High-rotating-speed pulling motor

A traction motor, high-speed technology, applied in the field of lubricating and sealing structure, high-speed traction motor, can solve the problems of easy damage to the transmission end bearing, affecting the lubrication effect, oil channeling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

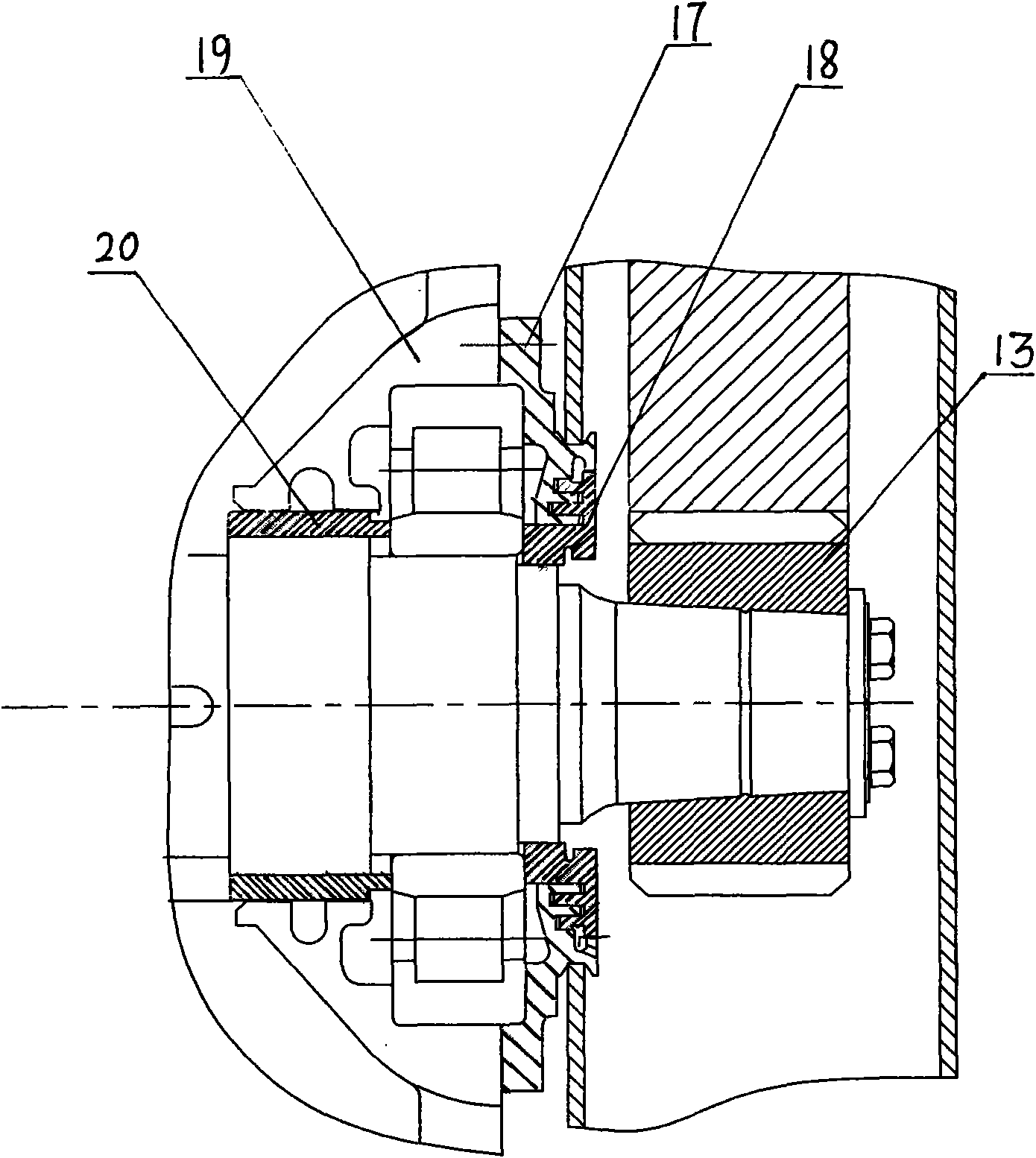

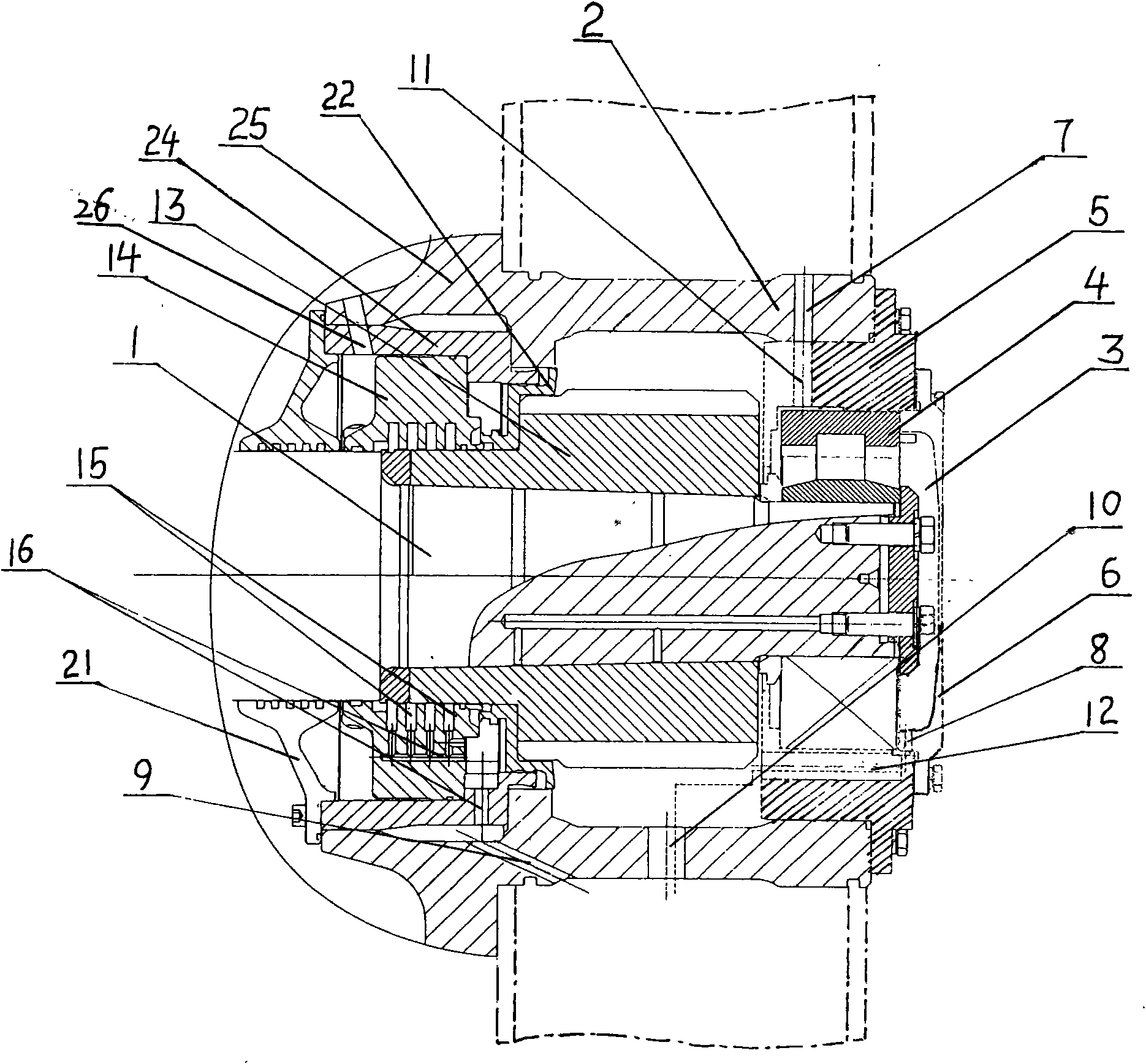

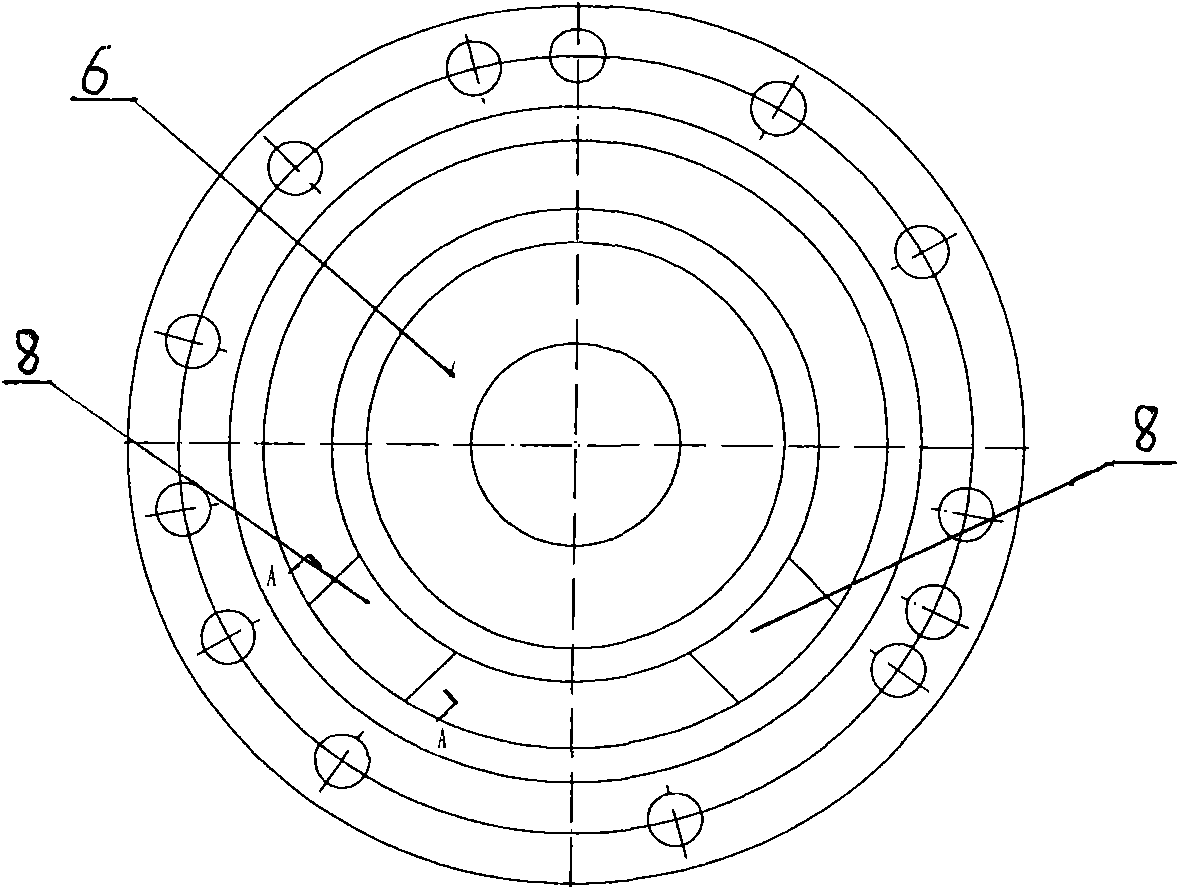

[0015] The high-speed traction motor includes a rotor shaft 1 and an end cover 25. The center of the end cover 25 is provided with a cylindrical sleeve 2 protruding forward. The front end of the rotor shaft 1 is placed in the cylindrical sleeve 2 through a bearing 4. The bearing 4 is sleeved with The bearing inner cover 5 fixed at the front end of the cylindrical sleeve 2, the bearing outer cover 6 fixed on the bearing inner cover 5 is pressed on the front end surface of the bearing 4, the pinion 13 fixed on the rotor shaft 1 is arranged on the rear side of the bearing 4, the pinion 13 is composed of the transmission gear part at the front and the shaft sleeve part at the rear. The cylindrical surface of the cylindrical sleeve 2 has an arc-shaped transmission hole 23 corresponding to the position of the transmission gear of the pinion 13; the top of the cylindrical sleeve 2 has an oil inlet port. Hole 7, the bearing inner cover 5 is provided with an oil through hole 11 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com