Extruder stagnant oil purification device and recovery and purification method thereof

A purification device and extruder technology, applied in chemical instruments and methods, separation methods, filtration circuits, etc., can solve the problems of insignificant impurity removal effect, inability to be recycled, and no specific solutions proposed, etc. Realize the effect of reuse, high degree of automation, and reduction of corrosion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

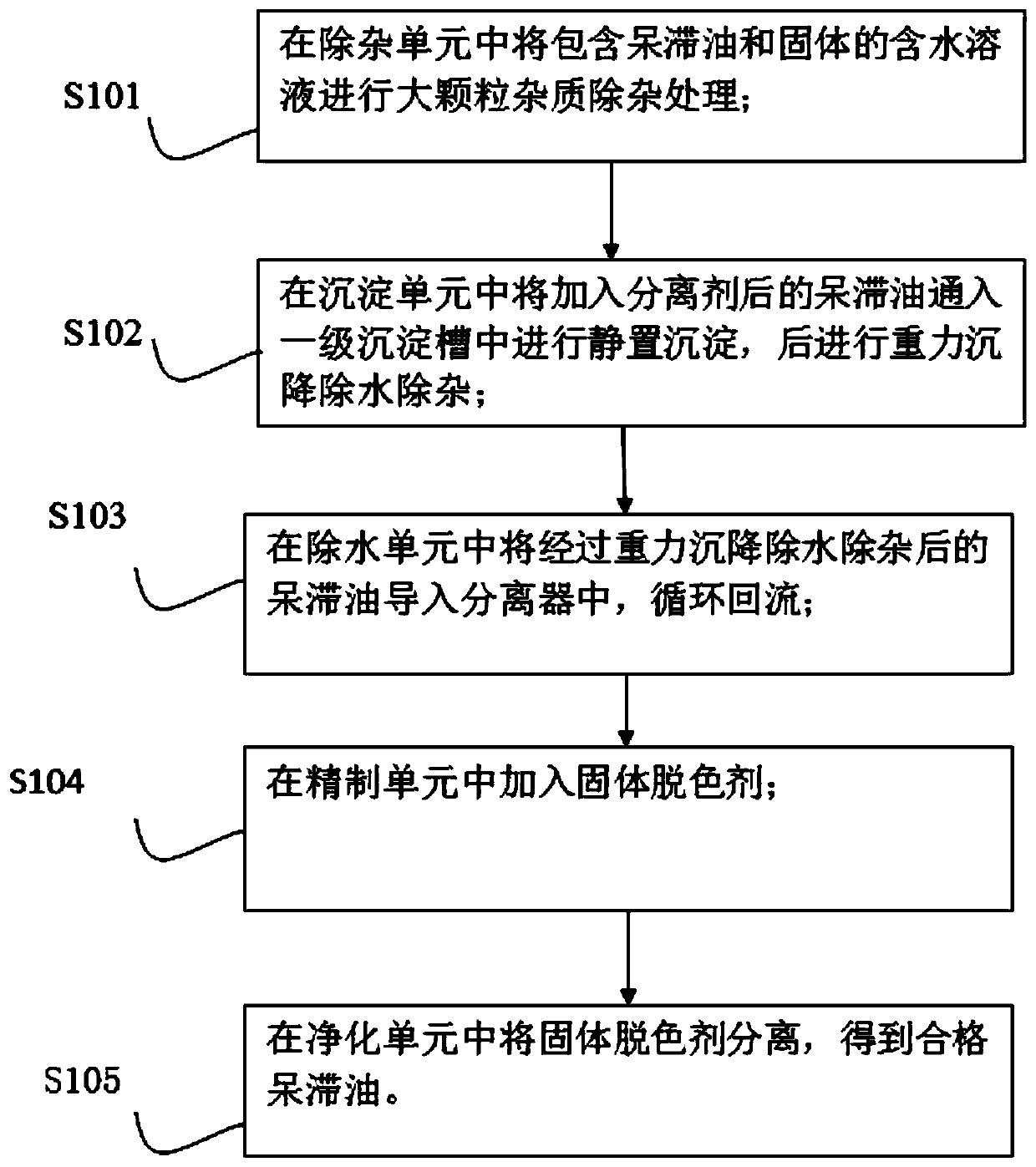

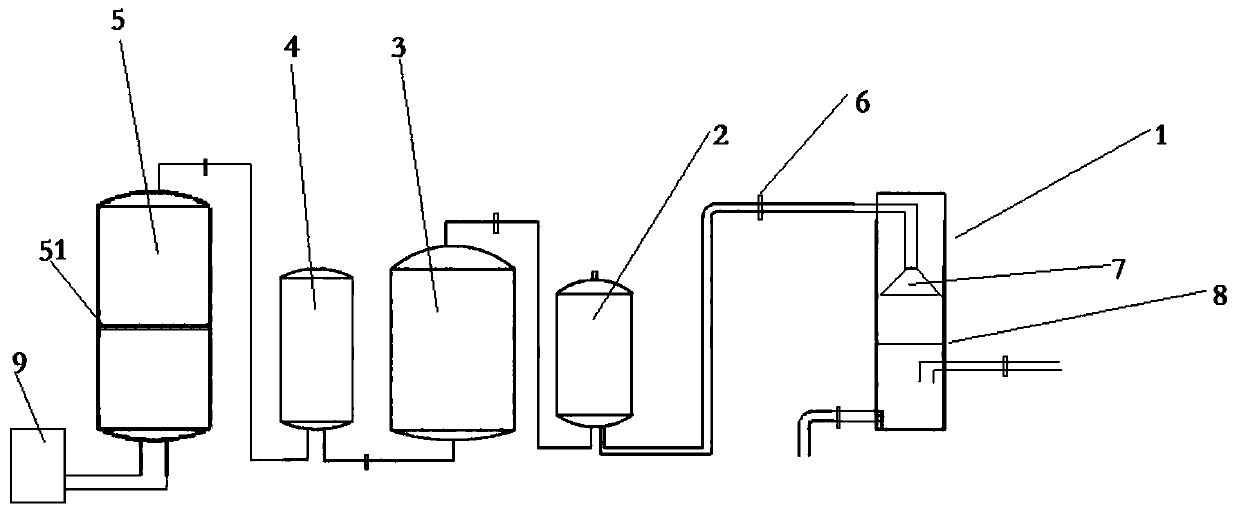

[0034] Such as figure 1 As shown, this embodiment provides a method for recovering and purifying sluggish oil of an extruder, comprising the following steps:

[0035] (1) Impurity removal: adjust the acidic pH of the aqueous solution containing sluggish oil and solids, and introduce the acidic aqueous solution containing sluggish oil and solids into the impurity removal unit for coarse filtration to remove large particles of impurities in the sluggish oil. After the oil is pre-precipitated, a separating agent is added, and the separating agent is a hydrophilic separating agent;

[0036] (2) Precipitation: Put the sluggish oil after adding the separating agent into the first-stage settling tank for static precipitation, the water and impurities in the sluggish oil settle to the bottom and then separate out, and the sluggish oil passes through the pump at the upper end of the first-stage settling tank The filter device enters the secondary sedimentation tank for gravity sedimen...

Embodiment 2

[0044] Such as figure 1 As shown, this embodiment provides a method for recovering and purifying sluggish oil of an extruder, comprising the following steps:

[0045] (1) Impurity removal: Adjust the acidic pH of the aqueous solution containing sluggish oil and solids to 5-6, and introduce the acidic aqueous solution containing sluggish oil and solids into the impurity removal unit for coarse filtration to remove large particles in the sluggish oil Impurities, the sluggish oil is added to the separating agent after preliminary precipitation, and the separating agent is a hydrophilic separating agent; in the present embodiment, the addition amount of the separating agent is 25-45% Separating agent, the separating agent is a high-molecular polymer, which has an extremely strong alkyl group and is hydrophilic. When in use, use a metering pump to control its addition amount, and add the separating agent to the impurity removal unit evenly and slowly , and controlling the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com