are provided with the sealing grooves and the sealing bars. The peripheries of the upper glass and the lower glass are automatically welded to each other through a low-temperature solder in an edge-sealing oven while the mounting holes are sealed automatically through the low-temperature solder. A sealed low-pressure layer, with a dot-array-arranged supporting object therein, is formed between the upper glass and the lower glass. The low-pressure glass is simple in manufacturing technology. The low-pressure glass and a tempered low-pressure glass are easy to install and use, are ensured in air tightness and are enhanced in strength, heat-insulating performance and sound-insulation performance.

Owner:戴长虹

Microwave-heated convex vacuum glass edge-sealed and port-sealed by using sealing strips, and preparation method thereof

InactiveCN104291560AGuaranteed tightnessHigh bonding strengthGlass reforming apparatusGlass productionMicrowave ovenThermal insulation

The invention relates to microwave-heated convex vacuum glass which is edge-sealed and port-sealed by using sealing strips. The glass comprises upper glass and lower glass which are convex glass. An air-exhaust port is provided on the upper glass. At least one sealing strip is provided at each of the periphery of the upper glass and the periphery of the air-exhaust port. At least two sealing strips are provided at the periphery of the lower glass. At least one sealing strip is provided on the lower glass at the place corresponding to the air-exhaust port. The sealing strips on the upper glass are inserted in between or in the sealing strips on the lower glass. The peripheries of the upper glass and the lower glass are welded together by using a low-temperature glass solder under normal pressure in a microwave oven. The air-exhaust port is automatically sealed by using a metal solder in a vacuum furnace. The vacuum glass and the preparation method thereof have simple process. The prepared vacuum glass and tempered vacuum glass can overcome defects of prior arts. Air-tightness of the vacuum glass can be effectively ensured. Strength, thermal insulation performance and sound insulation performance of the glass can be enhanced.

Owner:戴长虹

Convex low-pressure hollow glass with sealing strips, sealing grooves and mounting hole, and preparation method thereof

InactiveCN104291567AGuaranteed tightnessHigh strengthGlass reforming apparatusGlass productionThermal insulationAir tightness

The invention relates to convex low-pressure hollow glass with sealing strips, sealing grooves and a mounting hole. The glass comprises upper glass and lower glass, and is characterized in comprising the mounting hole. The upper glass and the lower glass are convex glass. Sealing strips are provided at the upper glass and at the periphery of the mounting hole. Sealing grooves are sealing strips are provided at the periphery of the lower glass and at the periphery of the mounting hole. The peripheries of the upper and lower glass are automatically welded together by using a low-temperature solder in an edge-sealing furnace. The mounting hole is automatically sealed by using a low-temperature solder. A sealed vacuum layer is formed between the upper glass and the lower glass. The low-pressure hollow glass and the preparation method thereof have simple process. Prepared low-pressure hollow glass and tempered low-pressure hollow glass are beneficial for mounting and application. Air-tightness of the low-pressure hollow glass can be ensured. Strength, thermal insulation performance and sound insulation performance of the glass can be enhanced.

Owner:戴长虹

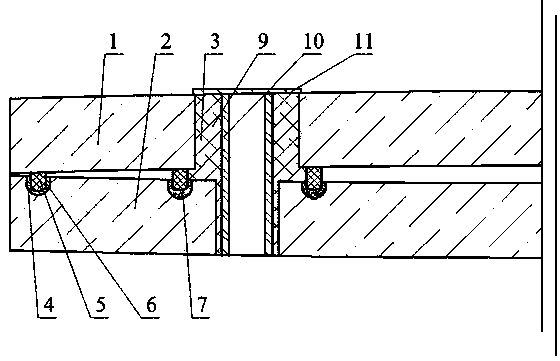

Glass welded flat vacuum glass with sealing strips and mounting holes

ActiveCN103420576BSimple structureLow costGlass reforming apparatusGlass productionManufacturing technologyEngineering

