Sheet cropping equipment

A cutting and equipment technology, used in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of labor and man-hours, low production efficiency, poor products, etc., to avoid manufacturing, facilitate the replacement of equipment, save money The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

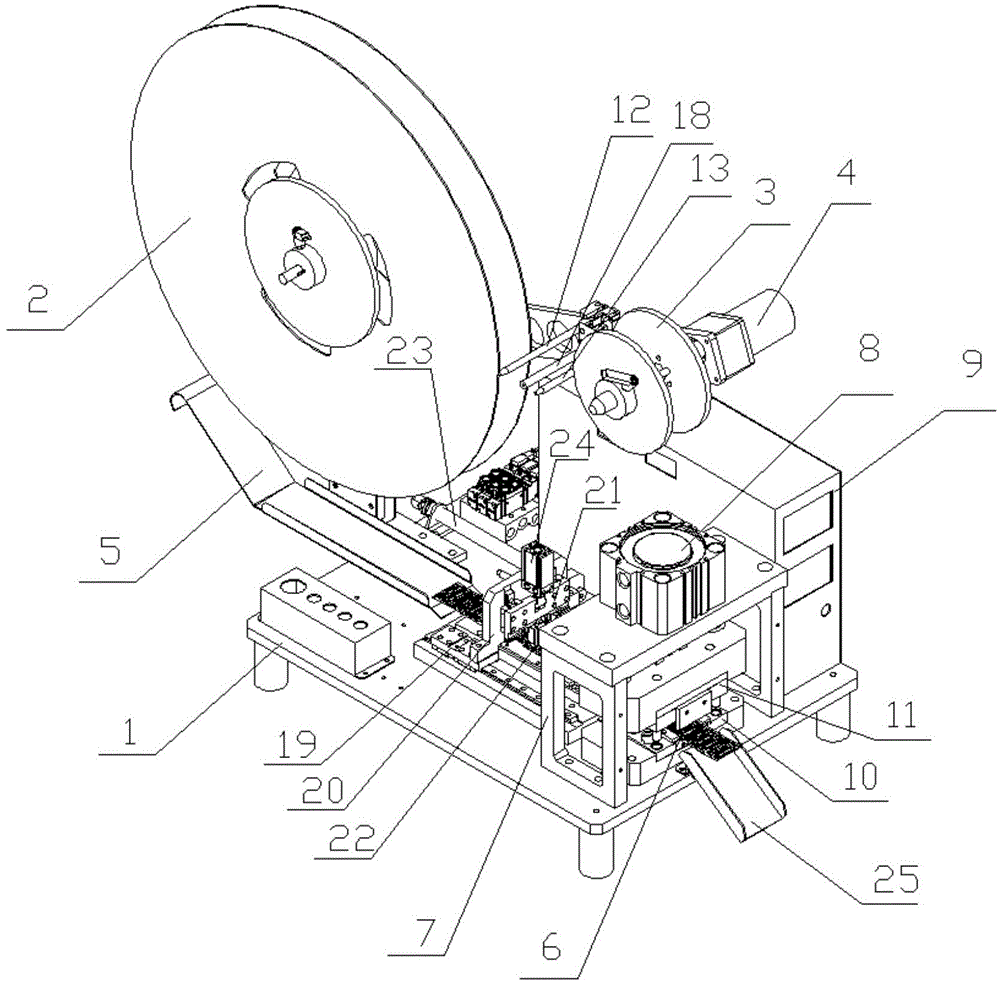

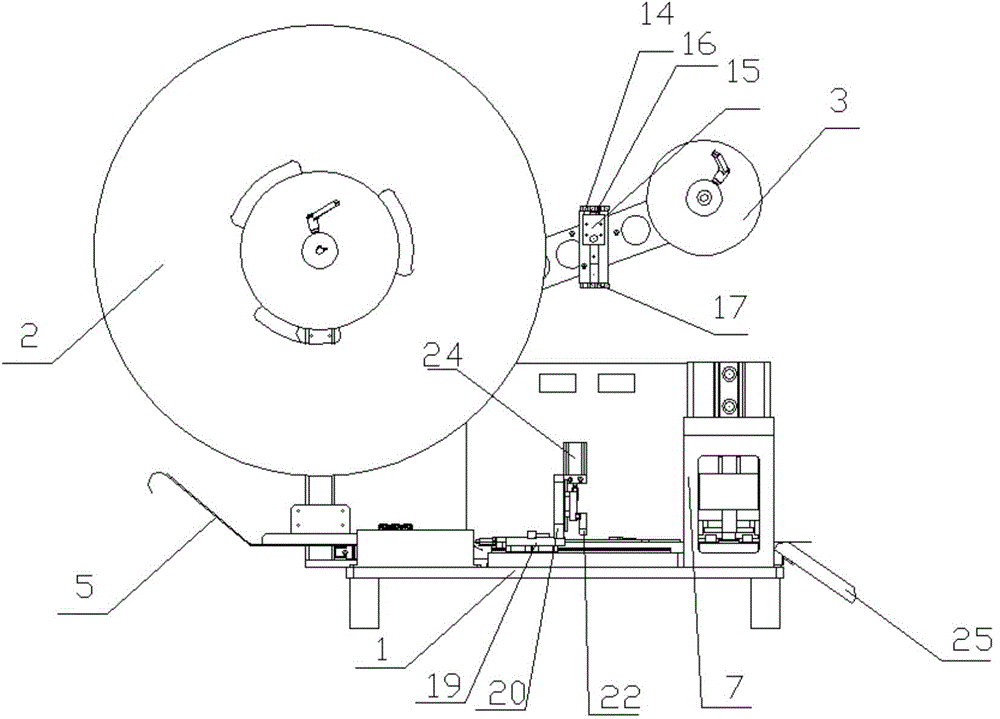

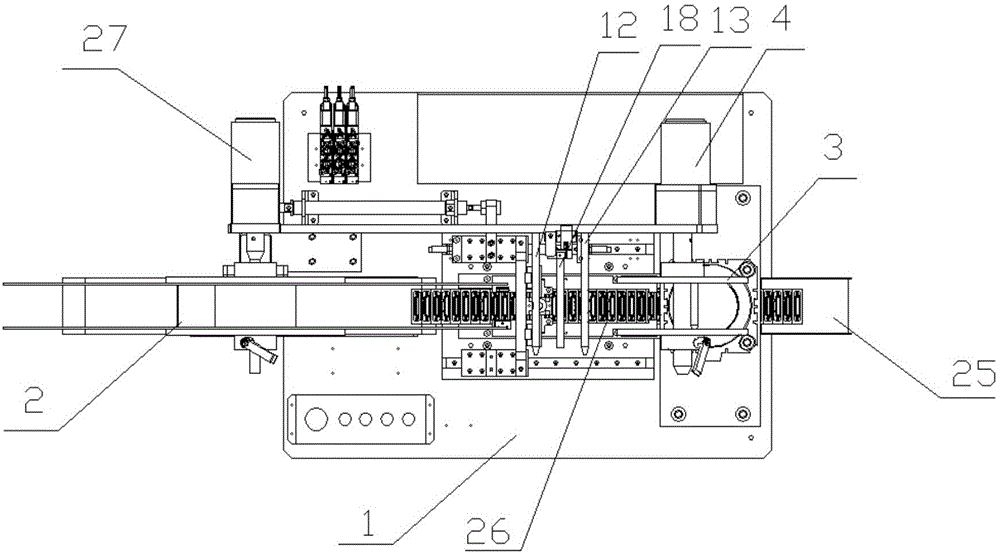

[0017] Embodiment: A kind of sheet material cutting equipment, comprises workbench 1, material tray 2, material tray support 20, paper tray 3, paper tape tension state sensing device, paper tray driving device 4, material tray driving device 27, material Belt track 5, material belt conveying channel 6, material pulling device, stamping die 7, material pulling driving device, punching driving device 8 and controller 9, the material tray bracket 20 is fixedly installed above one end of the workbench 1, and the material tray 2 and the paper tray 3 can be rotated and positioned on the tray support 20 respectively, the tray driving device 27 drives the tray 2 to rotate, the tray 2 is wound with a material tape wrapped with paper tape, and the tray driving device 4 drives the tray 3 to rotate , the paper tape tension state sensing device can sense the tension of the material tape pulled out from the material tray 2 into the paper tray 3 and send a letter to the controller 9. The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com