Placement structure of vacuum glass getter and method of making the same

A technology of vacuum glass and getter, which is applied in the field of vacuum glass to achieve the effects of high vacuum degree, improved production efficiency and qualified rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

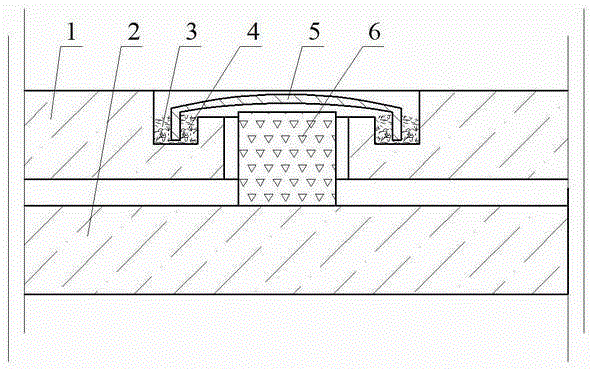

[0059] Embodiment 1: see figure 1 , the vacuum glass is made up of upper glass 1 and lower glass 2, a through hole is drilled on the upper glass 1 to form a suction port, and a U-shaped sealing groove 4 concentric with the suction port is made by a hollow drill on the upper surface of the upper glass 1, and sealed The inner edge of the groove 4 is lower than the upper surface of the upper glass 1; a sealing cover 5 is made according to the size of the sealing groove 4, and the edge of the sealing cover 5 can be inserted in the sealing groove 4, and the height of the sealing cover 5 is lower than that of the upper glass 1 The upper surface of the upper surface of the sealing cover 5 and the sealing groove 4 is an air extraction channel; the inner surface of the sealing groove 4 is coated with metal paste, and then sent into a tempering furnace to temper the upper and lower glass, or directly use low-temperature glass solder in the normal Edge sealing is carried out on the upper...

Embodiment 2

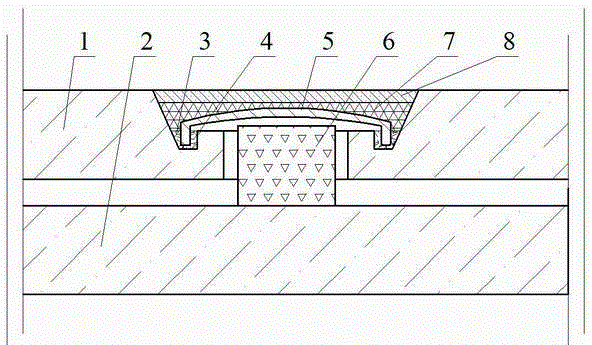

[0060] Example 2: see figure 2 , basically the same as in Example 1, the difference is that the sealing groove 4 is changed into a V-shaped groove, the metal solder 3 is changed into a zinc alloy, and the metal solder 3 is condensed into a solid to realize airtight sealing of the air inlet, and then the vacuum heating furnace is opened. Take out the vacuum glass. Put into the sealant 7 such as butyl glue in the suction port while it is hot, the top of the sealant 7 covers the product trademark 8, and the trademark 8 is flush with the upper surface of the upper glass 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com