Patents

Literature

40results about How to "Automate recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

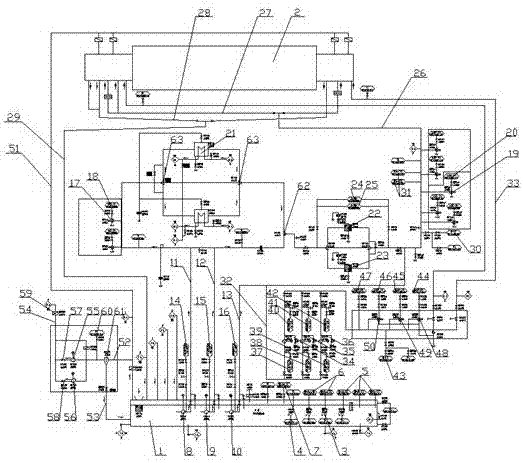

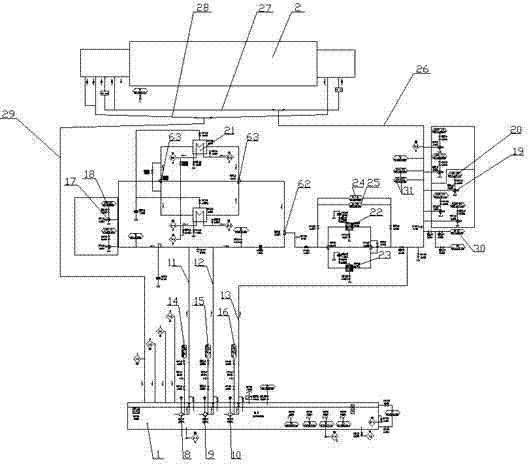

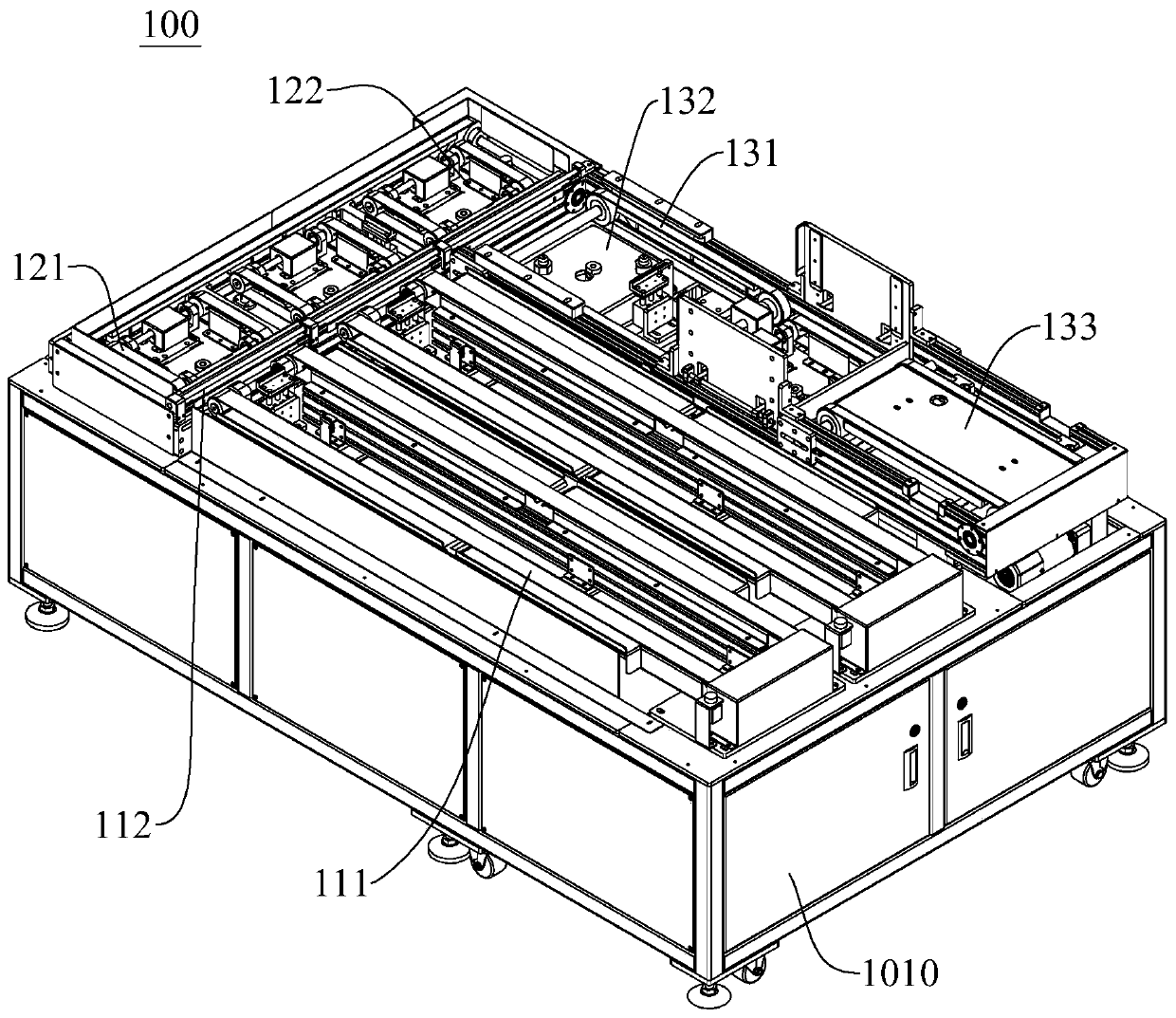

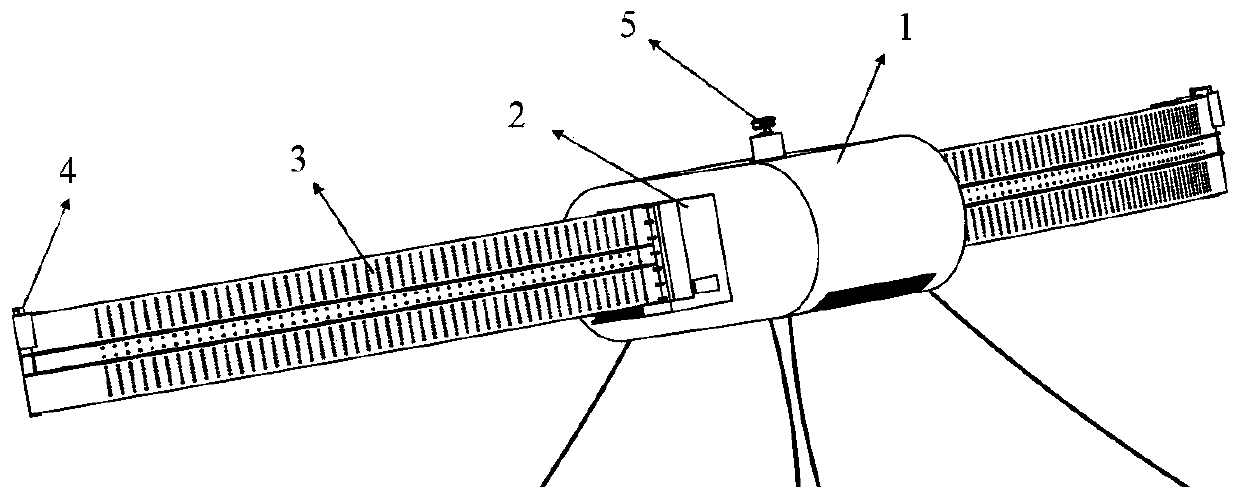

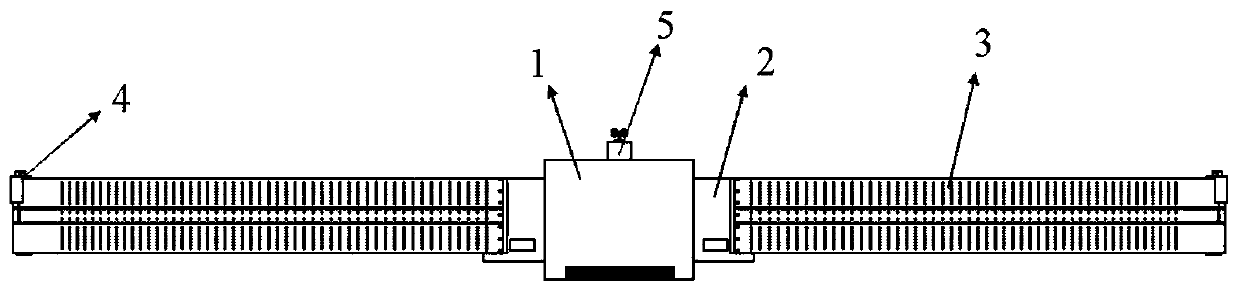

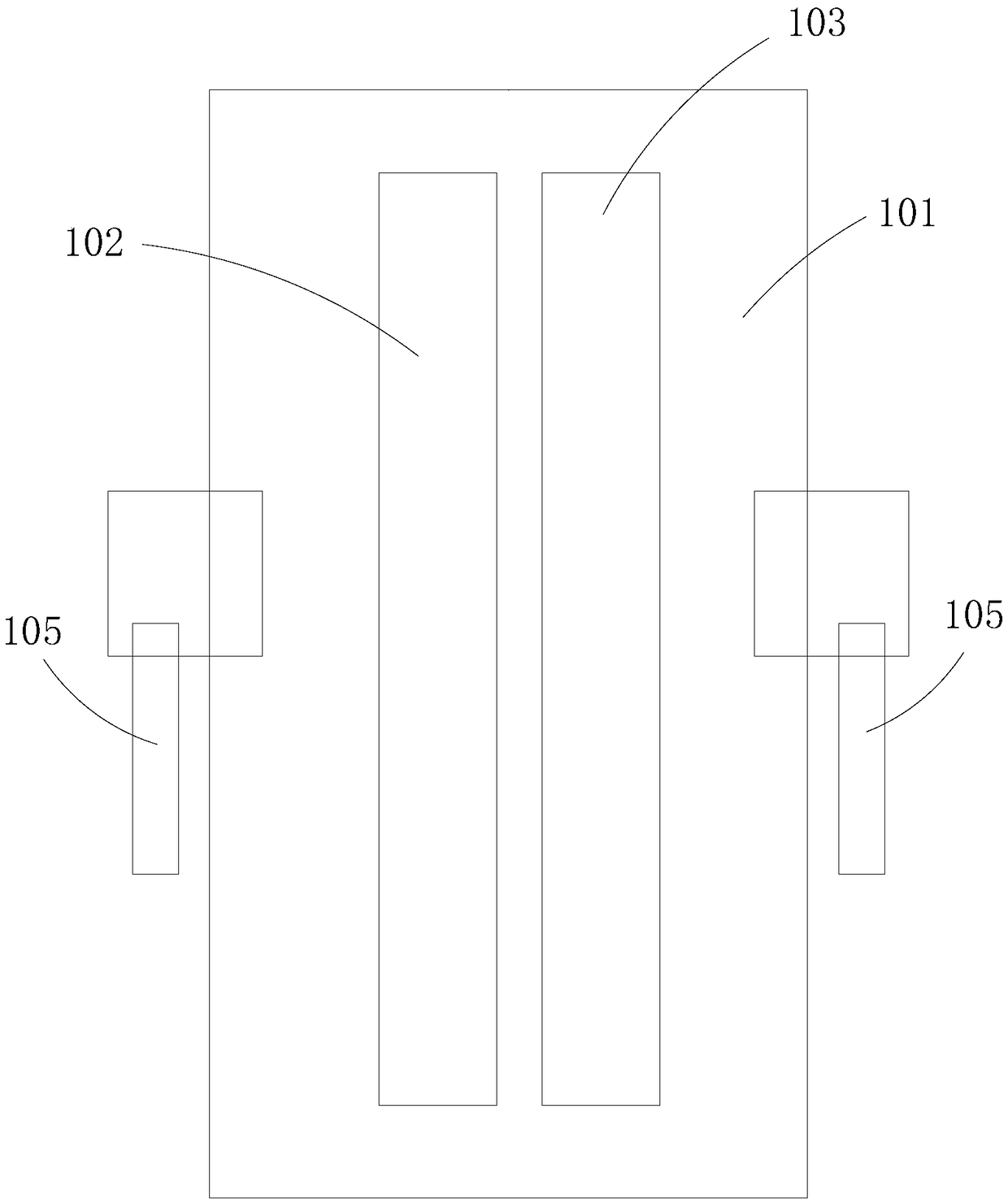

Full-automatic feeding machine for material tray type PCB boards

ActiveCN110950069AAutomate recyclingReduce manufacturing costConveyorsStacking articlesEngineeringMachine

