Method and Apparatus for Manufacturing Asymmetrical Roll-Formed Sections

a technology of asymmetrical roll-formed sections and rolling stands, which is applied in the field of rolling, can solve problems such as twisting, bowing, and other defects, and achieve the effect of improving the structure of the rolling stand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

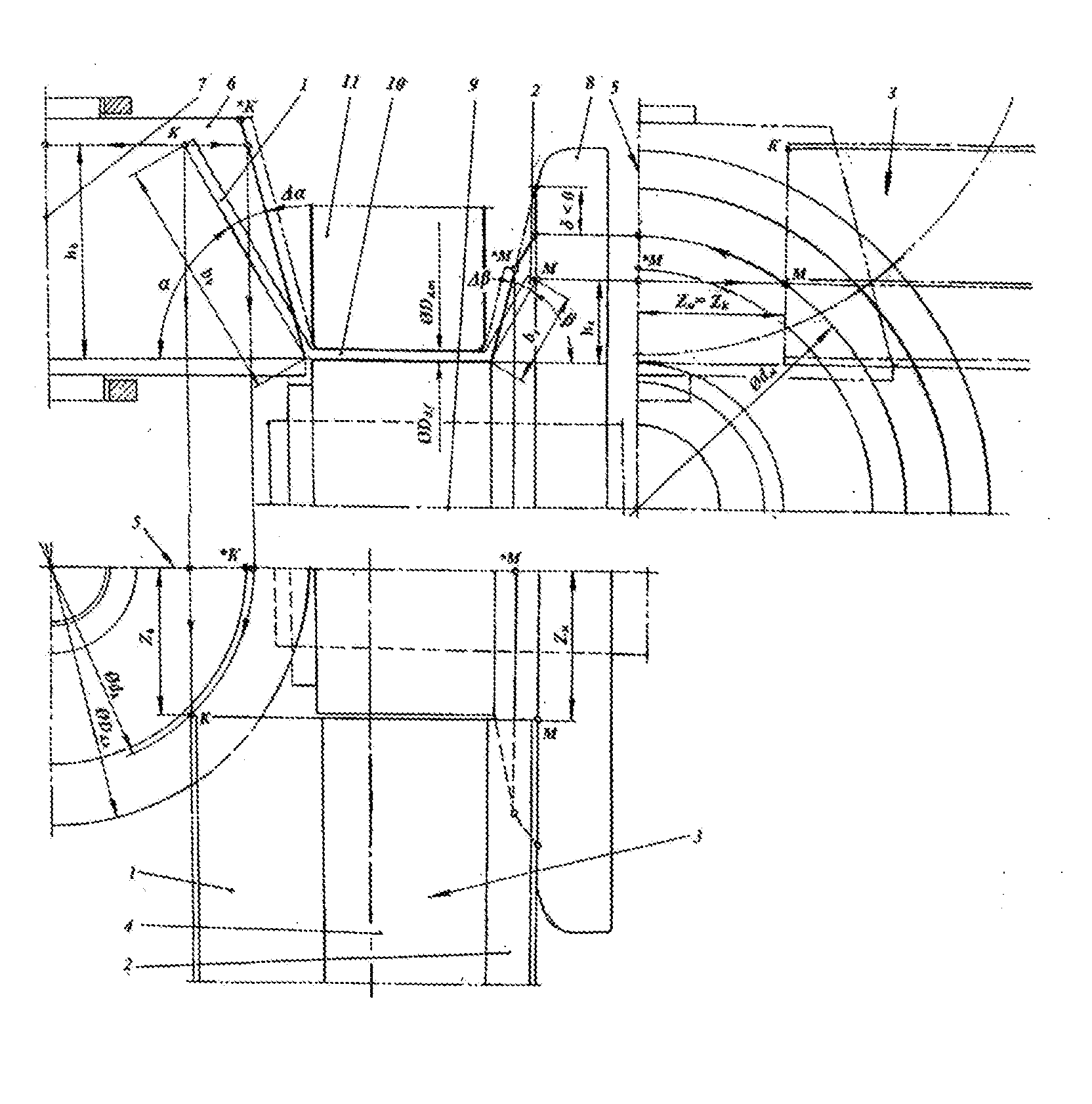

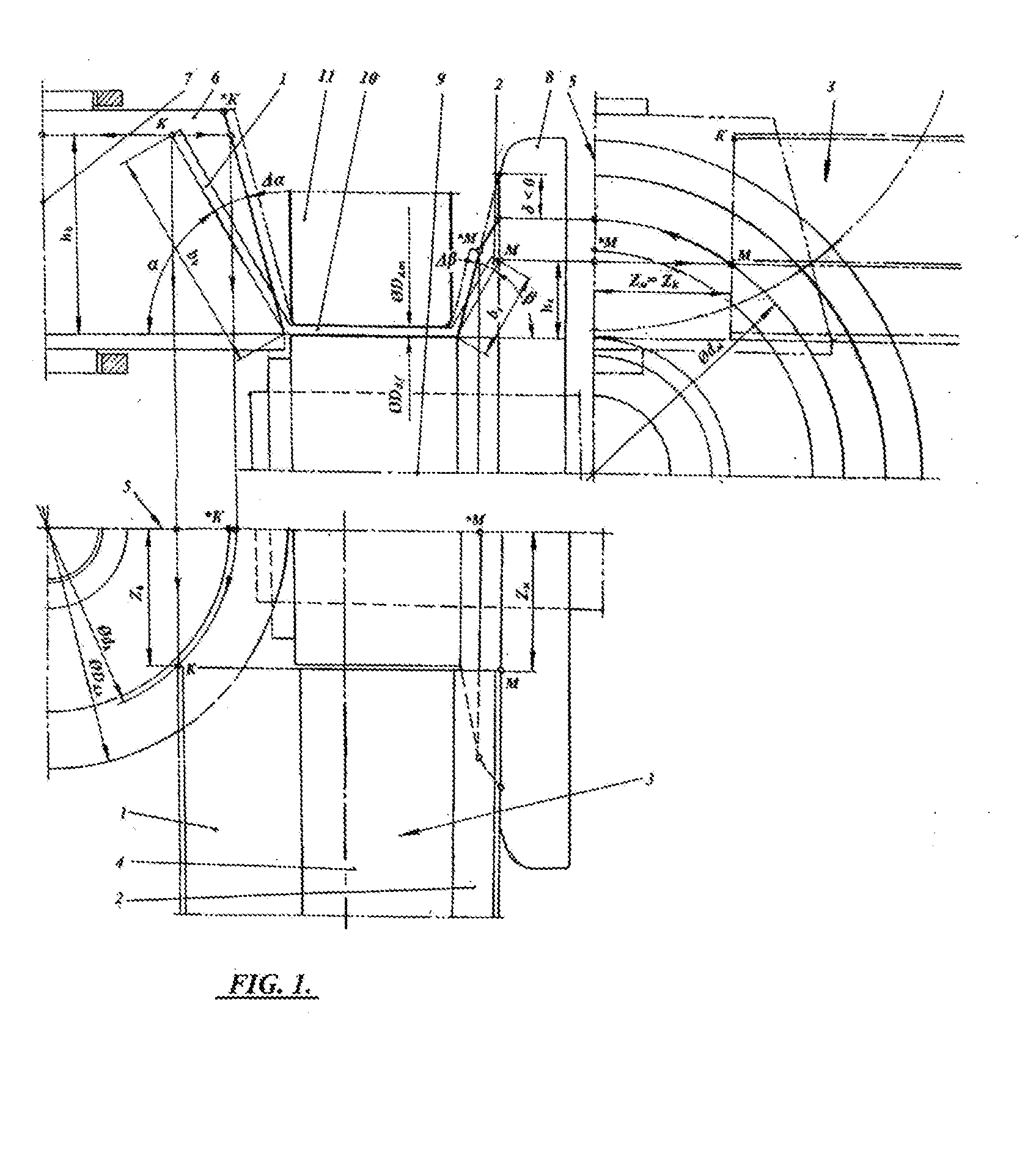

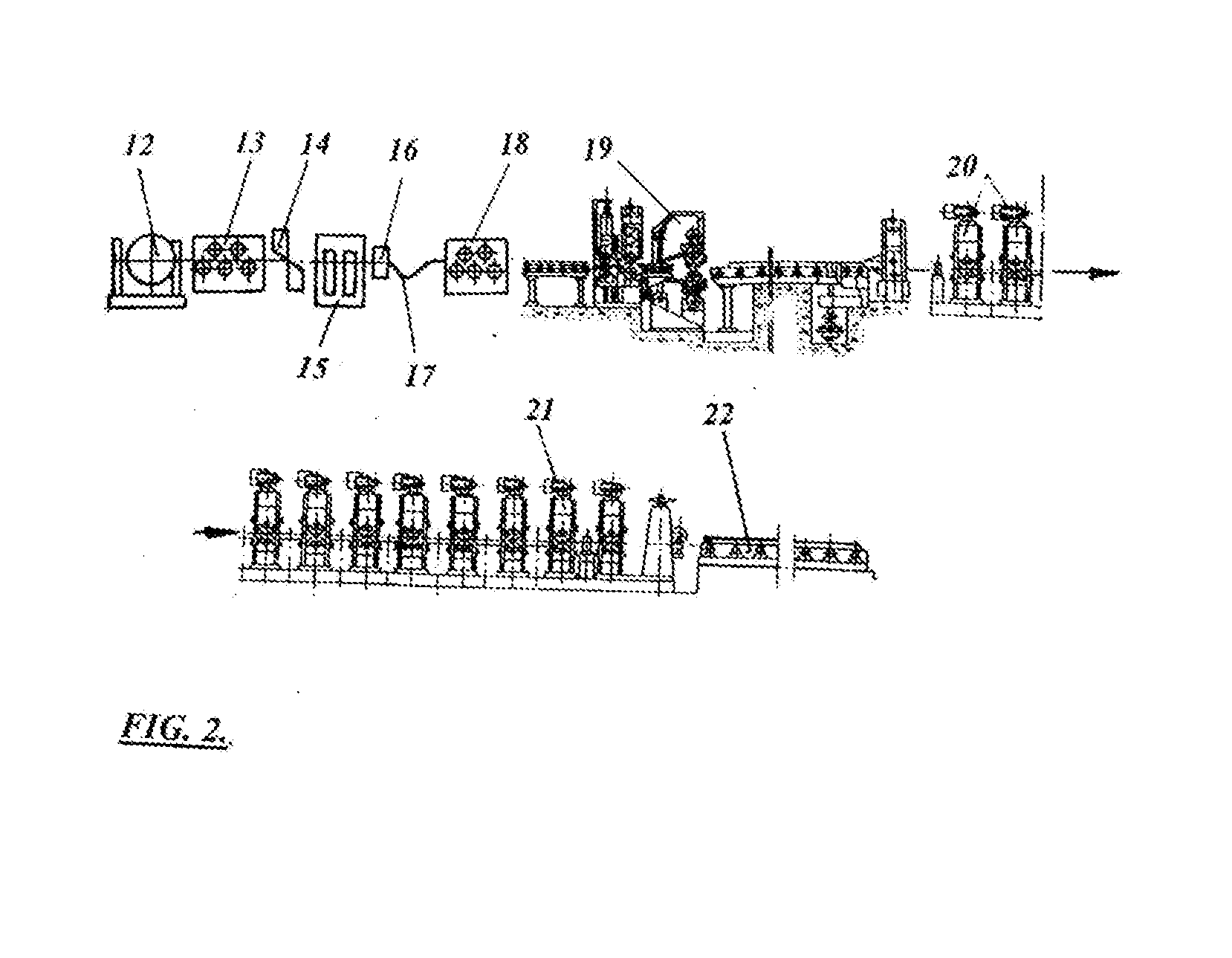

[0022]A method of manufacturing an unequal-flange channel section profile is described below as the preferred embodiment. It is to be understood that the invention is not limited to that particular profile, but is applicable to any other asymmetrical profile. FIG. 1 shows an intermediate stage in roll-forming an unequal-flange channel section profile 3. The longer flange 1 and the shorter flange 2 are bent in relation to the central region 4. The contact between the longer flange 1 and its forming roll is simultaneous with the contact between the shorter flange 2 and its forming roll. Also, the point of initial contact between the longer flange 1 and its forming roll is equidistant from plane 5 to the point of initial contact between the shorter flange 2 and its forming roll. The roll used to bend the longer flange 1 is the vertical female roll 6 (its vertical axis of rotation is 7), and the roll used to bend the shorter flange 2 is the horizontal female roll 8 (its horizontal axis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com