Submersible automatic laying and recovery device

A recovery device and submersible technology, applied in the field of marine engineering, can solve the problems of high cost of deployment operations, poor adaptability, difficulty in completing deployment and recovery by manpower, etc., to meet the needs of repeated deployment and recovery operations, reduce effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

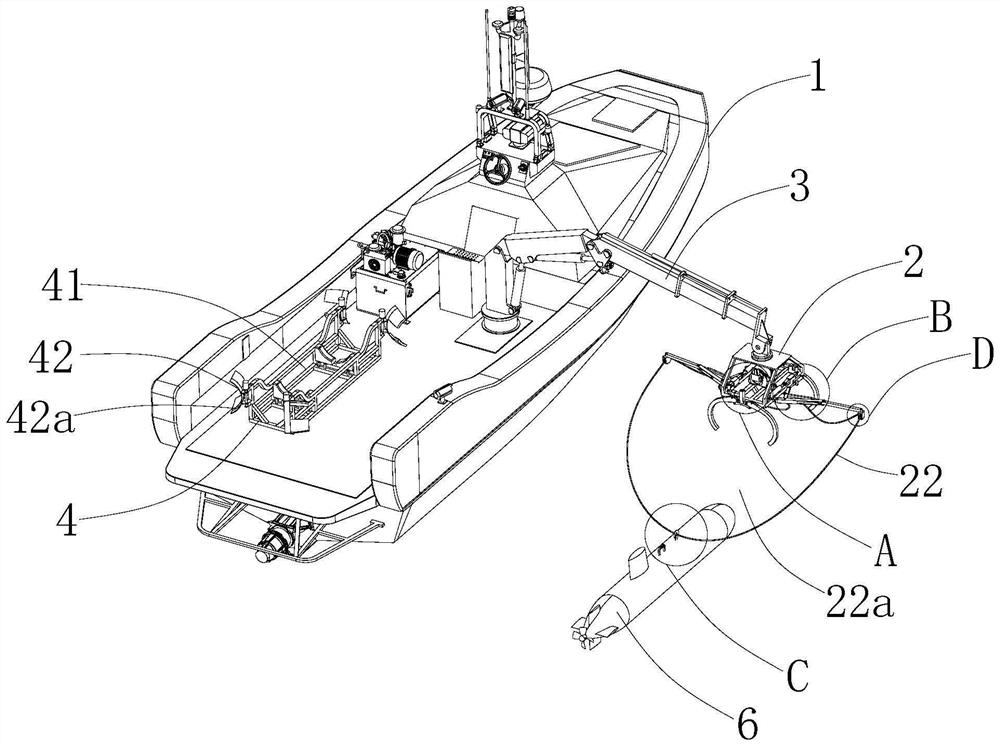

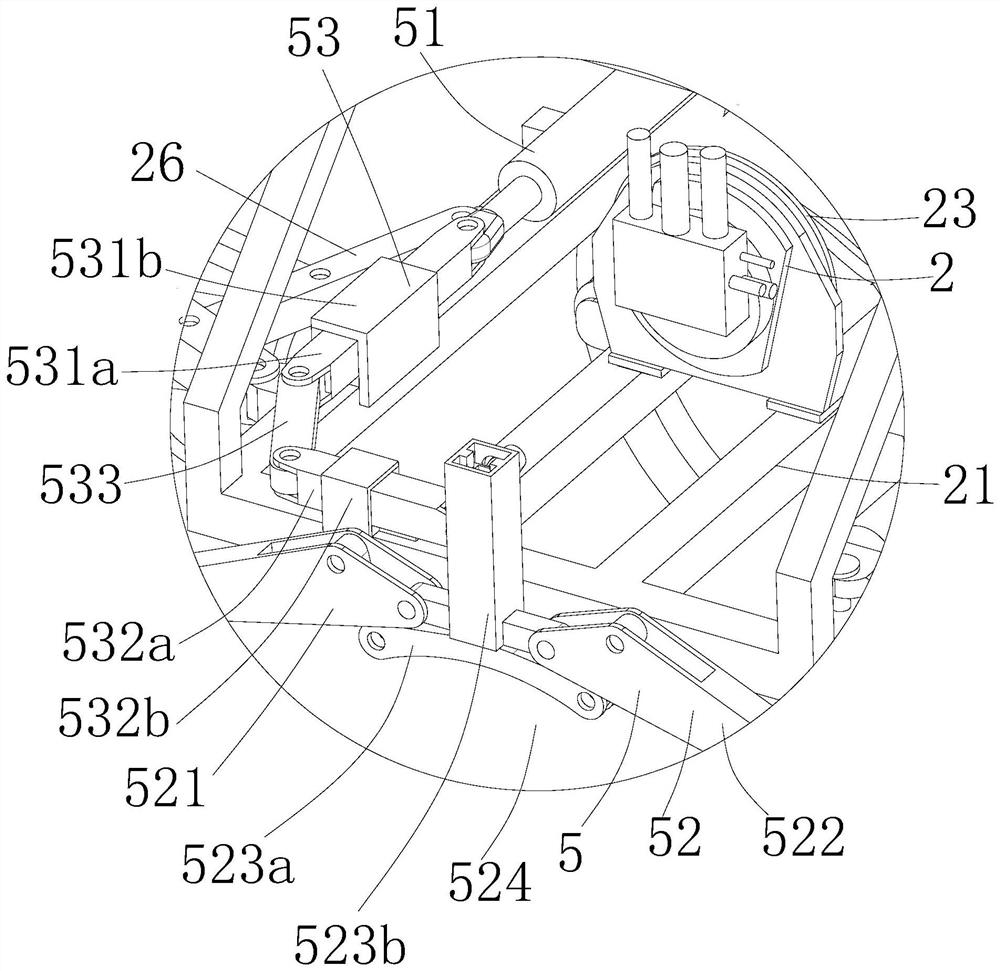

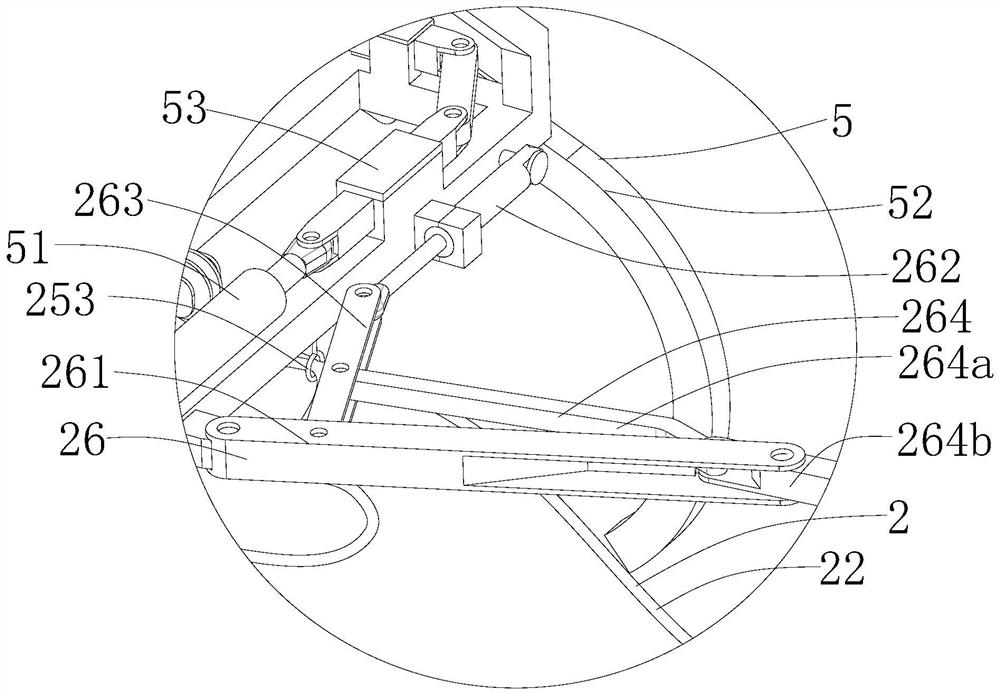

[0073] Example: a submersible automatic deployment and recovery device, such as Figure 1 to Figure 10 As shown, it can be applied to a submersible 6 with a hook 61, which includes: a carrier 1, a pulling and retracting device 2, a hoisting device 3, a bracket 4, a locking assembly 42, and a control system, as follows:

[0074] The carrier 1 is used as a mother ship for submersible operations on water; in this embodiment, the carrier 1 is an unmanned ship, but it is not limited to this, and can also be other marine structures capable of carrying the submersible 6 . This solution can be installed on an unmanned ship, and the carrier 1 as the unmanned ship provides power and control instructions, so as to realize a stable and reliable deployment and recovery operation of the submersible 6 .

[0075] The hoisting device 3 is arranged on the carrier 1, which can hoist or lower the submersible 6, and the pulling and retracting device 2 is arranged on the movable end of the hoisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com