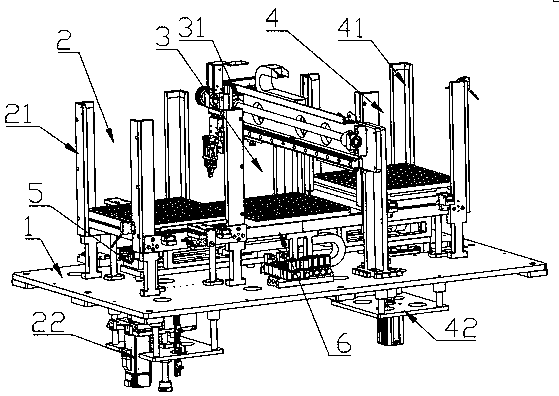

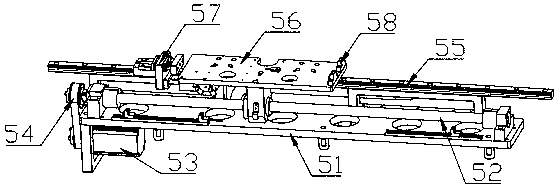

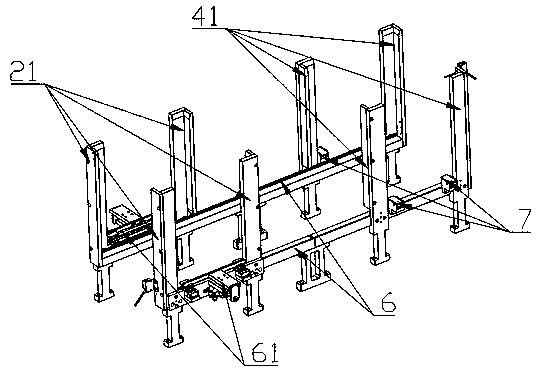

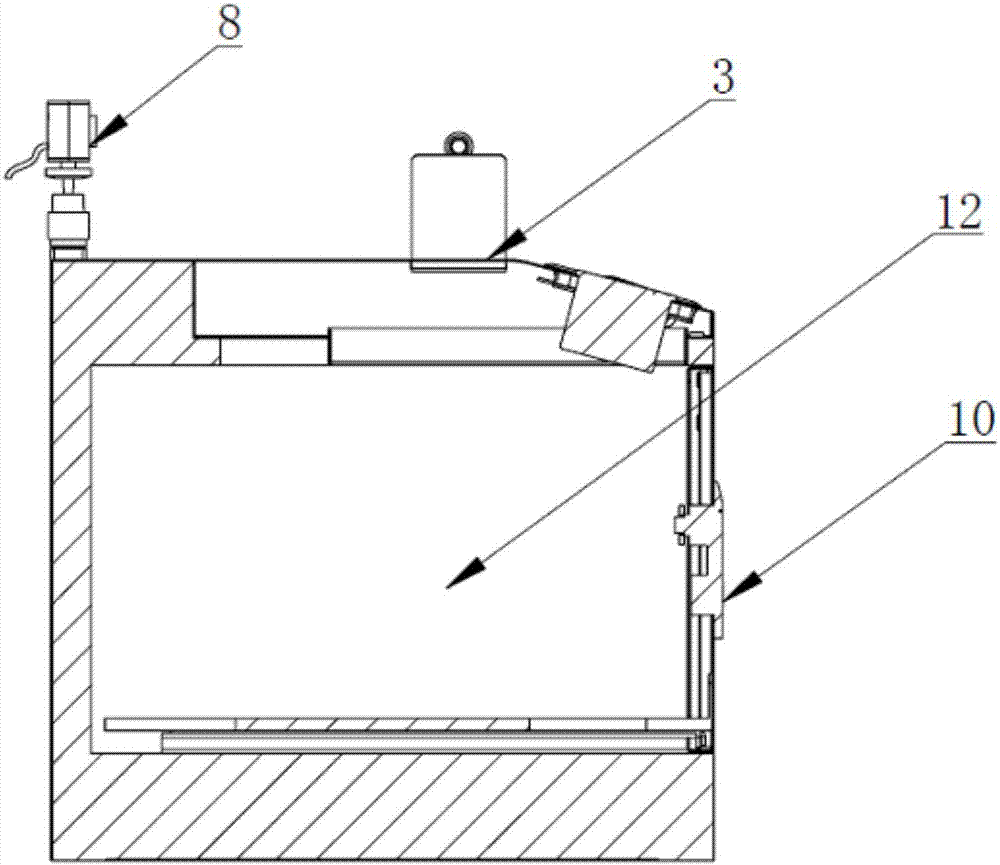

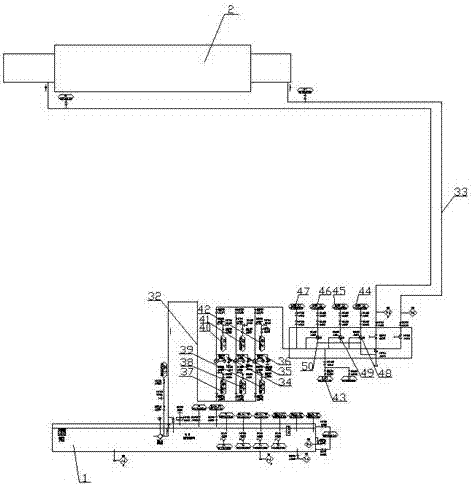

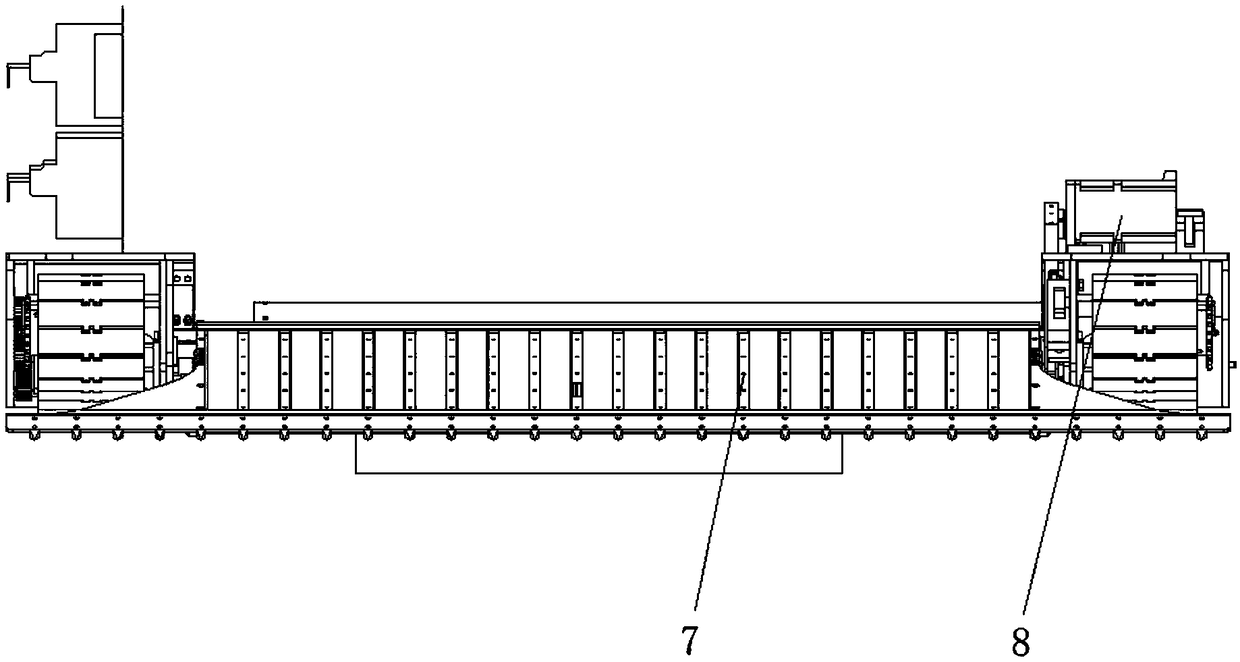

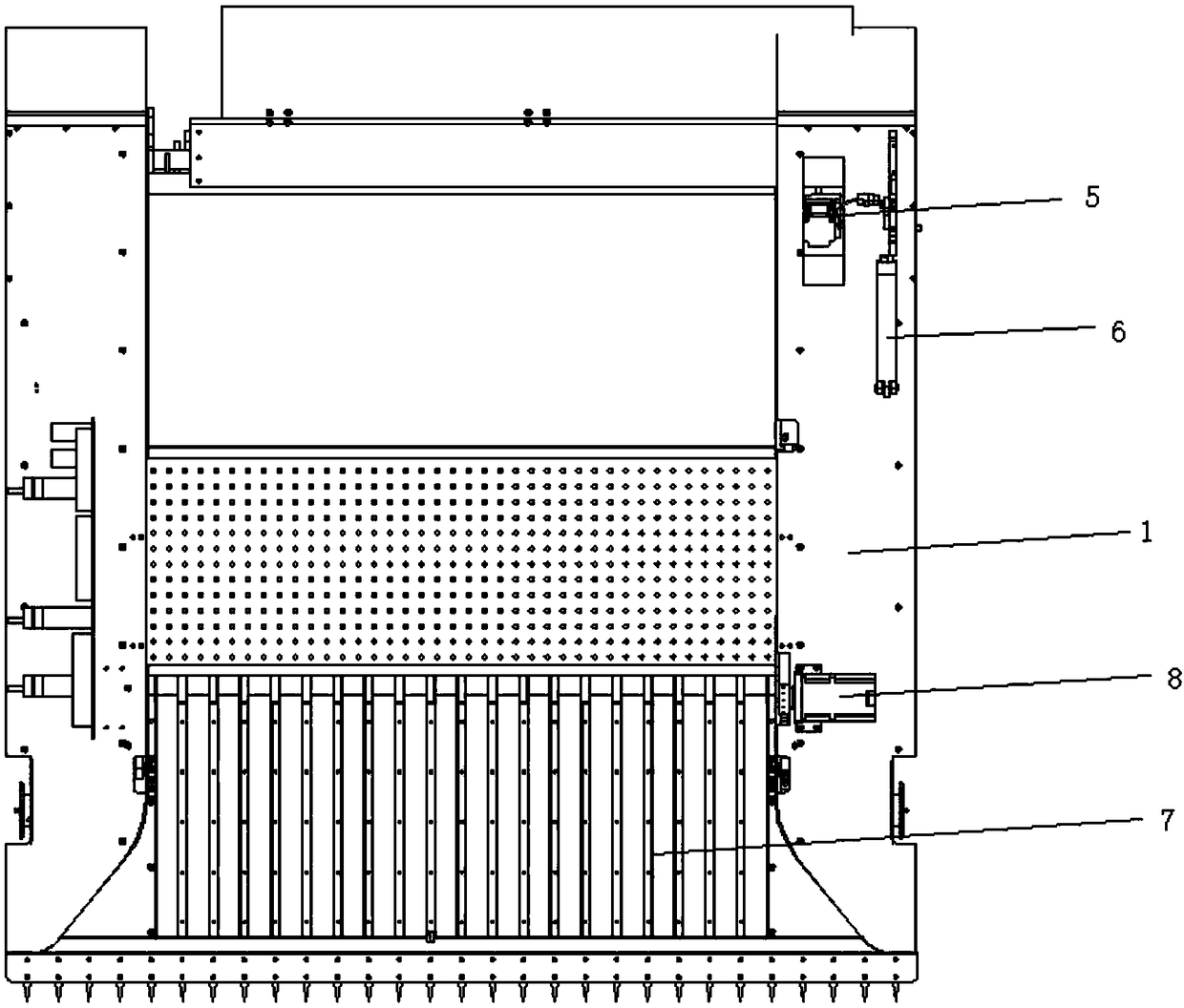

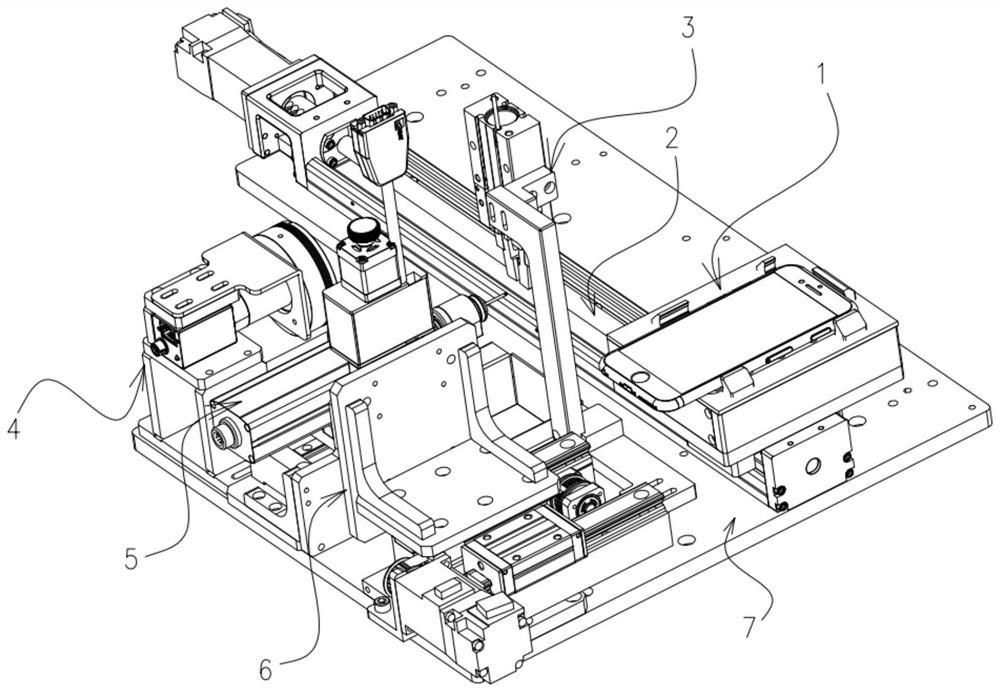

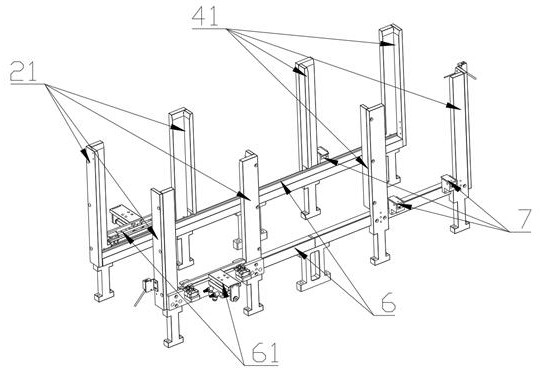

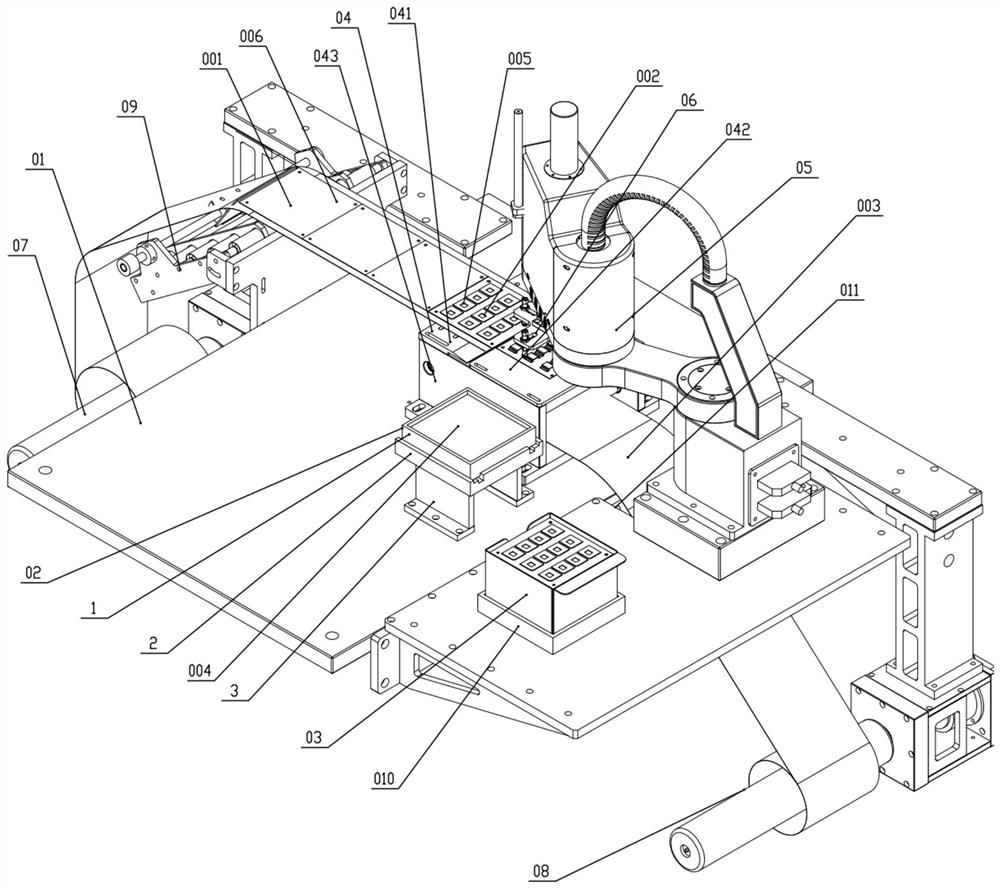

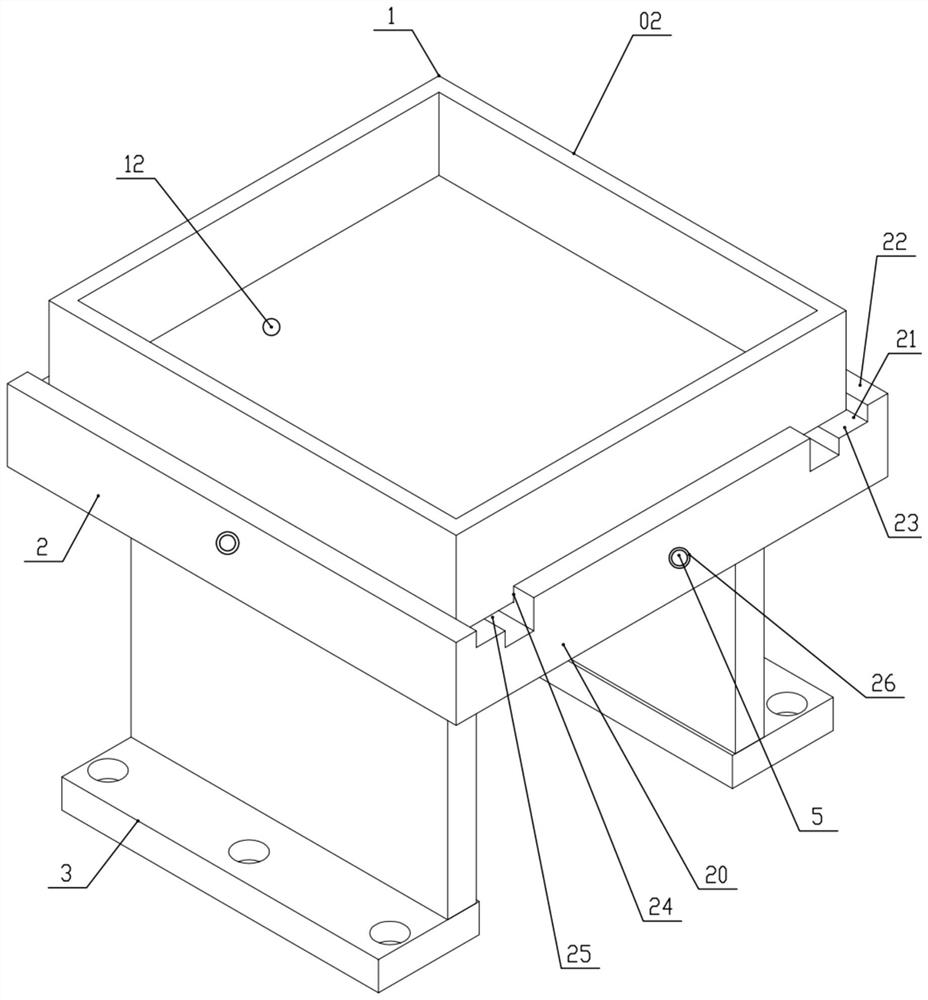

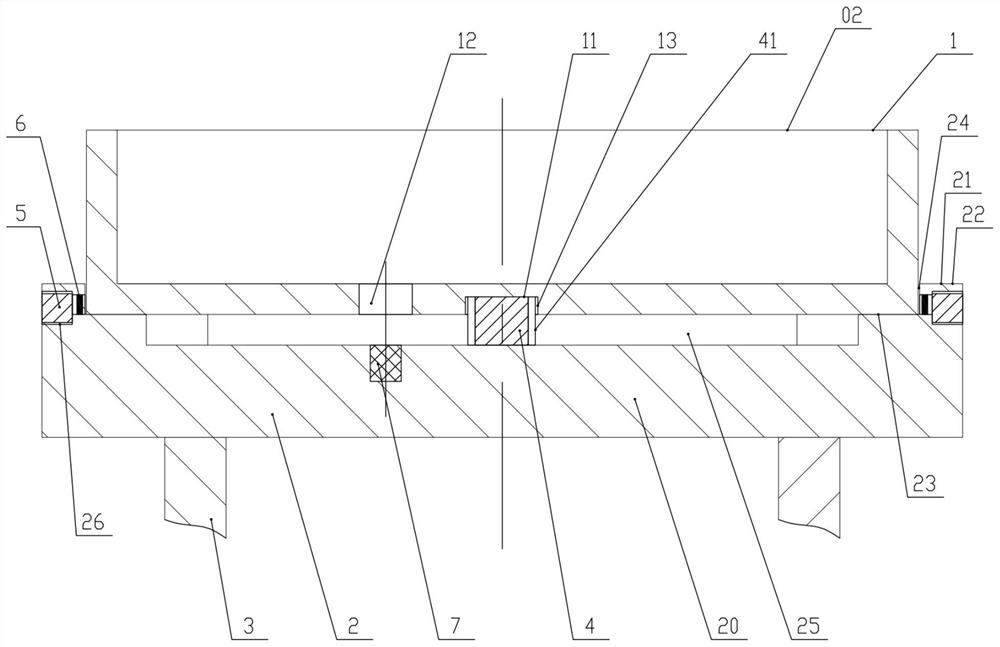

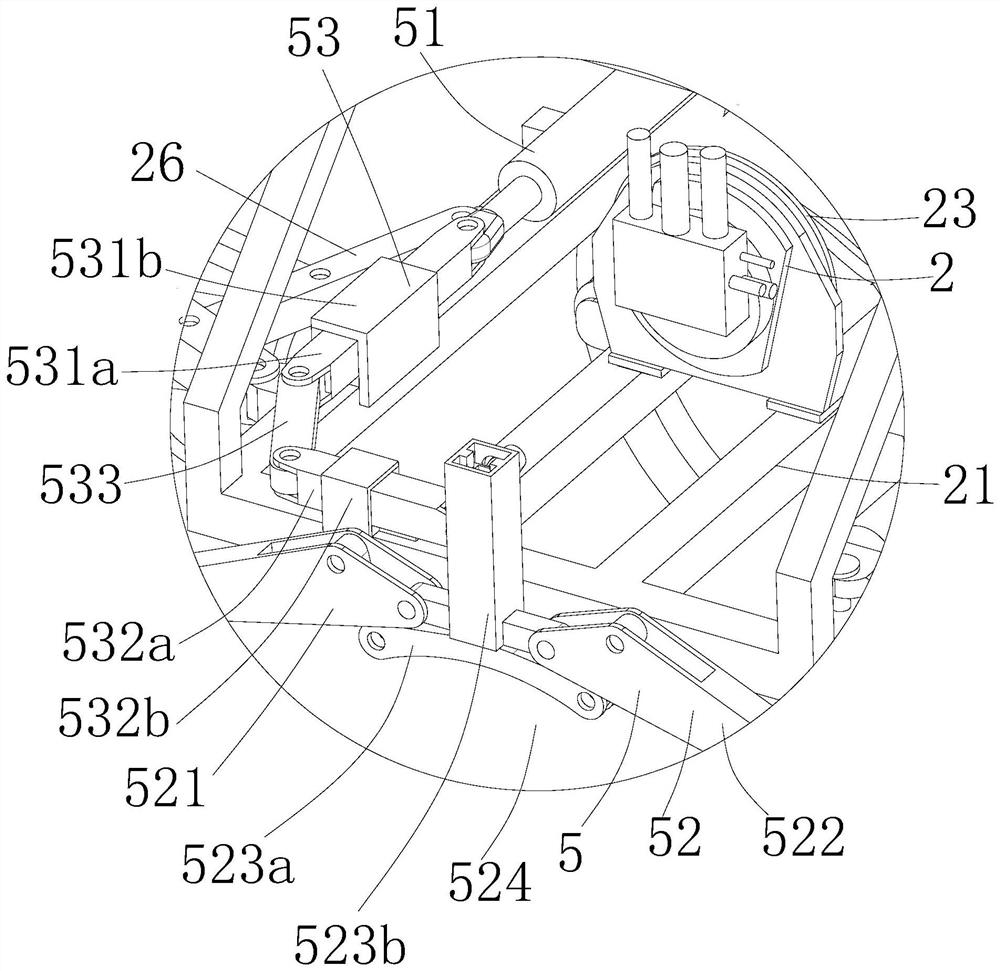

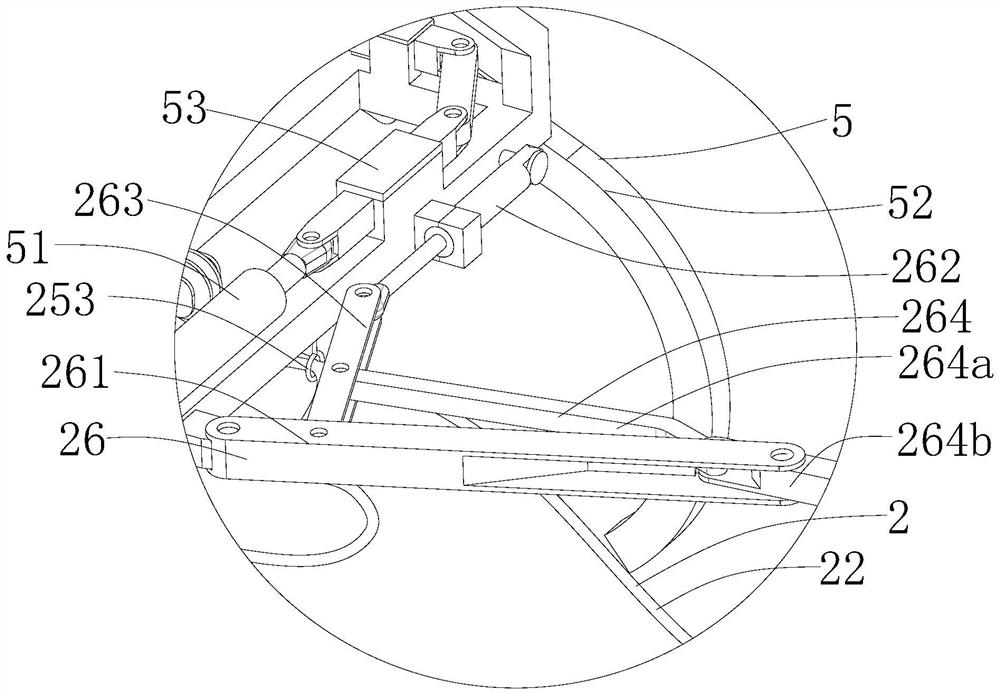

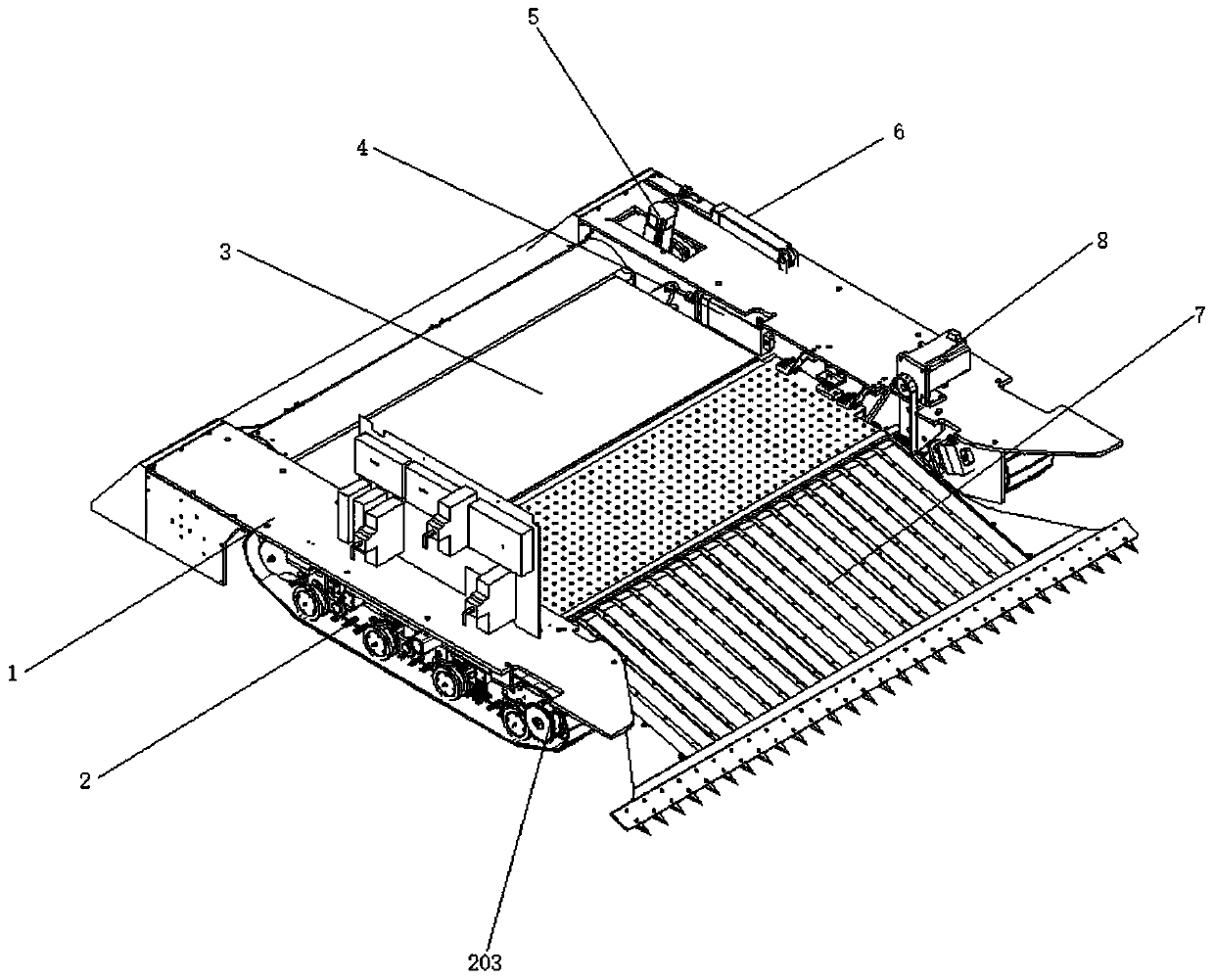

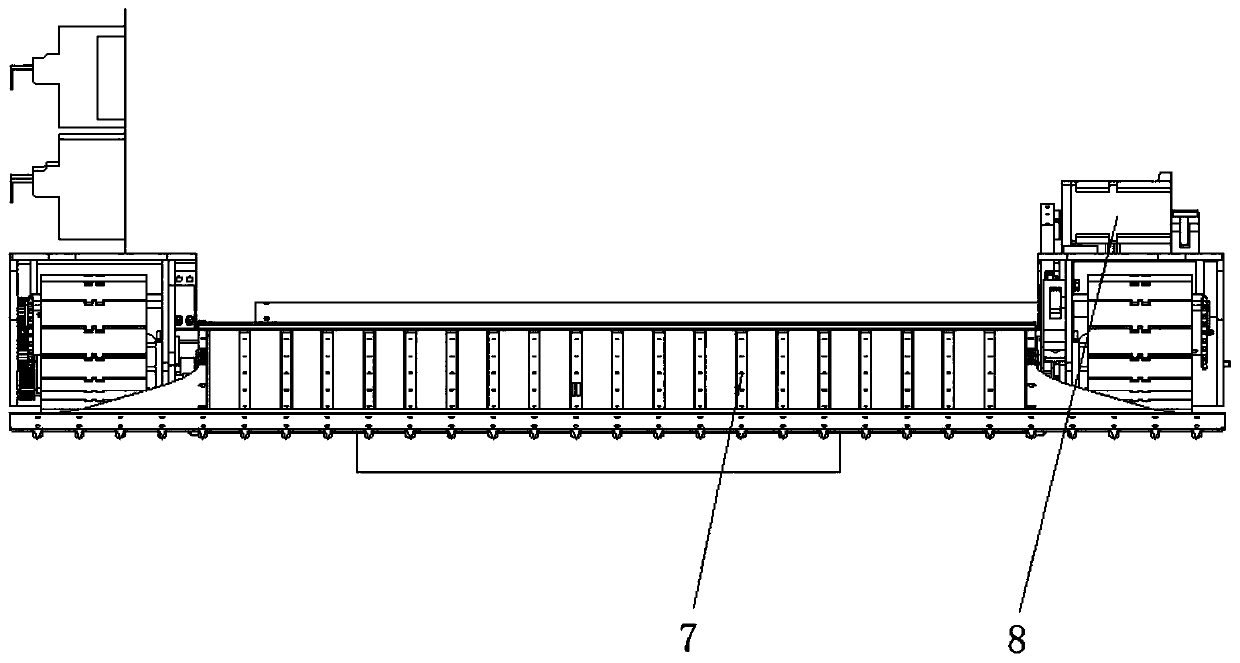

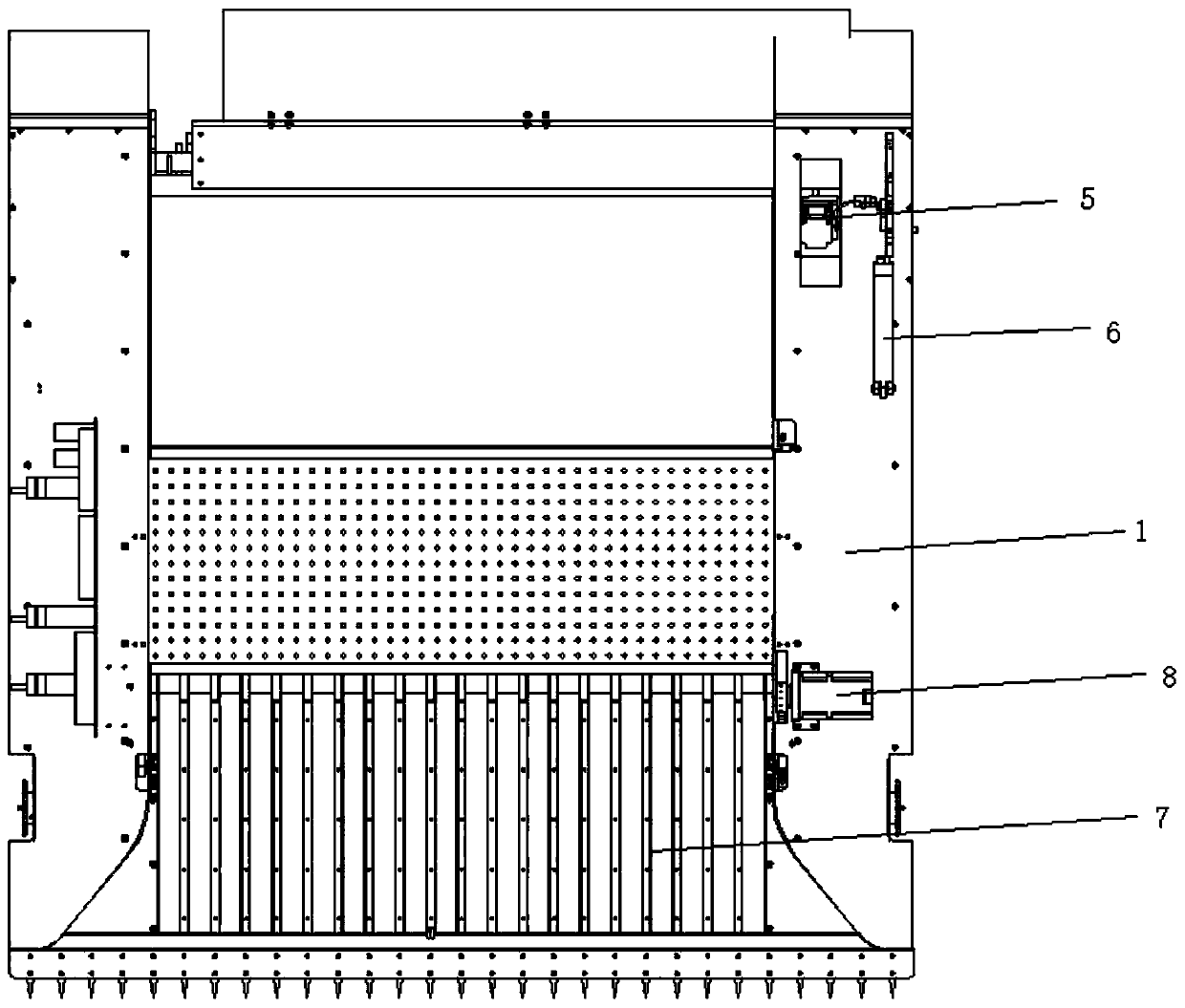

The invention discloses a full-automatic feeding machine for material tray type PCB boards. The machine comprises a machine table; the machine table is provided with three stations, namely a feeding station, a conveying station and a tray collecting station; the feeding station, the conveying station and the tray collecting station are sequentially arranged on a top plate of the machine table; a sliding table mechanism and double-track supporting rails are fixed on the top plate of the machine table; the sliding table mechanism is fixed between the double-track supporting rails; the sliding table mechanism and the double-track supporting rails communicate with the three stations; the sliding table mechanism is used for driving a material tray to transfer three stations on the double-tracksupporting rails; the feeding station is provided with a feeding frame and a feeding jacking mechanism; the feeding frame is vertically fixed on a top plate of the machine table; and the feeding jacking mechanism is fixed at the position right below the feeding frame. The machine has a high automation program, shortens the production period, improves the production efficiency, saves labor, reducesthe production cost of enterprises, realizes continuous production, and has good market application value.

