Forming method for instantly-molded decorating concrete component

A technology for decorative concrete and molding method, which is applied to ceramic molding machines, manufacturing tools, etc., can solve problems such as bending and modeling of concrete components, and achieve the effect of saving production costs and shortening production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

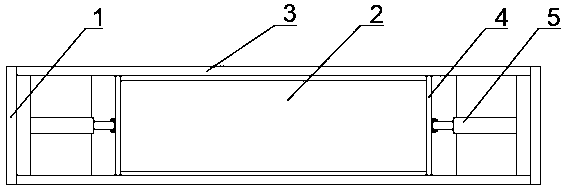

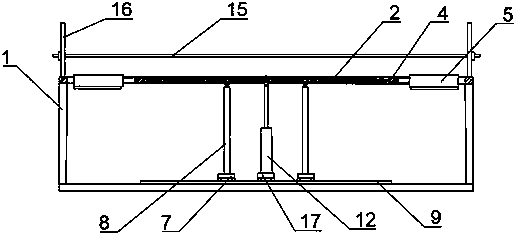

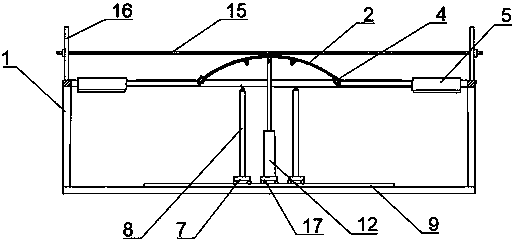

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] A method for forming a decorative concrete component of instant modeling comprises the following steps:

[0030] Step 1: Make the archetype;

[0031] The design shape of the concrete member is unfolded in a plane, and the shape obtained by the planar expansion is used to cut or splice the bottom form. Grinding to make the surface of the bottom form smooth and flat, and coating a layer of petrolatum on the surface of the bottom form to facilitate subsequent demoulding. The thickness of the bottom form is equal to the thickness of the concrete member, and then the bottom form is placed on the horizontal plate, and The shape of the bottom mold along the four sides of the bottom mold adds the enclosure to obtain the base mold; the gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com