Dust collection cart for spinning

A cart and textile technology, applied in the field of vacuum carts for textiles, can solve problems affecting the respiratory system, lung injury and inflammation, etc., to reduce injuries, ensure the effect, and reduce the effect of inhaling fiber short hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

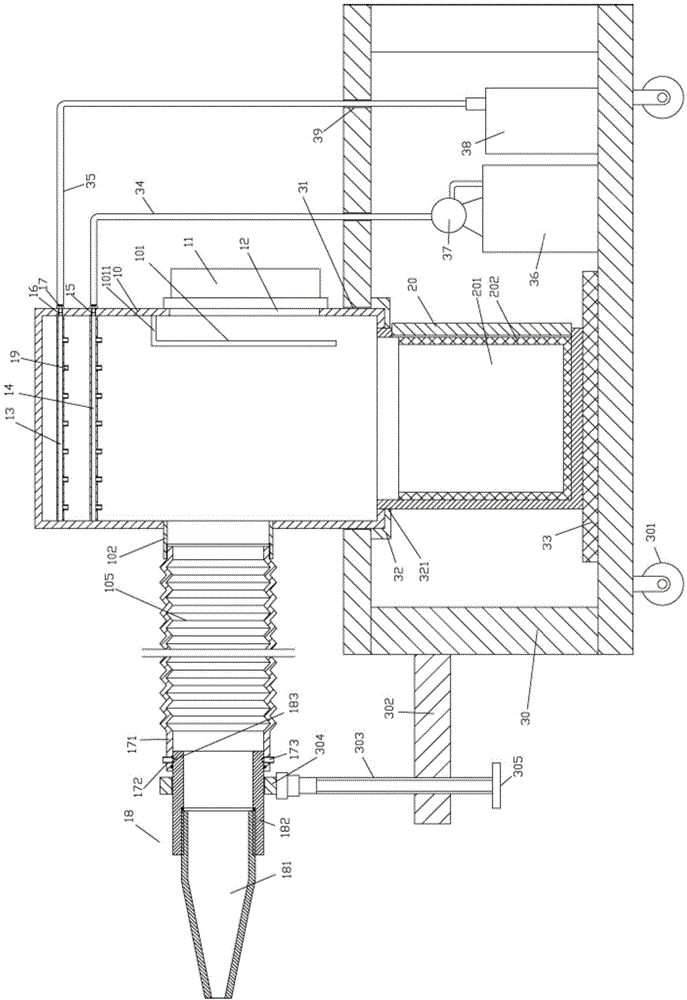

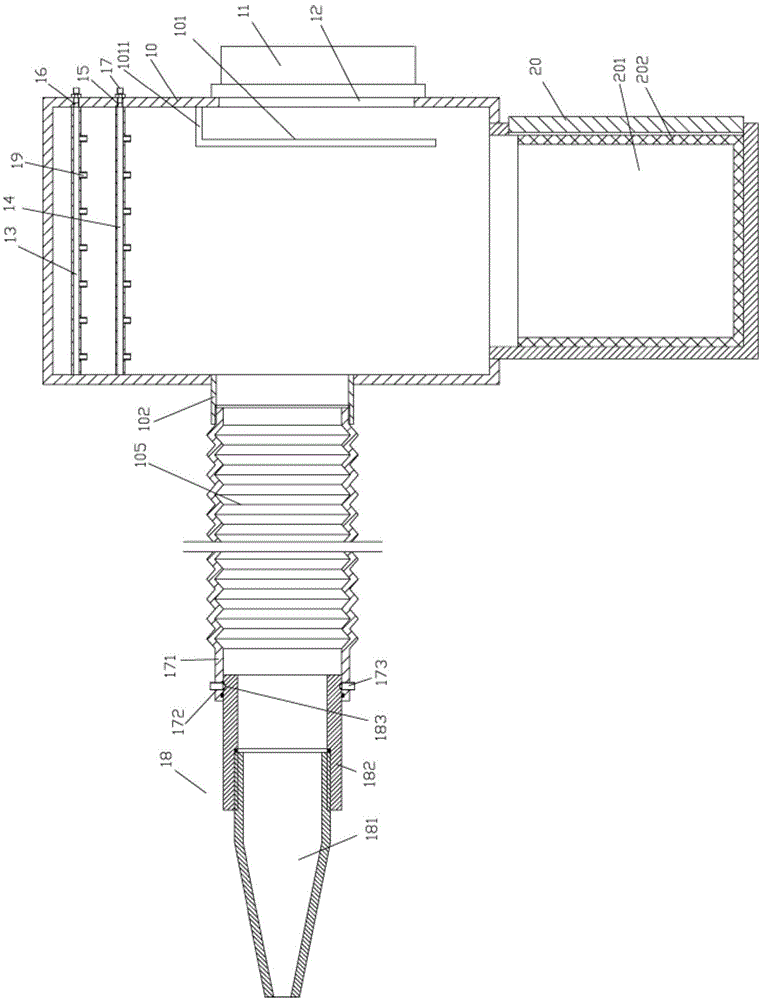

[0019] Example: see Figures 1 to 3 As shown, a vacuum cart for weaving comprises a transition box 10, a bottom collection box 20 and a trolley frame 30, the upper end of the bottom collection box 20 is connected to the bottom of the transition box 10, and the transition box The body 10 is inserted into the through hole 31 