Owner:SHENZHEN BILIAN ELECTRONICS LTD

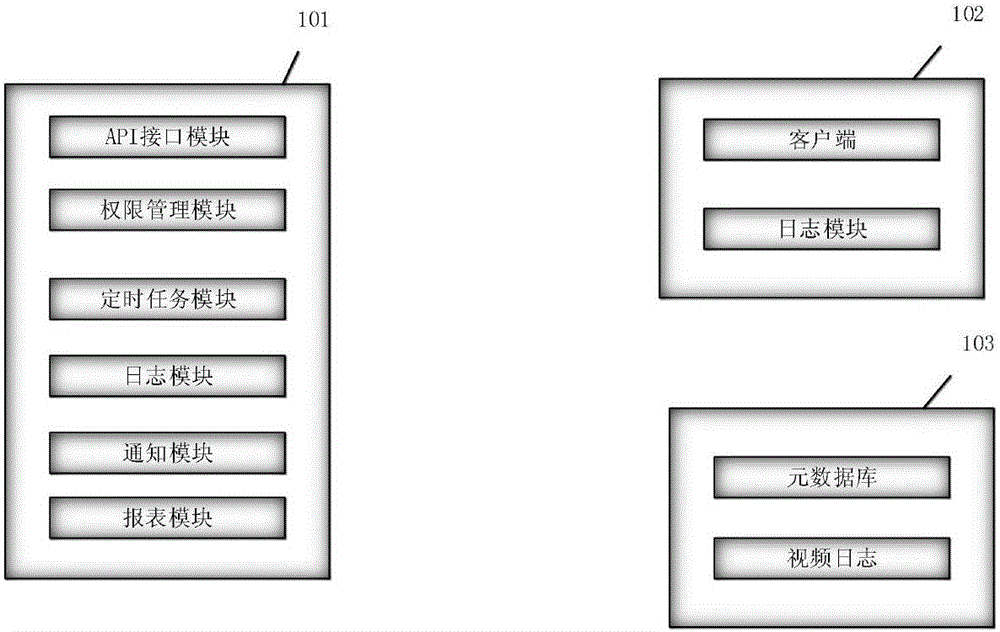

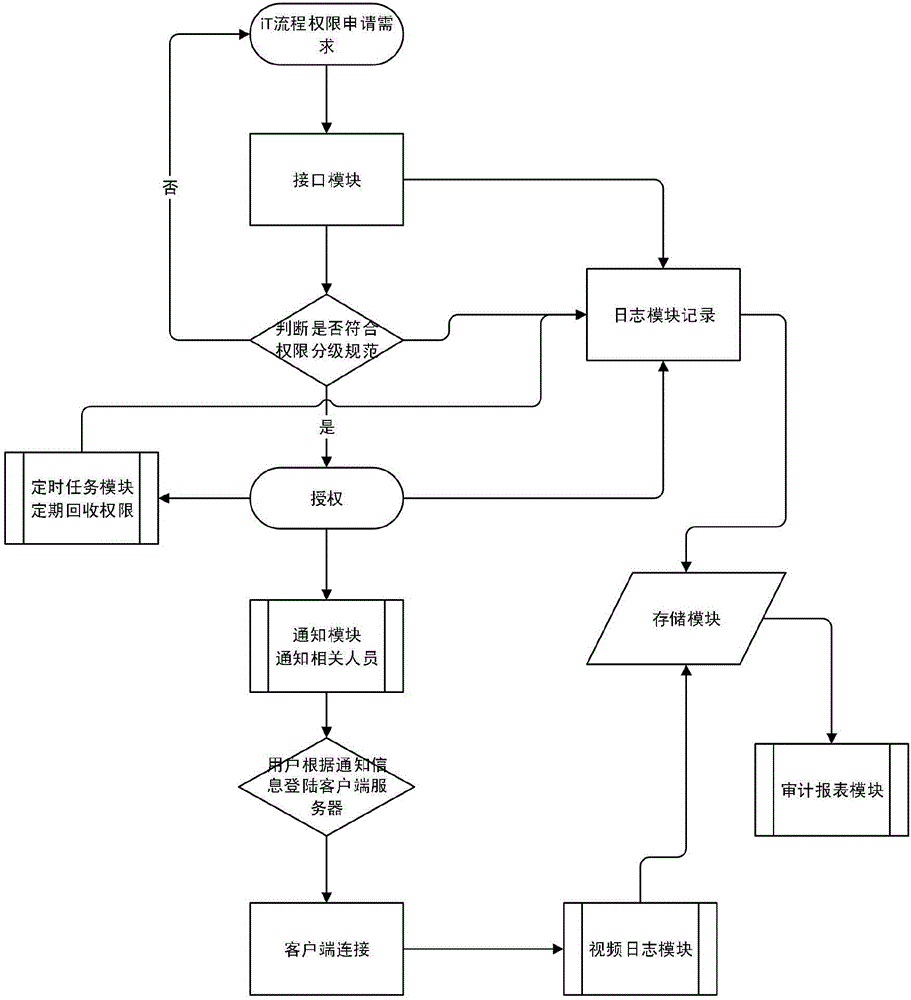

Process-based database permission automated management system meeting international auditing standards

InactiveCN106372469ARealize automatic managementReduce workloadDigital data protectionDigital data authenticationClient-sideProcess systems

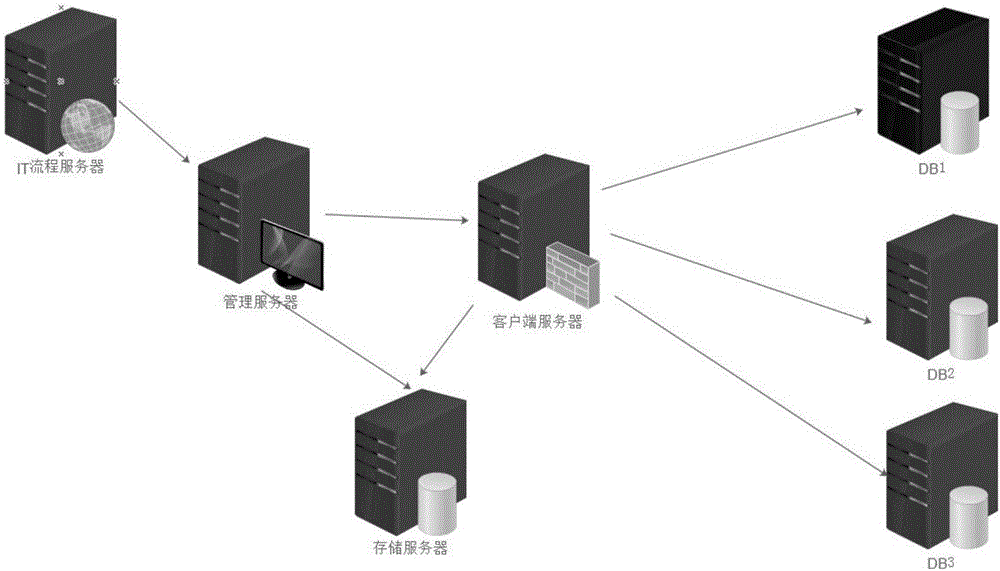

The invention discloses a process-based database permission automated management system meeting international auditing standards, and belongs to the field of electric digital data processing. The system comprises a management server, a storage server and a client server, wherein the management server is connected with an enterprise internal IT process system, provides a Web-based management interface, performs centralized management on a plurality of databases, performs permission grading processing on users according to a permission grading rule, and sends information to corresponding users by using a notification module; the client server is correspondingly connected with a plurality of clients; and the users logs in the databases on the clients according to received account information, the client server ''grants'' operation permissions of the users and starts timing, and after a predetermined set time is up, the client server ''revokes'' the operation permissions of the users. According to the system, simultaneous permission management of various databases, automated granting and revoking of the usage permissions of the users, customization of data grading query and automated output of operation behavior records and auditing reports are realized.

Owner:上海宝尊电子商务有限公司

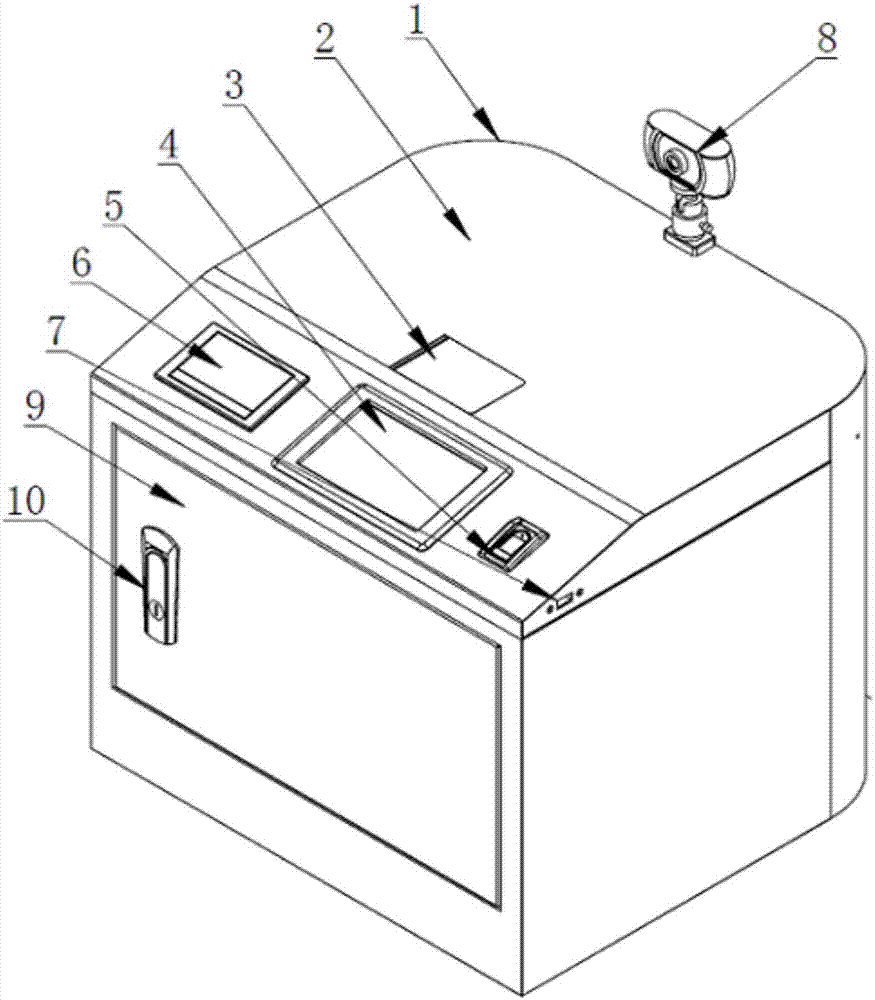

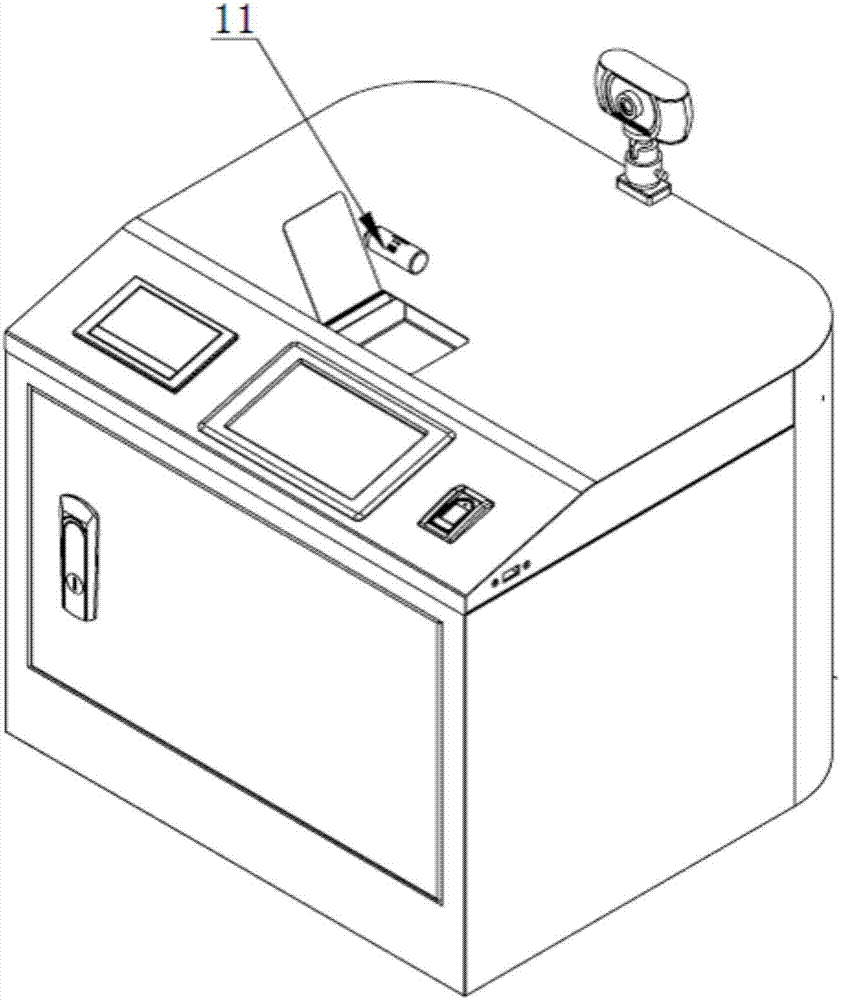

Drug container recycling system and method

PendingCN107973020AReduce workloadReduce the possibility of misuseWaste collection and transferRefuse receptaclesImage recordingEngineering

The invention discloses a drug container recycling system. The drug container recycling system comprises a drug container identification unit, a plurality of storage units and a drug container classifying unit. Automatic recycling of used and discarded drug containers is achieved, the workload of manual operation is greatly reduced, the possibility of misoperation is reduced, and overall recordingof recycling operator information, time information and drug container information is achieved through a visual operation interface and user login operation; and supervision of the drug container recycling process is strengthened, the possibility of drug container losing is reduced, image recording equipment is adopted to make the recycling process be overall recorded, and safety insurance is provided for recycling of the containers of controlled drugs.

Owner:北京华兴长泰物联网技术研究院有限责任公司

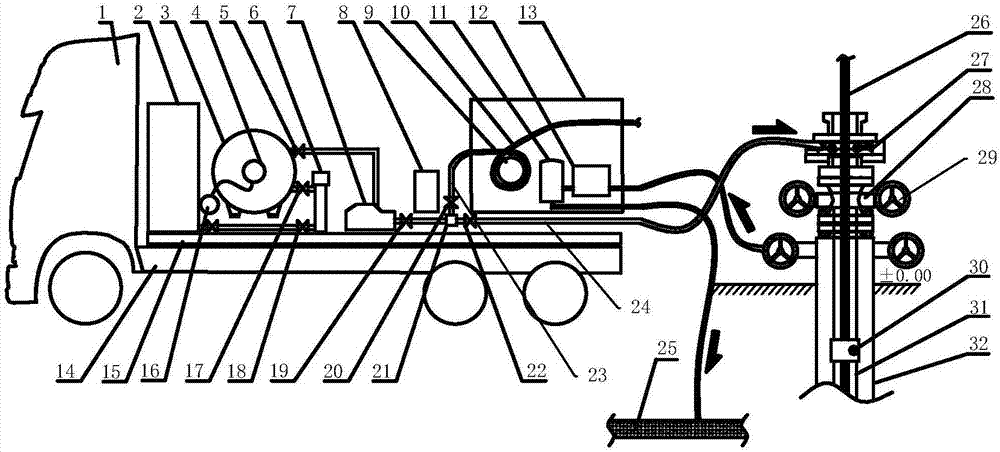

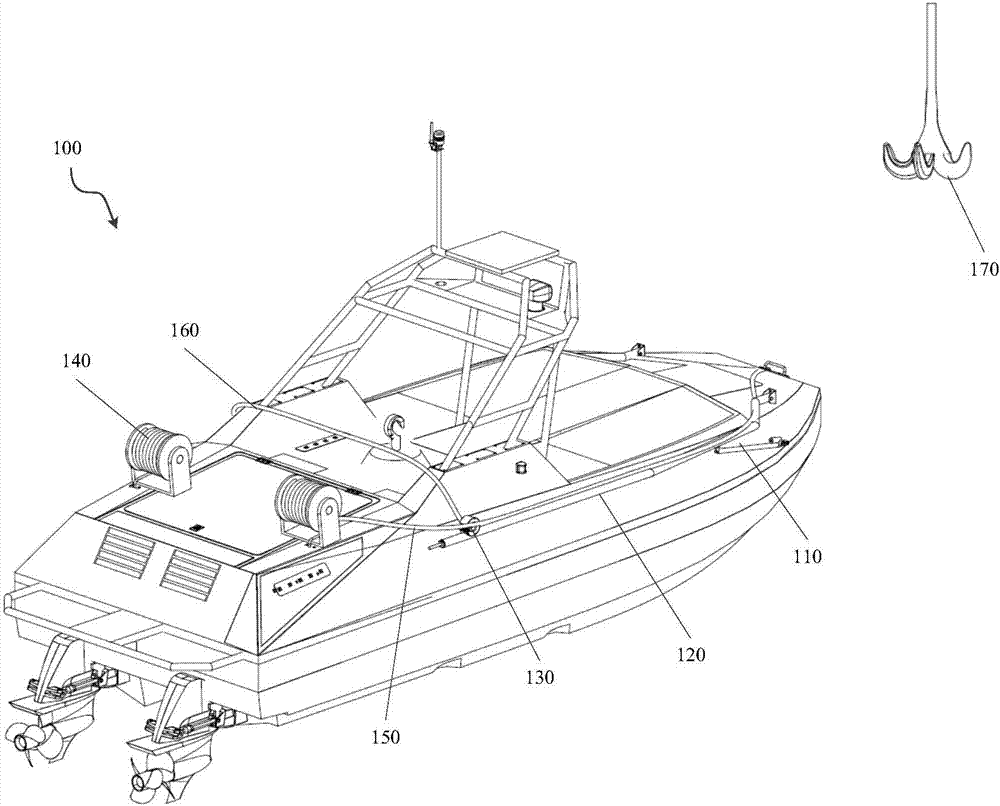

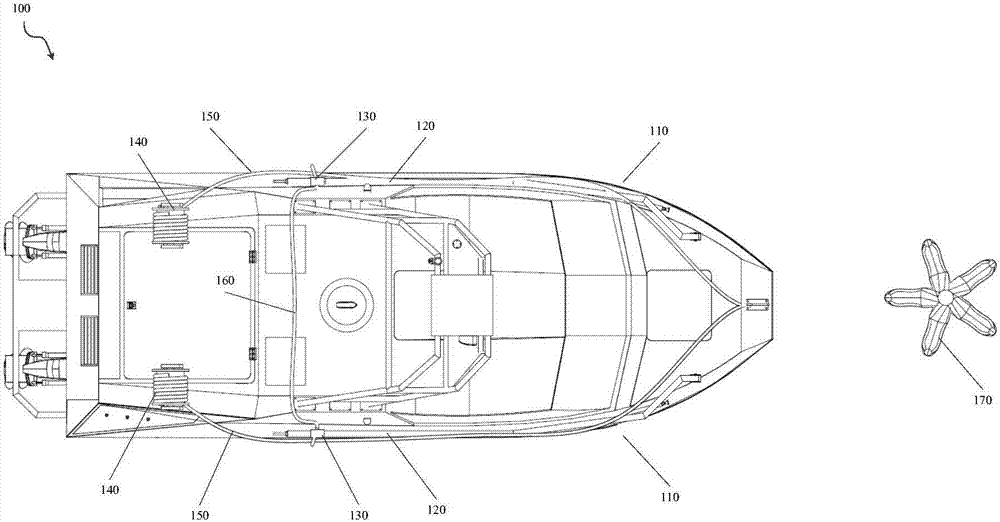

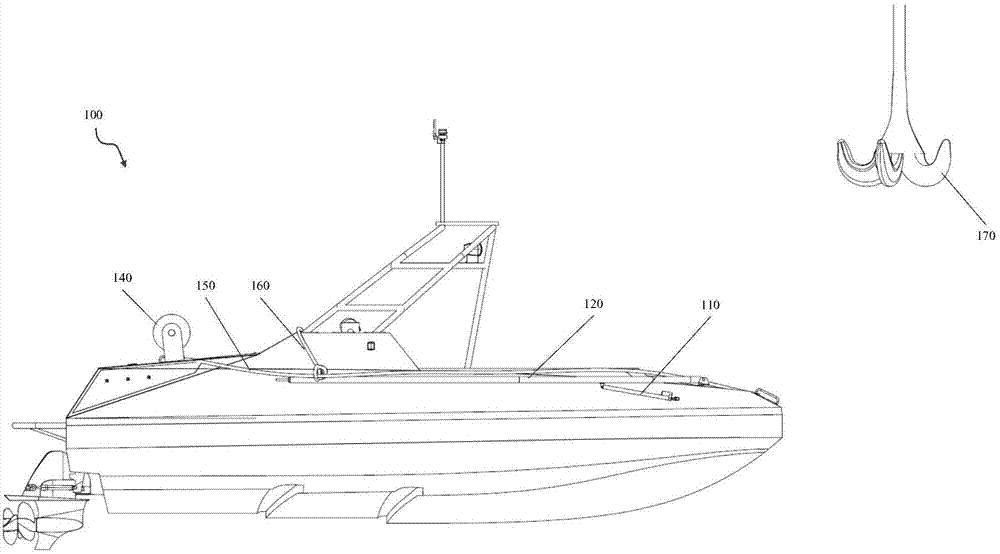

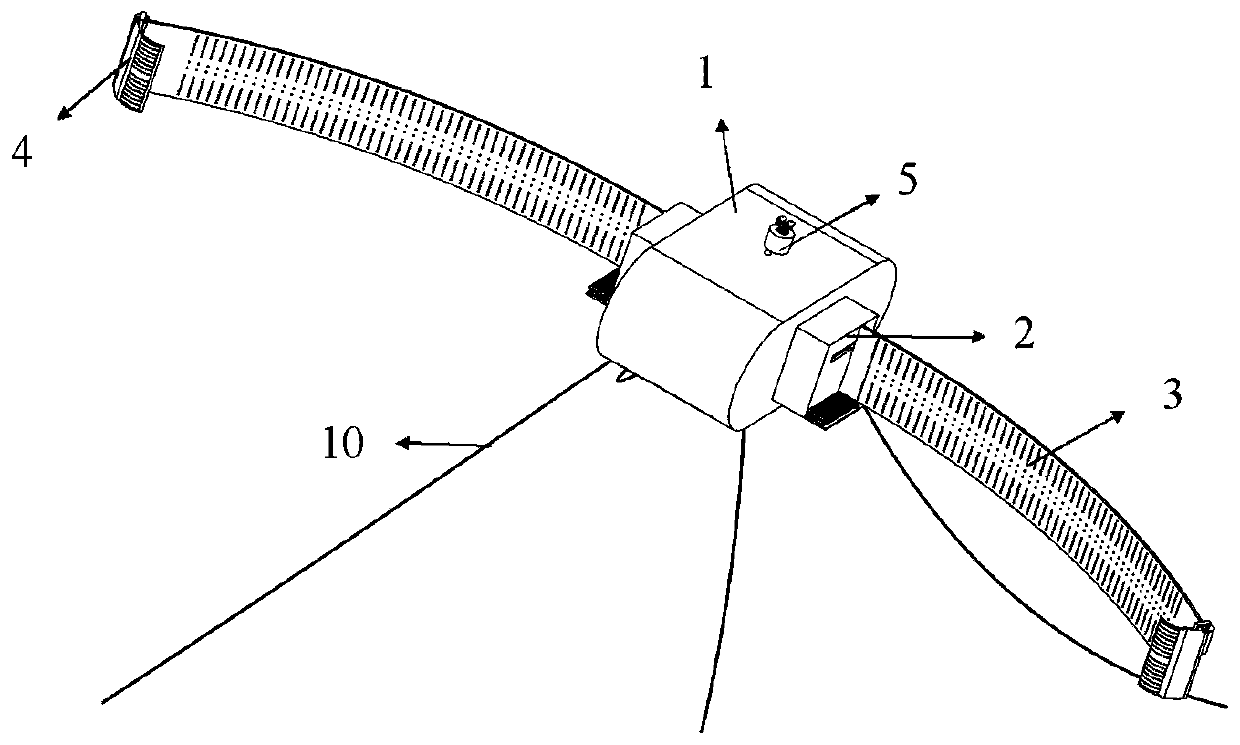

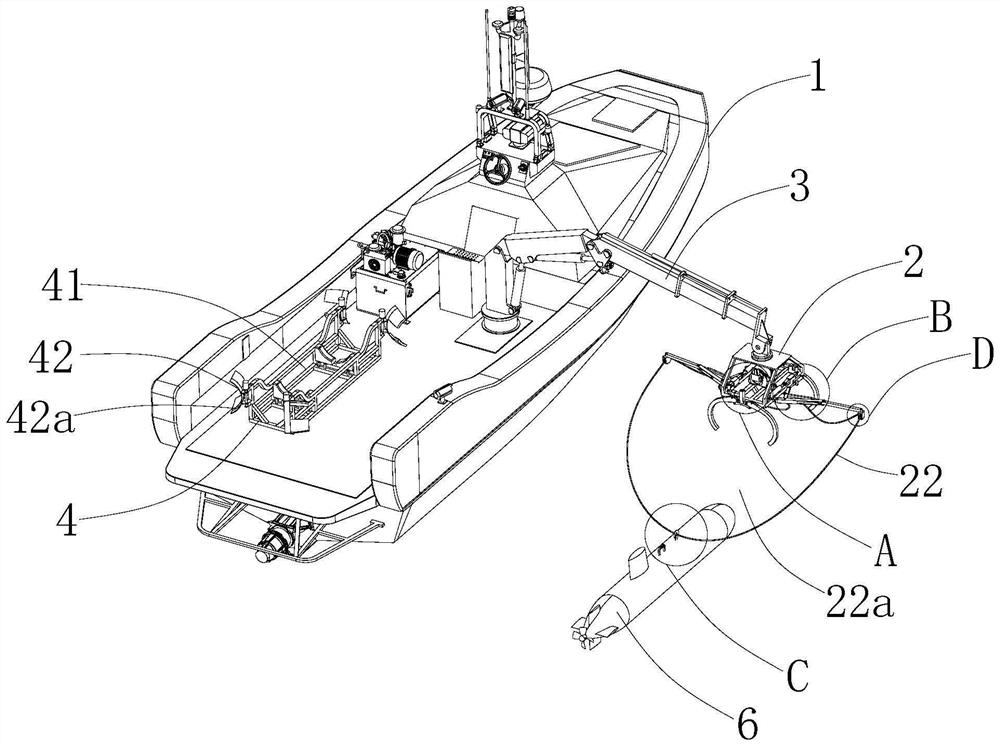

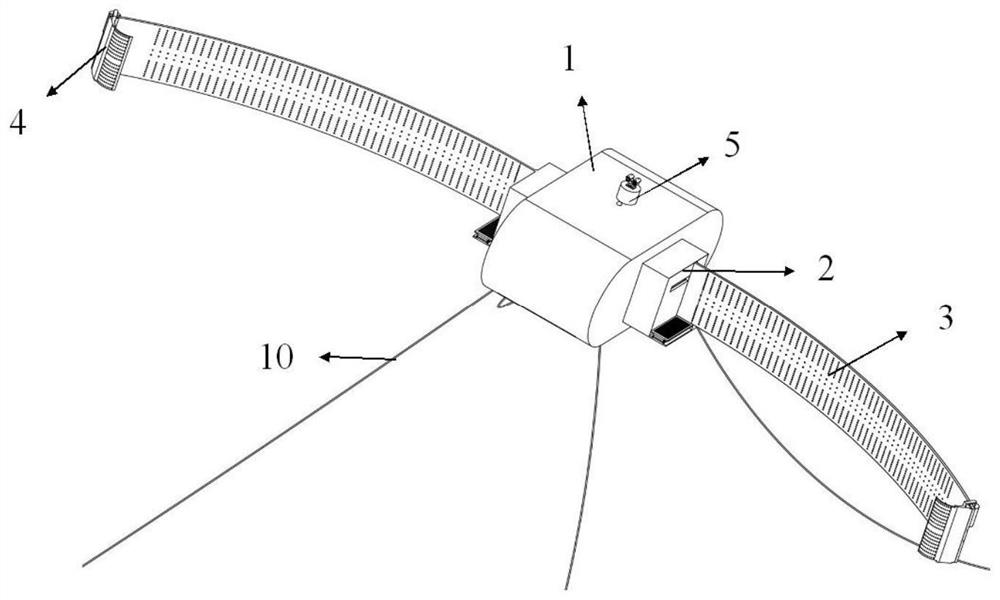

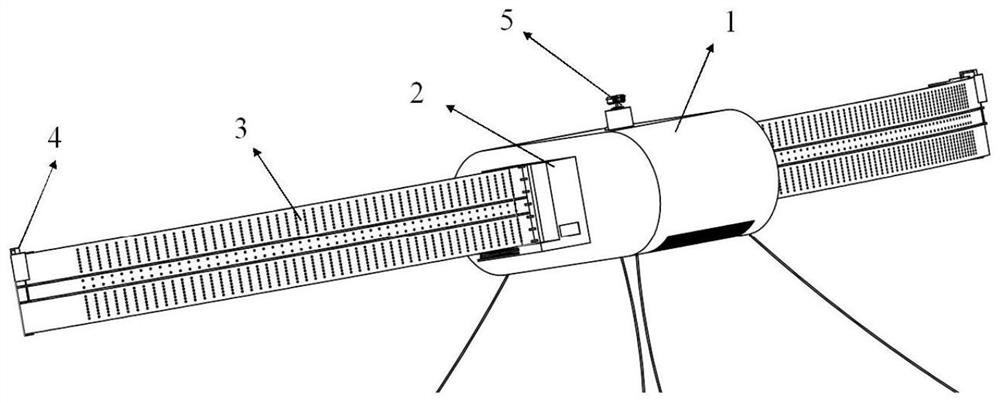

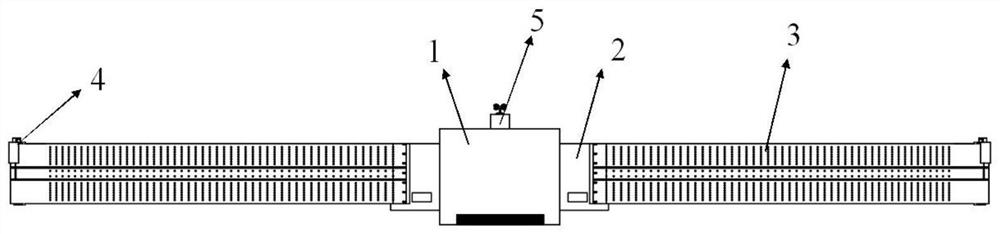

Launching and retrieving device, system and method for unmanned ship

PendingCN107344597AImprove securityAutomate recyclingDavitsCargo handling apparatusStructural engineeringMechanical engineering

