Environmentally friendly cleaning car for oil well operation

A technology for cleaning vehicles and oil wells, which is applied to cleaning appliances, wellbore/well components, earth-moving drilling, etc. It can solve the problems of difficulty in use, low efficiency and high cost, and achieve high cleaning efficiency and quality. The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

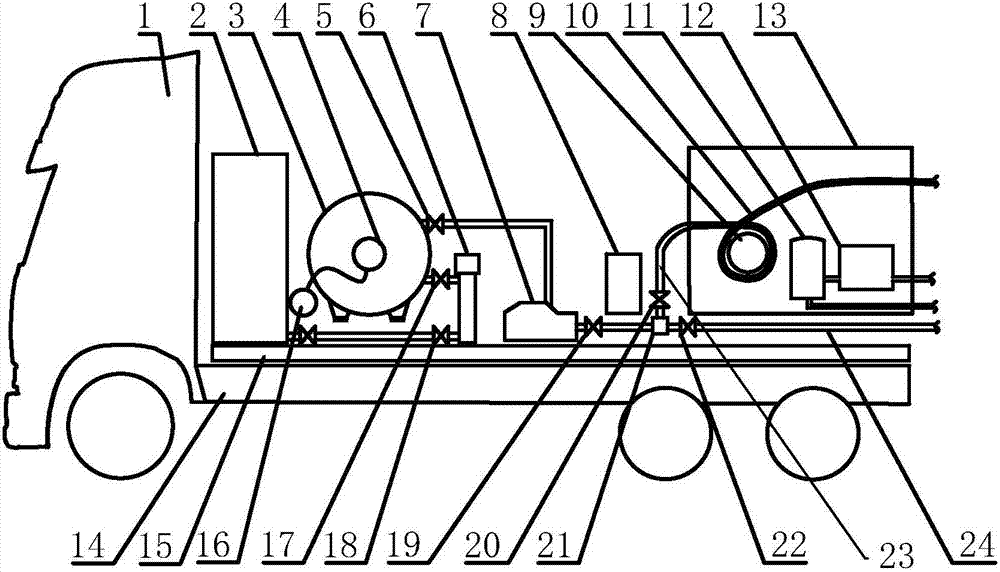

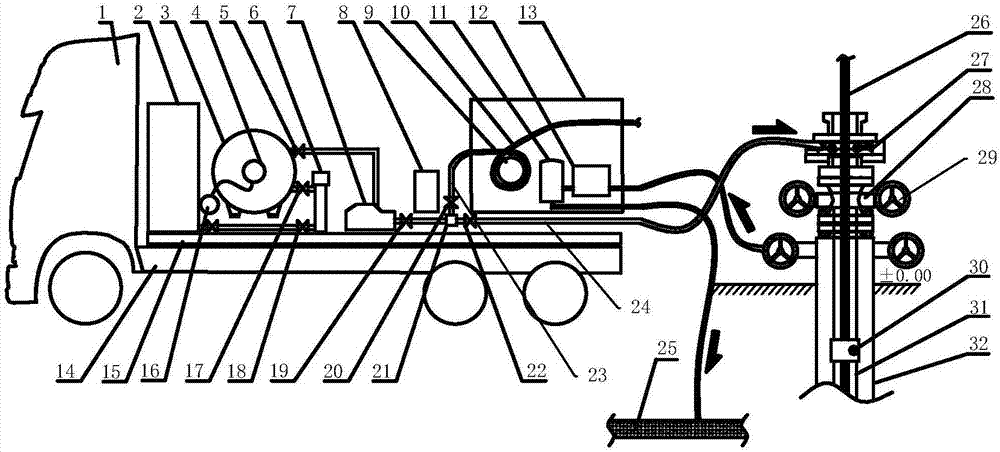

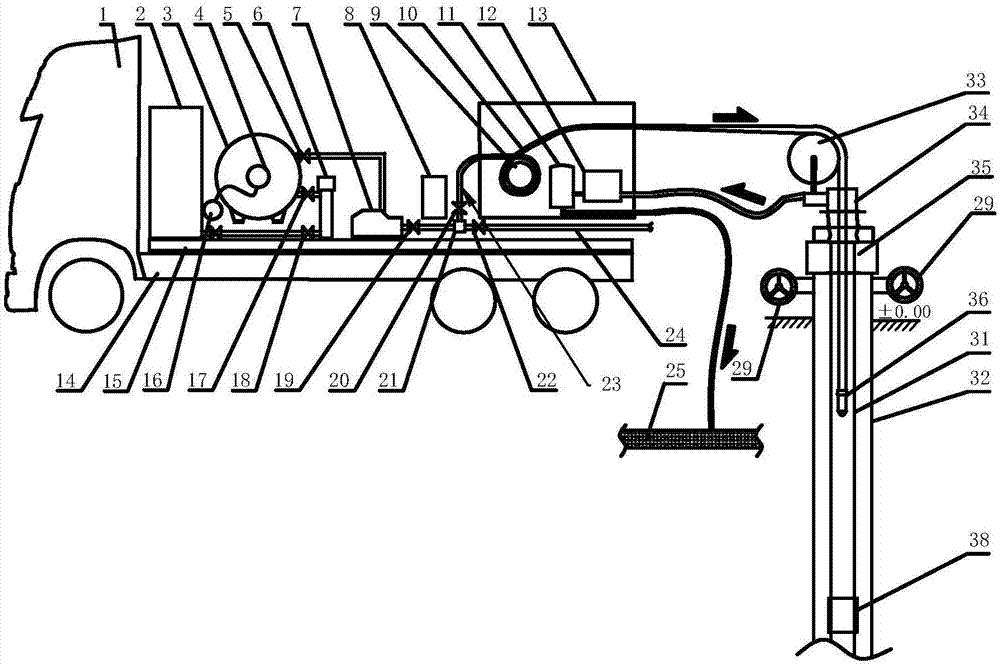

[0026] Such as Figure 1-4 As shown, the present invention is an environment-friendly cleaning vehicle for oil well operation, which corresponds to the position of the oil well. The oil well includes an oil well tubing 31 and an oil well Christmas tree. Rod 26, oil well tubing 31 is provided with an oil well casing 32, an annular space is formed between the oil well tubing 31 and the oil well casing 32, and the oil well Christmas tree includes a tubing spool 28 installed on the oil well tubing 31, the tubing A casing valve 29 is provided on the outside of the casing 32. When cleaning the inner wall of the tubing, a blowout preventer 35 is installed on the upper end of the casing 32 of the oil well, and a tubing drain tee 34 is installed on the blowout preventer 35;

[0027] The environmental protection cleaning vehicle comprises a body body 1, the body body 1 is provided with an automobile girder 14, and the automobile girder 14 is provided with an equipment bracket 15, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com