provided on the top plate of the cart frame 30, and the bottom end surface of the transition box body 10 is pressed against the bottom surface of the support sleeve 32 fixed on the bottom surface of the top plate of the cart frame 30. The bottom collection box 20 passes through the central through hole 321 of the bottom plate of the support sleeve 32 and presses against the buffer pad 33 fixed on the top of the bottom plate of the trolley frame 30;

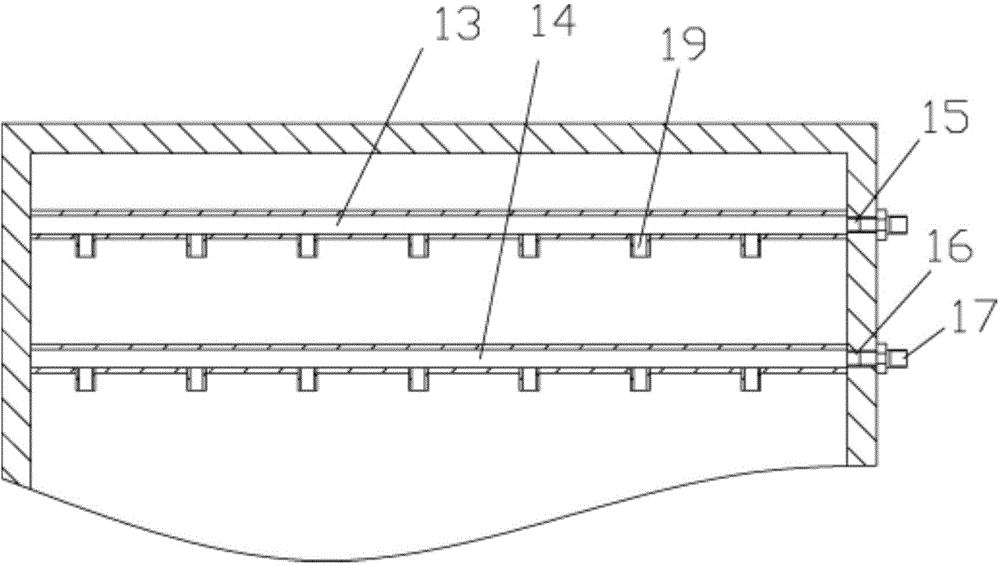

[0020] Fan 11 is fixed on the outer wall of the rear side plate of transition box body 10, and the suction end of fan 11 communicates with the through hole 12 that has on the rear side plate of transition box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com