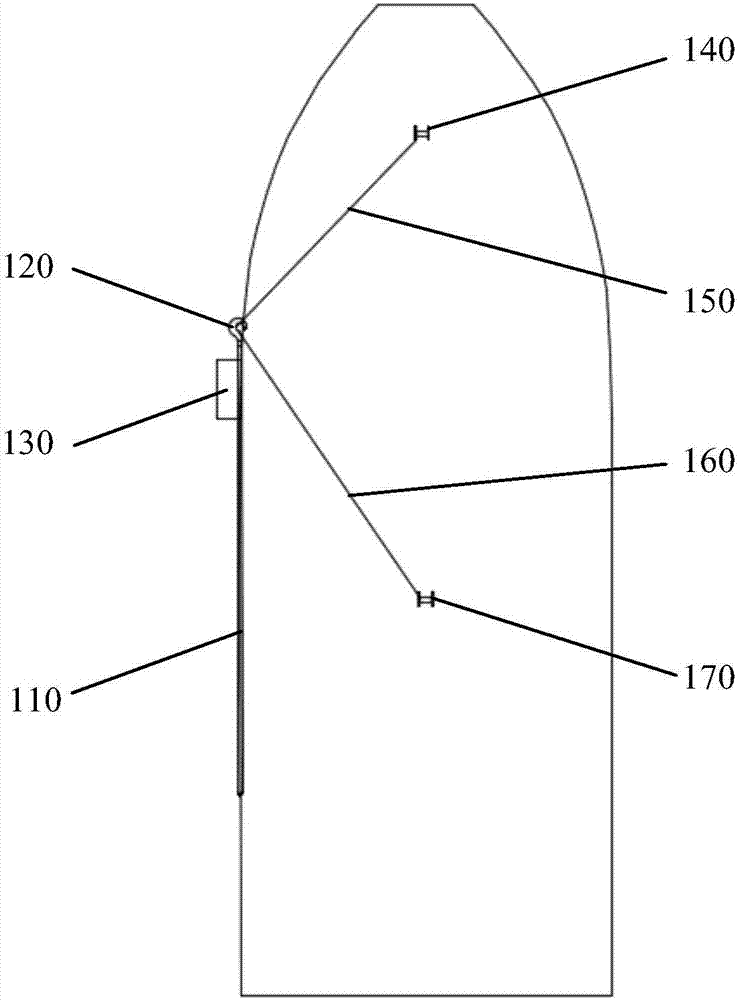

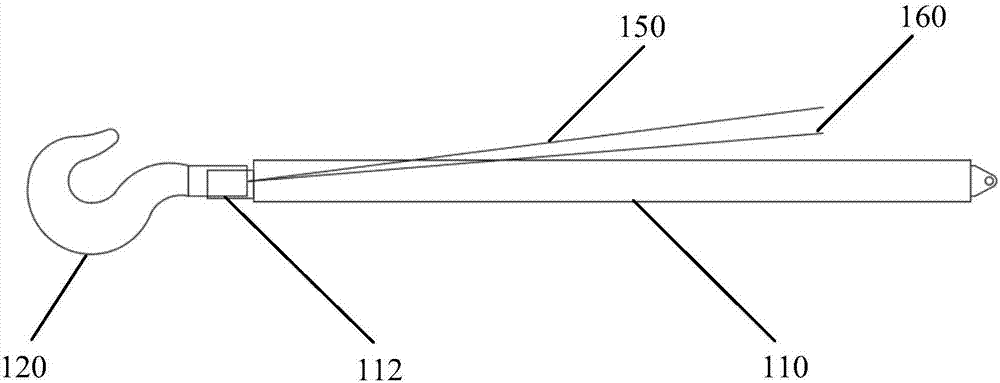

The invention discloses a launching and retrieving device for an unmanned ship. The launching and retrieving device is arranged on an unmanned ship and comprises a support rod, a pothook, a first locking device, a control system, a first cable coiler, a second cable coiler, a swinging-stopping rope and a guiding rope, wherein the support rod is arranged on one side of a ship body; one end of the support rod is hinged with the ship body while the other end is moveably connected with the pothook; the control system is used for folding and unfolding the support rod by controlling the first locking device to lock and unlock; the swinging-stopping rope and the guiding rope are connected with the pothook; the other ends of the swinging-stopping rope and the guiding rope are respectively wound in the first cable coiler and the second cable coiler; the first cable coiler and the second cable coiler are respectively fixed on the ship body. The invention also discloses a corresponding unmanned ship, a launching and retrieving system for the unmanned ship and a launching and retrieving method for the unmanned ship. According to the technical field of the invention, the launching and retrieving device for the unmanned ship can be matched with a hoisting structure on a mother ship, so as to realize the automatic launching and retrieving of the unmanned ship.

Owner:SHENZHEN YUNZHOU INNOVATION TECH COMPANY

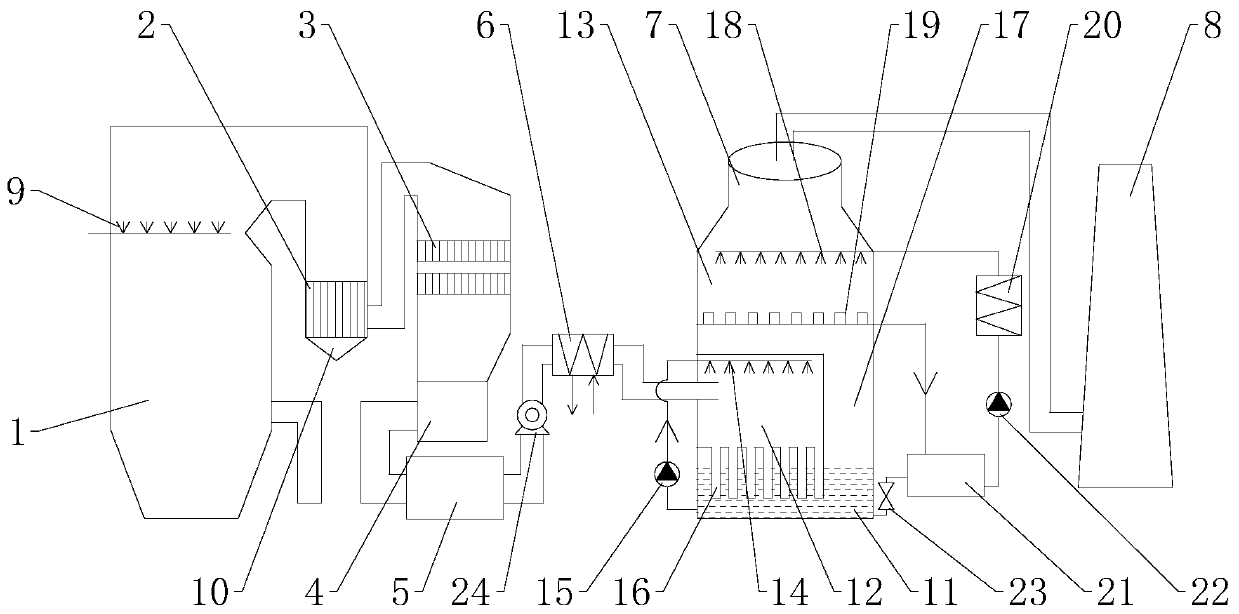

Efficient denitration and dust removal system and method for garbage power plant flue gas

InactiveCN110124486AEmission reductionReduce dust contentCombination devicesGas treatmentEngineeringWaste-to-energy plant

The invention discloses efficient denitration and dust removal system and method for flue gas of a garbage power plant. The dust removal system comprises a waste heat boiler; an SNCR sprayer is mounted in the waste heat boiler and is used for spraying ammonia or urea, so that NOx in the flue gas is primarily reduced, and primary denitration is completed; the high-temperature metal dust remover isused for filtering and intercepting heavy metals, dust and dioxin in the flue gas; the filtered flue gas selectively reacts with NOx under the action of a catalyst through a microporous SCR device togenerate N2 and H2O so as to complete deep denitration; initial deacidification is carried out to the denitrified flue gas in a deacidification device, and deep deacidification and dust removal are carried out in a wet-process tower, thereby achieving ultra-low emission. According to the system and the method, high-temperature dust removal is combined with microporous SCR to deeply remove pollutants such as dust and NOx, so that ultra-low emission is realized. The technology does not need high-temperature steam heating, a large amount of steam can be saved, and the power generation amount is increased.

Owner:凤阳海泰科能源环境管理服务有限公司

Scrap steel strap reeling, bending and recycling device and reeling, bending and recycling method thereof

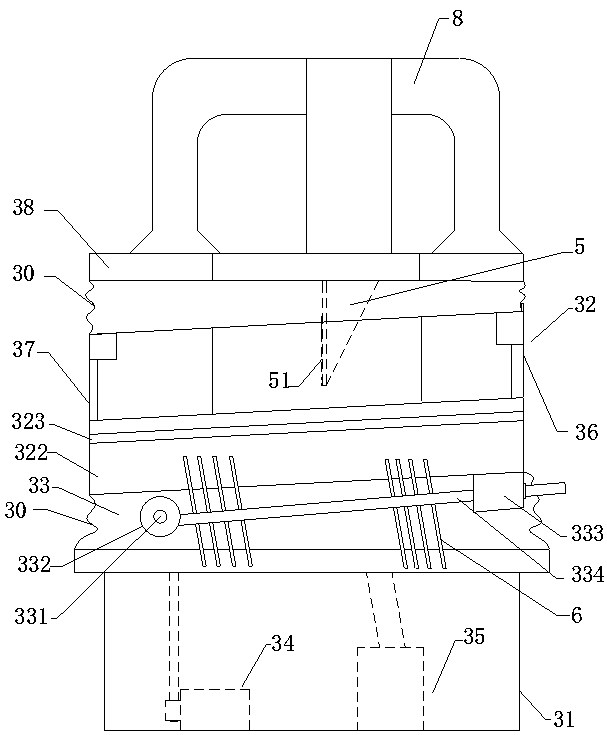

ActiveCN108687100ASolving Recycling ProblemsSolve shipping problemsSolid waste disposalHydraulic cylinderEngineering

The invention discloses a scrap steel strap reeling, bending and recycling device and a reeling, bending and recycling method thereof. The device comprises a rising and falling hydraulic cylinder, a pneumatic three-connection part, a first dual-lug-ring angle base, second dual-lug-ring angle bases, a first air cylinder, a second air cylinder and the like; a strap head waste joint is connected witha base assembly, the base assembly is connected with a waste box assembly, a first bolt and nut set is located above the strap head waste joint, the first bolt and nut set is connected with a third bolt and nut set, the third bolt and nut set is located below a fifth bolt connecting part, the fifth bolt connecting part is located below a second mounting plate, the second mounting plate is connected with a press head, the rising and falling hydraulic cylinder is located above the second mounting plate, a second sliding block is located on the right side of the third bolt and nut set, the second sliding block is connected with an air cylinder connecting support, and a cover shell is connected with the base assembly. Each long steel strap manually or automatically detached from a steel coilcan be reeled and bent automatically, and storage and transportation are facilitated.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

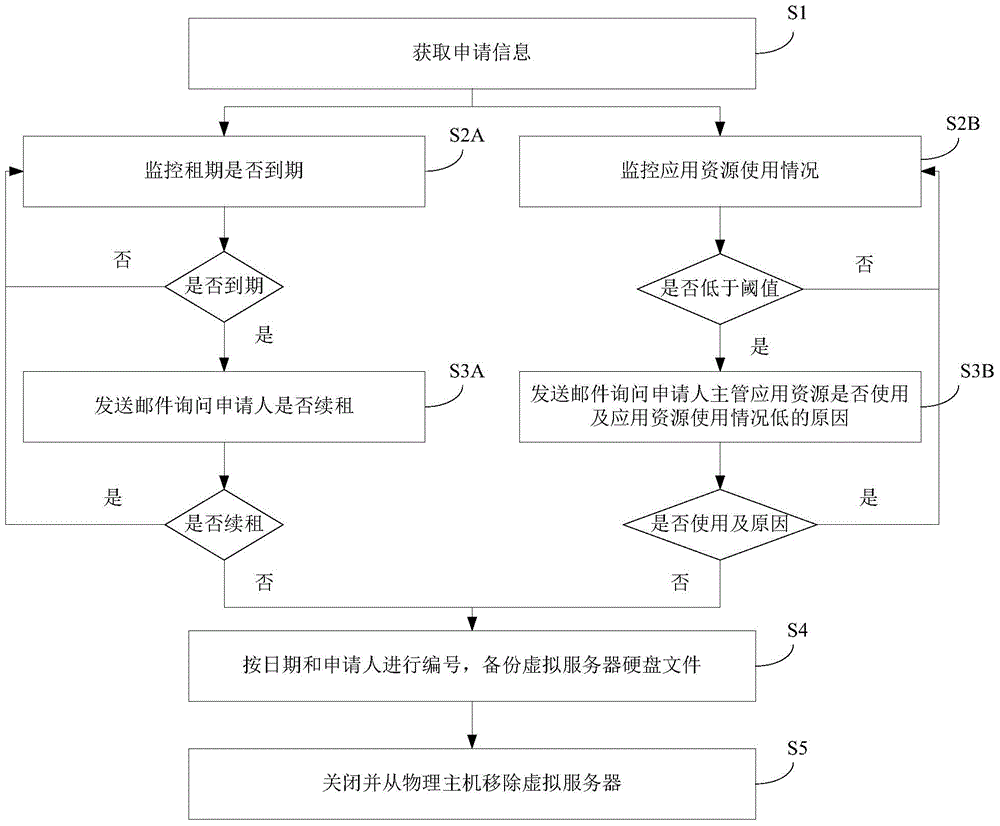

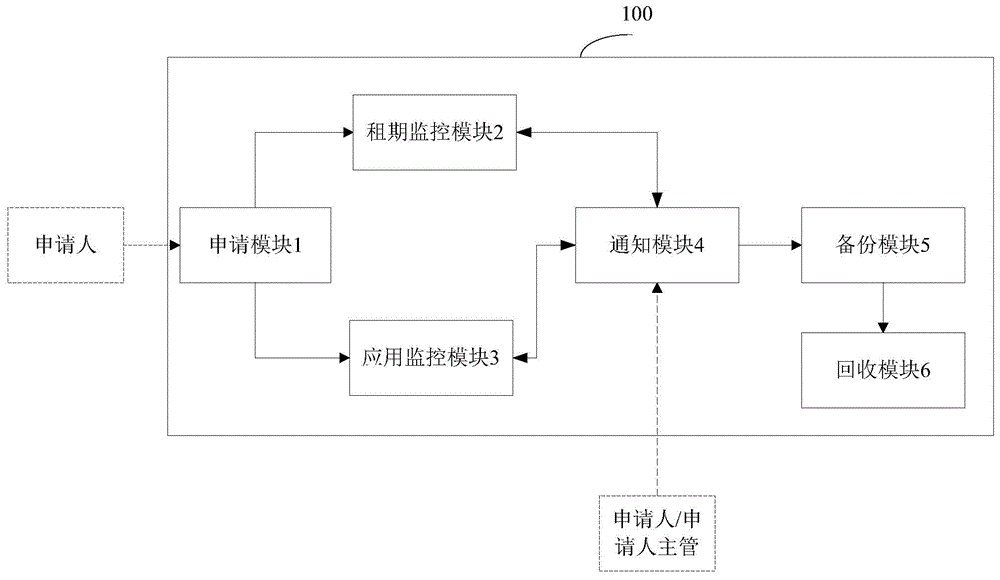

Recovery method and system of nuclear power service system virtual server resources

ActiveCN104598291AActual utilization is effectively derived fromAutomate recyclingResource allocationSoftware simulation/interpretation/emulationRecovery methodNuclear power

The embodiment of the invention discloses a recovery method and system of nuclear power service system virtual server resources. According to the method, by monitoring the tenancy term of a virtual server and the using situation of application resources, whether the virtual server is recovered automatically is determined. Through the traditional mode of virtual server tenancy term monitoring and the innovative method of virtual server practical using situation monitoring, automatic recovery of the nuclear power service system virtual server resources is achieved with an automatic inquiring informing function, the complexity of nuclear power service system operation and maintaining is effectively lowered, operation and maintaining workload is lowered, and hardware cost is saved. Meanwhile, the invention further provides a method for determining the virtual server practical using situations by analyzing the features of a nuclear power service system, and through the method, the practical using situation of the virtual server can be obtained effectively.

Owner:中广核工程有限公司 +1

Control method for phase modifier oil system

ActiveCN107355663AGuaranteed uptimeImprove efficiencyEngine temperatureEngine pressureAutomatic controlFuel tank

The invention discloses a control method for a phase modifier oil system. The control method for the phase modifier oil system comprises the following steps that (1) when starting is conducted, a self-checking signal is sent out by a controller of the phase modifier oil system, a lubricating oil supply system and a jacking oil system conduct self-checking; (2) the controller of the phase modifier oil system controls the temperature and the liquid level of lubricating oil in an oil tank automatically; (3) the controller connected with the oil tank sends out a lubricating oil supply instruction, and the lubricating oil passes a cooler and a filter sequentially and enters a phase modifier; (4) the controller sends out a jacking oil system jacking instruction; (5) the redundant lubricating oil in the phase modifier is controlled by the controller which sends out an oil return signal and enters the oil tank through an oil return pipeline; and (6) the controller sends out a discharge signal aiming at oil smoke of the phase modifier oil system. The control method for the phase modifier oil system has the advantages that full automated control of the phase modifier oil system over supply, jacking, return and oil contamination discharging of the lubricating oil is achieved, and normal operation of the system is ensured under the condition that main parts of the system fail.

Owner:JIANGSU JIANGHAI LUBRICANTS HYDRAULIC EQUIP

Automatic liquid recovering and supplementing apparatus for fully-closed tissue dewatering machine

PendingCN106546467ASave human resourcesAchieve recyclingPreparing sample for investigationEngineeringReagent

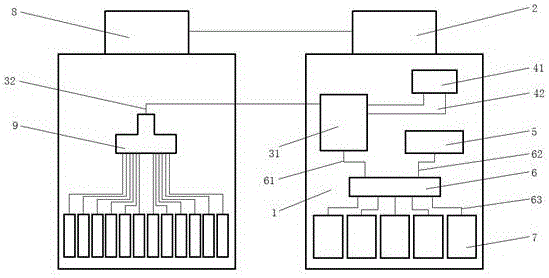

The invention discloses an automatic liquid recovering and supplementing apparatus for a fully-closed tissue dewatering machine. The automatic liquid recovering and supplementing apparatus comprises a box, wherein a control module, a reagent recovery and purification module, a gas path module, a concentration matching module, a liquid path module and a liquid supplementing module are arranged in the box, the control module, the reagent recovery and purification module and the gas path module are arranged above the internal of the box, the gas path module and the reagent recovery and purification module are communicated, the upper portion of the reagent recovery and purification module is communicated to a tissue dewatering machine, the lower portion of the reagent recovery and purification module is communicated to the liquid path module, the concentration matching module is communicated to the liquid path module, the liquid supplementing module is positioned below the liquid path module and is positioned on the bottom portion of the box, and the liquid supplementing module is communicated to the liquid path module. According to the present invention, with the automatic liquid recovering and supplementing apparatus, the automated recovery, the purification and the supplementing of the dewatering reagent in the fully-closed tissue dewatering machine are achieved, the human resource is saved, the recycling of the dewatering reagent is achieved, and the working efficiency is substantially improved.

Owner:无锡启盛实验设备有限公司

Device and method for recovery, purification and reusing of high-purity HE(helium) in crystal growth

ActiveCN103204483AReduce production costsAutomate recyclingNoble gas compoundsMolecular sieveProgrammable logic controller

The invention discloses a device and a method for recovery, purification and reusing of high-purity HE(helium) in crystal growth. The device comprises a gas booster pump, a first gas storage tank, an oil gas filter, a molecular sieve, a second gas storage tank, an ultralow temperature adsorbing cooling pump, a heat regenerator, a gas detector, a third gas storage tank and a PLC (programmable logic controller) controller. The method includes pressurizing, purifying, edulcorating and the like. The device and the method for recovery, purification and reusing of high-purity HE in crystal growth have the advantages that the molecular sieve and the cooling pump are taken as an adsorbing source to perform physical adsorption, an automatic detecting and control system is built up to perform circular purification and to reach the 5N high-purity level, HE filled in a cavity is recovered, purified and reused in the crystal growth to realize automatic HE recovery, purification and reuse, and more than 80 % HE production cost is saved.

Owner:贵阳嘉瑜光电科技咨询中心

Crushed aggregate separation device

PendingCN109859908AUniform sizeEasy to separateBasic electric elementsPneumatic tablesAirflowEngineering

The present invention discloses a crushed aggregate separation device. The crushed aggregate separation device comprises a crushing mechanism, a transportation mechanism, a shaking table separation mechanism and a dust removal mechanism. The crushing mechanism comprises a support, a case, a fixed cutting tool, a rotation cutting tool module and a first drive mechanism, material transportation between the crushing mechanism and the shaking table separation mechanism is achieved through the transportation mechanism, the shaking table separation mechanism comprises a pedestal, a shaking table arranged at the upper side of the pedestal, eccentric swing mechanisms, and a second drive mechanism and a blower mechanism which are arranged in the pedestal. Compared to the prior art, a discarded cable is cut to particle mixture through the crushing mechanism, particles in the particle mixture are more uniformly dispersed on the shaking table under the blowing of the blowing airflow to reduce bonding, then eccentric swing mechanisms are combined to perform further vibration separation for the shaking table to achieve automatic recycle of metal in the discarded cable so that the separation effect of the metal particulate matters and plastic particulate matters is good and the recycle profit is high.

