Linkage compressed type multihole drilling tool

A compact, multi-hole drilling technology, used in drilling/drilling equipment, manufacturing tools, components of boring machines/drilling machines, etc. Production and use, etc., to achieve the effect of good linkage effect, good cutting quality, and reduction of auxiliary production man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to accompanying drawing.

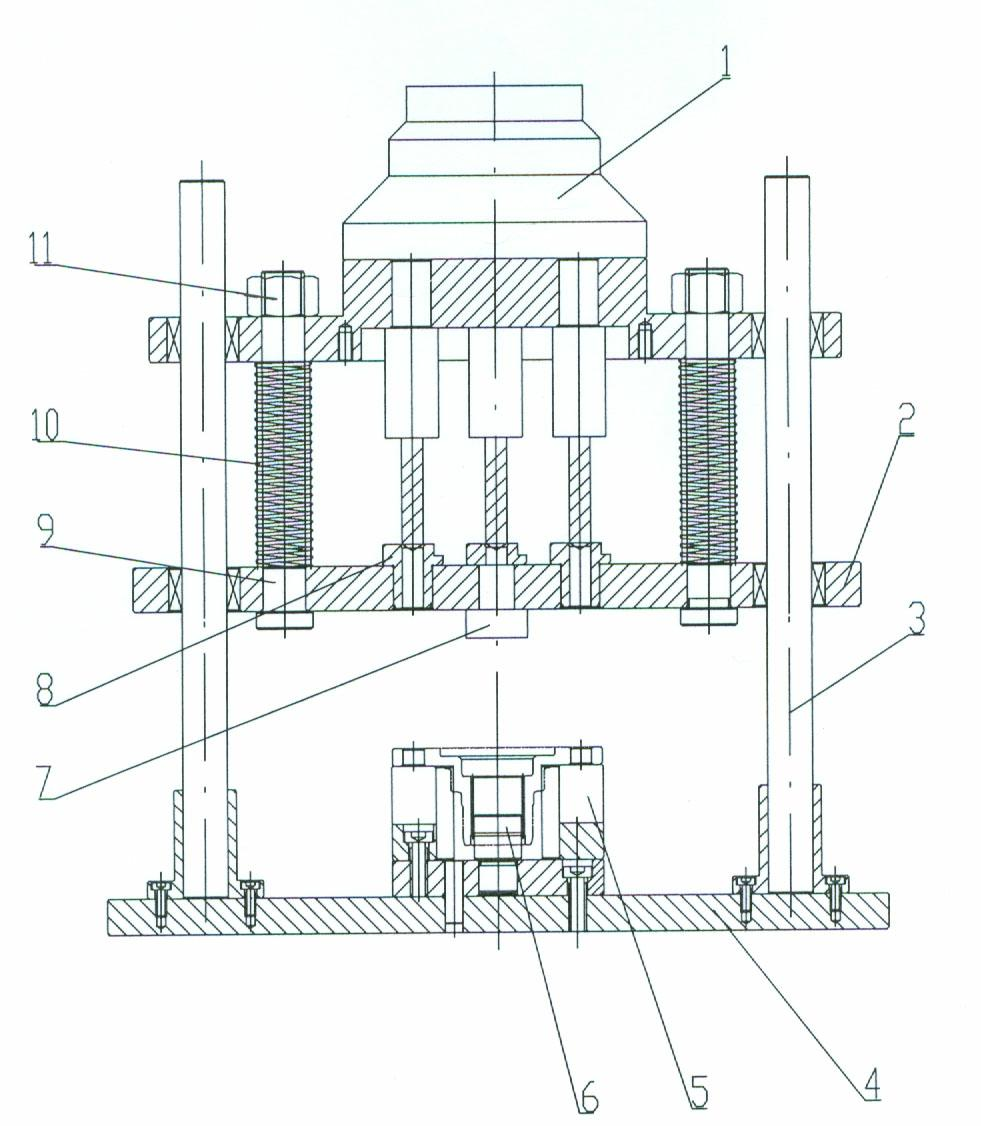

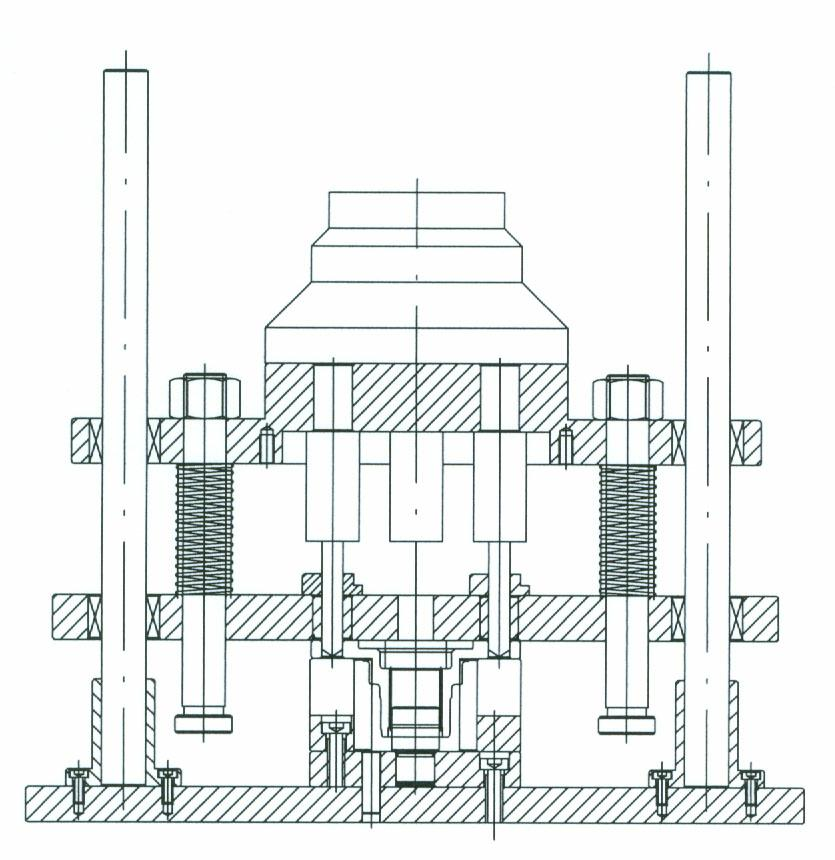

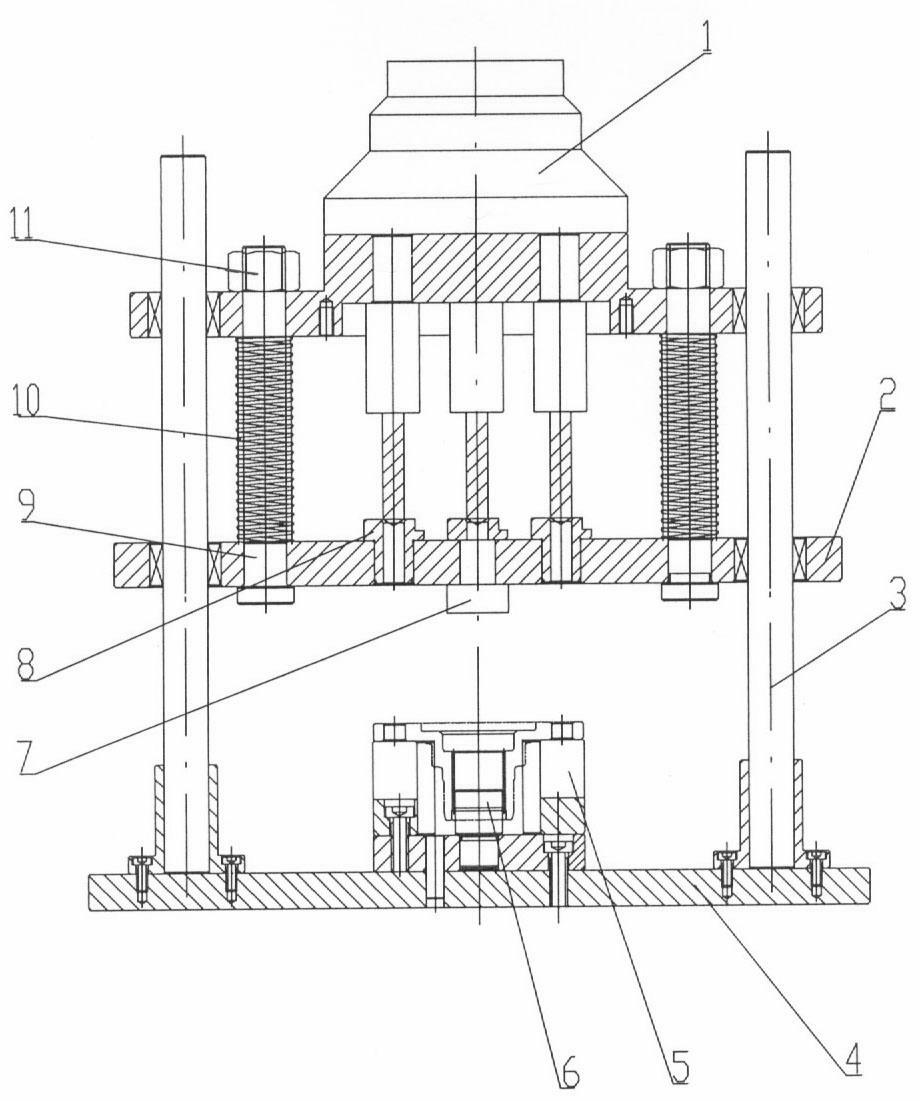

[0013] figure 1 The linkage compression multi-hole drilling tool shown is a structural schematic diagram when the workpiece is to be positioned and installed or the processed workpiece is to be taken. It includes a multi-axis drill chuck 1, a template 2, a guide rod 3, a base 4, a pad 5, a positioning Mandrel 6, pressure head 7, drill sleeve 8, small shaft 9, spring 10 and nut 11. Both sides of the base plate 4 at the bottom are respectively provided with vertical guide rods 3, and the middle part is provided with an upward positioning mandrel 6. The outer diameter of the positioning mandrel 6 is equal to the size of the inner hole of the workpiece, and the two are in clearance fit. Both sides of the positioning mandrel 6 are provided with spacers 5 of equal height, and the axis of the positioning mandrel 6 is perpendicular to the upper plane of the spacer 5 . The multi-axis dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com