Battery glue finished product tray placing machine

A technology of glue finished products and a weaving machine, which is applied in the field of 3C film material cutting devices, can solve the problems that the base film cannot be reused, is difficult to meet mass production, and is easy to damage the finished film. The effect of secondary reuse and high peeling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

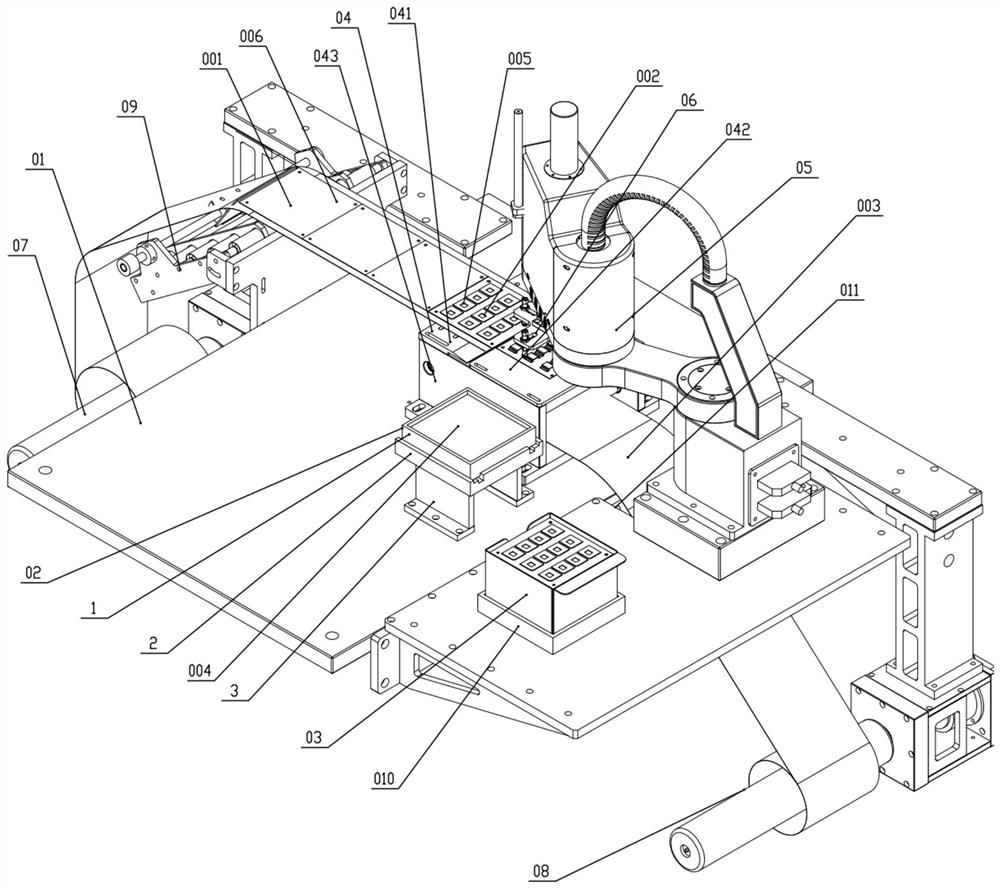

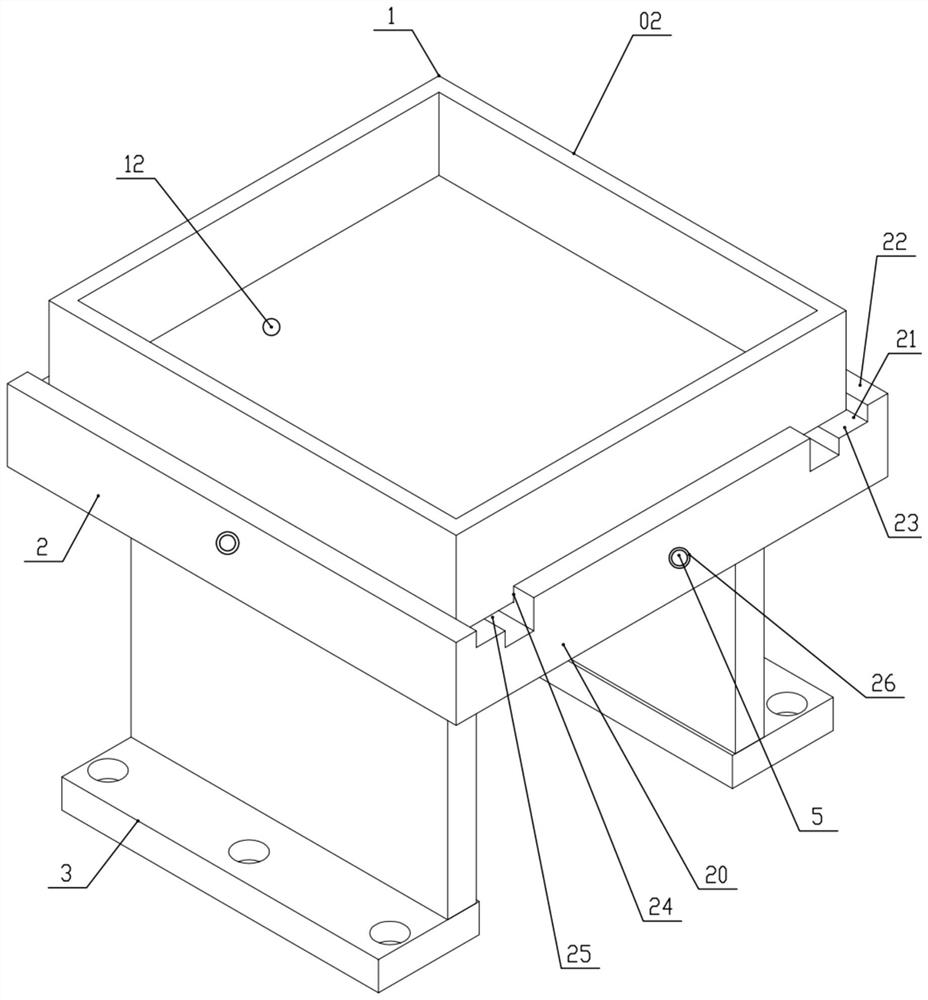

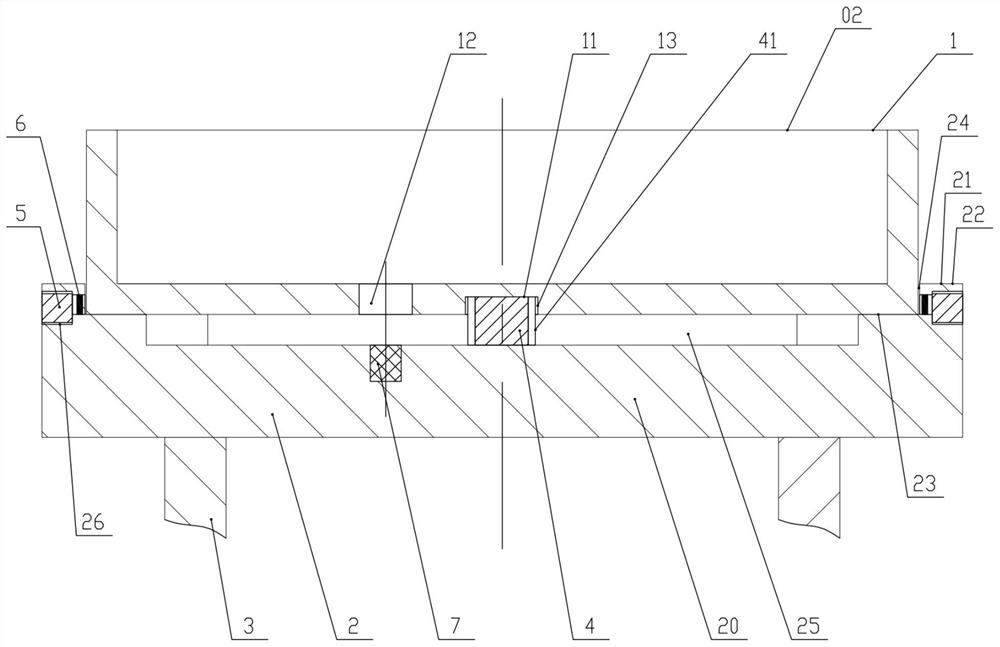

[0041] Figure 1 to Figure 6Schematically shows a battery glue finished product arranging machine according to an embodiment of the present invention. As shown in the figure, the device includes a base plate 01, a paper feeding part 02 fixed on the upper surface of the base plate 01, a finished product bin 03, a stripping table 04, and a manipulator 05. The left end of the base plate 01 is installed under the The discharging module 07 and the receiving module 08 are installed under the right end, the discharging module 07 continuously outputs the finished belt 001, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com