Owner:广东新中南电缆有限公司

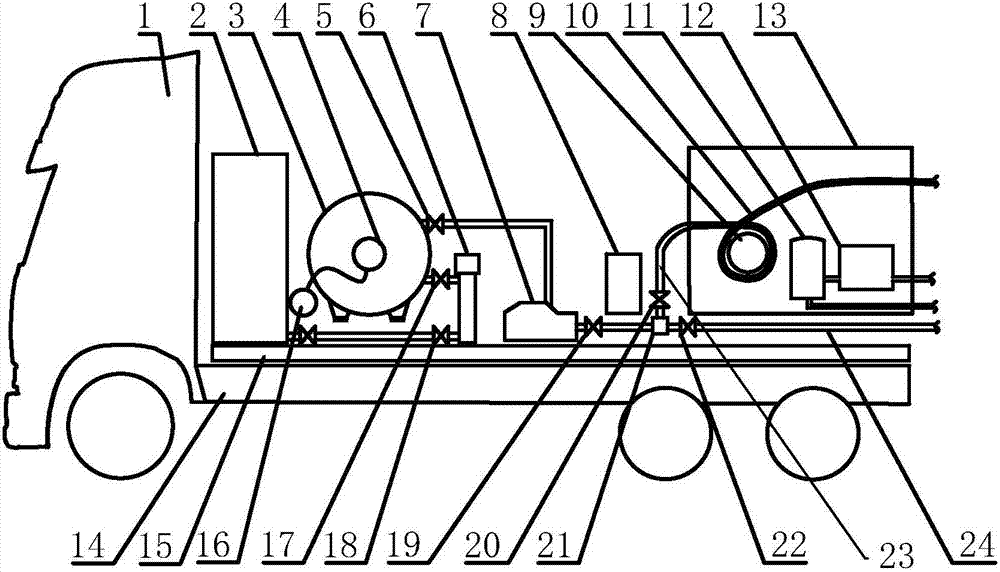

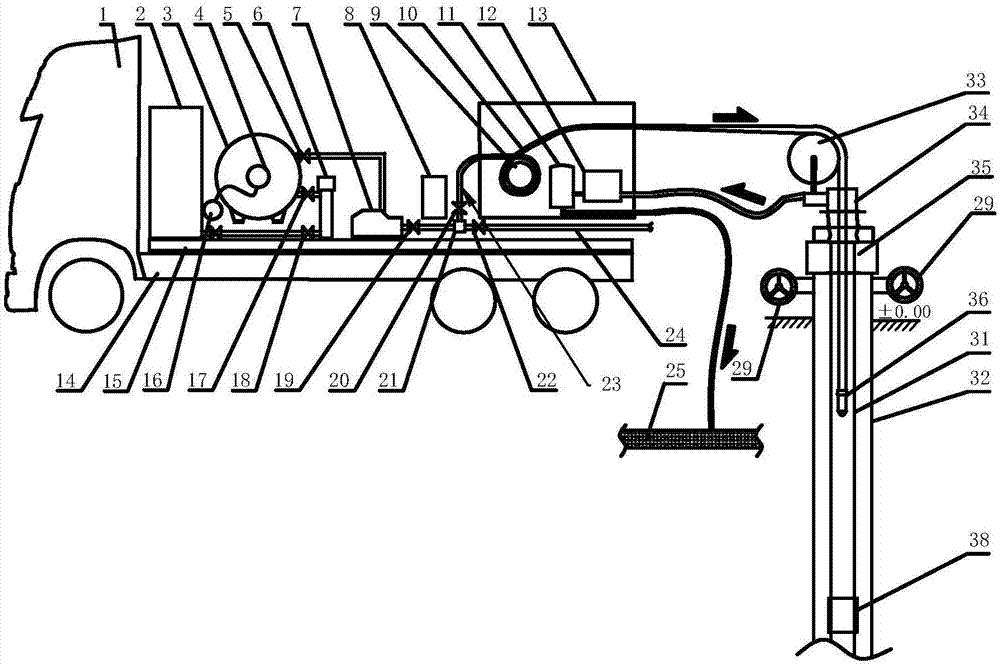

Environmentally friendly cleaning car for oil well operation

PendingCN106978989AAutomate recyclingImprove cleaning efficiencyCleaning apparatusEngineeringProduced water

An environmentally friendly cleaning car for oil well operation comprises a cold water heating and hot water pressurizing device, a cleaning device and an automatic recovery device, and the cold water heating and hot water pressurizing device comprises a water filling tank, a water filling pump, a heating furnace, a cleaning pump and an electric generator. The cleaning device comprises a sucker rod cleaner, an oil pipe inner wall cleaning assembly and an oil pipe outer wall cleaner, and the automatic recovery device comprises an oil and water automatic collecting box, a recovery pump and an underground oil collecting pipe network; when an oil well is subjected to cleaning operation, a sucker rod is cleaned by the sucker rod cleaner, and before an oil pipe is lifted out of the wellhead, the oil pipe inner wall is cleaned through the oil pipe inner wall cleaning assembly; and in the lifting process of the oil pipe, the oil pipe outer wall is cleaned through the oil pipe outer wall cleaner, and meanwhile, the generated mixture of oil and water is recovered through the automatic recovery device and pressed into the underground oil collecting pipe network. The environmentally friendly cleaning car for oil well operation integrates heating, cleaning and recycling as a whole which is energy-saving and environment-friendly, and automation degree is high.

Owner:玉人超导石油设备有限公司

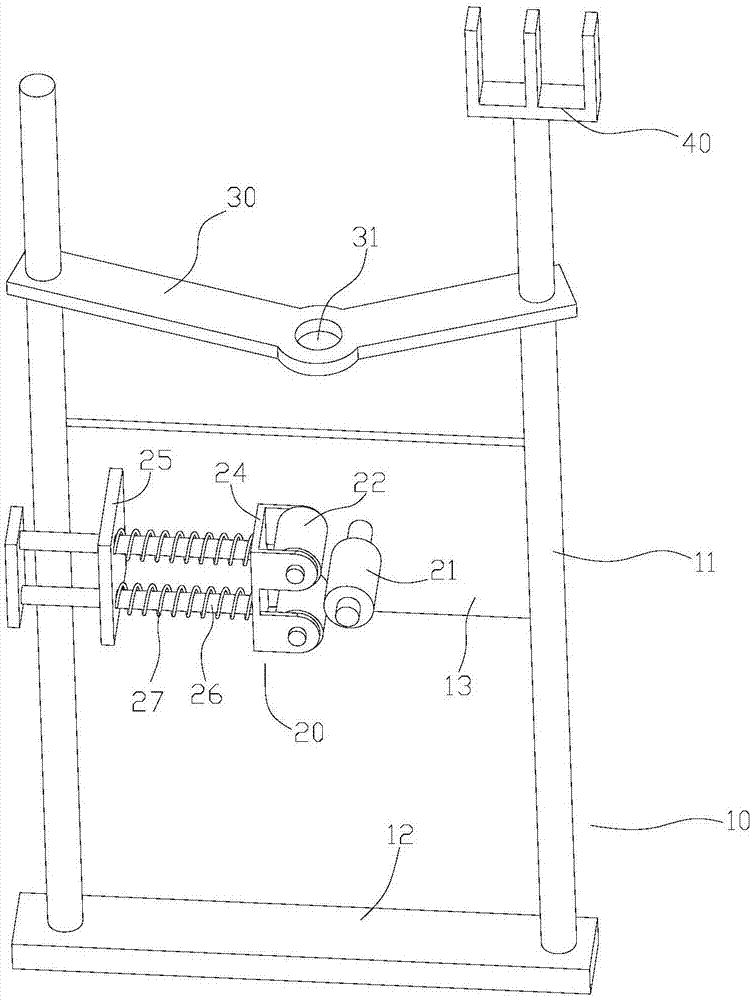

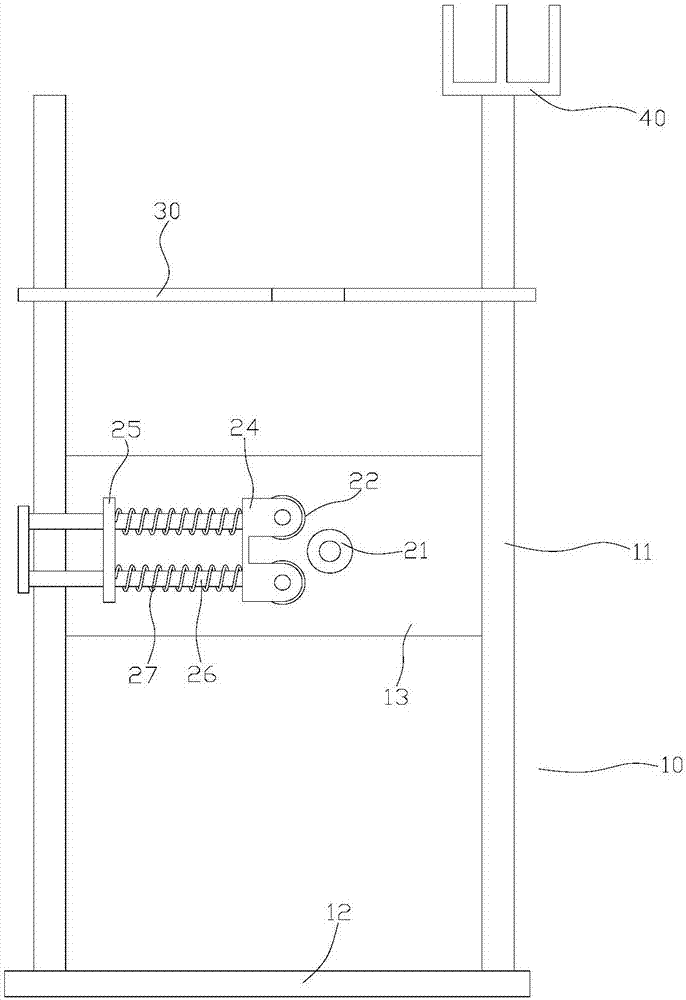

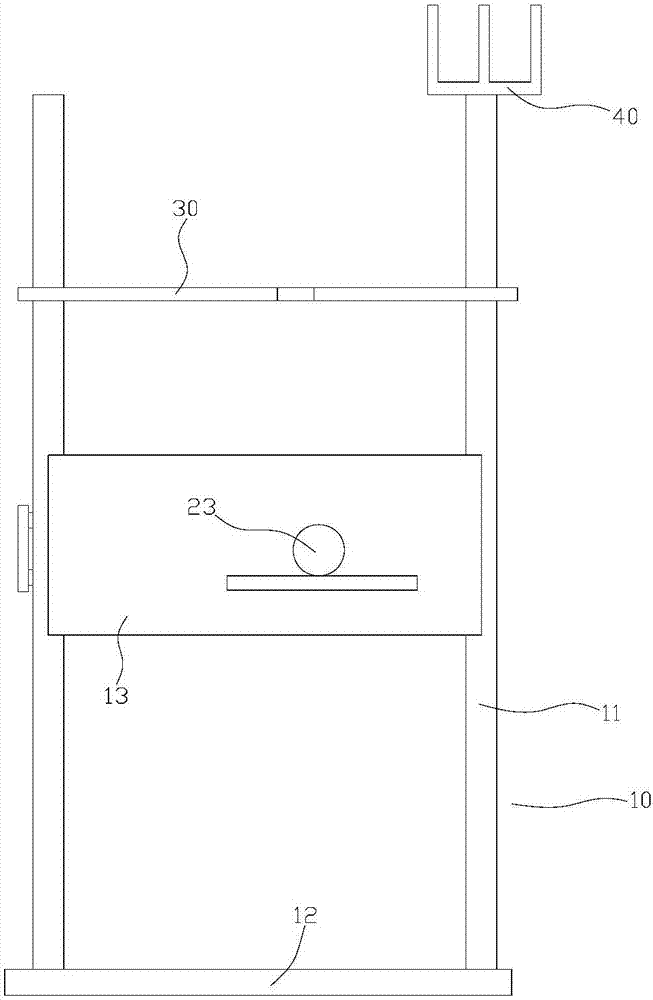

Automatic and quick rope recovery device

PendingCN106865334AAutomate recyclingImprove recycling efficiencyFilament handlingSupport planeElectric motor

The invention discloses an automatic and quick rope recovery device. The automatic and quick rope recovery device comprises a supporting frame and a rope draw-off mechanism; the rope draw-off mechanism is arranged in the middle of the supporting frame and comprises a driven roll shaft and a driving roll shaft driven by a motor to rotate; the driving roll shaft and the driven roll shaft are coaxially arranged in a spaced mode; the outer surface of the driving roll shaft and the outer surface of the driven roll shaft are each coated with a rubber layer; a supporting plate is arranged in the position, above the rope draw-off mechanism, of the supporting frame; and a positioning hole is formed in the supporting plate. According to the automatic and quick rope recovery device, manpower is replaced with the rope draw-off mechanism to conduct rope recovery, automatic rope recovery is achieved, and the rope recovery efficiency is improved; and the positioning hole in the supporting plate is used for supporting and gathering two ropes and preventing the two ropes from being scattered, so that the ropes are pulled more successfully in the pulling process, and the rope recovery efficiency is further improved.

Owner:EXTRA HIGH VOLTAGE POWER TRANSMISSION NANJING OF CHINA SOUTHERN POWER GRID

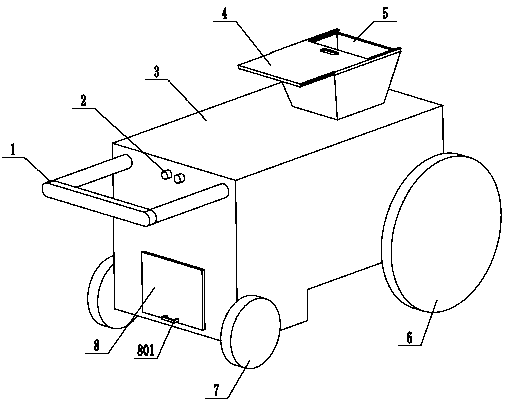

Landscaping waste recycling and processing device

InactiveCN109533740ASmash in timeRealize the collectionRefuse vehiclesWaste recyclingAutomotive engineering

The invention discloses a landscaping waste recycling and processing device. The landscaping waste recycling and processing device comprises a vehicle box, a crushing device, a battery, a motor and aswitch, wherein an expansion box used for expanding the volume is arranged at the lower end of the rear side of the vehicle box, front wheels are arranged on the front side of the lower end of the vehicle box, rear wheels are arranged at the lower end of the expansion box, the diameter of the front wheels is larger than that the diameter of the rear wheels, a feeding box is arranged at the upper end of the vehicle box, a lower baffle is arranged in the vehicle box, a feeding bin is arranged at the upper end of the lower baffle, a power bin is arranged at the lower end of the lower baffle, oneside of the lower baffle is a storage bin, the crushing device is arranged in the vehicle box, the crushing device is arranged between the feeding bin and the storage bin, an upper baffle is arrangedat the upper end of the crushing device, the upper baffle is connected with the wall of the vehicle box, the motor and the battery are arranged in the power bin, the battery is electrically connectedwith the motor, the motor is connected with an axles of the front wheels through gears, the axles are connected with the crushing device through chains, the switch is electrically connected with the motor and the switch is arranged on the wall of the vehicle box

Owner:深圳景丹软件科技有限公司

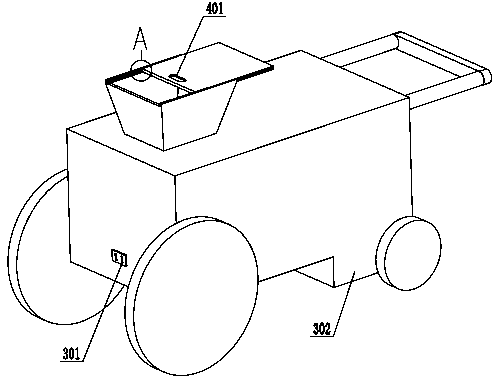

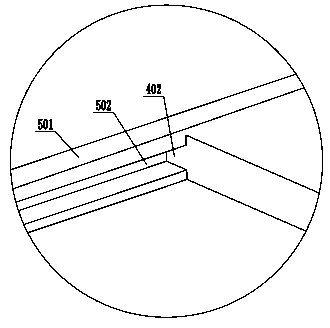

Overall mechanism of livestock robot

InactiveCN108967252AHigh degree of automationAutomate recyclingBird housingsHydraulic cylinderElectric machinery

The invention discloses an overall mechanism of a livestock robot. The overall mechanism comprises a rack. A crawler belt mechanism is fixedly connected to the bottom of the rack; a dumping mechanismis fixedly connected to the middle part of the top of the rack; and a plunger cylinder is fixedly connected to the right side of the dumping mechanism. A plowing motor is fixedly connected to the position, close to the rear side, of the right side of the top of the rack; a lifting mechanism hydraulic cylinder is fixedly connected to the position, close to the plowing motor, of the edge of the right side of the top of the rack; a scraping mechanism is fixedly connected to the top of the rack in front of the dumping mechanism; and a scraping mechanism motor is fixedly connected to the top of therack at the right side of the scraping mechanism and is in transmission connection with the scraping mechanism by a belt. The invention relates to the field of husbandry technology. With the overallmechanism, the automation degree of the mechanism is improved; automatic recycling of dead chickens and chicken manures is realized; the environment temperature, humidity and gas of the chicken housecan be detected; and the environment inside the chicken house is improved.