Plane vacuum glass with sealing strip and mounting hole welded in glass comprises upper glass and lower glass, and is characterized in that the mounting hole and an air extracting hole are combined into a whole; the upper glass and the lower glass are both plane glass; at least one sealing strip is arranged at the periphery of the upper glass and the air extracting hole; at least two sealing strips are arranged at the periphery of the lower glass and the air extracting hole; the sealing strip of the upper glass is inserted into the sealing strips of the lower glass; the peripheries of the upper glass and the lower glass are welded together under normal pressure in an edge bonding furnace through low temperature glass solder; the air extracting hole is automatically sealed in a vacuum furnace through metal solder. The vacuum glass and the manufacturing technology thereof are simple; the vacuum glass and the toughened glass can facilitate the mounting and the use, and can guarantee the airtightness of the vacuum glass and improve the intensity, heat insulation performance and sound insulation performance of the glass.

Owner:戴长虹

Microwave-welded planar toughened vacuum glass provided with extraction opening with edges being sealed by sealing strips

InactiveCN104291589AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionElastomerMicrowave oven

The invention discloses microwave-welded planar toughened vacuum glass provided with an extraction opening with edges being sealed by sealing strips. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar toughened glass; the upper glass is provided with the extraction opening; the sealing strips are arranged on the peripheries of the upper glass and the extraction opening, the periphery of the lower glass and corresponding positions of the extraction opening; the peripheries of the upper glass and the lower glass are welded together in a microwave oven under the normal pressure by using a low-temperature glass solder; the extraction opening is automatically enclosed in a vacuum furnace by using a metal solder; an enclosed vacuum layer is formed between the upper glass and the lower glass; support objects are arranged in the vacuum layer in a lattice form; the sealing strips and / or the support objects consist of toughened glass ink and / or a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at the room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a room temperature and in high vacuum.

Owner:戴长虹

Flat tempered vacuum glass edge-sealed with sealing bar and having vacuumizing hole and manufacturing method thereof

InactiveCN104291660AExtend your lifeImprove productivityGlass reforming apparatusGlass productionElastomerRoom temperature

A flat tempered vacuum glass edge-sealed with sealing bars and having a vacuumizing hole is characterized in that an upper glass and a lower glass are flat tempered glass. A vacuumizing hole is formed in the upper glass. Peripheries of the upper glass and the vacuumizing hole are provided with the sealing bars and the periphery of the lower glass and positions corresponding to the vacuumizing hole are provided with the sealing bars. The peripheries of the upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through a metal solder. A sealed vacuum layer, with a dot-array-arranged support object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and / or the support object are composed of tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. Finally the pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Convex tempered vacuum glass edge-sealed with sealing bars and having vacuumizing hole and manufacturing method thereof

InactiveCN104291653AEasy edge banding and sealingHigh bonding strengthGlass reforming apparatusGlass productionVacuum furnacePrinting ink

A convex tempered vacuum glass edge-sealed with sealing bars and sealing groove and having a vacuumizing hole is characterized in that an upper glass and a lower glass are convex tempered glass. A vacuumizing hole is formed in the upper glass. Peripheries of the upper glass and the vacuumizing hole are provided with the sealing bars and the periphery of the lower glass and positions corresponding to the vacuumizing hole are provided with the sealing bars. The peripheries of the upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through a metal solder. A sealed vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar is manufactured from tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

