High-performance anti-cracking anticorrosive water reducing agent composition and preparation method thereof

A composition and high-performance technology, applied in the field of water reducing agent compositions, can solve the problems of ineffectiveness and high energy consumption in the improvement and improvement of anti-cracking and anti-corrosion properties, achieve excellent economic and social benefits, reduce production costs, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

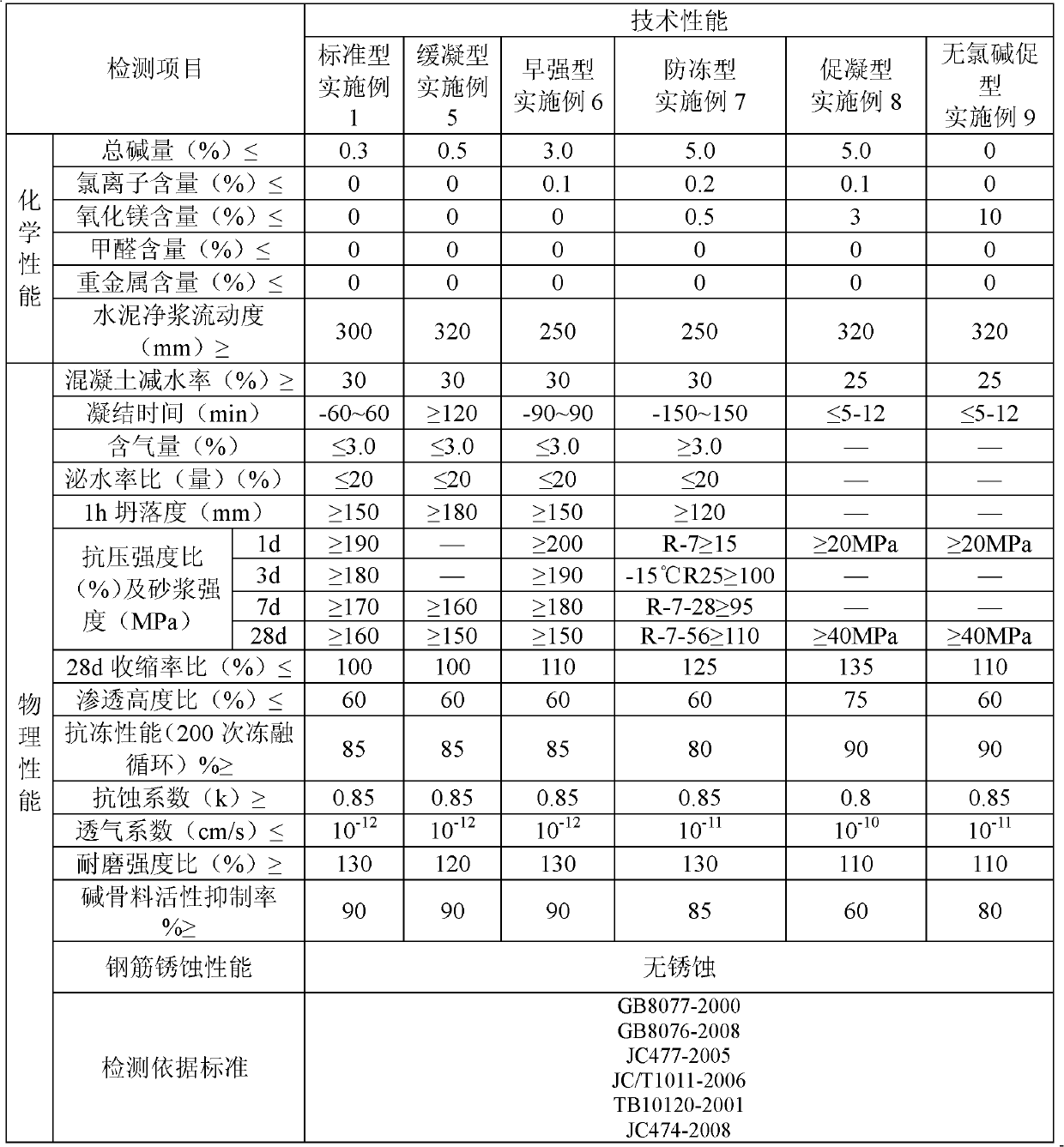

[0028] Standard high-performance anti-crack anti-corrosion water reducer

[0029] The proportion of the standard high-performance anti-cracking anti-corrosion water-reducing agent is: 35 parts by weight of allyl polyethylene glycol, 6.0 parts by weight of hydroxyethyl acrylate, 0.2 parts by weight of mercaptopropionic acid, 0.15 parts by weight of ammonium persulfate, vitamin C0. 15 parts by weight, 5.0 parts by weight of magnesium sulfate, 3.0 parts by weight of sodium hydroxide and 50.5 parts by weight of water.

[0030] Take the production of 10000kg product as an example:

[0031] Add 3315kg tap water in the jacketed pot reactor of 10 tons (10000L), start agitator, add allyl polyethylene glycol 3500kg, pass into nitrogen, after making the material all dissolve, add ammonium persulfate solution 95kg (by persulfate Ammonium 15kg+tap water 80kg miscible), stirred for 5 minutes, added dropwise No. 1 solution (made by mercaptopropionic acid 20kg+vitamin C15kg+tap water 315kg m...

Embodiment 2

[0033] Standard high-performance anti-crack anti-corrosion water reducer

[0034] The ratio of standard high-performance anti-cracking anti-corrosion and water-reducing agent can also be:

[0035] 30 parts by weight of polyoxypropylene ether, 6.0 parts by weight of polyethylene glycol monomethyl ether, 5.0 parts by weight of methyl methacrylate, 0.3 parts by weight of mercaptopropionic acid, 0.2 parts by weight of hydrogen peroxide, 0.2 parts by weight of Antioxidant 168 type, 6.0 parts by weight of zirconium sulfate, 4.0 parts by weight of potassium hydroxide and 48.3 parts by weight of water.

[0036] Take the production of 10000kg product as an example:

[0037] In the jacketed pot reactor of 10000L, add deionized water 3111kg, start agitator and drop into polyoxypropylene ether 3000kg, polyethylene glycol monomethyl ether 600kg, pass into nitrogen, after making material dissolve, add hydrogen peroxide 99kg (by Hydrogen peroxide 20kg+deionized water 79kg), stirred for 5 m...

Embodiment 3

[0039] Standard high-performance anti-crack anti-corrosion water reducer

[0040] The ratio of standard high-performance anti-cracking anti-corrosion and water-reducing agent can also be:

[0041] 33 parts by weight of allyl polypropylene glycol, 5.0 parts by weight of butyl methacrylate, 0.3 parts by weight of thioglycolic acid, 0.2 parts by weight of hydrogen peroxide, 0.2 parts by weight of vitamin E, 6.0 parts by weight of aluminum sulfate, 3.0 parts by weight of sodium carbonate, 52.3 parts by weight of deionized water.

[0042] Take the production of 10000kg product as an example:

[0043] Add 3511kg of deionized water into the 10000L jacketed kettle, start the agitator and put in 3300kg of allyl polypropylene glycol, feed nitrogen, after the material is dissolved, add 99kg of hydrogen peroxide (by hydrogen peroxide 20kg+deionized water 79kg ), stirred for 5 minutes, added dropwise No. 4 solution 400kg (made by thioglycolic acid 30kg+vitamin E20kg+deionized water 350kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com