Water-based quick-drying externally-crosslinked functional paint and preparation method thereof

A functional coating and cross-linking technology, applied in the direction of coating, etc., can solve the problems of slow drying speed, insufficient heat resistance and solvent resistance, poor hardness, etc., achieve fast curing speed, low content of volatile organic compounds, and low odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

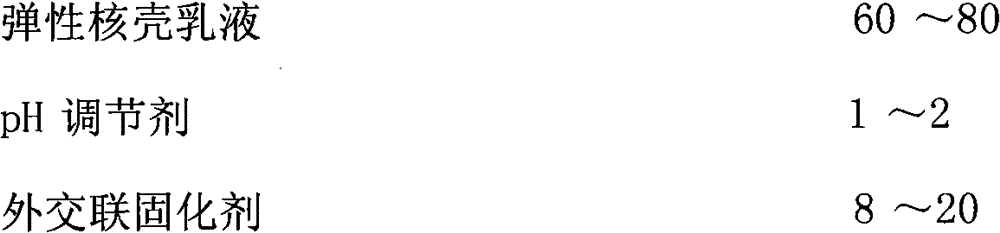

[0030] The composition of the water-based quick-drying externally linked functional coating is:

[0031]

[0032]

[0033] Add deionized water to 100%.

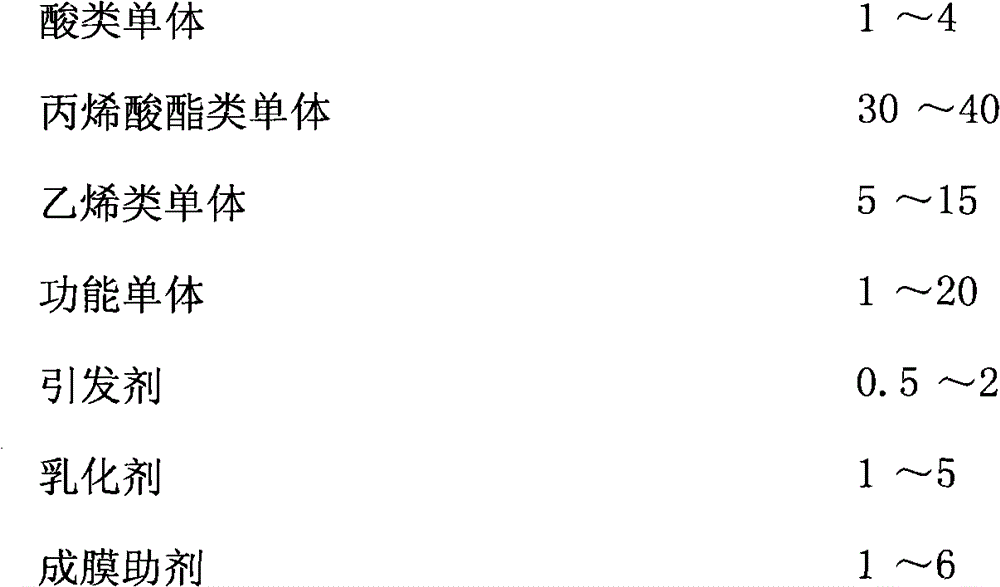

[0034] The composition of the elastic core-shell emulsion by mass percentage is:

[0035]

[0036] Add deionized water to 100%.

[0037] Preparation:

[0038] (1) Add unsaturated fatty acid, methyl (meth)acrylate, ethyl (meth)acrylate, butyl (meth)acrylate in the reactor equipped with thermometer, stirrer, reflux condenser and dropping funnel , styrene, (meth)acrylamide, deionized water and potassium sulfate to obtain pre-emulsions (including core and shell emulsions).

[0039] (2) Take 20% of the core pre-emulsion and add it to the reactor, and heat it to 80-85 ° C. After the emulsion turns blue and refluxes, start to drop the remaining pre-emulsion, and the dripping is completed in 2 to 3 hours, and the reaction is continued for more than 2 hours. , after the monomer conversion rate reached 99.9%, the temperatu...

Embodiment 2

[0042] The composition of the water-based quick-drying externally linked functional coating is:

[0043]

[0044]

[0045] Add deionized water to 100%.

[0046] The composition of the elastic core-shell emulsion by mass percentage is:

[0047]

[0048] Add deionized water to 100%.

[0049] Preparation:

[0050] (1) Add (meth)acrylic acid, itaconic acid monomer, butyl (meth)acrylate, ethyl (meth)acrylate to the reactor equipped with thermometer, stirrer, reflux condenser and dropping funnel , 2-ethylhexyl (meth)acrylate, dimethylstyrene, glycidyl (meth)acrylate, deionized water, and ammonium persulfate to obtain pre-emulsions (including core emulsions and shell emulsions).

[0051] (2) Take 15% of the nuclear pre-emulsion and add it to the reactor, and heat it to 80-85 ° C. After the emulsion turns blue and refluxes, start to drip the remaining pre-emulsion, and the dripping is completed in 2 to 3 hours, and the reaction is continued for more than 2 hours. After ma...

Embodiment 3

[0054] The composition of the water-based quick-drying externally linked functional coating is:

[0055]

[0056] Add deionized water to 100%.

[0057] The composition of the elastic core-shell emulsion by mass percentage is:

[0058]

[0059] Add deionized water to 100%.

[0060] Preparation:

[0061] (1) In the reactor equipped with thermometer, stirrer, reflux condenser and dropping funnel, add phthalic acid, methyl (meth)acrylate, ethyl (meth)acrylate, butyl (meth)acrylate Esters, dimethylstyrene, diacetone acrylamide, acrylonitrile, deionized water and ammonium persulfate, tert-butyl hydroperoxide gave pre-emulsions (including core and shell emulsions).

[0062](2) Take 20% of the nuclear pre-emulsion and add it to the reactor, heat it to 80-85°C, after the emulsion turns blue and refluxes, start adding the rest of the pre-emulsion dropwise, finish dripping in 2-3 hours, and continue to react for more than 2 hours , after the monomer conversion rate reached 99.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com