Air supplementing and stirring device for biological fertilizer

A technology of mixing device and biological fertilizer, which is applied in fertilization device, biological organic part treatment, organic fertilizer and other directions, can solve the problems of high maintenance and labor costs, and achieve the effect of low production cost and good linkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through specific implementations:

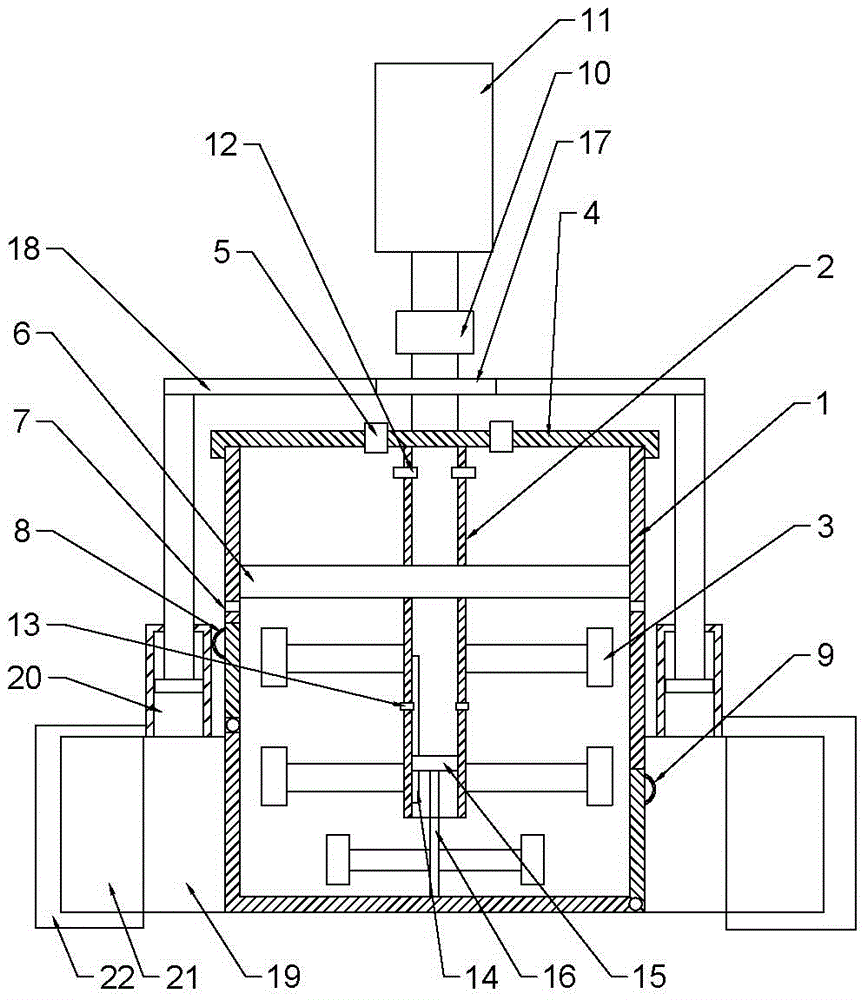

[0015] The reference signs in the drawings of the specification include: stirring tank 1, stirring rod 2, stirring paddle 3, sealing cover 4, first one-way air inlet valve 5, first piston plate 6, through hole 7, first hinge door 8. The second hinge door 9, the spline sleeve 10, the stepping motor 11, the second one-way air inlet valve 12, the one-way air outlet valve 13, the rib 14, the second piston plate 15, the rotating shaft 16, the collar 17 , Connecting rod 18, water bag 19, piston pump 20, water tank 21, refrigerator 22.

[0016] Example basic reference figure 1 Shown: Biological fertilizer supplemental gas fermentation stirring device, including stirring tank 11, stirring rod 2 and stirring paddle 3. The stirring rod 2 is set in the stirring tank 11, the upper end of the stirring tank 11 is screwed with a sealing cover 4, and the sealing cover 4 is arranged There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com