On-line cargo stacking method based on under-complete information

A kind of cargo and complete technology, applied in the field of online cargo palletizing with incomplete information, can solve the problems of increased cost and low palletizing efficiency, and achieve the effect of reducing enterprise production cost, improving operation efficiency and improving automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

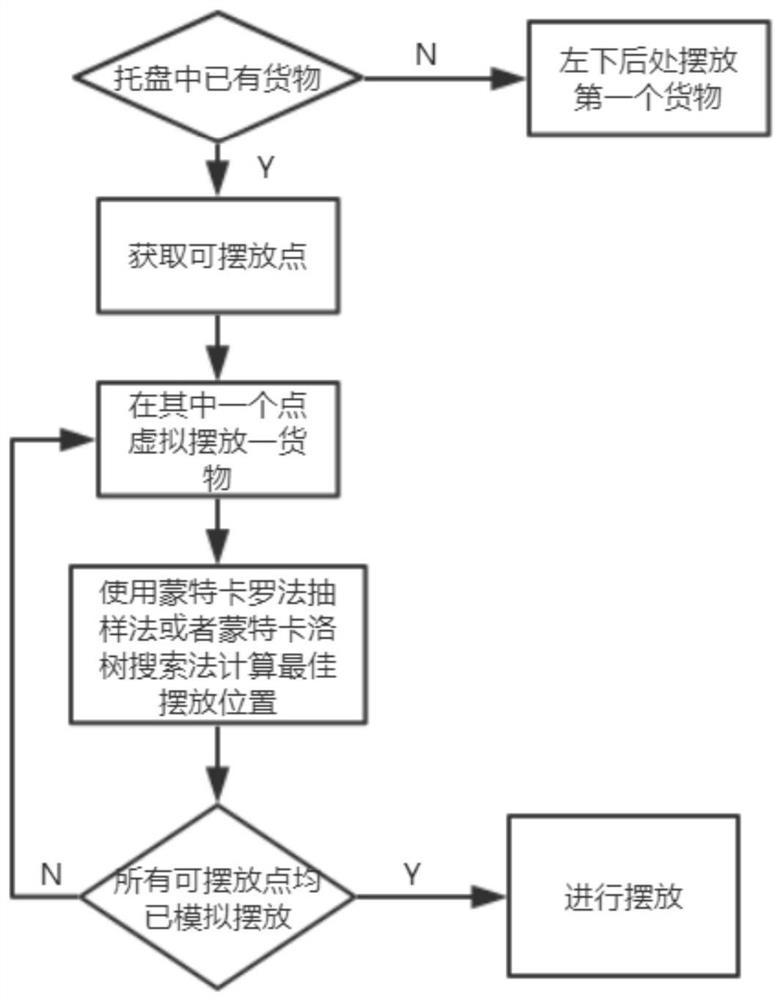

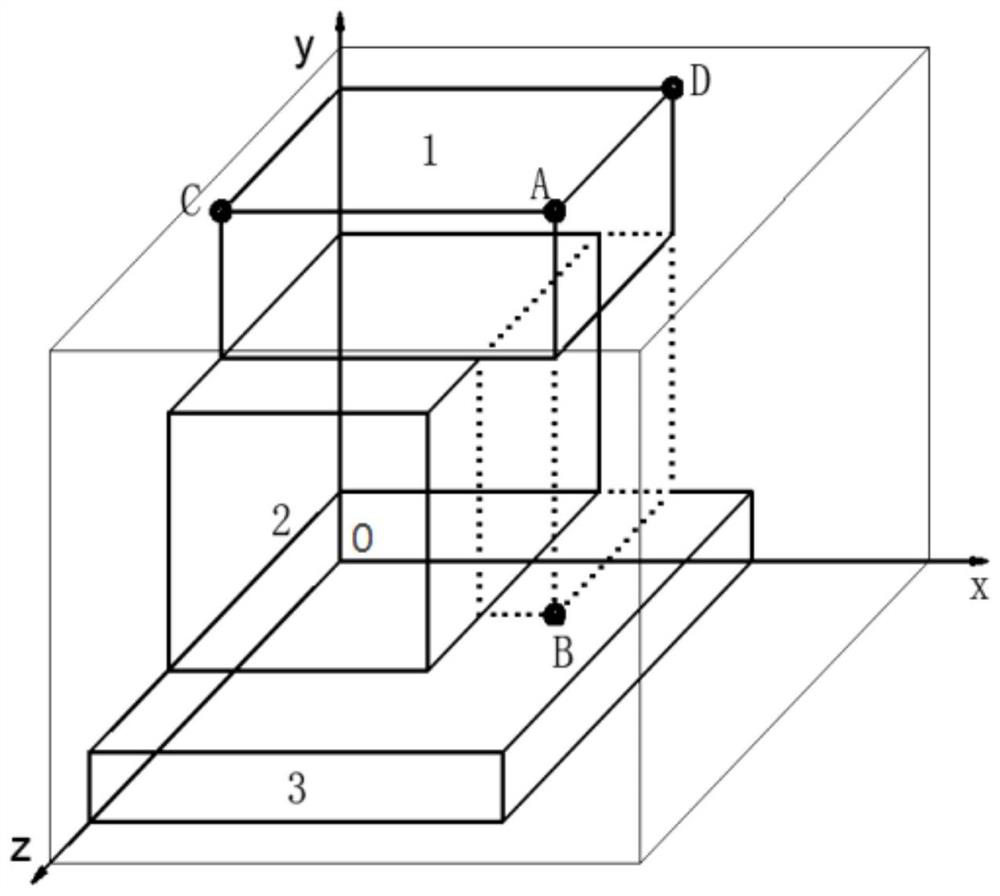

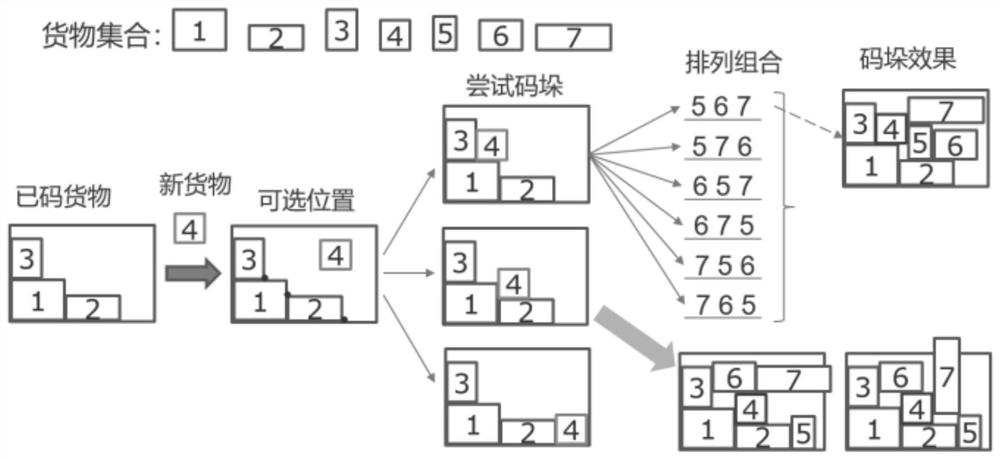

[0037] like Figure 1-Figure 3 As shown, an online cargo palletizing method with insufficient information includes the following steps:

[0038] Step 1, judge whether the space of the pallet in each two-dimensional plane parallel to the bottom surface of the pallet can accommodate the goods to be placed a 1 , if not possible, the goods a 1 Place it on the next pallet; if possible, judge whether the height space of the pallet can accommodate the goods to be placed a 1 , if not possible, the goods a 1 Place it in the next tray, and record the position if possible l 1 to the location collection L;

[0039] Step 2, judge each position l i When placing the goods to be placed a 1 time and goods a 1 Whether the contact area of the bottom is greater than or equal to the safe placement area, if not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com