Rubber-covered roller laser detector

A detector and laser technology, used in instruments, measuring devices, optical devices, etc., can solve the problems of printed matter wrinkles, large measurement errors, and low product qualification rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

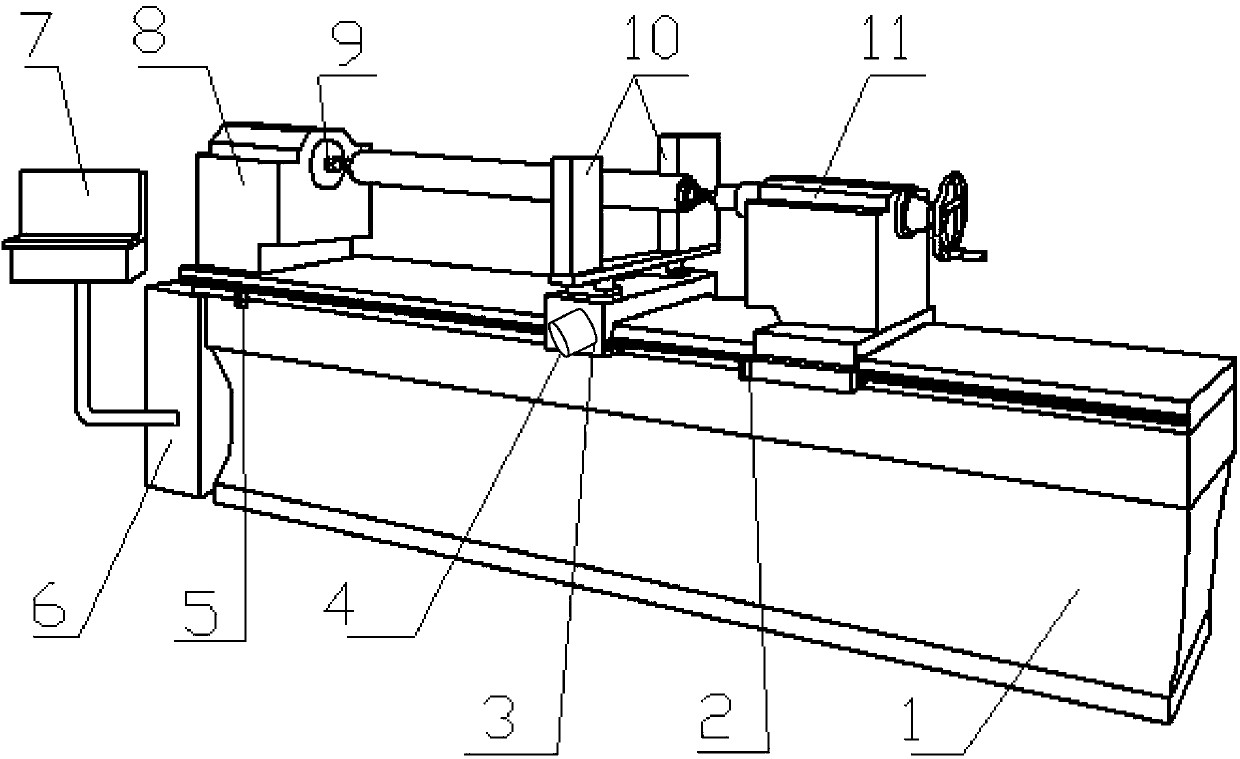

[0024] A rubber roller laser detector, combined with figure 1 , comprising a bed 1 and a tailstock 11, one end of the bed 1 is provided with a headstock 8, the headstock 8 is provided with a workpiece-driven stepping motor 9, and the workpiece-driven stepping motor 9 is connected with the workpiece chuck, One side of bedside box 8 is provided with distribution box 6, operation box 7, and distribution box 6 is electrically connected with operation box 7, and distribution box 6 is connected with power supply, and lathe bed 1 other side is provided with tailstock 11, described A detection frame 4 is provided between the headstock 8 and the tailstock 11, and a laser detector 10 is arranged on the detection frame 4. The detection frame 4 is matched with the bed 1 as a linear guide rail, and the detection frame 4 moves with the measuring head. The stepping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com