Novel batched type circulated drying machine

A cycle drying and batch-type technology, applied in dryers, grain drying, drying solid materials, etc., can solve the problems of increasing maintenance and monitoring difficulty, reducing drying efficiency, and many equipment applications, so as to facilitate the dismantling and assembly process, The effect of avoiding stuttering and improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

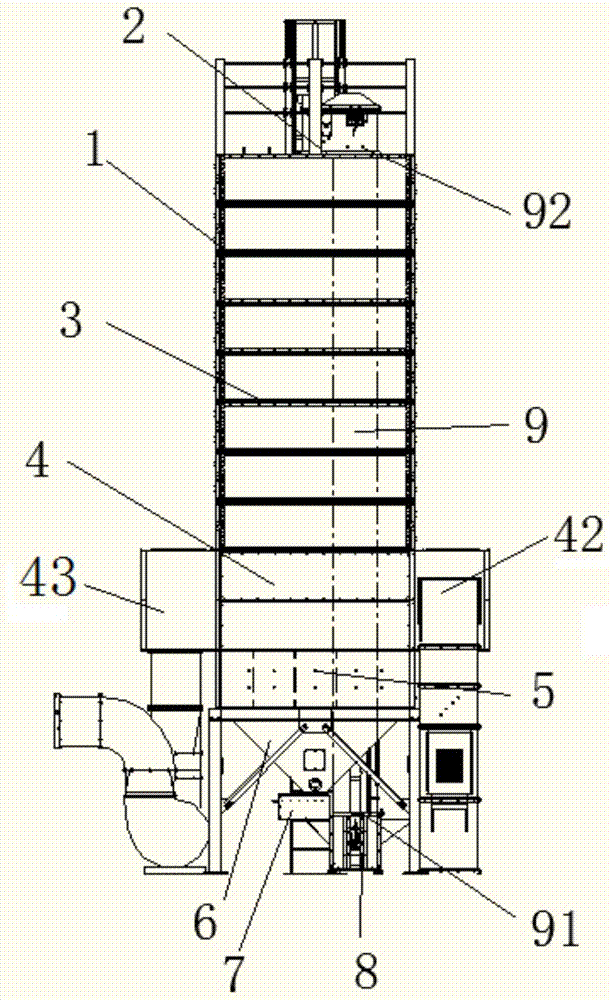

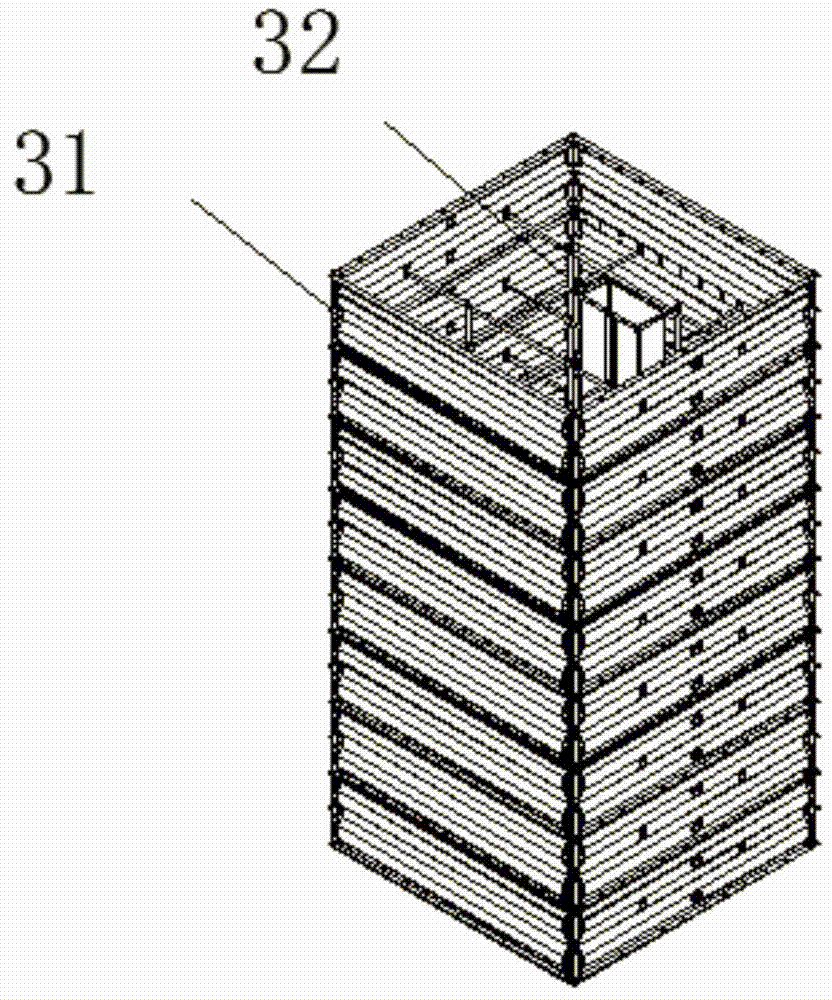

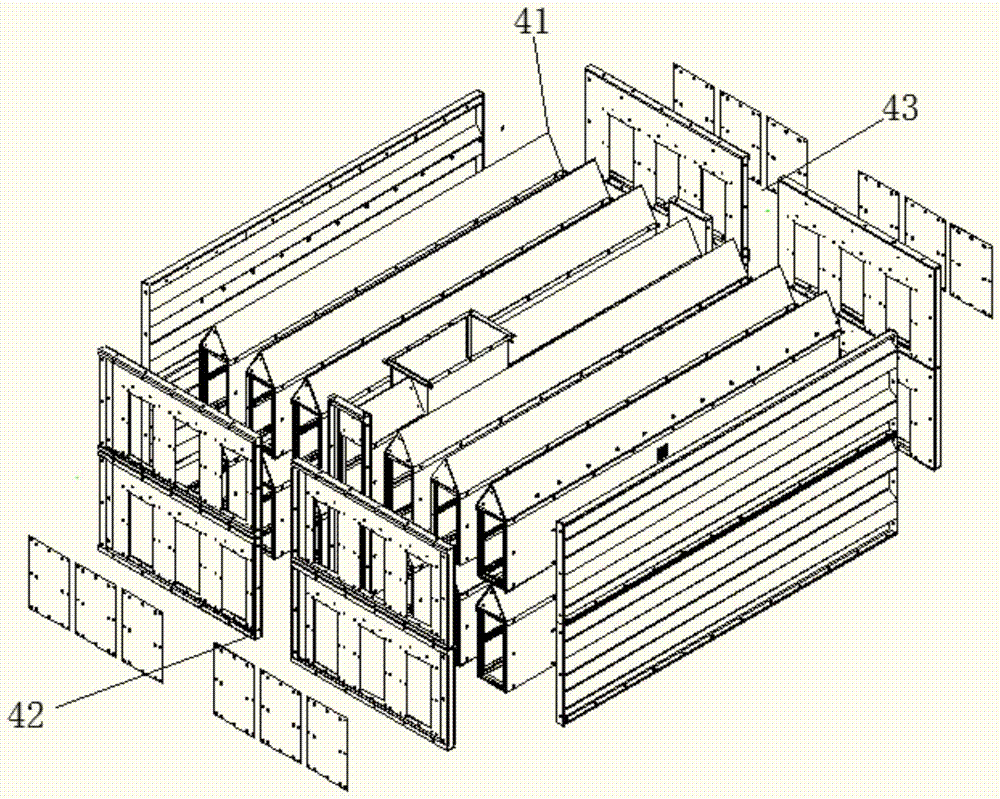

[0037] The upper end of the shell 1 of the dryer is provided with a feed port 2, at this time, the material can be poured into the dryer 1 from the feed port 2 through an external feeding mechanism, and the staff can also be used to dump it. The material entering from the feeding port 2 enters the material storage part 3 . The storage part 3 is composed of 32 identical storage side plates 31 to form four end faces. At this time, each end face is formed by connecting 8 storage side plates 31 side by side by bolts. The four end surfaces surround and form a storage area 32 . The four end faces are connected by bolts. When moving the position of the storage unit 3 , the connecting bolts can be removed to release the connection relationship between the storage side plates 31 , and then disassembled, which facilitates the transportation of the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com