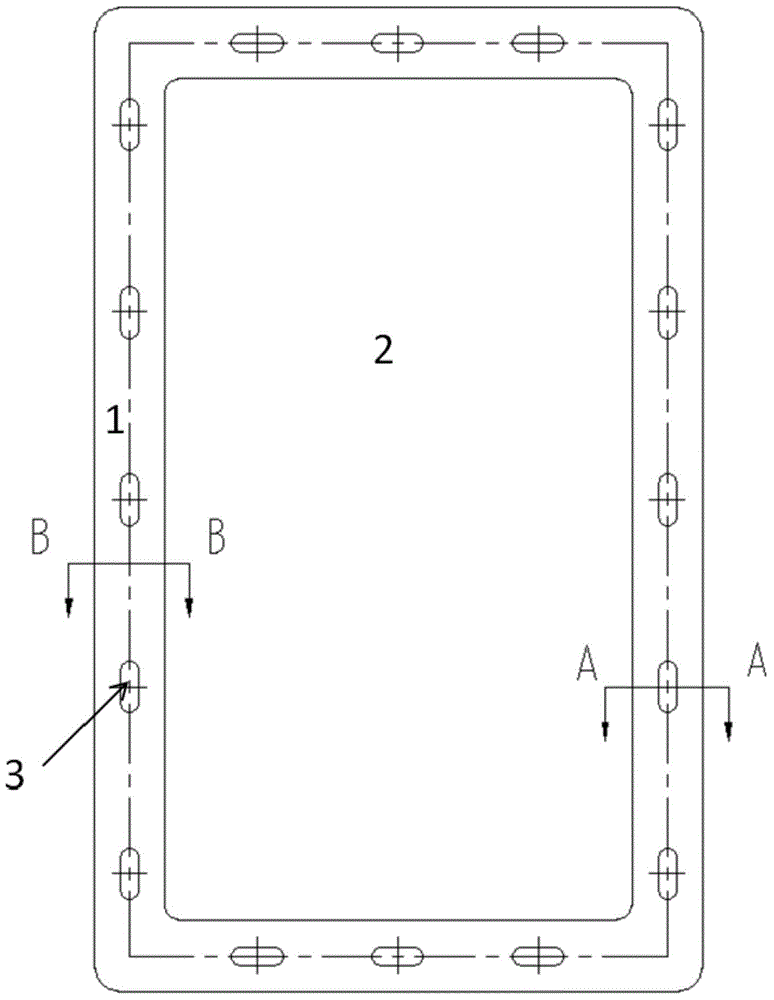

High-reliability thin bipolar plate sealing structure

A technology of sealing structure and bipolar plate, which is used in fuel cell parts, fuel cell additives, fuel cells, etc. Electrode physical structure failure and other problems, to achieve the effect of preventing short circuit between metal thin bipolar plates, convenient positioning and placement, and preventing single cell overvoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

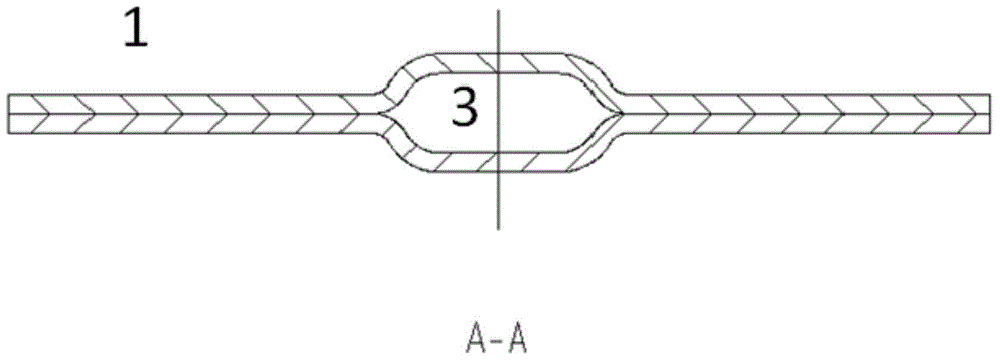

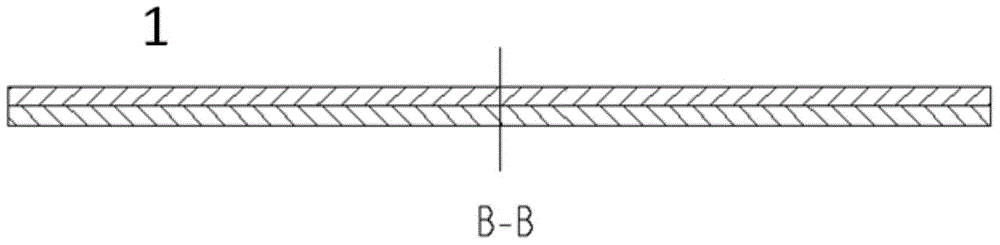

[0032] The sealing area 1 of the thin bipolar plate is a planar structure, and the width of the sealing area 1 is 3.0mm. The protrusion 4 of the cathode plate and the protrusion 3 of the anode plate are circular with the same shape and a diameter of Φ1.0mm. The height is 0.5mm, the pole plate protrusions are arranged equidistantly, and the outer edge interval of the pole plate protrusions is 10mm; the thickness of the cathode plate side seal 8 and the anode plate side seal 7 is 1.0mm; the width of the seals on both sides of the cathode and anode plates is equal, The outer edge of the thin bipolar plate protruding from both sides of the sealing sheet is 1.0 mm; the convex and concave sealing structure on both sides of the sealing sheet is a dovetail groove and a dovetail structure, the quantity is 1, and it is connected by pressurizing the tooling; the material of the sealing sheet is engineering plastics.

Embodiment 2

[0034] The sealing area 1 of the thin bipolar plate is a planar structure, the width of the sealing area 1 is 10.0 mm, the cathode plate protrusion 4 and the anode plate protrusion 3 are dislocated rectangles, the length of the rectangle is 1.0 mm, the width is 3.0 mm, and the height is 0.5mm, the electrode plate protrusions are arranged at equal distances, and the outer edge of the electrode plate protrusions is spaced at 50mm; the thickness of the cathode plate side sealing sheet 8 and the anode plate side sealing sheet 7 is 0.5mm; the sealing sheets on both sides of the cathode and anode plates are equal in width, The outer dimension of the side protruding thin bipolar plate is 5.0mm; the convex and concave sealing structures on both sides of the cathode and anode plates are circular grooves and round protrusions, two in number, connected by zipper; the material of the sealing sheet is expanded graphite.

Embodiment 3

[0036] The sealing area 1 of the thin bipolar plate is a planar structure, and the width of the sealing area 1 is 8.0mm. The protrusion 4 of the cathode plate and the protrusion 3 of the anode plate are dislocated and different shapes. The shape of the protrusion 4 of the cathode plate is It is a circle with a diameter of Φ1.0mm. The shape of the anode plate protrusion 3 is a rectangle, the rectangle is 0.5mm long and 0.2mm wide, and the height of the pole plate protrusion is 0.3mm. The pole plate protrusions are arranged equidistantly. The distance between the protruding outer edge of the plate is 20mm; the thickness of the sealing sheet 8 on the side of the cathode plate and the sealing sheet 7 on the side of the anode plate is 2.0mm; the width of the sealing sheets on both sides of the cathode and anode plates is equal, and the outer edge of the thin bipolar plate is 3.0mm; The convex and concave sealing structures on both sides of the sealing sheet are dovetail grooves and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com