Automatic oil tank water draining method

An oil tank and automatic technology, which is applied in the field of automatic water cutting of oil tanks, can solve the problems of high manual operation intensity, low safety factor and high oil content in drainage, so as to reduce oil waste and environmental pollution, overcome major safety hazards, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

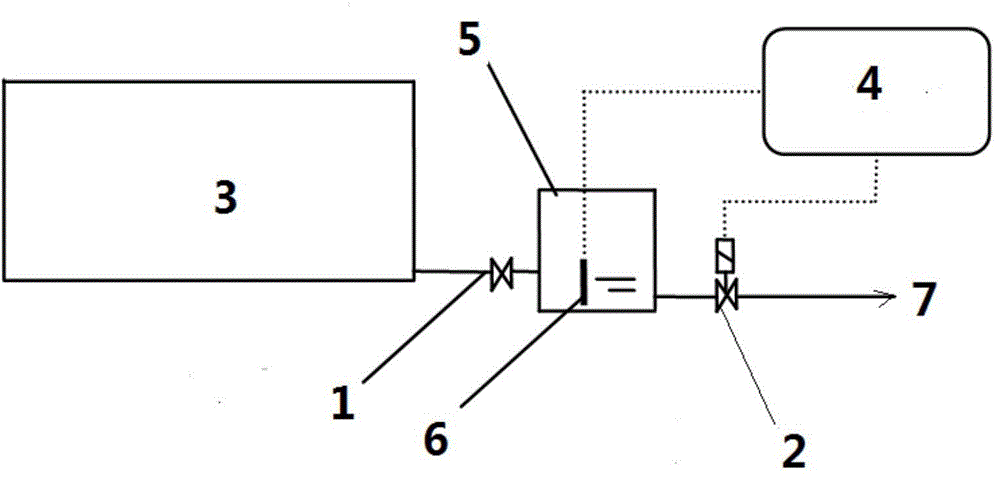

Embodiment 1

[0014] In the water cutting operation of an oil storage tank A, the water produced in the oil tank enters the water cutting tank through valve 1. The original water level of the water cutting tank is 40cm high. As the water in the oil tank gradually flows into the water cutting tank, the water level rises to 60cm. The oil-water interface monitoring sensor detects that the thickness of the oil film is 0.025-0.03mm, and sends a signal to the controller. The controller switches the solenoid valve 2 remotely to discharge the water in the water cutting tank. No obvious oil blooms can be seen in the water, and the water is cut into the sewage treatment system. , When the water level in the water cutting tank drops to 45cm, the solenoid valve 2 is closed, and the water cutting ends.

Embodiment 2

[0016] In the water cutting operation of an oil storage tank B, the water produced in the oil tank enters the water cutting tank through valve 1. The original water level of the cutting water tank is 80cm high. As the water in the oil tank gradually flows into the water cutting tank, the water level rises to 120cm, and the oil and water The interface monitoring sensor detects that the thickness of the oil film is 0.025-0.03mm, and sends a signal to the controller. The controller switches the solenoid valve 2 remotely to discharge the water in the water cutting tank from the bottom. No obvious oil blooms can be seen in the water, and the water is cut into the sewage treatment system, when the water level in the cutting water tank drops to 85cm, the solenoid valve 2 is closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com