Comprehensive recovery technique of zinc vertical retorting residue

A technology for smelting zinc and vertical cans, applied in the field of comprehensive recycling of non-ferrous metal smelting, can solve the problems of short furnace life, many equipment, long process, etc., and achieve the effect of saving production cost, simple process and optimized combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

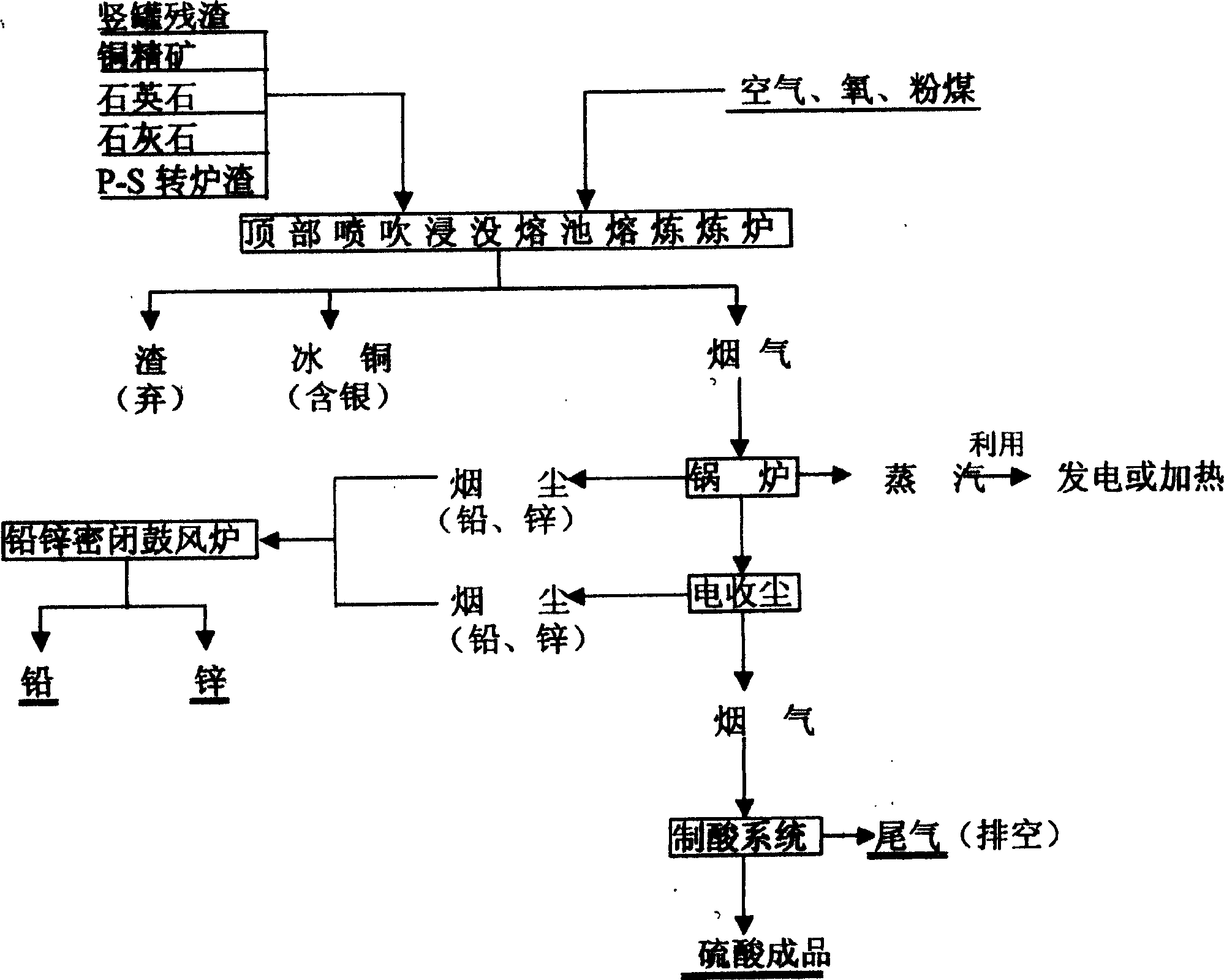

[0022] The process flow of comprehensive recovery of zinc smelting residues in vertical tanks is attached image 3 .

[0023] Zn

Pb

Ag(g / t)

C

S

Fe

SiO 2

Calorific value (KJ / Kg)

1-6%

1%

140

30%

3.8%

20%

10%

15000

[0024] The vertical tank zinc smelting residue contains 1% zinc (Zn1%). Recycled P·S converter slag contains 5% Cu, 1.6% Zn, 0.3% Pb,

[0025] Fe45.9%, SiO 2 26.9%. Flux quartz containing SiO 2 85%, limestone contains Ca50%. The copper concentrate contains 23% Cu, 3% Zn, 26.5% S, and 2% Pb.

[0026] 1. Ingredients, vertical tank zinc smelting residue, copper concentrate, limestone, quartz stone, and converter slag are stored in their own feeding bins, and each bin is equipped with a weight-controlled feeder to adjust the discharge speed. The ingredients: vertical Can smelting zinc residue, copper concentrate, limestone, quartz stone, and converter slag ac...

Embodiment 2

[0030] The difference between Example 2 and Example 1 is: the vertical tank zinc smelting residue contains 6% zinc, and the flow rate of the spray gun during smelting: air 32700Nm 3 / h, enriched oxygen 11300Nm 3 / h, smoke discharge 54500Nm 3 / h. Its temperature is 1210°C, and the dust content of the flue gas enriched with lead and zinc is 45g / Nm 3 , soot contains 39.1% lead, 16.3% zinc, and the others are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com