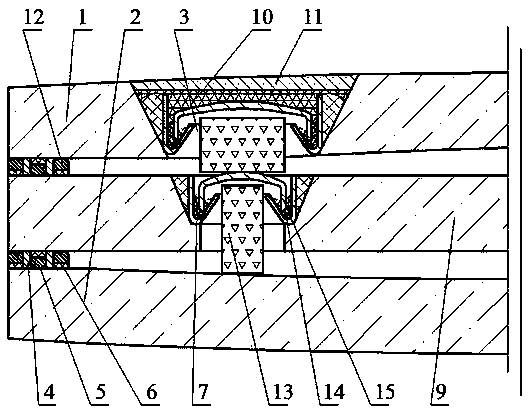

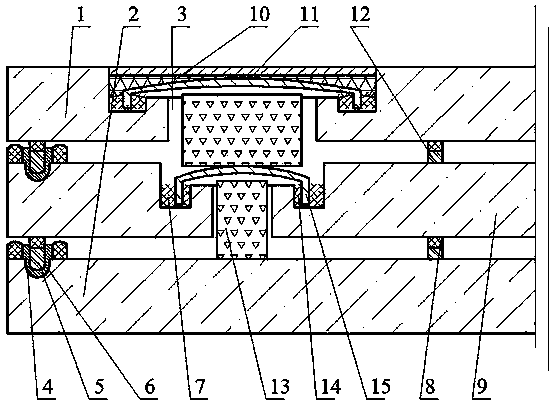

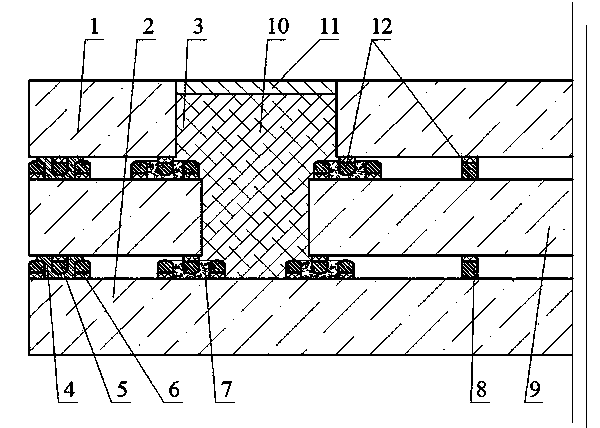

Microwave-heated convex dual-vacuum-layer glass with edges and openings being sealed by sealing grooves and manufacturing method

InactiveCN104291580AAchieving tightnessHigh bonding strengthGlass reforming apparatusGlass productionMicrowave ovenEngineering

The invention discloses microwave-heated convex dual-vacuum-layer glass with edges and openings being sealed by sealing grooves. The convex dual-vacuum-layer glass comprises upper glass, lower glass and middle glass, wherein the upper glass and the lower glass are convex glass; the middle glass is planar glass; the upper glass and the middle glass are provided with an extraction opening; the peripheries of the upper surfaces of the upper glass and the middle glass and the extraction opening are provided with sealing strips; sealing grooves are formed in the peripheries of the upper surfaces of the middle glass and the lower glass and in corresponding positions of the extraction opening; the peripheries of the three pieces of glass are welded together in a microwave oven under a normal pressure through a low-temperature glass solder; the extraction opening is automatically enclosed in a vacuum furnace by using a metal solder; and two vacuum layers are formed between the upper glass and the middle glass as well as between the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process. Through adoption of the manufactured vacuum glass and toughened vacuum glass, defects in the prior art can be overcome. The air tightness of the vacuum glass can be ensured effectively, and the strength, heat insulation performance and sound insulation performance of the vacuum glass can be enhanced.

Owner:戴长虹

Microwave-welded convex tempered vacuum glass edge-sealed with sealing bar and having vacuumizing hole

InactiveCN104291657AAchieving tightnessGuaranteed tightnessGlass reforming apparatusGlass productionElastomerMicrowave oven

A microwave-welded convex tempered vacuum glass edge-sealed with sealing bars and sealing grooves and having a vacuumizing hole includes an upper glass and a lower glass which are characterized by being convex tempered glasses. The vacuumizing hole is arranged in the upper glass. Peripheries of the upper glass and the vacuumizing hole are provided with sealing bars and the peripheries of the lower glass and positions corresponding to the vacuumizing hole are provided with the sealing bars and the sealing grooves. The peripheries of the upper glass and the lower glass are welded to each other in a microwave oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through a metal solder. A sealed vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar is manufactured from tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Planar toughened vacuum glass provided with extraction opening with edges being sealed by sealing strips and sealing grooves and manufacturing method thereof

InactiveCN104291624AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionElastomerRoom temperature

The invention discloses planar toughened vacuum glass provided with an extraction opening with edges being sealed by sealing strips and sealing grooves. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar toughened glass; the upper glass is provided with the extraction opening; the sealing strips are arranged on the peripheries of the upper glass and the extraction opening, and the sealing strips and the sealing grooves are arranged on the periphery of the lower glass and corresponding positions of the extraction opening; the peripheries of the upper glass and the lower glass are welded together in an edge-sealing furnace under a normal pressure through a glass solder; the extraction opening is automatically enclosed in a vacuum furnace by using a metal solder; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the sealing strips and / or the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum.

