Automatic disassembling equipment for screws at bottom of mobile phone

A screw and mobile phone technology, applied in the field of automatic dismantling equipment for screws at the bottom of mobile phones, can solve the problems of complex dismantling equipment, inability to realize fully automated dismantling, poor effect, etc., and achieve the effect of simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

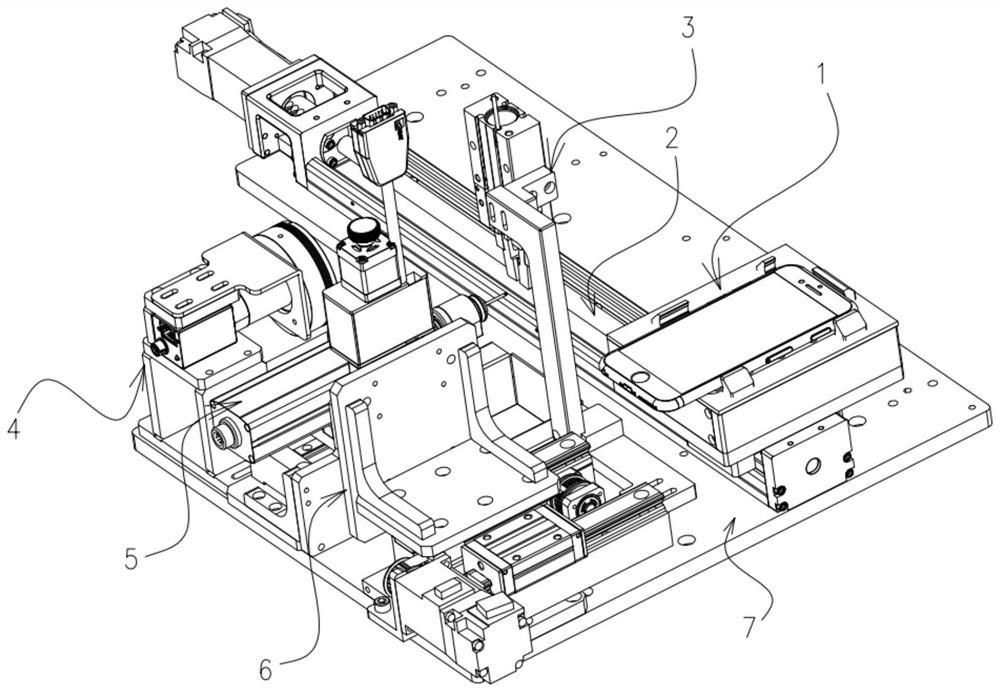

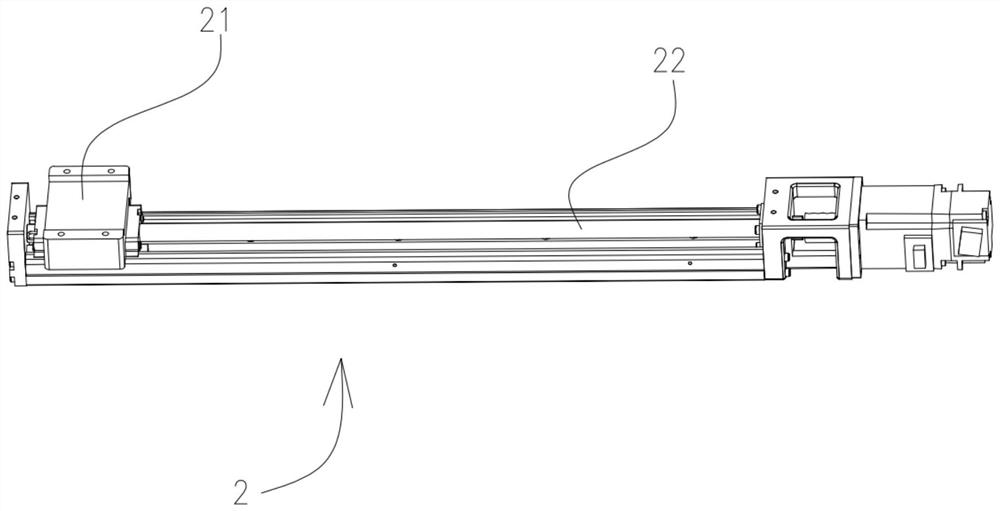

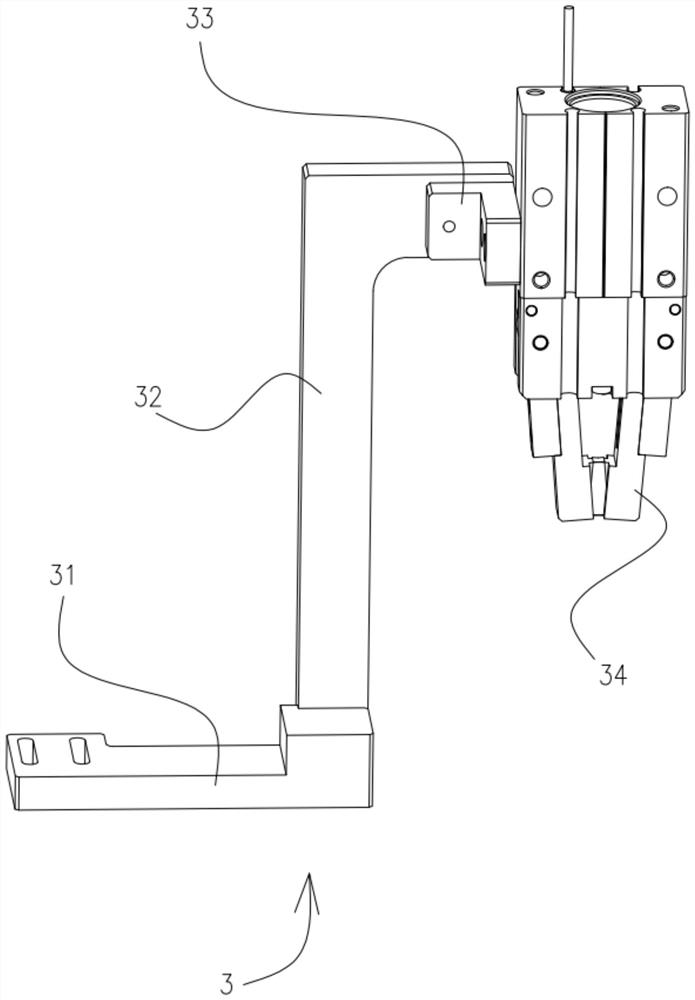

[0026] Such as Figure 1 to Figure 9 As shown, the present invention provides an automatic dismantling device for screws at the bottom of a mobile phone, including a mobile phone fixture 1, a fixture moving mechanism 2, a screw cleaning mechanism 3, a visual mechanism 4, a screw dismantling mechanism 5, a dismantling moving mechanism 6, and a bottom plate 7. The visual mechanism 4 includes a visual seat plate 41, a visual side plate 42, a camera bottom plate 43, a CCD camera 44, a camera side plate 45, a camera top plate 46, a bracket 47, and a light source 48; the screw disassembly mechanism 5 includes dismantling Solution base plate 51, adjusting rod 52, dismantling guide rail 53, dismantling slide block 54, backing plate 55, dismantling slide rail 56, connecting rod 57, support plate 58, electric batch 59; Described base plate 7 is L shape, And the base plate 7 is provided with a screw box 71; the clamp moving mechanism 2, the screw cleaning mechanism 3, the vision mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com