Vacuum glass getter placement structure and manufacturing method thereof

A technology of vacuum glass and getter, which is used in glass forming, glass re-forming, glass manufacturing equipment and other directions to achieve the effect of improving heat insulation, high vacuum degree and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

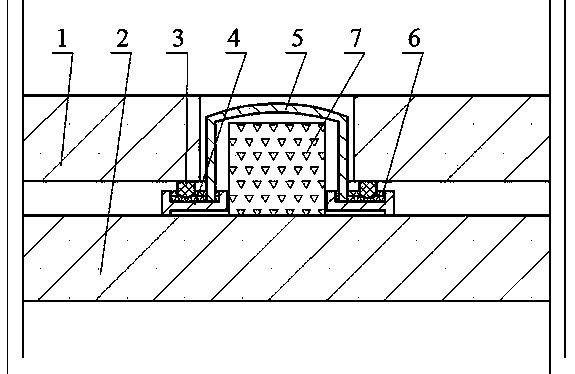

[0044]Embodiment: Referring to the accompanying drawings, the vacuum glass is composed of an upper glass 1 and a lower glass 2. A through hole is drilled on the upper glass 1 to form an air extraction port, and a sealing ring 3 concentric with the air extraction port is made on the lower surface of the upper glass 1. Place an annular sealing box 4 concentric with the air inlet on the upper surface of the glass 2, the sealing ring 3 of the upper glass 1 can be inserted in the annular sealing box 4; according to the size of the annular sealing box 4, make a sealing cover 5 again, the sealing cover The edge portion of 5 can be inserted into the annular sealing box 4, and the height of the sealing cover 5 is lower than the upper surface of the upper glass 1; the upper and lower glasses are tempered, or the upper and lower glasses after being combined in an atmospheric pressure and high temperature furnace are directly used with low temperature glass solder. The glass is edge-sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com