Owner:戴长虹

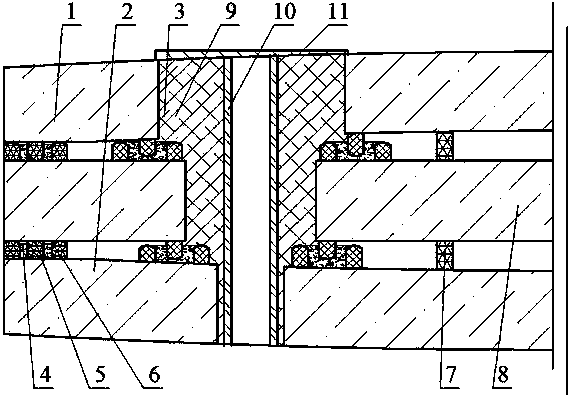

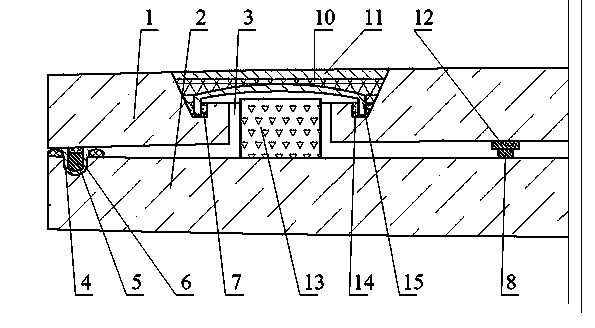

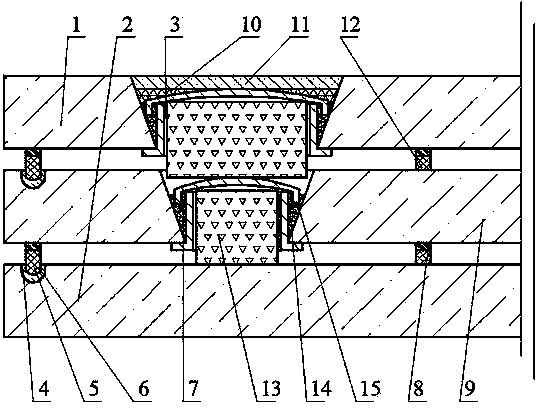

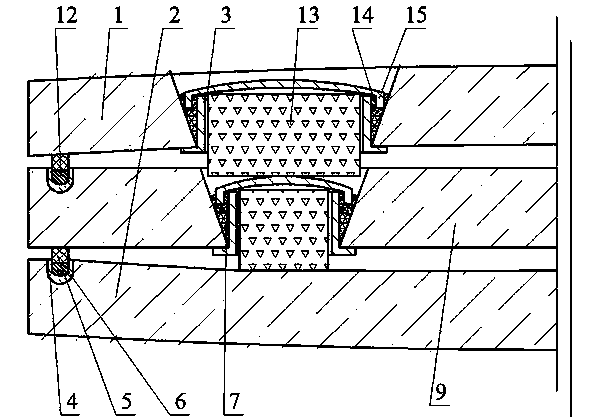

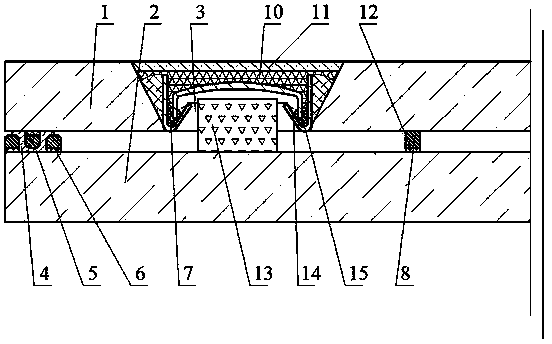

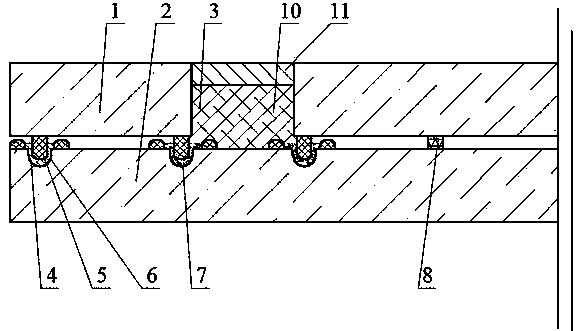

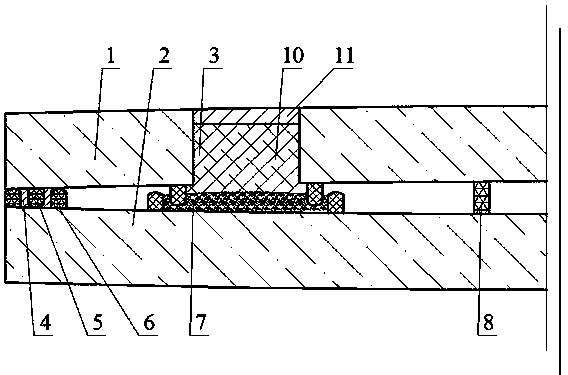

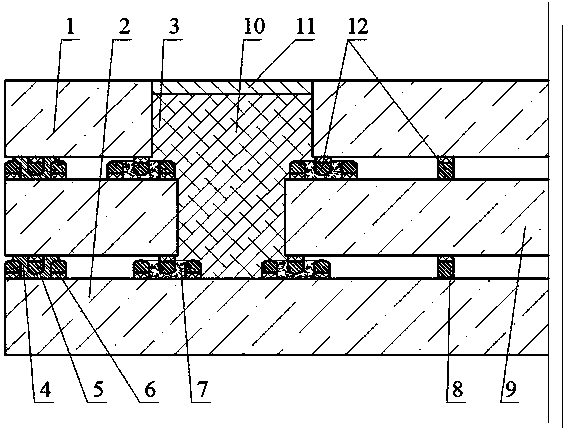

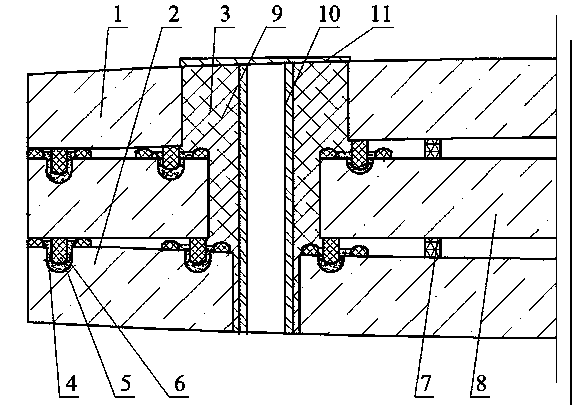

Metal-welded convex double-vacuum-layer glass with sealing strips, sealing grooves, and mounting hole.

InactiveCN104291631AHigh strengthLow costGlass reforming apparatusGlass productionThermal insulationConvex side

The invention relates to metal-welded convex double-vacuum-layer glass with sealing strips, sealing grooves, and a mounting hole. The glass comprises upper glass, lower glass and intermediate glass. The glass is characterized in comprising the mounting hole. The upper glass and the lower glass are convex glass. The intermediate glass is planar glass. Sealing strips are provided at the peripheries of the upper surfaces of the upper glass and the intermediate glass, and at the periphery of the mounting hole, on the upper surfaces of the upper glass and the intermediate glass. Sealing grooves and sealing strips are provided at the peripheries of the upper surfaces of the intermediate glass and lower glass, and at the periphery of the mounting hole, on the upper surface of the intermediate glass and the lower glass. The peripheries of the three pieces of glass are automatically welded together by using a metal solder in a vacuum furnace. The mounting hole is also automatically sealed by using the metal solder. Two sealed vacuum layers are formed between the three pieces of glass. The vacuum glass and the preparation method have simple process. The prepared vacuum glass and tempered vacuum glass are beneficial for mounting and application. Air-tightness of the vacuum glass can be effectively ensured. Strength, thermal insulation performance and sound insulation performance of the glass can be enhanced.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com