Metal vacuum composite panel with sealing strips and getter and manufacturing method thereof

A technology of getter and composite board, which is applied in the direction of building components, heat preservation, sound insulation, etc., can solve the problems of cold bridge and heat preservation performance not reaching the best state, and achieve simple sealing structure, good air tightness, welding firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The implementation of the present invention will be described in detail below with examples and accompanying drawings, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

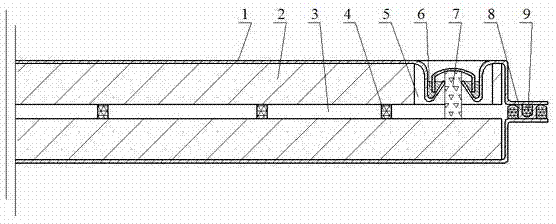

[0042] Referring to the accompanying drawings, the metal vacuum composite panel with sealing strip and getter is composed of a shell 1, a core plate 2, a vacuum chamber 3 and a support 4, and the shell 1 is made of a low-carbon steel plate with a thickness of 0.3-1.0mm; the core plate 2 is a metal plate, ceramic plate, glass plate, plastic plate or composite plate, etc., preferably a 1-2mm thick aluminum alloy plate or a 3-5mm thick tempered glass plate, etc.; the support 4 is made of metal, ceramics, glass or high polymer It is made by printing, printing, spraying, mechanical layout, etc. to form a dot matrix and distribute between the core boards 2. The support height of the support 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com