Owner:深圳市金石智控股份有限公司

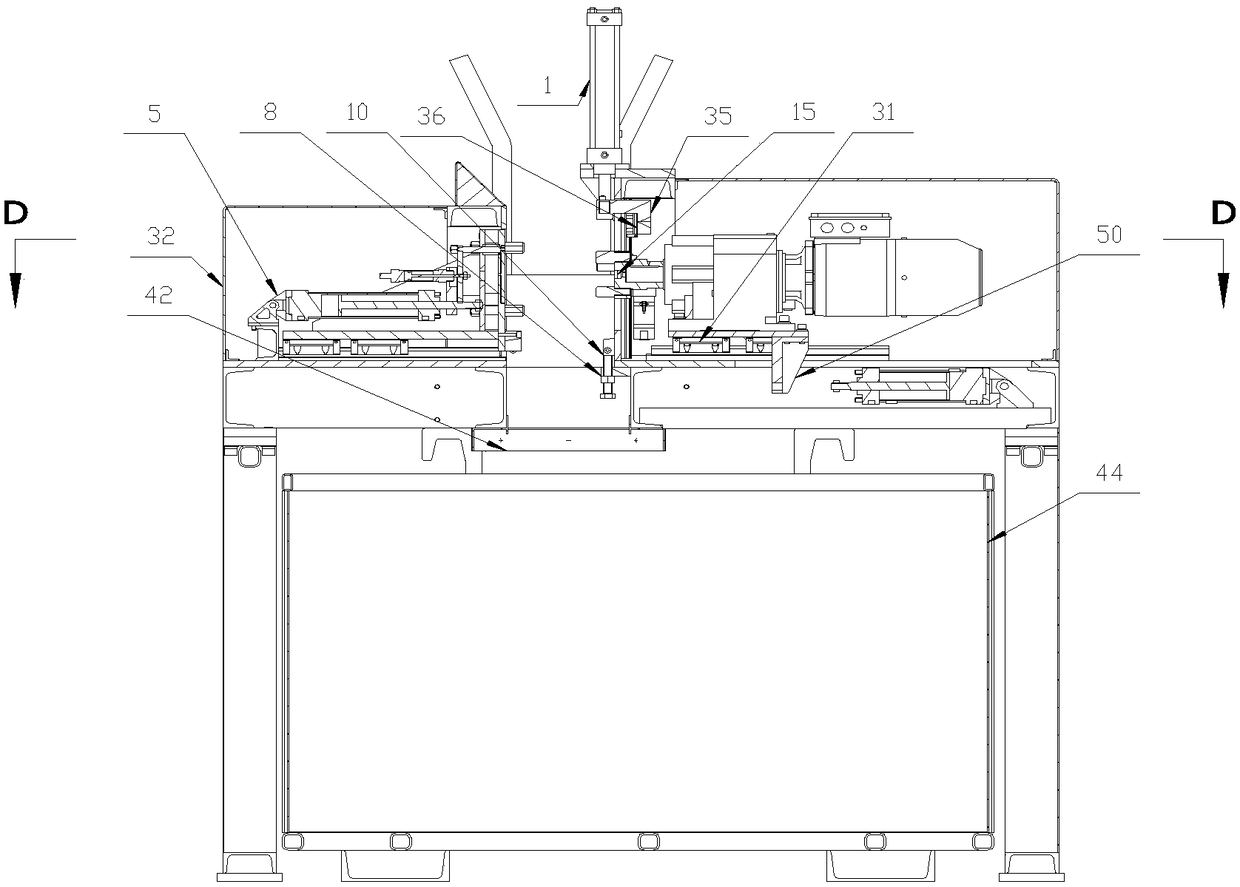

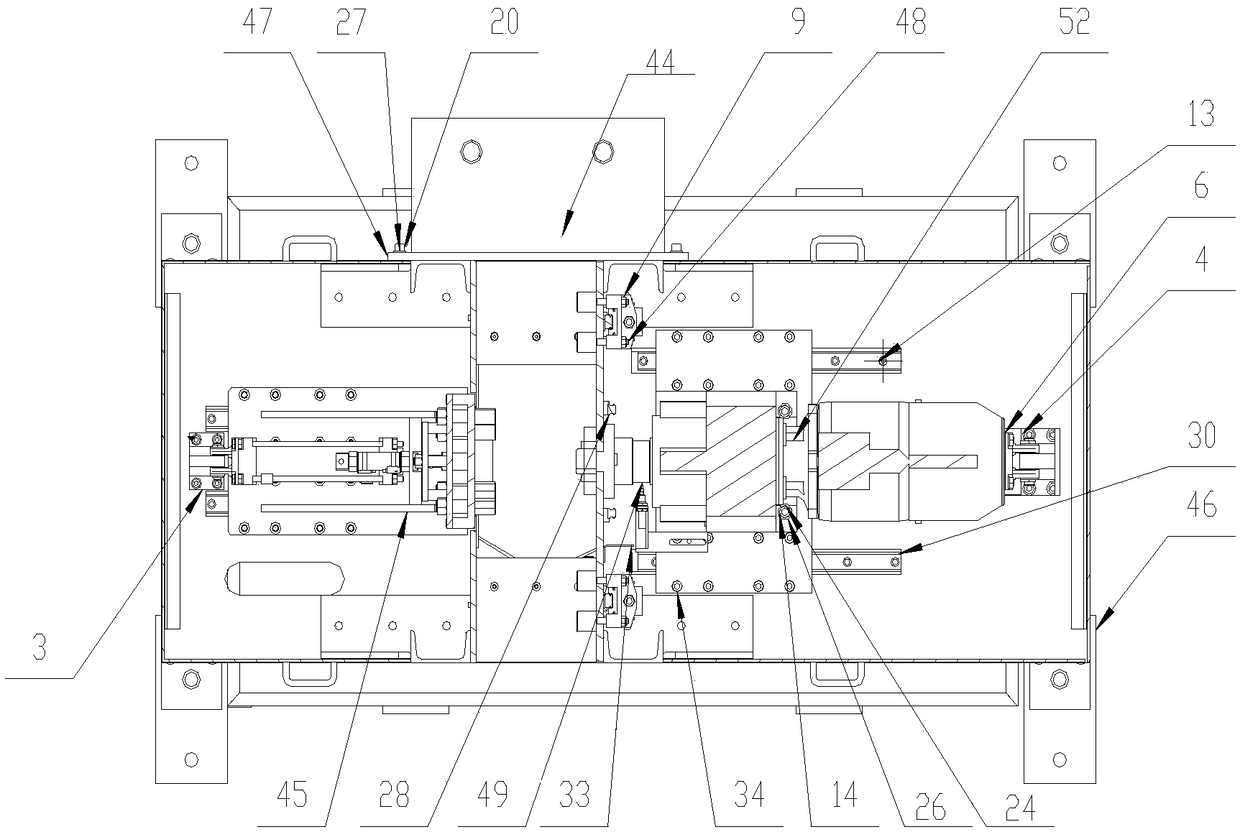

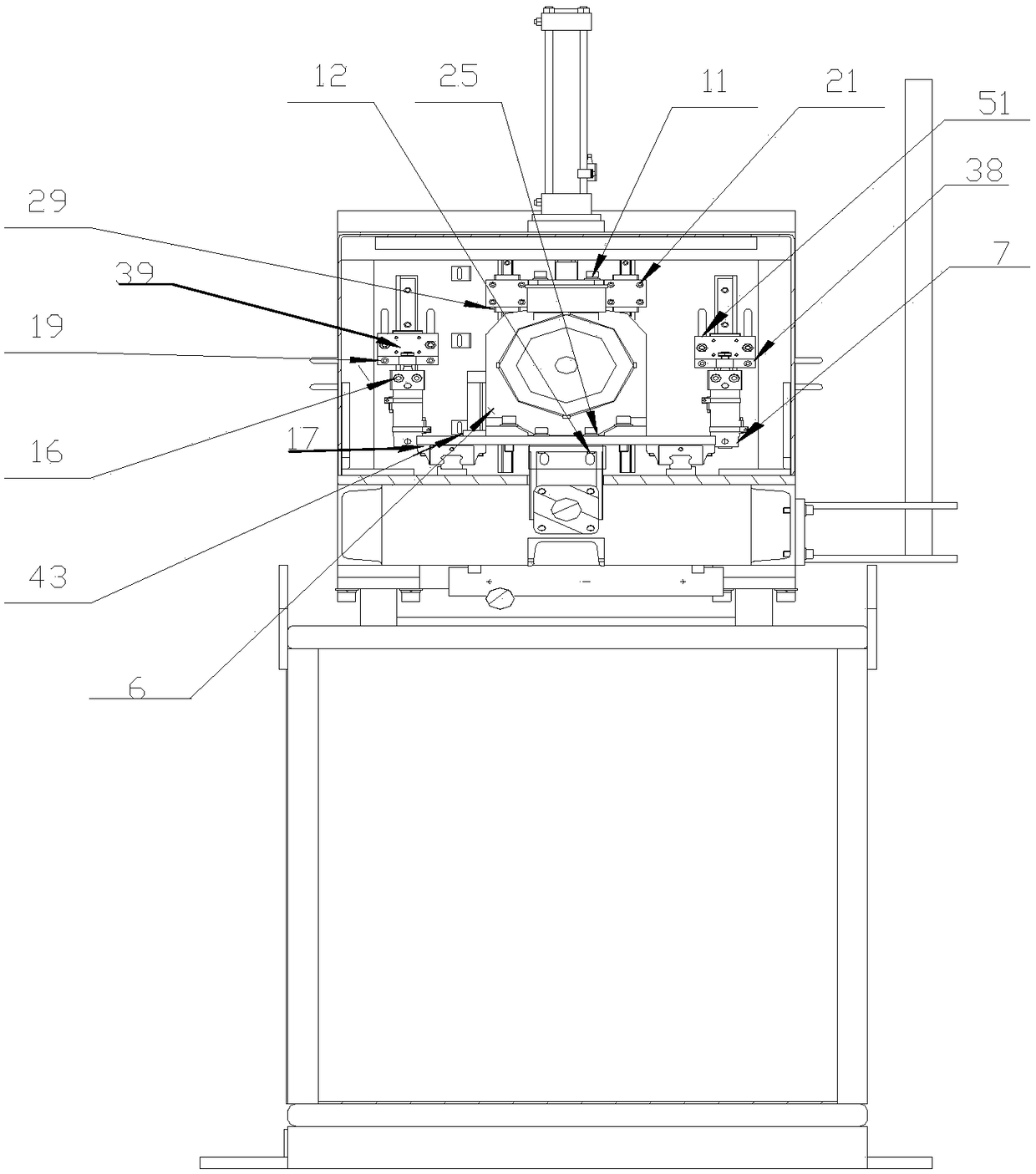

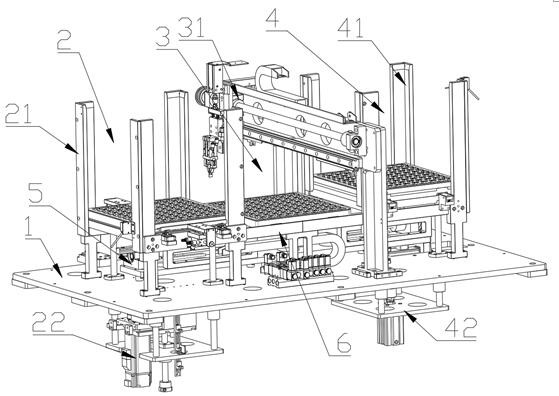

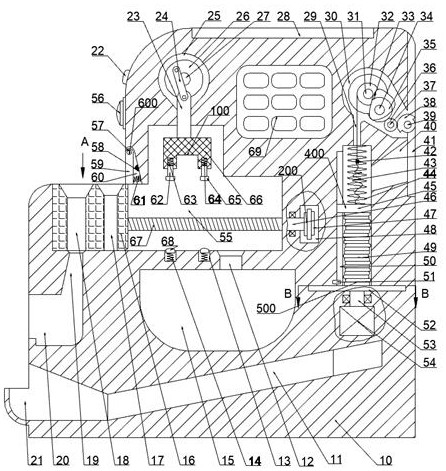

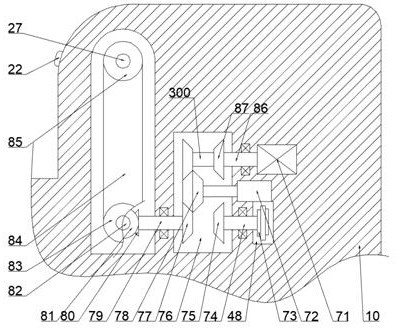

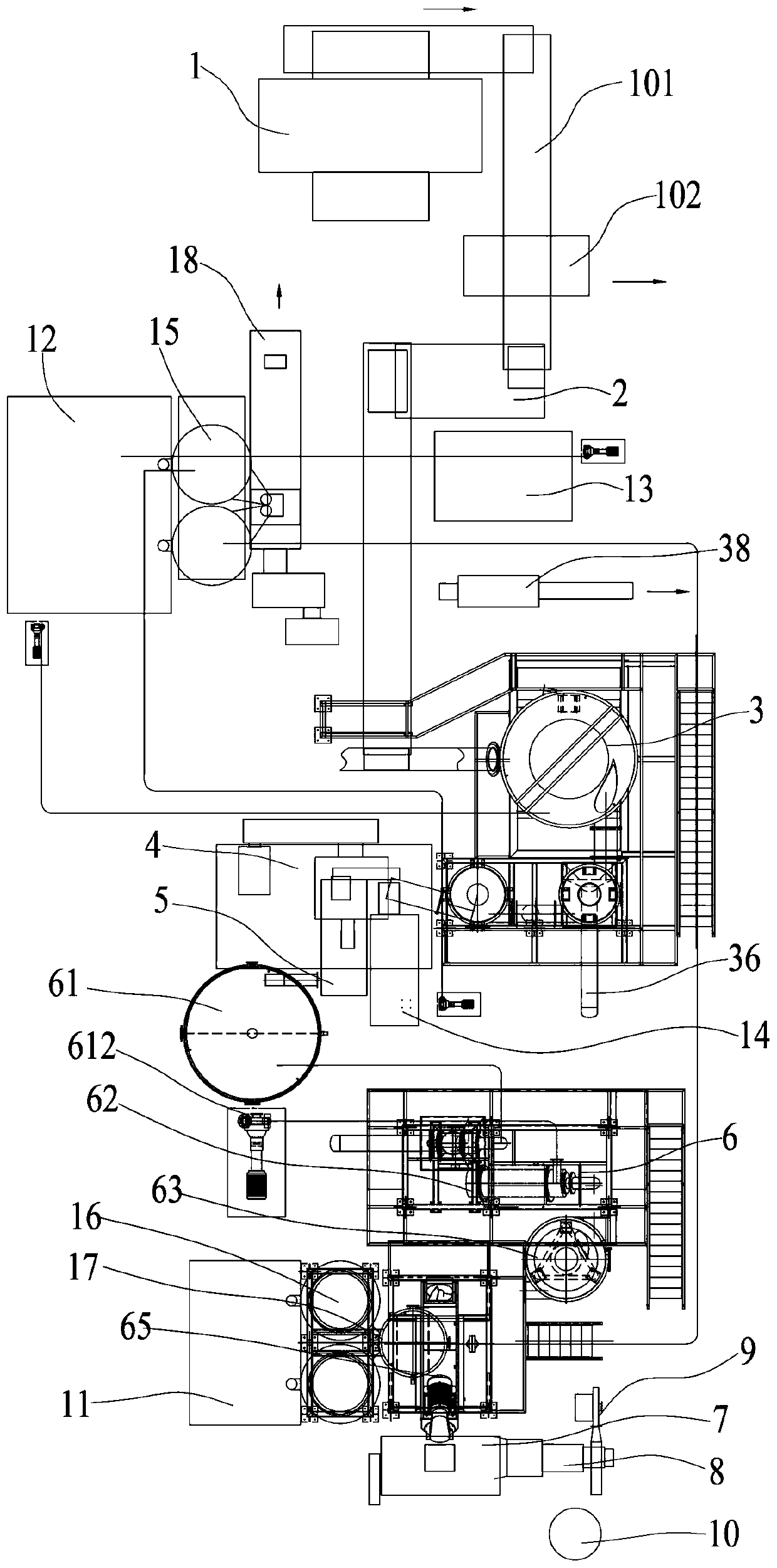

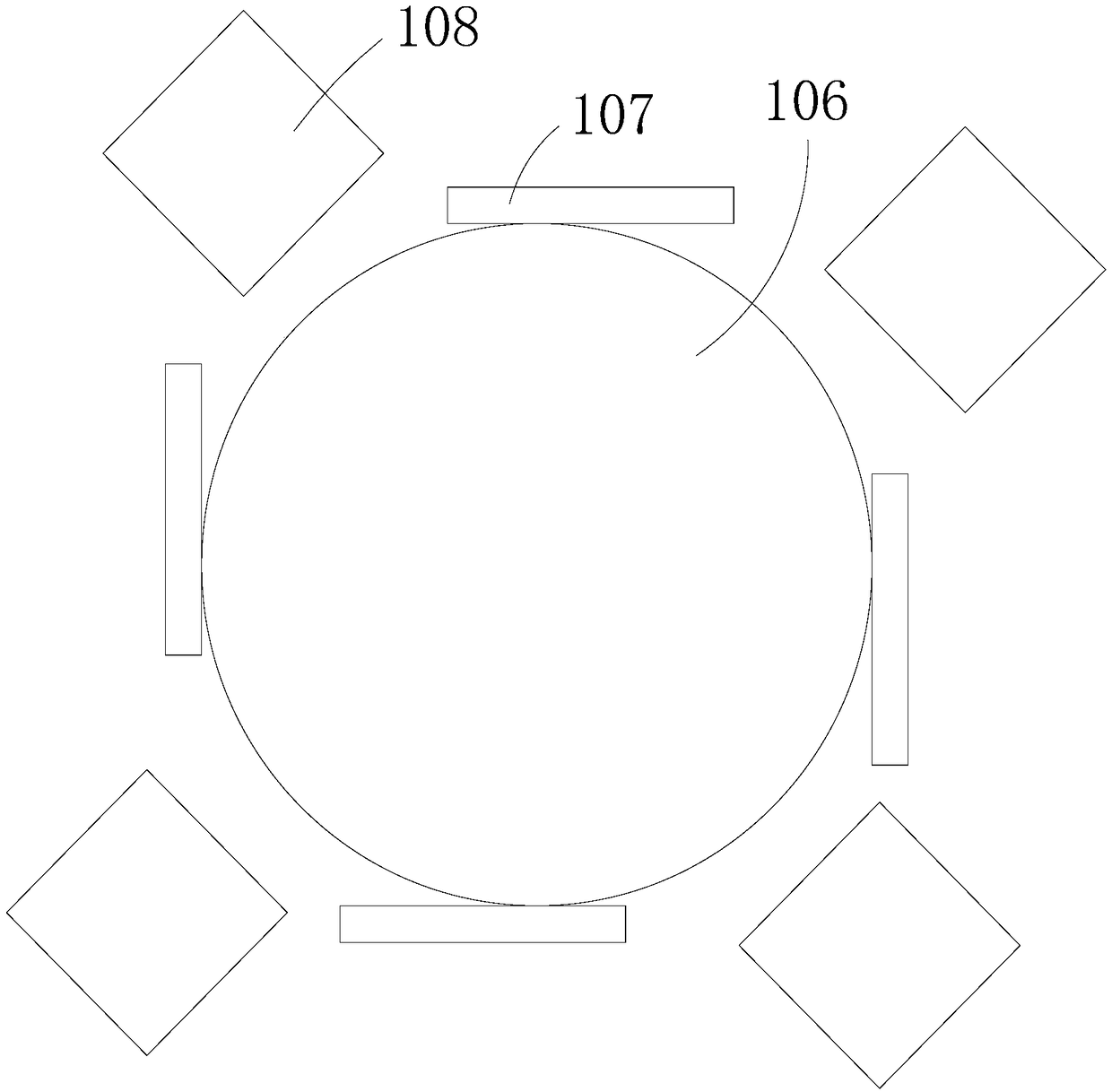

Photosensitive drum assembly equipment

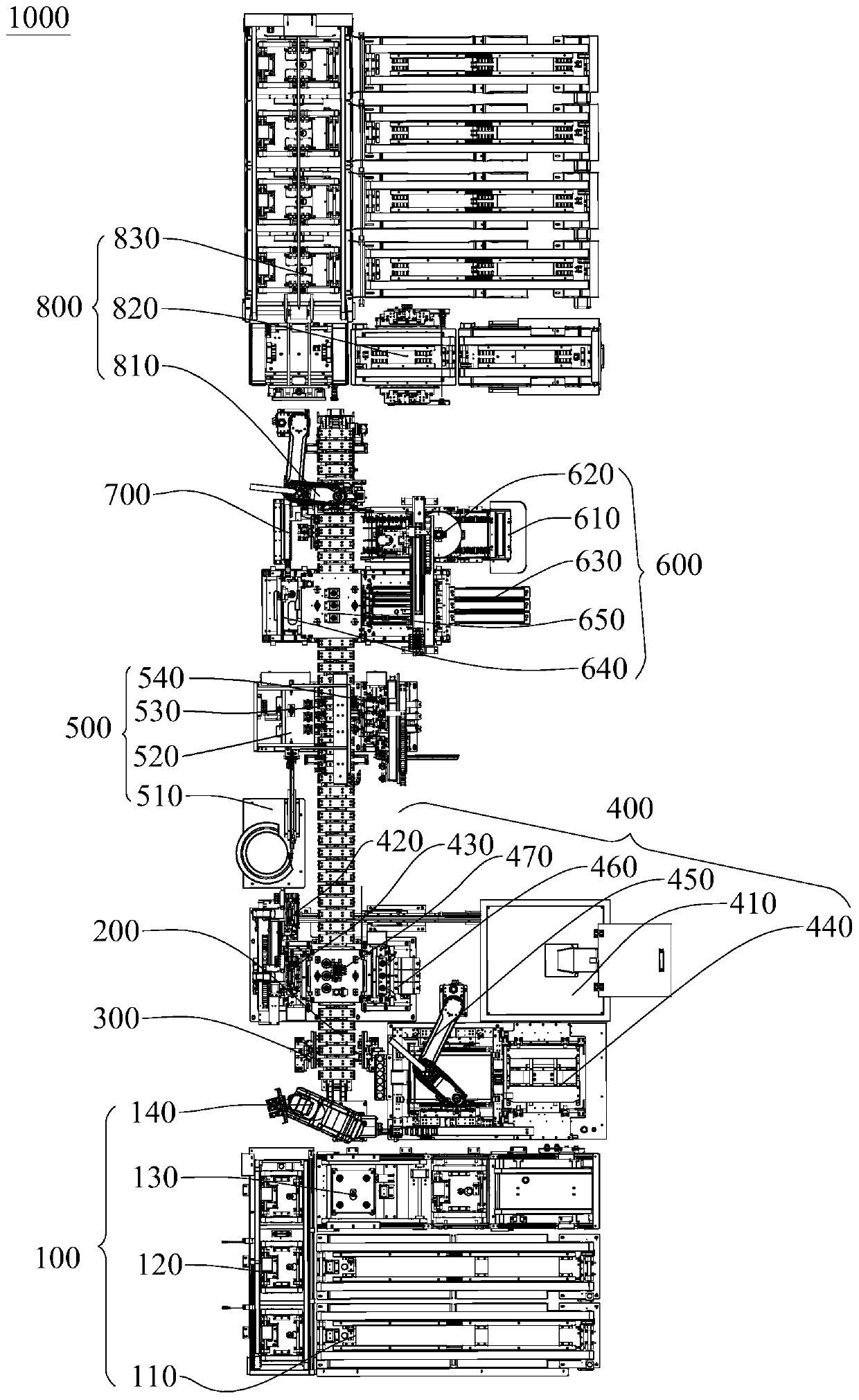

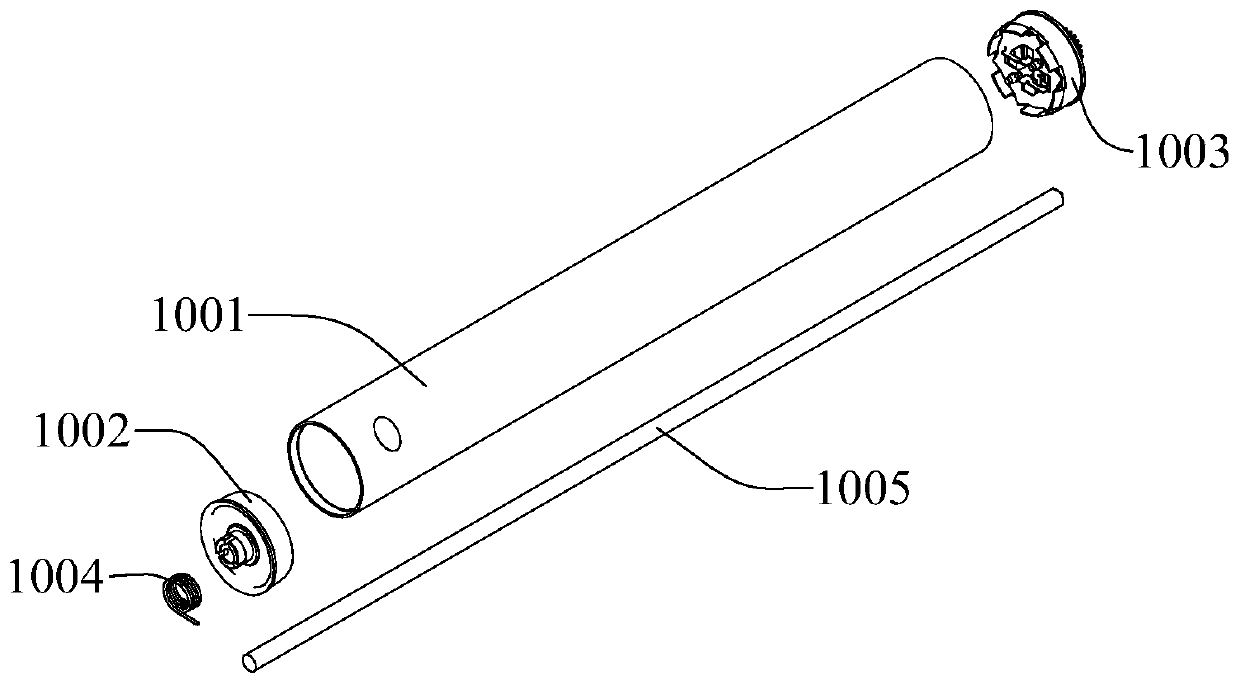

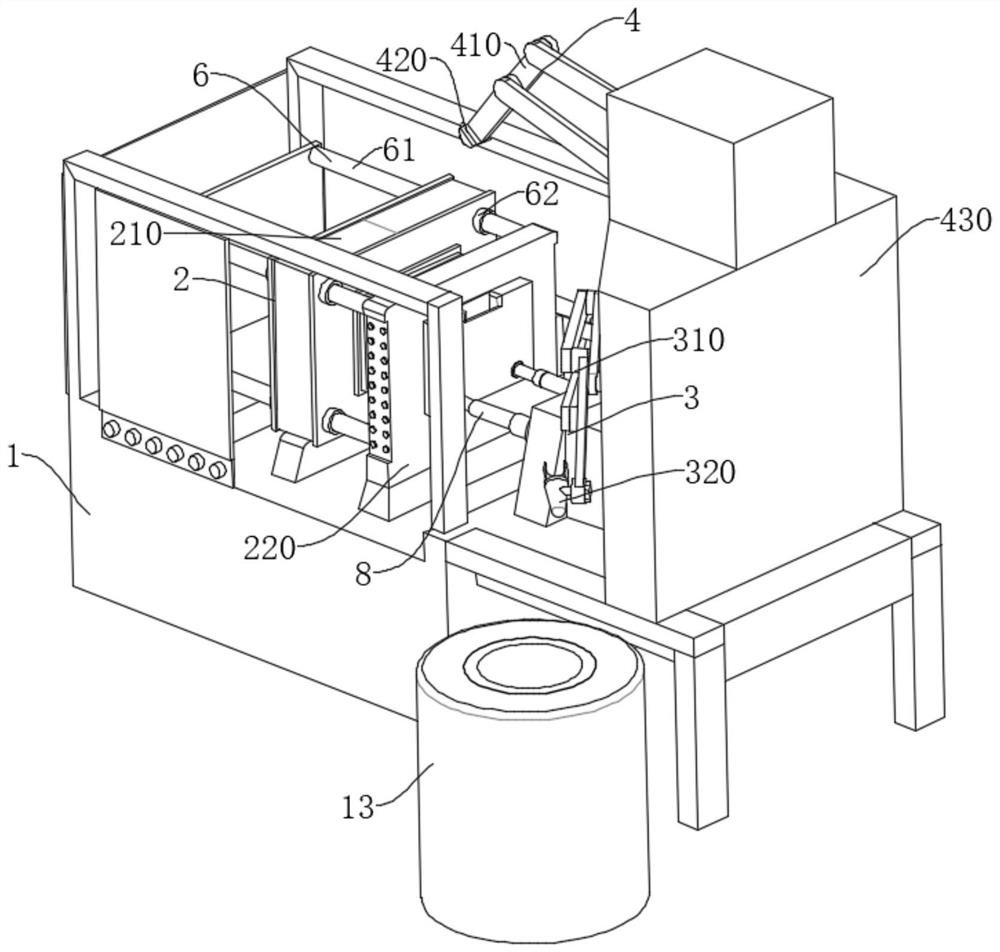

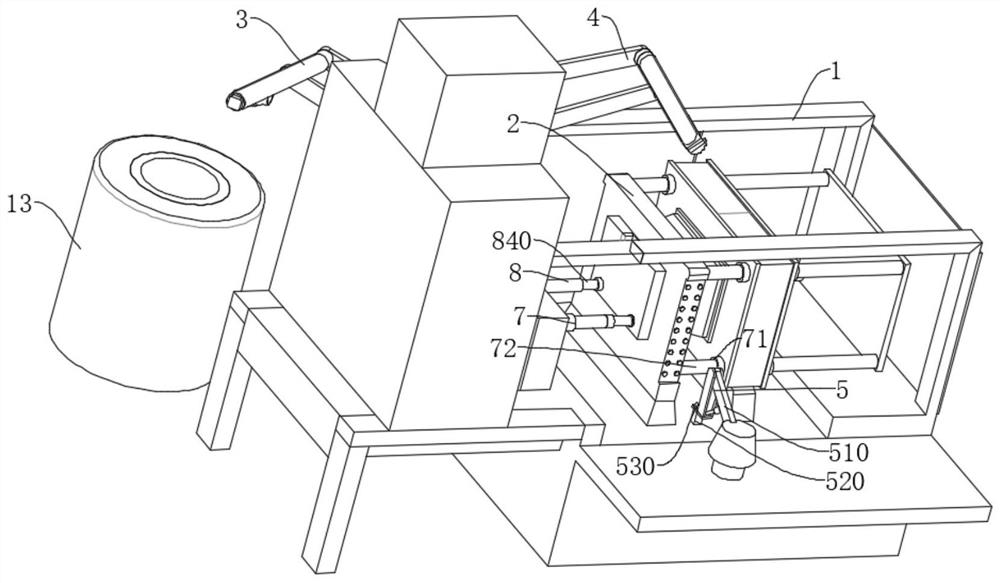

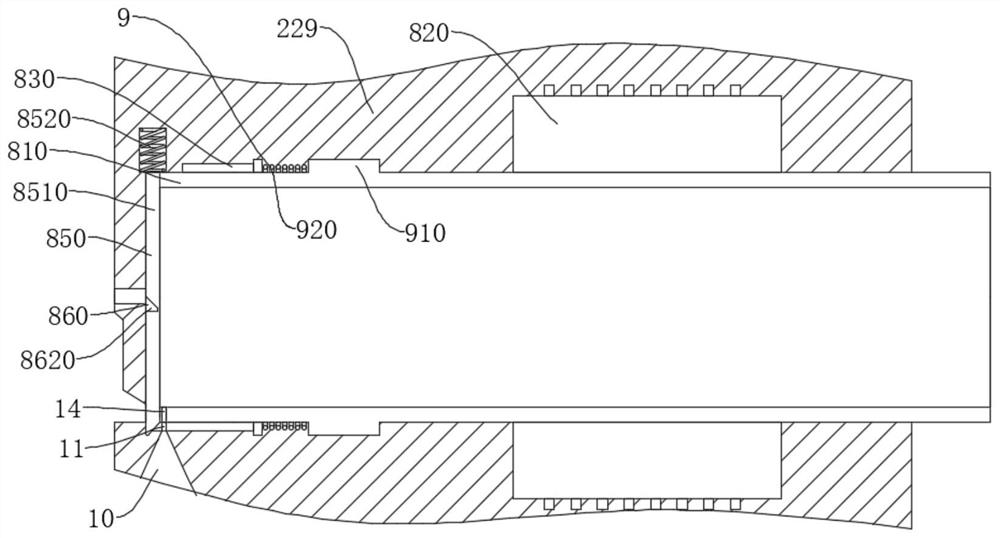

PendingCN111300040AAutomate recyclingCompact and reasonable structureAssembly machinesMetal working apparatusEngineeringMechanical engineering

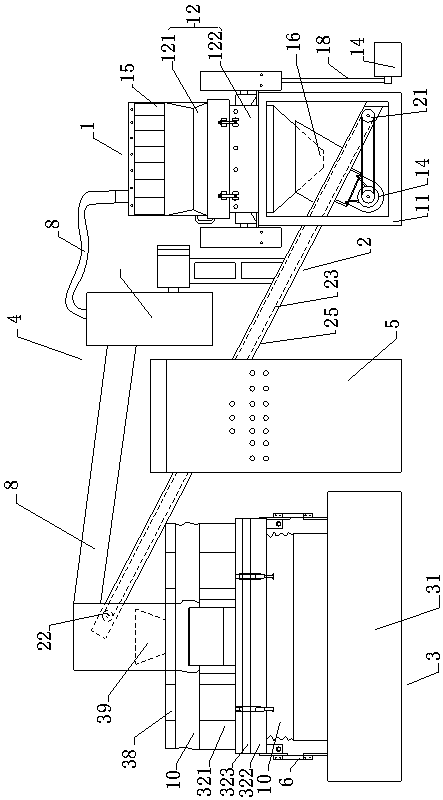

The invention discloses photosensitive drum assembly equipment. The photosensitive drum assembly equipment is used for assembling parts of photosensitive drums and comprises a conveying device arranged on a machine frame, a photosensitive pipe feeding device, a first assembling device used for simultaneously assembling end covers and gears by the photosensitive drums, a second assembling device used for assembling springs by the photosensitive drums, a third assembling device used for assembling shaft cores by the photosensitive drums, a detection device used for detecting the assembly size ofthe shaft cores and a photosensitive drum discharging device, wherein the photosensitive pipe feeding device, the first assembling device, the second assembling device, the third assembling device, the detection device and the photosensitive drum discharging device are sequentially distributed along the conveying device. According to the photosensitive drum assembly equipment, the whole structurelayout is compact and reasonable, through the cooperation of assembly jigs and the assembling devices, automatic feeding, photosensitive drum transferring, assembling, detecting and discharging are realized, automatic recycling of material trays can be realized, and the production efficiency ratio and yield are greatly improved.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Unmanned ship recycling device and unmanned ship

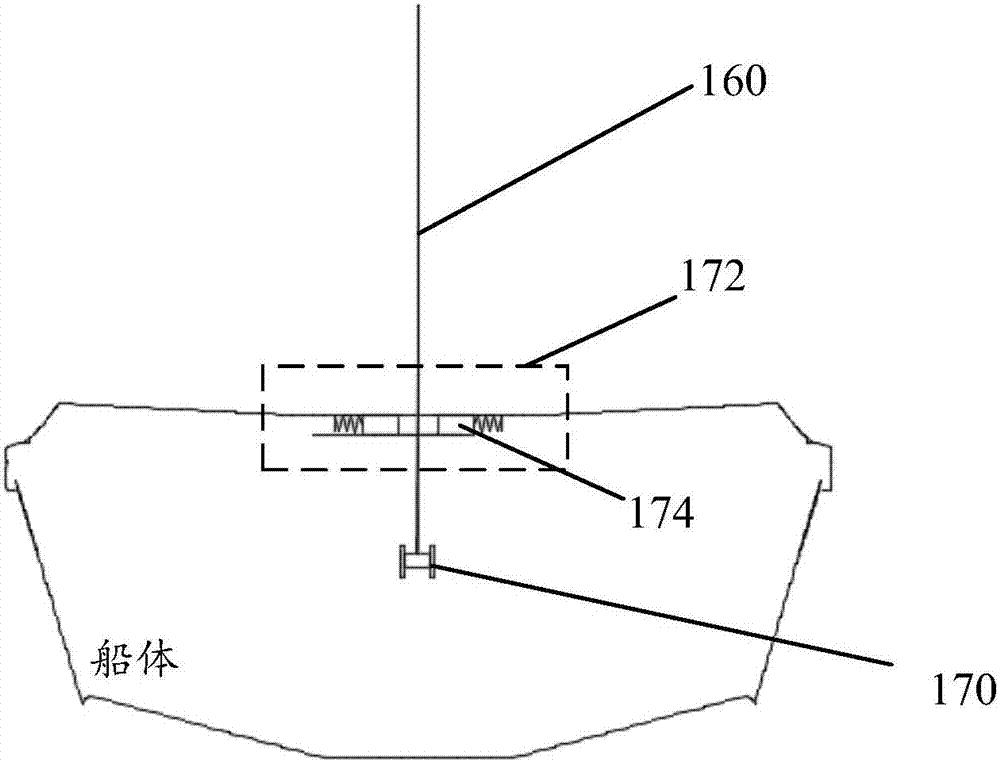

The invention discloses an unmanned ship recycling device and an unmanned ship. The recycling device comprises at least one power device fixed to both sides of a hull respectively; a control system applicable for controlling extension and contraction of the power device; at least one lifting strut which is connected to the power device at both sides of the hull correspondingly and driven by the power device to rotate upward, and the top of the lifting strut is provided with a cable locking mechanism; at least one cable winding device fixed to both sides of the hull respectively; at least one lifting rope of which the head is fixed to the hull and the tail is wound in the cable winding device at the same side of the hull, and the head and the tail of the lifting rope are located at both ends of the hull respectively; and a lifting breast rope which is used for connecting the lifting rope and hung in the cable locking mechanism, and the lifting breast rope is applicable for disconnecting the cable locking mechanism after cables are hung by lifting hooks, and used for driving the unmanned ship to move under the action of the lifting hooks.

Owner:江苏云洲智能科技有限公司 +2

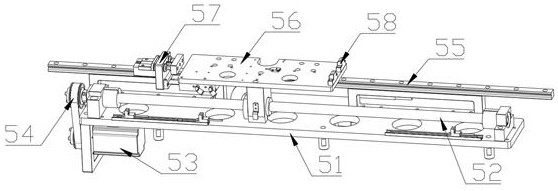

Automatic disassembling equipment for screws at bottom of mobile phone

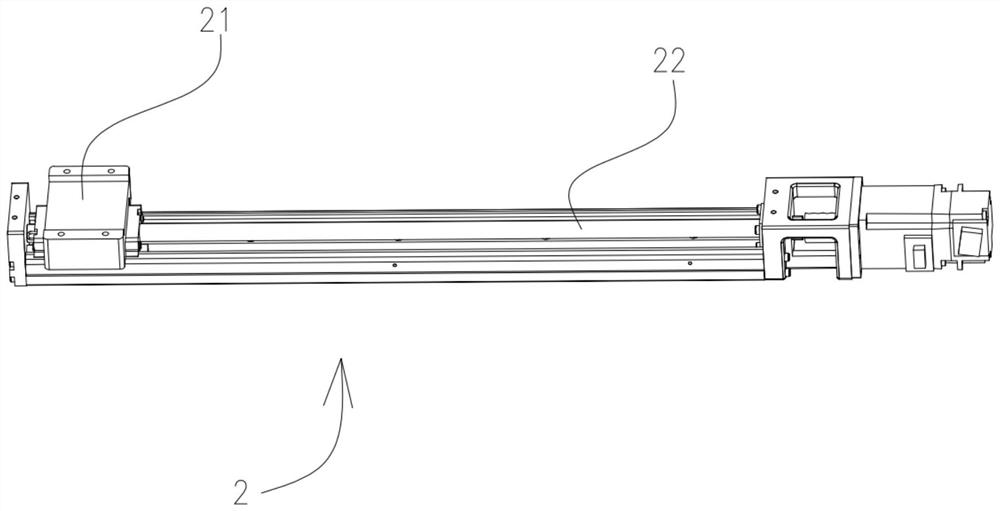

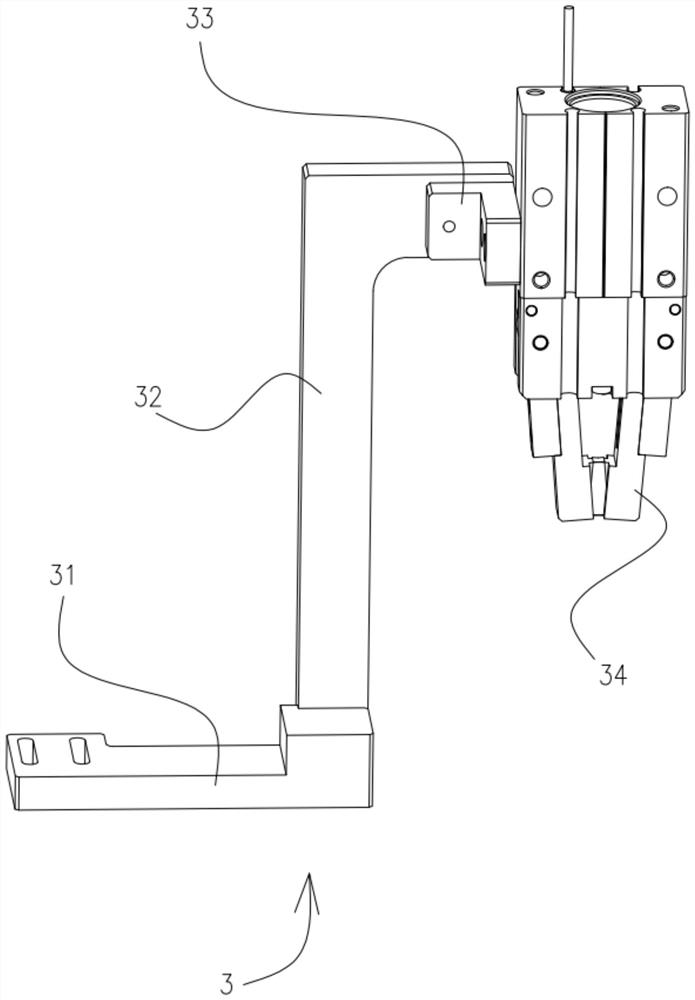

InactiveCN113414581AAutomatic disassembly is accurateAutomate recyclingMetal working apparatusEngineeringCcd camera

The invention discloses automatic disassembling equipment for screws at the bottom of a mobile phone. The automatic disassembling equipment comprises a mobile phone clamp, a clamp moving mechanism, a screw cleaning mechanism, a visual mechanism, a screw disassembling mechanism, a disassembling moving mechanism and a bottom plate. The visual mechanism comprises a visual seat plate, a visual side plate, a camera bottom plate, a CCD camera, a camera side plate, a camera top plate, a support and a light source. The equipment of the invention has the beneficial effects that precise positioning and automatic disassembling of mobile phone bottom screws are achieved through the visual mechanism, the clamp moving mechanism, the disassembling moving mechanism and the screw disassembling mechanism; automatic recovery of the screws after disassembling is achieved through the screw cleaning mechanism; full-automatic removal is realized; and the mechanical structure is simple, stable and efficient.

Owner:深圳明京环境科技有限公司

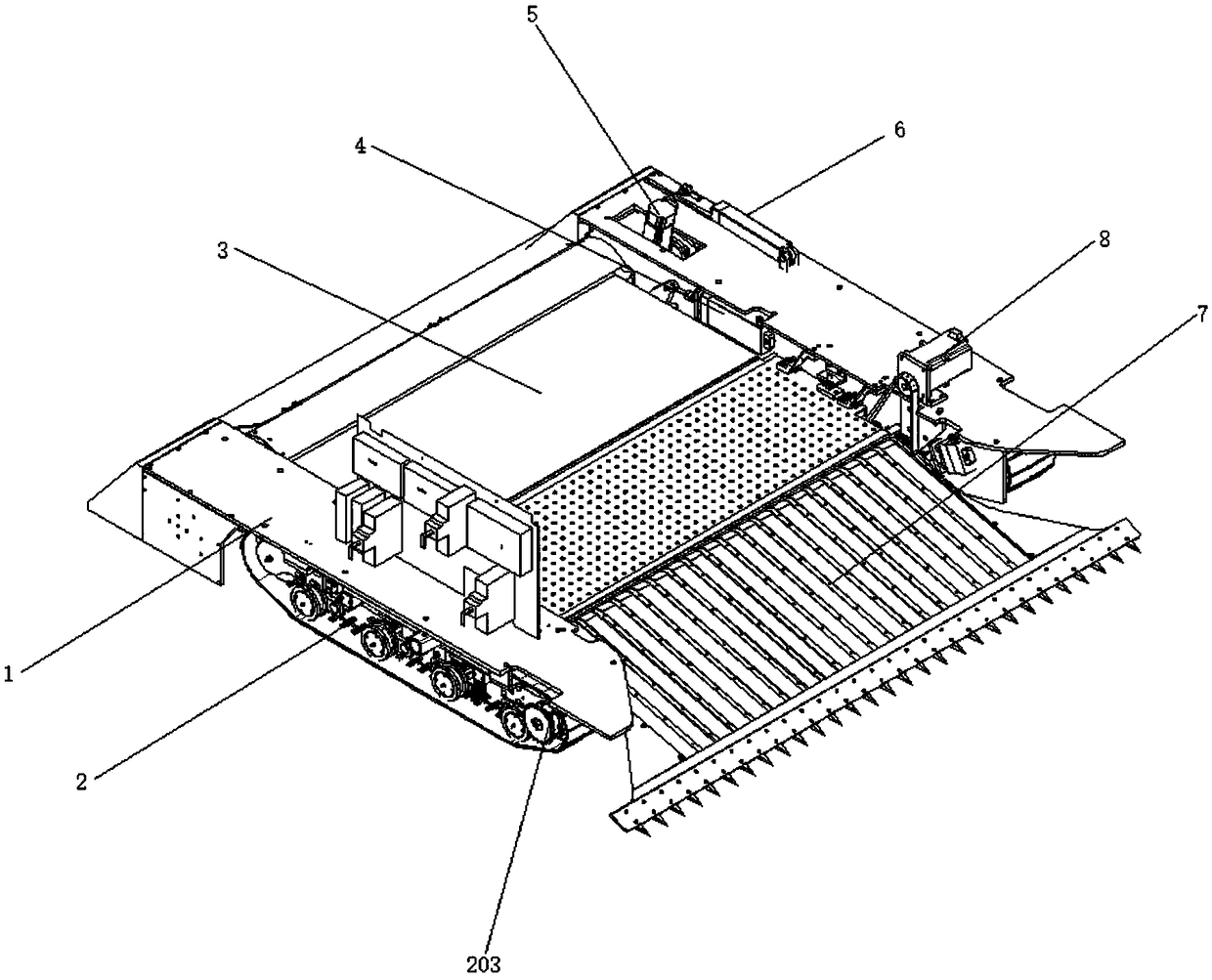

Floating breakwater garbage recycling system and control method thereof

ActiveCN111188312AAutomate recyclingLow costHydro energy generationMachines/enginesEnvironmental engineeringMechanical engineering

The invention discloses a floating breakwater garbage recycling system and a control method thereof. The floating breakwater garbage recycling system comprises a breakwater main body, an anchoring system, recycling devices located on the two sides of the breakwater main body, baffles located on the outer sides of the recycling devices and sweeping devices slidably connected with the baffles; a central processing unit, a power generation device and an energy storage device are arranged in the breakwater main body; the top of the breakwater body is provided with a monitoring device and a signaltransceiver; and the recovery device is fixedly connected with the breakwater body, the baffle is connected with the recovery device and can rotate relative to the recovery device, the sweeping deviceslides in the longitudinal direction of the baffle, and the central processing unit sends a control instruction to the sweeping device and the recovery device. The system can be used for a sea area polluted by marine garbage, floating garbage can be efficiently intercepted, the whole system can complete garbage recycling and post-treatment, and the marine garbage recycling cost and manpower resource waste can be reduced to a great extent.

Owner:JIANGSU UNIV OF SCI & TECH

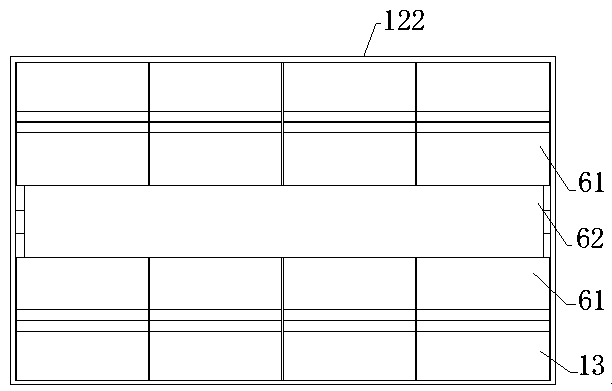

A tray-type pcb board automatic feeding machine

ActiveCN110950069BAutomate recyclingReduce manufacturing costConveyorsStacking articlesMachineIndustrial engineering

The invention discloses a full-automatic loading machine for tray-type PCB boards, which includes a machine platform, and the machine platform is provided with three stations, which are respectively a loading station, a handling station and a closing station. The station, the handling station and the closing station are sequentially arranged on the top plate of the machine table, and the sliding table mechanism and the double-track support rail are fixed on the top plate of the machine table, and the slide table mechanism is fixed on the double-track support rail Between, the slide table mechanism and the double-track support rail are connected to three stations, and the slide table mechanism is used to drive the material tray to transfer the three stations on the double-track support rail; A feeding rack and a feeding jacking mechanism are arranged, and the feeding rack is vertically fixed on the top plate of the machine platform, and the feeding jacking mechanism is fixed directly below the feeding rack; the automatic procedure of the present invention is highly , shorten the production cycle, improve production efficiency, save labor, reduce the production cost of the enterprise, realize continuous production, and have good market application value.

Owner:SHENZHEN BILIAN ELECTRONICS LTD

Pouring forming equipment for automatic production of transmission shell

PendingCN113459359ARealize automated productionHigh degree of automationLiquid storage tankHydraulic ram

The invention discloses pouring forming equipment for automatic production of a transmission shell. The pouring forming equipment comprises a pouring liquid storage tank, and a mold closing assembly, a pouring execution assembly, a mold cooling assembly and a discharging mechanism which are arranged on a rack, wherein the mold closing assembly comprises a first closing mold and a second closing mold, the first closing mold is arranged on the rack in a sliding manner through a guide mechanism, and the second closing mold is fixedly mounted on the rack and is relatively parallel to the first closing mold; the pouring execution assembly comprises a first mechanical arm unit rotatably arranged on the rack and a pouring cup rotatably mounted at the end of the first mechanical arm unit; the mold cooling assembly comprises a second mechanical arm unit rotatably arranged on the rack, an atomizing nozzle and a water tank; and the discharging mechanism comprises a third mechanical arm unit rotatably mounted on the rack, a first hydraulic oil cylinder and an electric clamping jaw. According to the equipment, automatic production of pouring processing can be achieved, the production efficiency is higher, the automation degree is high, the labor cost is reduced, and the safety and practicability are higher.

Owner:镇江市明辰压铸有限公司

Battery glue finished product tray placing machine

PendingCN112010025AEasy to placeHigh precisionConveyor partsWebs handlingElectrical batteryMechanical engineering

The invention discloses a battery glue finished product tray placing machine. The battery glue finished product tray placing machine comprises a base table plate, a partition paper feeding part, a finished product bin, a stripping table and a mechanical arm, wherein the partition paper feeding part, the finished product bin, the stripping table and the mechanical arm are fixed to the upper surfaceof the base table plate, a discharging module is installed below the left end of the base table plate, a collecting module is installed below the right end of the base table plate, the discharging module continuously outputs finished product belts, material sheet units on the upper sides are stripped through the stripping table, and each material sheet unit is formed by adhering a plurality of material sheets to a base film; bottom films on the lower sides are wound by the material receiving module through a first through hole of the base table plate; and a first gripper is mounted on the mechanical arm. The battery glue finished product tray placing machine has the effects that the multiple material sheets are automatically stripped at a time, the mechanical arm automatically places partition paper, the finished products are moved by an automatic discharging swing disc, the speed is high, the production efficiency is high, and the bottom films can be recycled.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

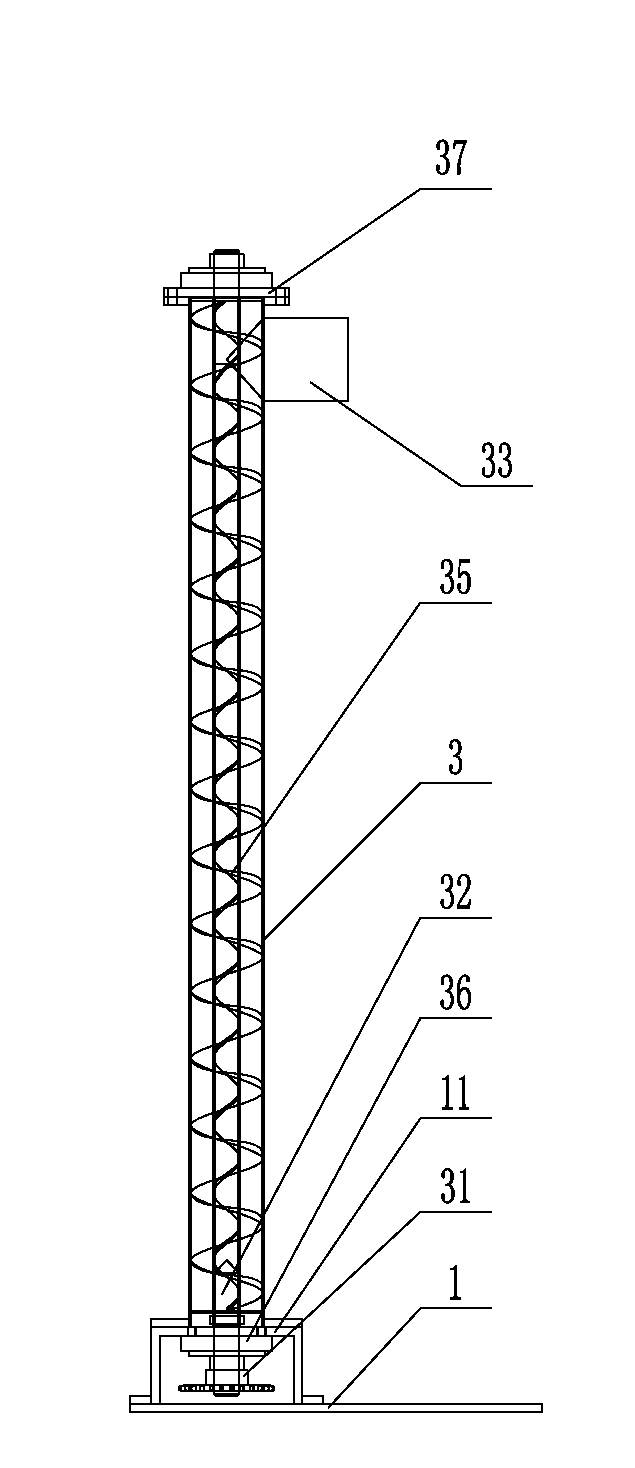

Material recovery device of mochi machine

InactiveCN103005650ARealize automatic feedingAutomate recyclingFood shapingElectric machineryEngineering

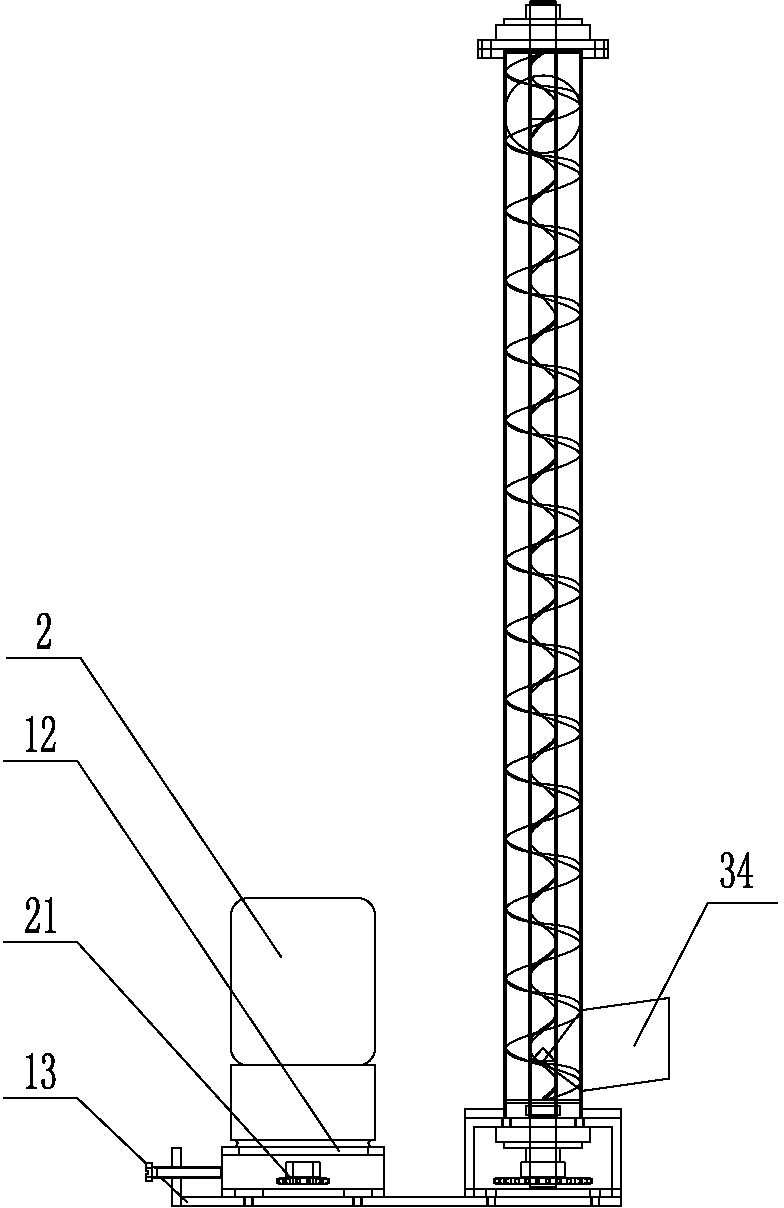

The invention discloses a material recovery device of a mochi machine. The material recovery device of the mochi machine comprises a bottom plate, wherein a rotary cylinder bracket and a motor bracket are arranged on the bottom plate; a motor is arranged on the motor bracket; a first chain wheel is arranged at one side of the motor; a rotary cylinder is arranged on the rotary cylinder bracket; a second chain wheel matched with the first chain wheel is arranged at the bottom part of the rotary cylinder; a center shaft is arranged inside the rotary cylinder; the center shaft is connected with the second chain wheel; a spiral strip rotating around the center shaft is arranged on the center shaft; a product output port is arranged at the top end of the rotary cylinder; and a product input port connected with the mochi machine is arranged at the bottom end. The material recovery device is connected with the mochi machine for recovering the excess stock after the mochi machine product is formed; a positive recovery mode is adopted; automatic feeding of the mochi machine can be realized; and the material recovery device has the following advantages that the excess stock is recovered by positive recovery and conveyed to the mochi machine when the mochi machine works; by adopting the device, automatic recovery can be achieved; time and labor can be saved; the production efficiency is improved; and the conveying part takes auger delivery as powder, so as to recycle the excess stock after fully balancing. The material recovery device is safe and reliable.

Owner:DONGGUAN CHAOSHUN MECHANICAL & ELECTRIC INSTALLATION ENG

Waste battery recycling equipment

InactiveCN112581683ANovel structureEasy to manufactureReturnable containers actuationBattery recyclingEnvironmental engineering

The invention relates to the technical field of waste battery treatment, in particular to waste battery recycling equipment which comprises a machine body. A judgment cavity with an upward opening inthe left side is formed in the machine body, and a sliding body is arranged in the judgment cavity in a left-right sliding mode. The waste battery recycling equipment is novel in structure, easy to manufacture, convenient to use, and convenient to widely popularize and use, a user only needs to put waste batteries into the corresponding battery containing grooves to achieve automatic recycling ofthe batteries, the relation between the input number of the waste batteries and the number of output coins is controlled through the sensor and the single-chip microcomputer system, paid recycling ofthe waste batteries is achieved, and the enthusiasm of people for recycling the waste batteries is improved. And people are encouraged not to discard the waste batteries at will, so that the waste batteries are conveniently recycled in a centralized manner by the country, the environmental awareness of people is improved, and the environmental pollution caused by untimely battery recycling is effectively reduced.

Owner:上海驰持电子科技有限公司

Submersible automatic laying and recovery device

ActiveCN114834601AAutomate recyclingReach protectionCargo handling apparatusGeneral water supply conservationMarine engineeringStructural engineering

The invention discloses an automatic launching and recovering device for a submersible, relates to the technical field of ocean engineering, and solves the problems that the adaptability to severe sea conditions is not strong and the equipment is possibly impacted and damaged due to shaking because a lifting arm is generally manually operated to fix the submersible, and the key point of the technical scheme is that the automatic launching and recovering device comprises a carrier; the traction winding and unwinding device comprises a traction winding and unwinding frame arranged on the carrier; the folding mechanism is arranged on the traction folding and unfolding frame; one end of the traction cable is connected with the traction retractable frame, the other end of the traction cable is connected with the movable end of the folding mechanism, and the traction cable is provided with a traction area; according to the scheme, a specific implementation mode for realizing the recovery and laying operation of the submersible through the traction recovery and laying device is provided, the device can adapt to the working condition that the submersible is subjected to the recovery operation in the state that the motion response of a carrier is large, and the complexity of the recovery operation can be effectively reduced; and the automatic recovery process of the submersible can also be achieved.

Owner:广东智能无人系统研究院(南沙)

Livestock robot overall mechanism

InactiveCN110419465AHigh degree of automationAutomate recyclingBird housingsHydraulic cylinderFarming environment

The invention relates to the technical field of livestock, and discloses a livestock robot overall mechanism which comprises a frame. The bottom end of the frame is fixedly connected with a crawler mechanism, the middle of the top of the frame is fixedly connected with a tipping mechanism, the right side of the tipping mechanism is fixedly connected with a plunger cylinder, the right side of the top of the frame and a position close to the back are fixedly connected with a plowing and harrowing motor, the edge of the right side of the top of the frame and a position close to the plowing and harrowing motor are fixedly connected with a lifting mechanism hydraulic cylinder, the top of the frame is fixedly connected with a field shoveling mechanism which is positioned right ahead the tippingmechanism, the top of the frame is fixedly connected with a field shoveling mechanism motor which is positioned on the right side of the field shoveling mechanism, and the field shoveling mechanism motor is in transmission connection with the field shoveling mechanism through a belt. The livestock robot overall mechanism has the advantages that the automation degree of the mechanism is improved, dead chicken and chicken manure are automatically recycled, chicken farm environment temperature, humidity and gas can be detected, and environments in chicken farms are improved.

Owner:深圳市金石智控股份有限公司

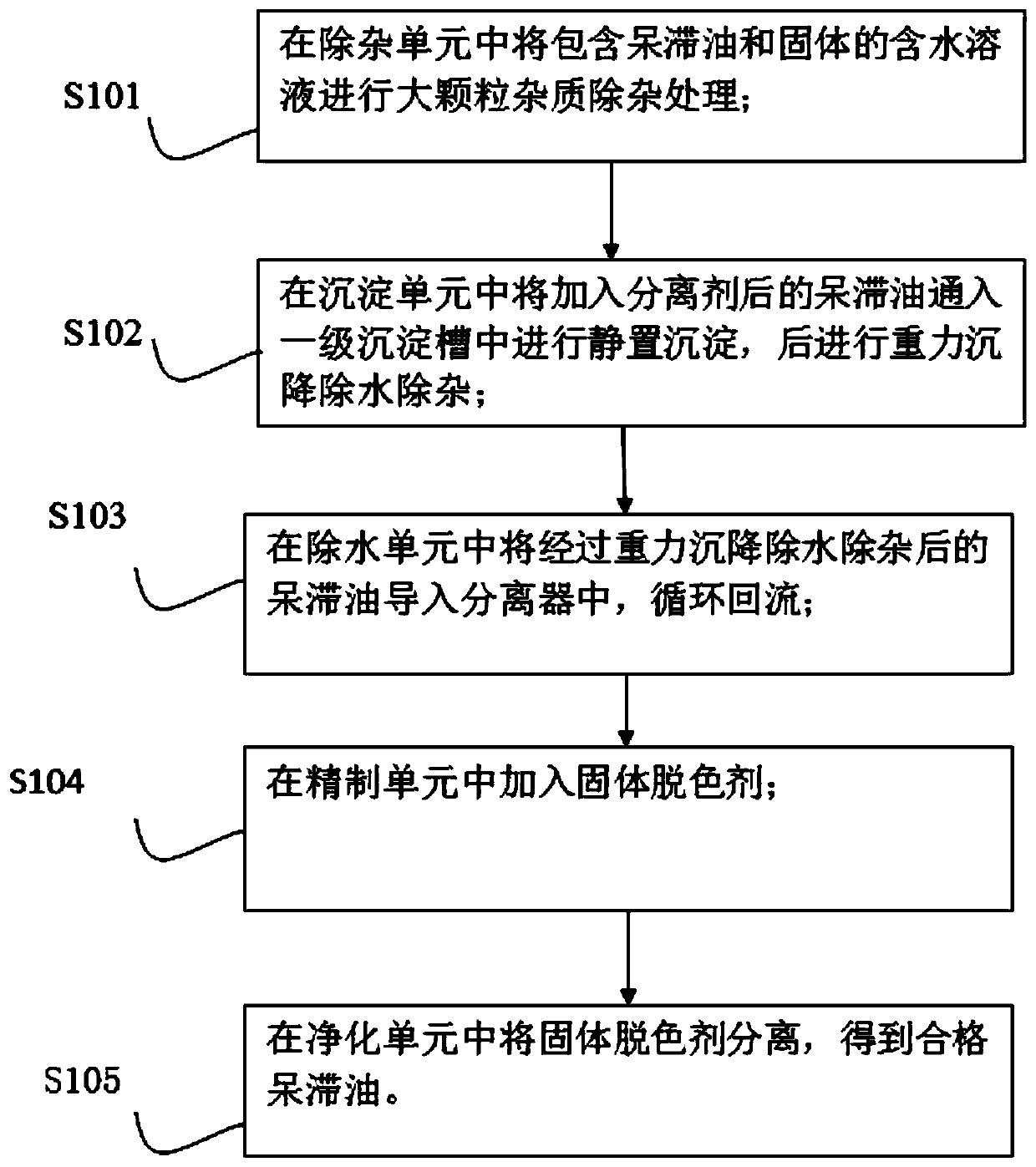

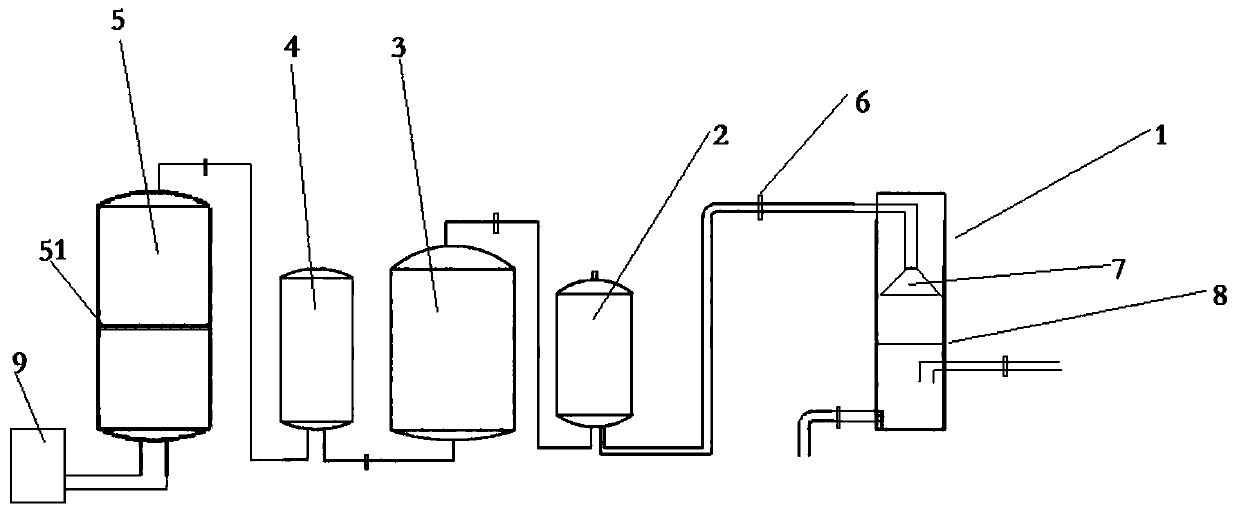

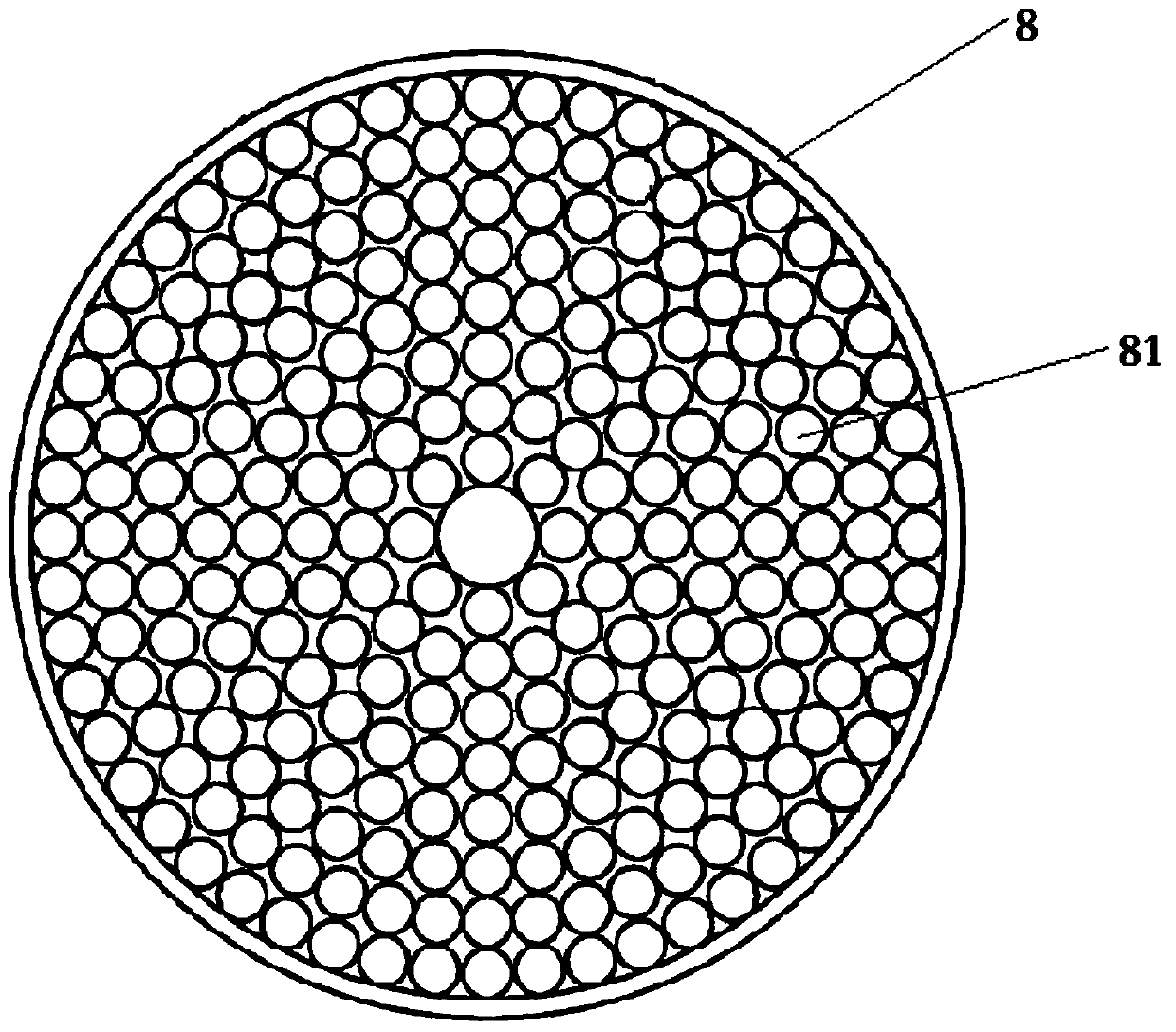

Extruder stagnant oil purification device and recovery and purification method thereof

The invention provides an extruder stagnant oil purification device and a recovery and purification method thereof. Recyclable purified stagnant oil is prepared through the steps of impurity removal,precipitation, water removal, refining and purification, and the problems that stagnant oil resources are wasted and the environment and production are affected are solved. Besides, an impurity removal unit, a precipitation unit, a water removal unit, a refining unit and a purification unit are arranged in the purification device in one-to-one correspondence with the steps in the purification method. The corrosion loss of production can be reduced, and the separation efficiency of oil, water, particles and impurities is high. The purification device is simple and convenient to use. The stagnant oil can be automatically recycled as long as the purification device is started and purification conditions are set. The automation degree is high, and manual operation is reduced.

Owner:广东精美特种型材有限公司

A floating breakwater garbage recovery system and its control method

ActiveCN111188312BAutomate recyclingLow costHydro energy generationMachines/enginesTransceiverEnvironmental engineering

The invention discloses a floating breakwater garbage recovery system and a control method thereof, comprising a breakwater lift main body and an anchoring system, recovery devices located on both sides of the breakwater main body, baffles located outside the recovery device, and sweeping devices slidingly connected to the baffles The main body of the breakwater is equipped with a central processing unit, power generation device, and energy storage device. The top of the main body of the breakwater is equipped with a monitoring device and a signal transceiver device; the recovery device is fixedly connected to the main body of the breakwater, and the baffle is connected to the recovery device and can be recovered relative to the The device rotates, the sweeping device slides longitudinally along the baffle, and the central processing unit issues control commands to the sweeping device and the recovery device. The invention can be used in sea areas polluted by marine garbage, can efficiently intercept floating garbage, and the whole system can complete recycling and post-processing of garbage, and can greatly reduce the cost of recycling marine garbage and the waste of human resources.

Owner:JIANGSU UNIV OF SCI & TECH

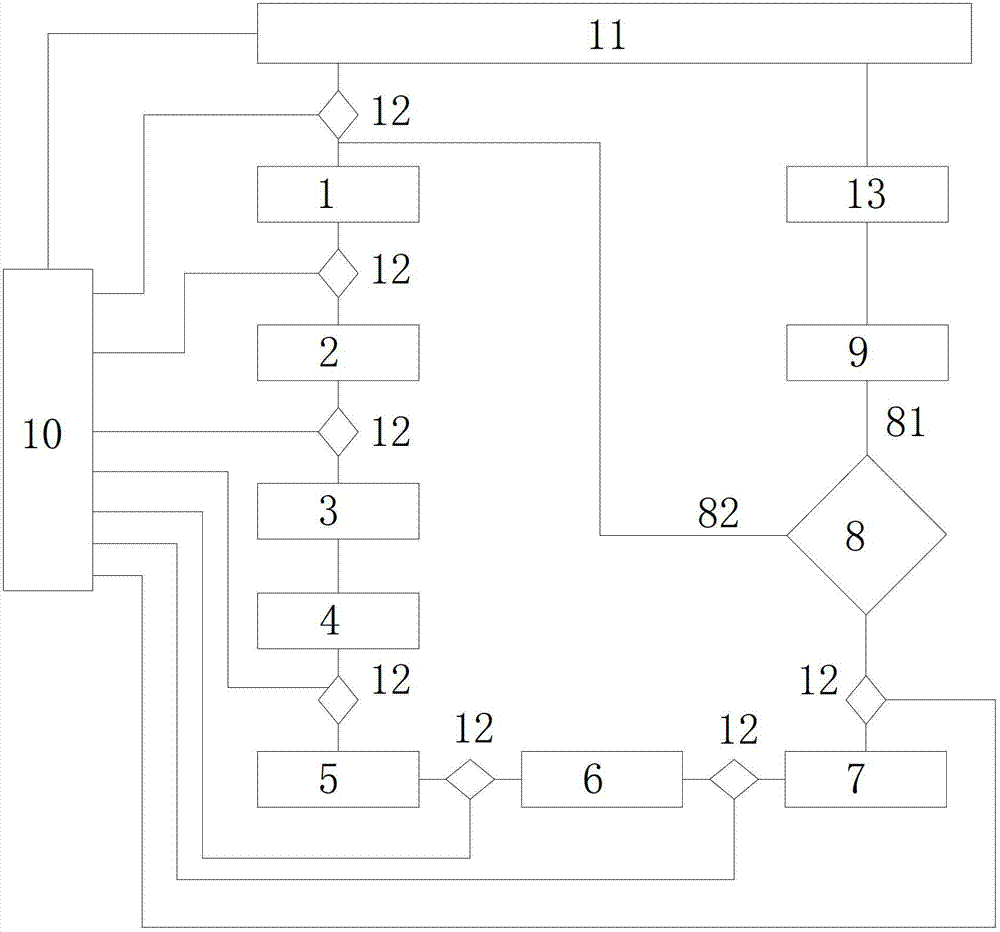

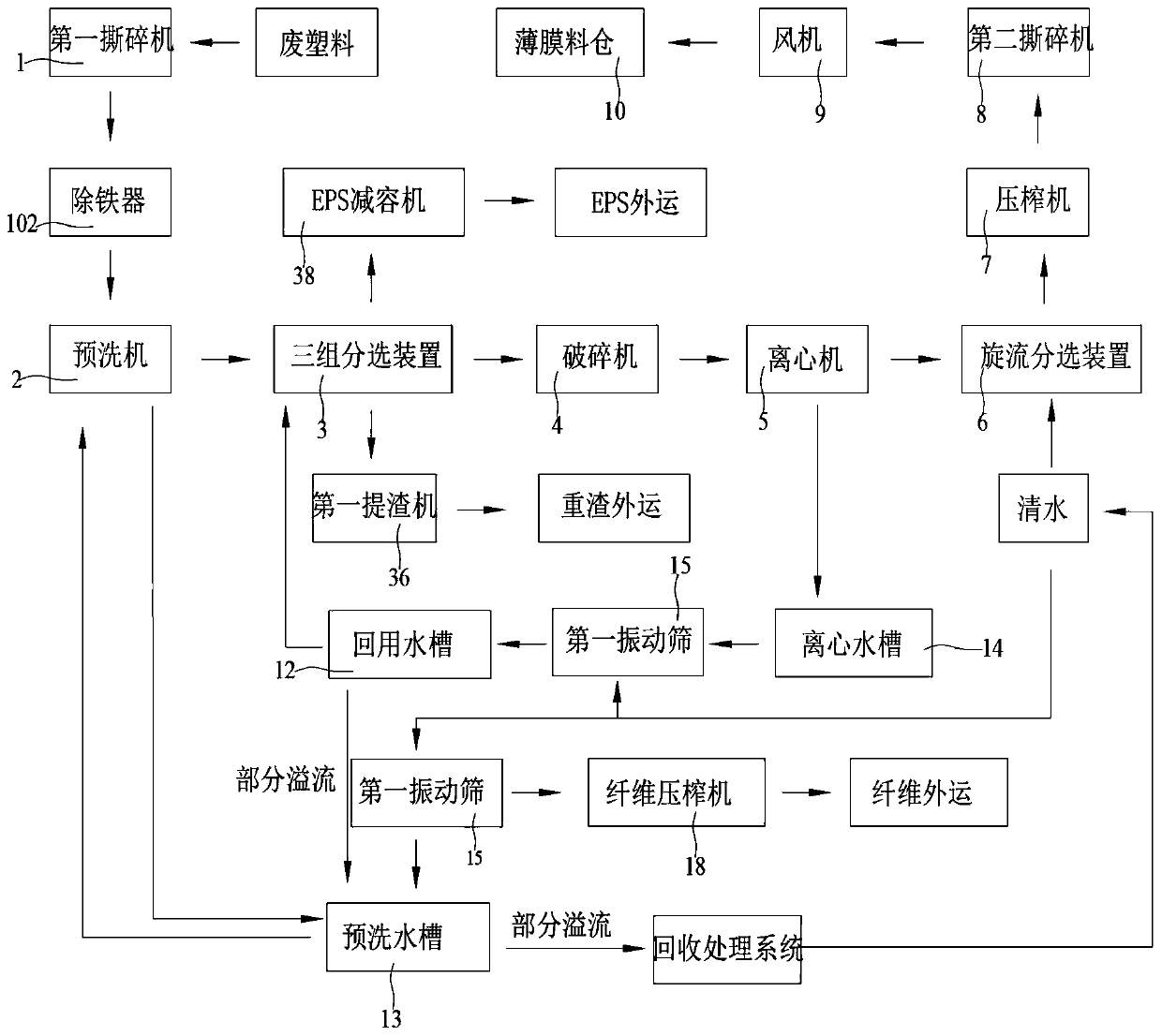

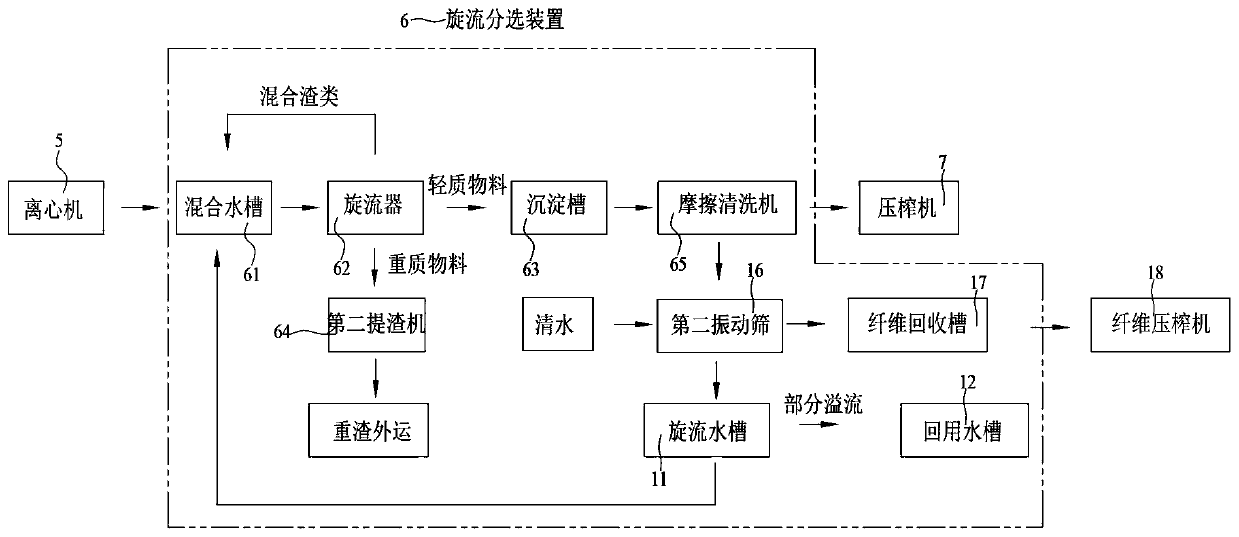

Waste plastic cleaning and sorting system

The invention discloses a waste plastic cleaning and sorting system. The waste plastic cleaning and sorting system comprises a first shredding machine, a pre-washing machine, a three-group sorting device, a crusher, a centrifugal machine and a cyclone separation device; the first shredding machine is used for shredding waste plastic; an input end of the pre-washing machine is connected with the first shredding machine and is used for receiving the shredded waste plastic; the three-group sorting device comprise a feeding screw, a mixing tank, a stirrer, a precipitator, a heavy slag filling machine, a first slag extracting machine and a light material filling machine; an input end of the crusher is connected with an output end of the light material filling machine; an input end of the centrifugal machine is connected with an output end of the crusher; the cyclone separation device comprises a mixing water tank, a swirler, a sedimentation tank, a second slag extractor and a friction cleaning machine; an input end of the mixing water tank is connected with an output end of the centrifugal machine; an output end of the swirler is respectively connected with the mixing water tank, the sedimentation tank and the second slag extractor; the precipitation tank is connected with the friction cleaning machine; and the friction cleaning machine is used for cleaning and outputting PP / PE (polyethylene) plastic. According to the waste plastic cleaning and sorting system, the automatic recovery is achieved, the plastic recovery rate is improved, and the operation is stable.

Owner:RECULTURE REGENERATION ENERGY

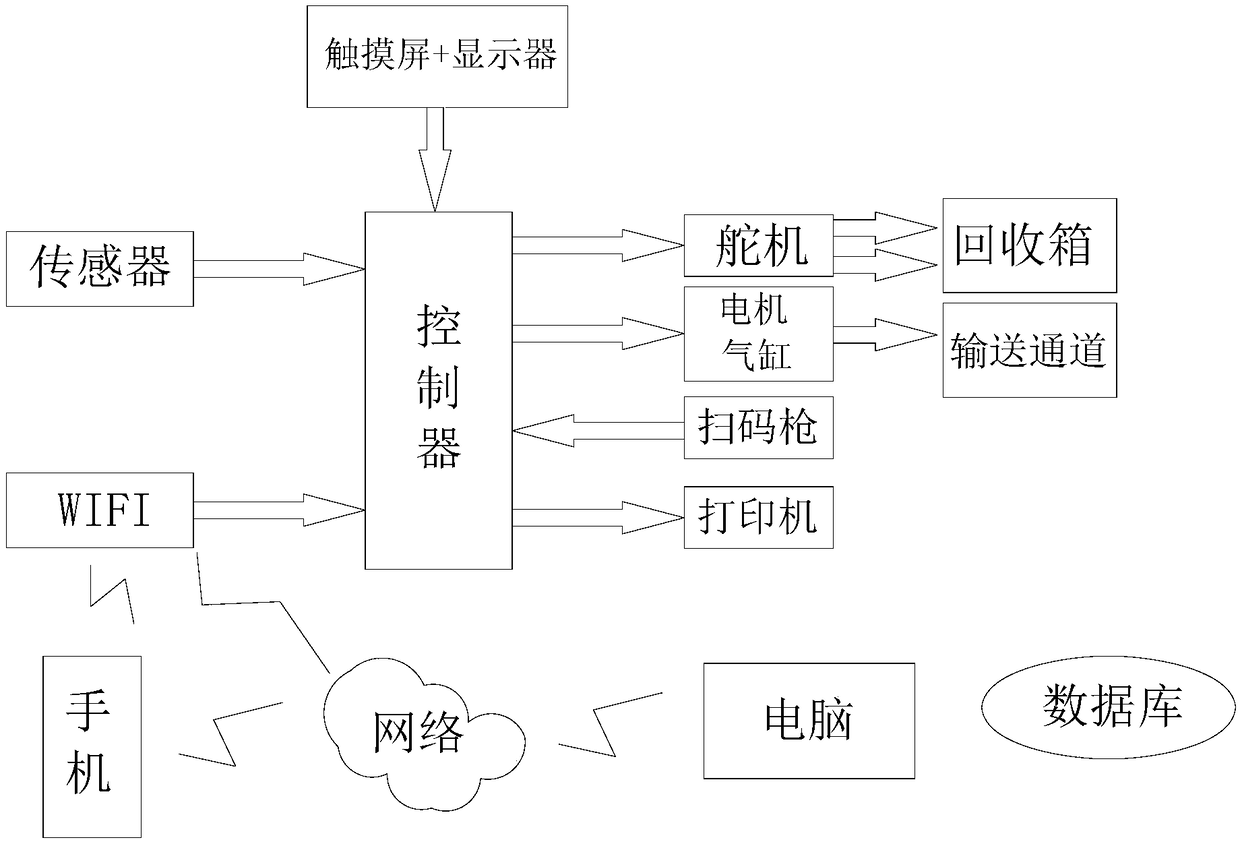

Automatic waste package sorting and recycling method

InactiveCN108910351AAutomate recyclingImprove recycling efficiencyWaste collection and transferRefuse receptaclesBarcodeWaste management

The invention relates to the technical field of waste package sorting and recycling, and discloses an automatic waste package sorting and recycling method. The automatic waste package sorting and recycling method comprises the steps that a barcode scanning gun is used for scanning waste package entering a conveying channel, the barcode scanning gun feeds information of the scanned waste package toa controller, the controller sorts the information of the waste package, and the waste package after being scanned falls into a sorting table; and a plurality of different sorting recycling bins arearranged on the periphery of the sorting table, the sorting table is provided with a plurality of pushing mechanisms, according to the information of the corresponding waste package, and the controller controls the corresponding pushing mechanisms to push the waste package on the sorting table into the recycling bins of the corresponding category. The waste package before entering the conveying channel is subjected to information sorting, the controller sorts the scanned information, then the controller is used for sorting and recycling the waste package conveyed onto the sorting table, the waste package is correspondingly recycled is in the recycling bin of the corresponding category, the automatic recycling of the waste package is realized, and the recycling efficiency is better.

Owner:GUANGDONG CONSTR VOCATIONAL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com